A Comprehensive Guide to Gas Flow Meters: Types, Applications, and Selection Tips

2025-03-14

Gas flow meters are essential devices used to measure the rate at which gas flows through a system. They play a critical role in monitoring, controlling, and optimizing gas usage across various industries, from industrial manufacturing to residential applications. Whether measuring volumetric flow (e.g., cubic meters per second) or mass flow (e.g., kilograms per second), gas flow meters ensure efficient and accurate gas management.

Gas flow meters are critical instruments for monitoring and optimizing gas usage across various industries. Understanding the different types and their applications helps in selecting the best solution for your specific needs. Whether you require precision, durability, or cost-efficiency, there’s a gas flow meter designed for the job.

If you want to know more about the flow meter or flow meter selection, please consult the Aister flow meter manufacturer email: sales@aistermeter.com for help.

What is a Gas Flow Meter?

A gas flow meter is a device used to measure the rate at which gas flows through a system. It quantifies either volumetric flow (e.g., cubic meters per second) or mass flow (e.g., kilograms per second), depending on the specific requirements. Gas flow meters are widely used in industrial, commercial, and residential settings to monitor, control, and optimize gas usage.

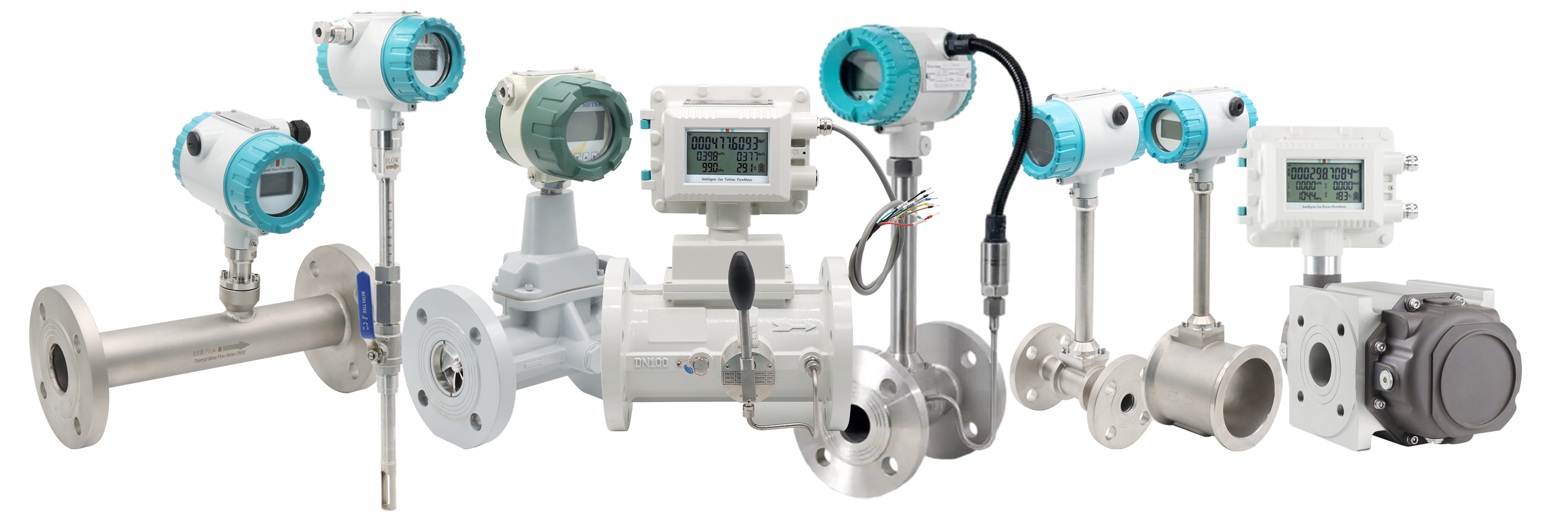

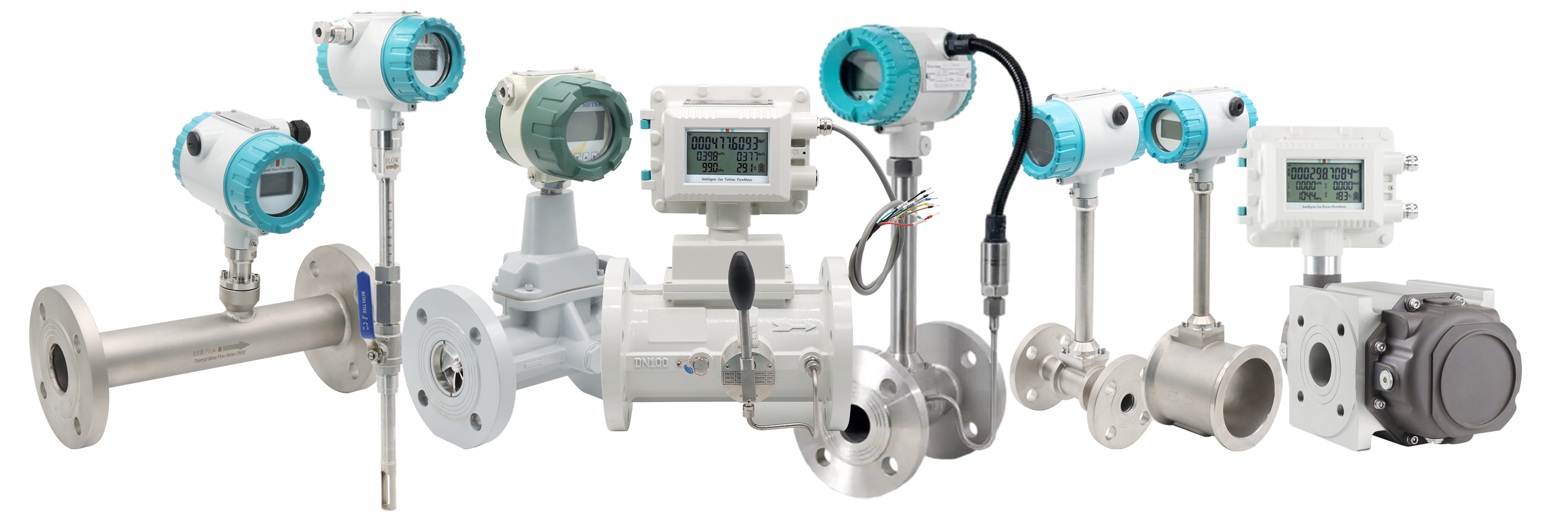

Types of Gas Flow Meters

There are several types of gas flow meters, each designed for specific applications, gas types, and flow conditions. Below are the most common gas flow meter types and their key features.

1. Differential Pressure (DP) Flow Meters

- How They Work: Measure the pressure drop across a restriction (such as an orifice plate or Venturi tube) to calculate flow rate.

- Common Applications: High-pressure gas systems like natural gas pipelines.

- Advantages: Simple design, cost-effective, and widely used in the industry.

2. Thermal Mass Flow Meters

- How They Work: Use heat transfer principles to measure the mass flow of gas.

- Common Applications: Compressed air systems, biogas monitoring, and industrial gas control.

- Advantages: High accuracy, no moving parts, ideal for low flow rates.

3. Turbine Flow Meters

- How They Work: A turbine spins as gas flows through it; the rotational speed correlates with the flow rate.

- Common Applications: Natural gas distribution and custody transfer.

- Advantages: High accuracy and reliability in clean, steady gas flow conditions.

4. Vortex Flow Meters

- How They Work: Measure vortices created by a bluff body placed in the gas stream.

- Common Applications: Industrial steam and gas flow measurement.

- Advantages: No moving parts, durable, and effective in high-temperature environments.

5. Coriolis Flow Meters

