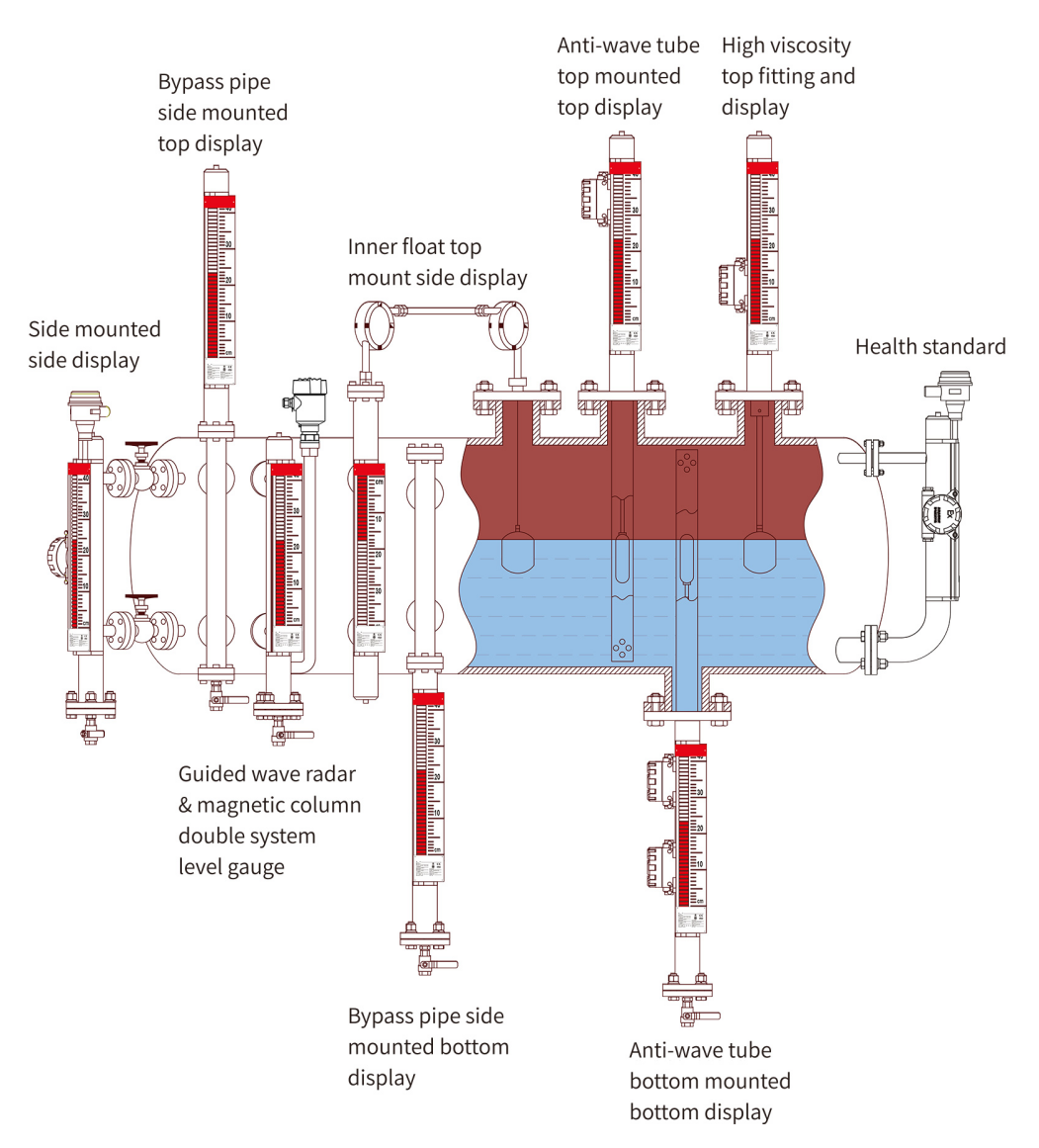

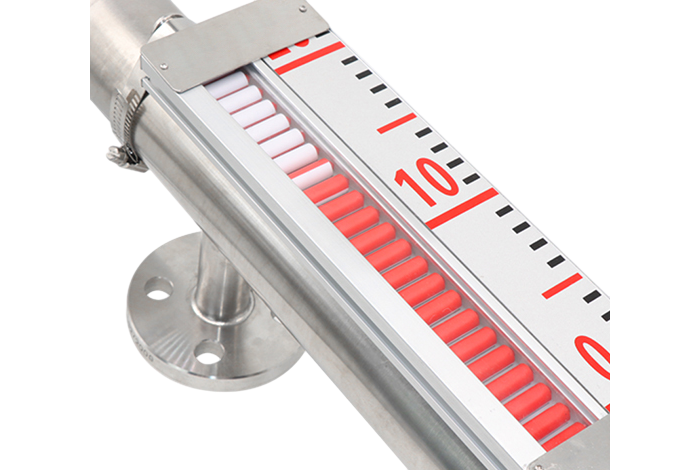

Magnetic Level Gauge

Medium temperature:

-120°C~80°C, -20°C~80°C, -20°C~140°C, -20°C~350°C

Power supply:

13~36 VDC

Output signal:

Two-wire system 4~20mA DC

Switch output signal:

AC70VA, DC50W

The magnetic flap level gauge is an on-site instrument that measures and controls liquid levels in tanks. It utilizes a magnetic float that rises with the liquid, causing a color-changing visual indicator to display the level. Beyond this visual display, the gauge can also provide 4-20mA remote signals, switch outputs, and digital level readouts. Designed for use in both open and closed pressure vessels, the gauge employs specialized high-temperature, high-pressure, and corrosion-resistant materials along with advanced manufacturing techniques to ensure suitability for a variety of applications. Additionally, customizable options like drain valves can be incorporated to meet specific on-site needs.