What are the installation requirements for mass flowmeters

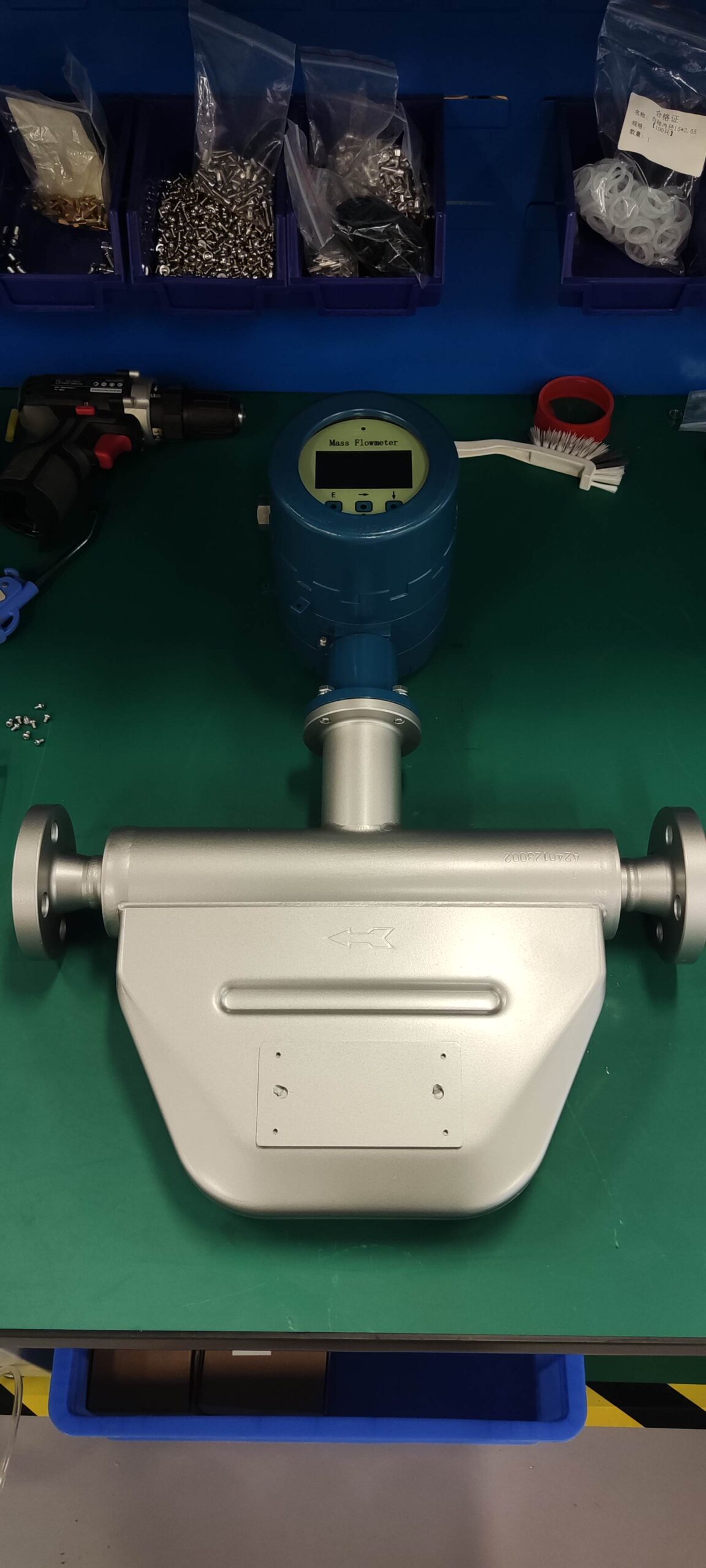

When installed correctly, the Coriolis mass flowmeter can directly measure the mass and density of the fluid. Only with reasonable installation can the accuracy and stability of the mass flowmeter be maintained.

