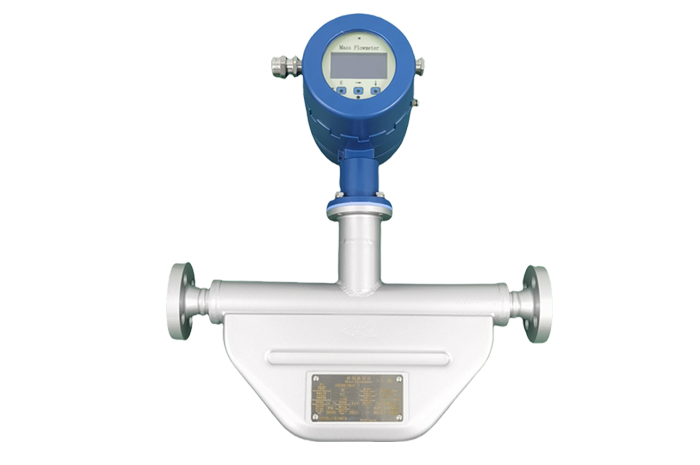

ATCMF Coriolis mass flow meter

Medium:

Liquid, gas, slurry

Accuracy:

0.1%, 0.15%, 0.2%, 0.5%

Power Supply:

DC24V、AC220V

Pressure (MPa):

1.6、2.5、4.0、6.3; Customized for high pressure: 10.0, 16.0, 26.0

The Coriolis Mass Flow Meter is an advanced, high-precision device designed to measure mass flow, density, and temperature of liquids and gases directly. Leveraging the Coriolis principle, it ensures highly accurate and reliable data, making it ideal for a wide range of industrial applications such as chemical processing, oil & gas, food & beverage, and pharmaceuticals.