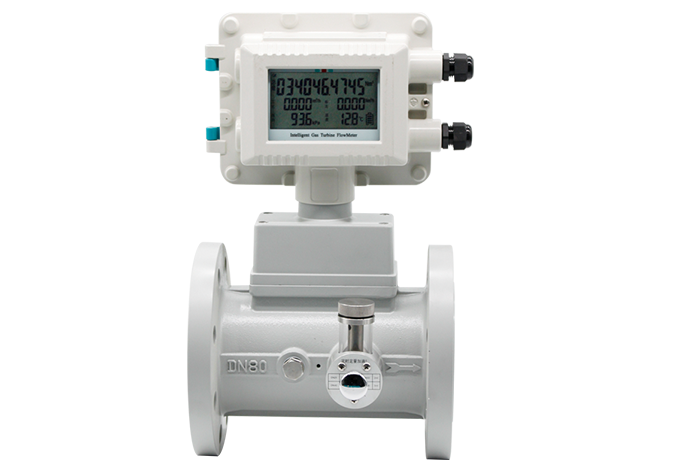

ATMF-C Gas Mass Flow Controller

Measuring medium:

Various clean gases

Measuring range:

Micro flow

Accuracy Degree:

±0.5%,±1.0%

Output signal:

4-20mA, pulse (optional)

Mass Flow Controller (MFC) used to accurately measure and control the mass flow of gas. They play an important role in scientific research and production in various fields such as semiconductors and integrated circuit industries, special materials disciplines, chemical industry, and industrial, pharmaceutical, environmental protection, and vacuum lamps. Typical applications include: electronic process equipment such as diffusion, epitaxy, CVD, oxidation, plasma etching, sputtering, and ion implantation; and coating equipment, optical fiber smelting, microreaction devices, mixed gas distribution systems, capillary measurement, Gas chromatographs and other analytical instruments

.png)

.png)