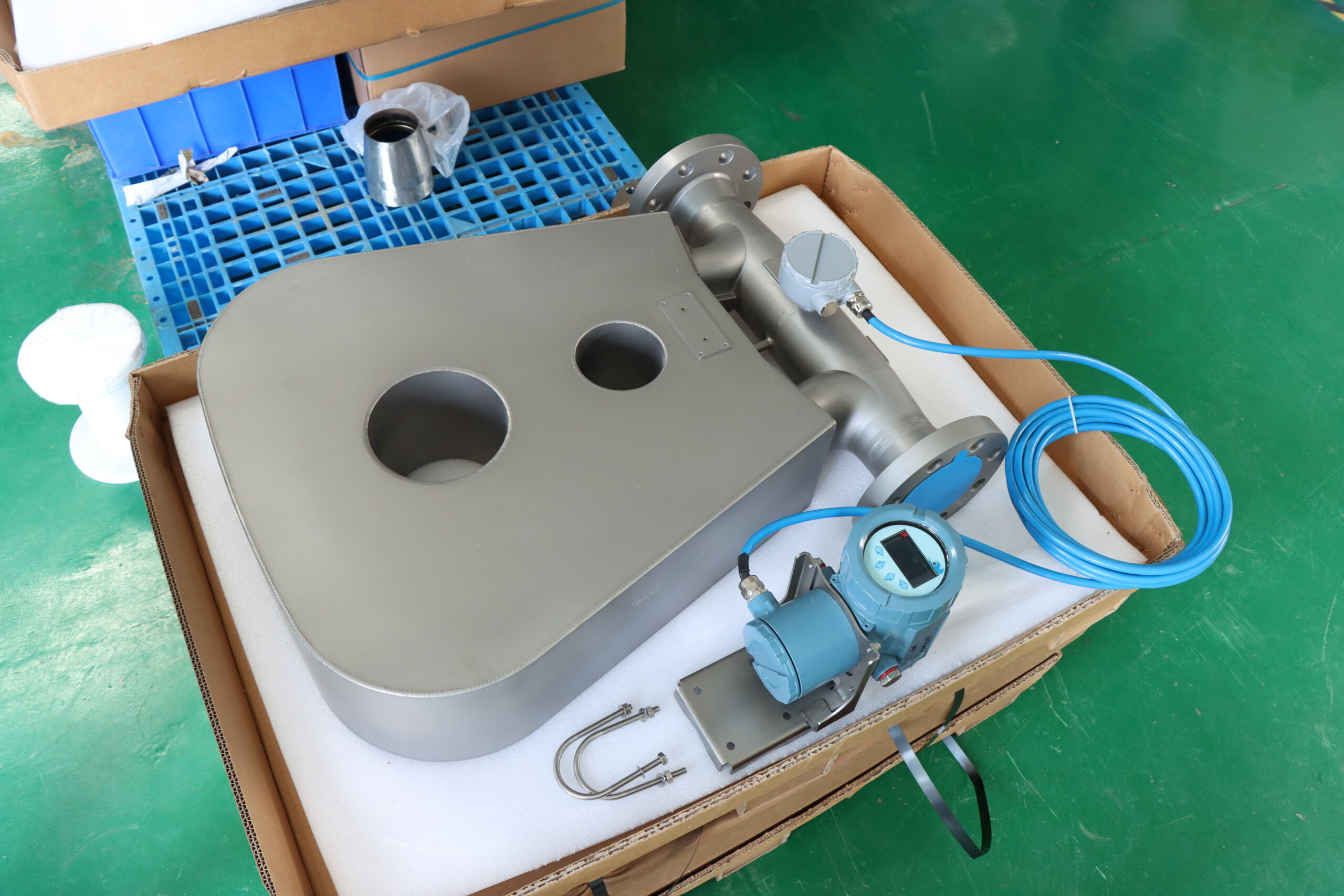

1. Key points for the installation of Coriolis mass flowmeters

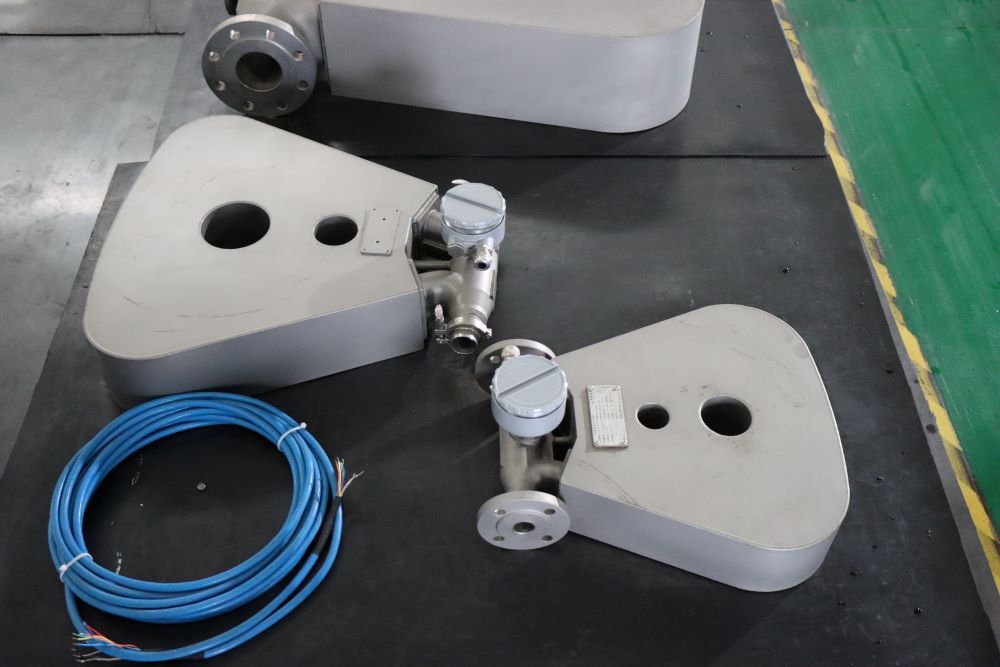

There should be at least a distance of 0.6 meters between the sensor and the large transmitter or motor. Since the sensor’s operation relies on electromagnetic fields, it is essential to avoid installing the sensor near large interfering electromagnetic fields. In addition, the installation location should be carefully selected to avoid vibration as much as possible.

