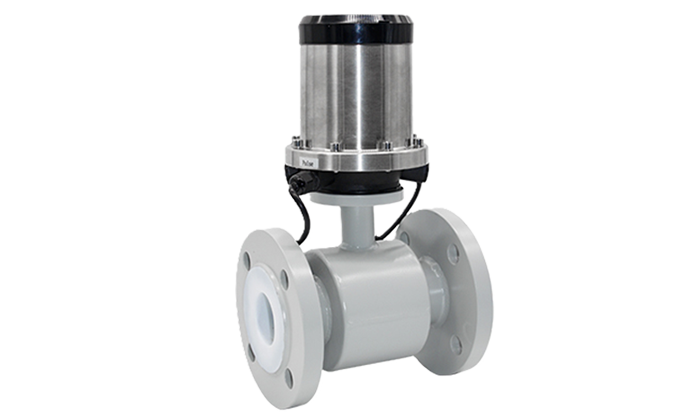

Battery Powered Electromagnetic Flow Meter

Size:

DN10mm-DN2000mm

Nominal Pressure:

0.6-1.6Mpa(2.5Mpa/4.0Mpa/6.4Mpa...Max 42Mpa)

Accuracy:

+/-0.5%(Standard)

Liner:

PTFE, Neoprene, Hard Rubber, EPDM, FEP, Polyurethane, PFA

Battery Operated Flow Meter adopts lithium battery, which is capable of working 3~6 years consecutively. If a high-capacity battery is applied, the converter will have longer working time. The measurement of flow rate of the electromagnetic flow meter is based on Faraday's law of electromagnetic induction. The battery powered electromagnetic flowmeter can be remotely communicated with the base station type radio communication network system. Date collection and management can also be realized through GPRS wireless network system. In addition, IP68 protection helps the flowmeter itself to be placed underground or underwater.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)