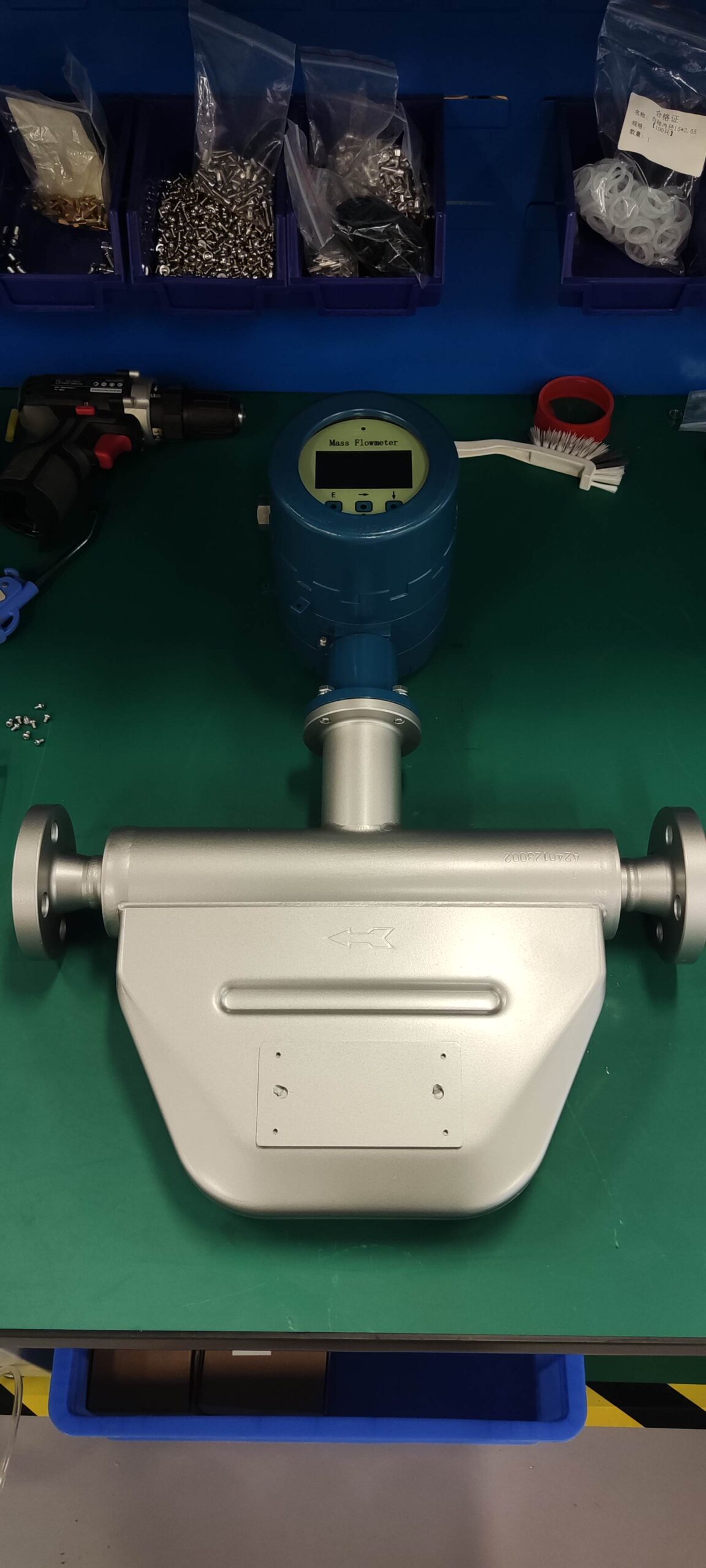

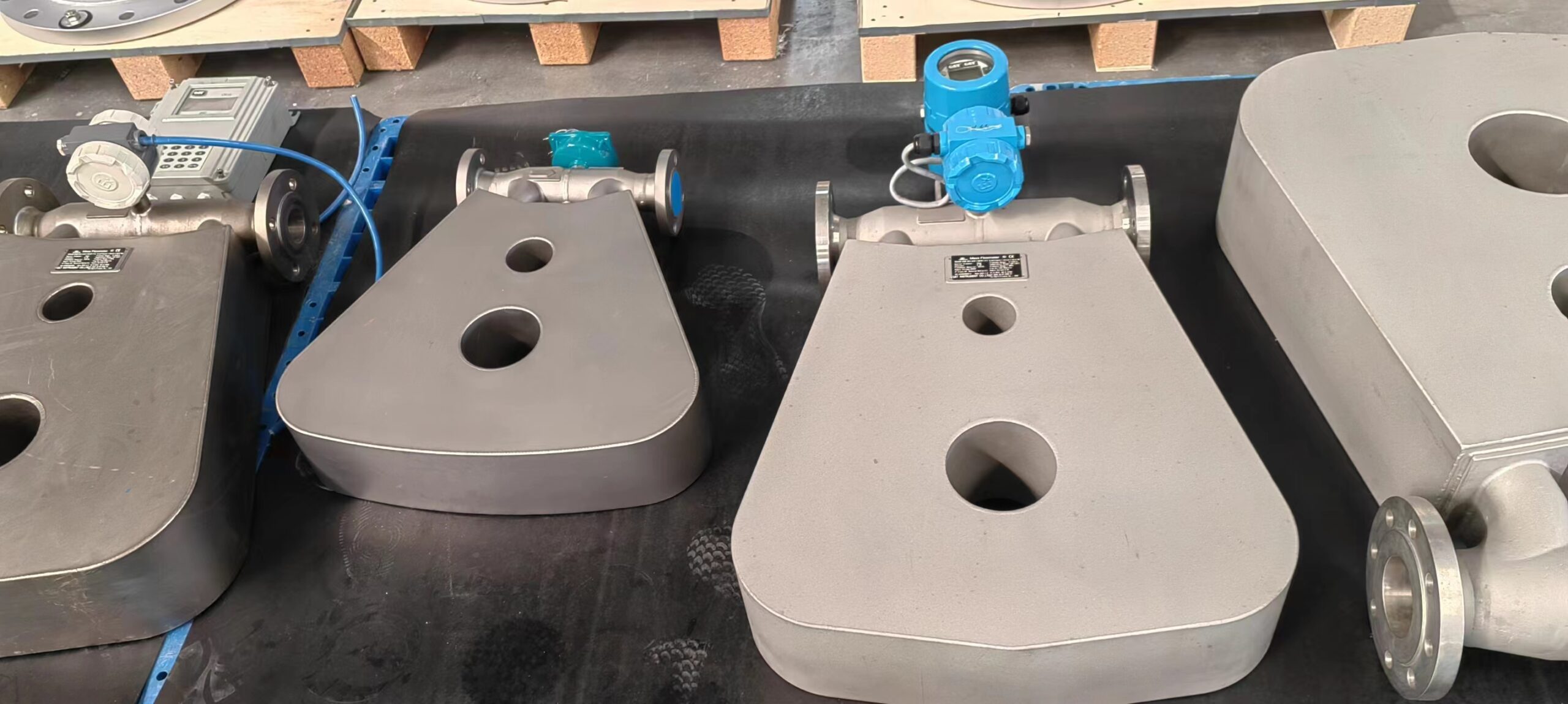

High Accuracy Liquid Mass Flow Meter Double Power Supply Coriolis Flow Meter

Coriolis mass flowmeters are robust instruments, but like any measurement device, they can experience faults or issues. Here are some common faults with Coriolis mass flowmeters and their possible solutions:

Zero Drift: Zero drift occurs when the flowmeter’s zero point gradually shifts over time, resulting in inaccurate measurements even when there is no flow. This can be caused by factors such as sensor aging, temperature fluctuations, or changes in the fluid properties.

Solution: Recalibrate the flowmeter regularly to reset the zero point and restore accuracy. Check for any environmental factors that may be affecting the zero stability, such as temperature variations or mechanical stress on the sensor. Consider upgrading to a flowmeter with improved zero stability if drift persists.

Fluid Density Variation: Coriolis mass flowmeters rely on accurate measurement of fluid density to calculate mass flow rate. Variations in fluid density, such as changes in temperature, pressure, or composition, can lead to measurement errors.

Solution: Install temperature and pressure compensation devices to account for changes in fluid density. Use flowmeters with advanced algorithms that can compensate for variations in fluid properties and provide accurate measurements under changing conditions.

Fluid Viscosity Effects: High viscosity fluids can affect the performance of Coriolis mass flowmeters, causing damping effects and reducing measurement accuracy, especially at low flow rates.

Solution: Choose a flowmeter with a design optimized for measuring high viscosity fluids, such as a larger tube diameter or specialized sensor coatings. Consider using viscosity compensation algorithms or additional viscosity sensors to improve accuracy in viscosity-sensitive applications.

Pipe Installation Issues: Improper installation of the flowmeter, such as incorrect pipe alignment, inadequate straight pipe runs, or improper grounding, can lead to measurement errors and instability.

Solution: Ensure proper installation according to the manufacturer’s guidelines, including adequate straight pipe runs upstream and downstream of the flowmeter to minimize flow disturbances. Use proper mounting hardware and ensure secure pipe connections to prevent vibration and ensure stability.