- How They Work: Detect the Coriolis effect on a vibrating tube to measure mass flow directly.

- Common Applications: Chemical processing, custody transfer, and high-precision measurements.

- Advantages: Extremely accurate and unaffected by gas composition.

6. Rotameters (Variable Area Flow Meters)

- How They Work: A float moves up and down in a tapered tube, indicating the flow rate.

- Common Applications: Laboratories and low-pressure gas systems.

- Advantages: Simple, easy to install, and budget-friendly.

Common Applications of Gas Flow Meters

Gas flow meters are versatile tools used in a wide range of industries:

- Oil and Gas Industry: Monitoring natural gas flow in pipelines and refineries.

- Chemical Processing: Controlling gas flow in reactors and storage tanks.

- HVAC Systems: Managing airflow in heating, ventilation, and air conditioning.

- Environmental Monitoring: Tracking greenhouse gas emissions and ensuring regulatory compliance.

- Healthcare: Measuring medical gases like oxygen and nitrous oxide in hospitals.

- Energy Management: Monitoring gas consumption in power plants and utilities.

- Residential and Commercial Use: Accurate billing and monitoring of natural gas usage in homes and businesses.

How to Choose the Right Gas Flow Meter

Selecting the right gas flow meter depends on several key factors:

- Gas Type: Consider the gas properties such as density, viscosity, and corrosiveness.

- Flow Rate Range: Ensure the meter can accurately measure the full range of expected flow rates.

- Operating Conditions: Account for pressure, temperature, and environmental factors.

- Accuracy Requirements: Choose a meter that meets your application’s precision needs.

- Installation and Maintenance: Look for meters that are easy to install, calibrate, and maintain over time.

Gas flow meters are critical instruments for monitoring and optimizing gas usage across various industries. Understanding the different types and their applications helps in selecting the best solution for your specific needs. Whether you require precision, durability, or cost-efficiency, there’s a gas flow meter designed for the job.

If you want to know more about the flow meter or flow meter selection, please consult the Aister flow meter manufacturer email: sales@aistermeter.com for help.

Share To:

Previous Post:

News

- Why is the thermal gas mass flowmeter not affected by pressure strength and temperature?

- What to do when a thermal gas mass flow meter fails?

- How are thermal gas mass flow meters used? What are the applications?

- Under what circumstances is the gas measurement need to be regulated compensated vortex flowmeter

- Why Is The Aister Thermal Gas Mass Flowmeter So Popular ?

- Gas turbine flowmeter manufacturers explain their main advantages in measurement

- Gas turbine flowmeter manufacturer Aister instrument field experience summary

- Aister Instrument Empowerment Conference