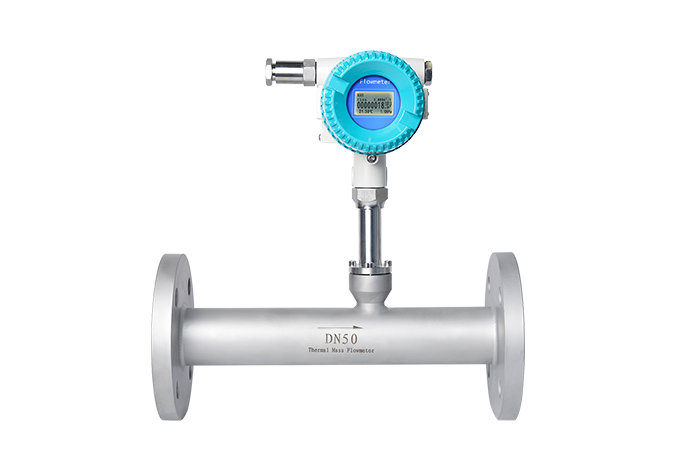

ATWU Gas Ultrasonic Flow Meter

Measuring medium:

Non-corrosive gases such as natural gas, air and nitrogen

Nominal diameter:

DN25-DN200

Accuracy class:

±1.0%, ±1.5%

Enclosure material:

Cast aluminum

The ATWU series gas ultrasonic flowmeter is based on the principle of ultrasonic time difference method. It is equipped with independent digital temperature transmitters and pressure transmitters, and integrates a wireless remote transmission module. It is a velocity-type gas metering instrument that integrates flow measurement, volume correction and remote data transmission.

.png)