Electrical or Signal Interference: Electrical noise or interference from nearby equipment or power sources can affect the performance of Coriolis mass flowmeters, leading to signal drift or erratic readings.

Solution: Install shielding or grounding measures to minimize electrical interference. Keep the flowmeter away from sources of electromagnetic interference, such as motors, transformers, or radio frequency (RF) devices. Use high-quality cables and connectors to ensure reliable signal transmission.

Mechanical Damage: Physical damage to the flowmeter, such as impacts, vibrations, or exposure to harsh environmental conditions, can cause sensor misalignment, tube deformation, or other mechanical issues.

Solution: Protect the flowmeter from mechanical damage by installing it in a stable, secure location away from potential hazards. Implement regular inspection and maintenance procedures to check for signs of wear or damage and address any issues promptly.

Sensor Fouling or Contamination: Buildup of deposits, coatings, or contaminants on the flowmeter sensor or tube walls can affect measurement accuracy and cause flow disturbances.

Solution: Implement regular cleaning and maintenance procedures to remove any fouling or contaminants from the flowmeter sensor and tubing. Use appropriate cleaning agents and techniques recommended by the manufacturer to avoid damage to the sensor or coatings.

Software or Firmware Issues: Software bugs or firmware glitches in the flowmeter’s control system can cause erratic behavior, communication errors, or other operational issues.

Solution: Check for software updates or firmware patches provided by the manufacturer to address known issues or improve performance. Follow proper procedures for updating the flowmeter’s software or firmware, and ensure compatibility with existing systems and protocols.

By addressing these common faults and implementing appropriate solutions, you can maintain the accuracy, reliability, and performance of Coriolis mass flowmeters in your industrial processes. Regular inspection, calibration, and maintenance are essential to ensure optimal performance and minimize downtime due to faults or issues.