2. Installation direction

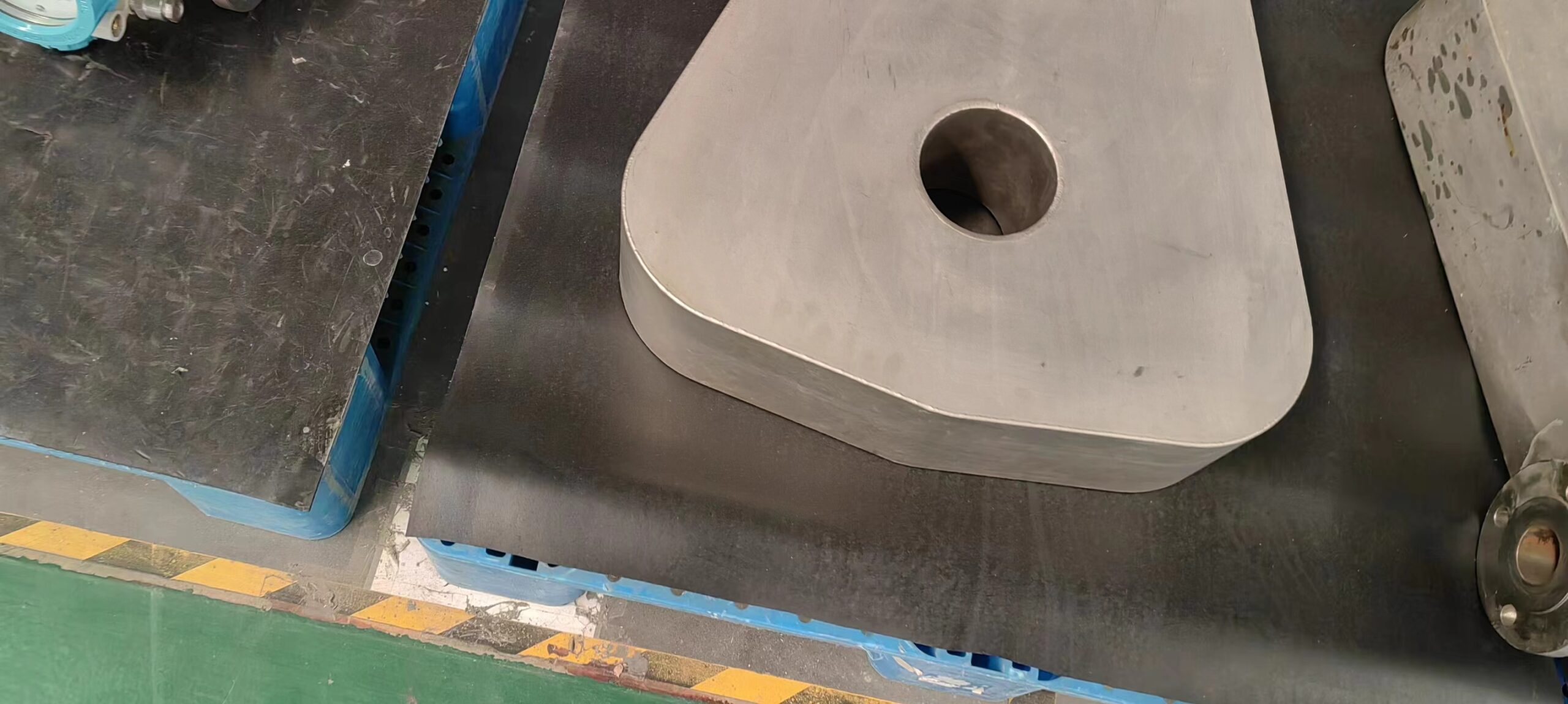

The requirements of the process and the positions of the already arranged process pipelines determine the installation directions of most sensors. Although the installation Angle of the sensor does not affect the operation of the flowmeter, the following suggestions should be considered as much as possible:

When measuring liquids, the sensor housing should be installed facing down to prevent air from accumulating in the flow tube.

2) When measuring gas, the sensor housing should be installed upwards to prevent condensation water from accumulating in the flow tube.

3) When measuring liquid slurry, the sensor should be installed vertically like a flag to prevent particles from accumulating in the flow tube. The process medium should flow from bottom to top to avoid jet empty pipes.

3. Valve

To facilitate the zero adjustment of the flowmeter, a stop valve should be installed downstream of the sensor. To facilitate batch operation, the sensor and the stop valve should be as close as possible to the receiving container. Hoses should not be installed between the sensor and the stop valve to avoid batch errors caused by expansion or compression. In addition, a regulating valve can be installed downstream to prevent the medium from vaporizing or evacuating.

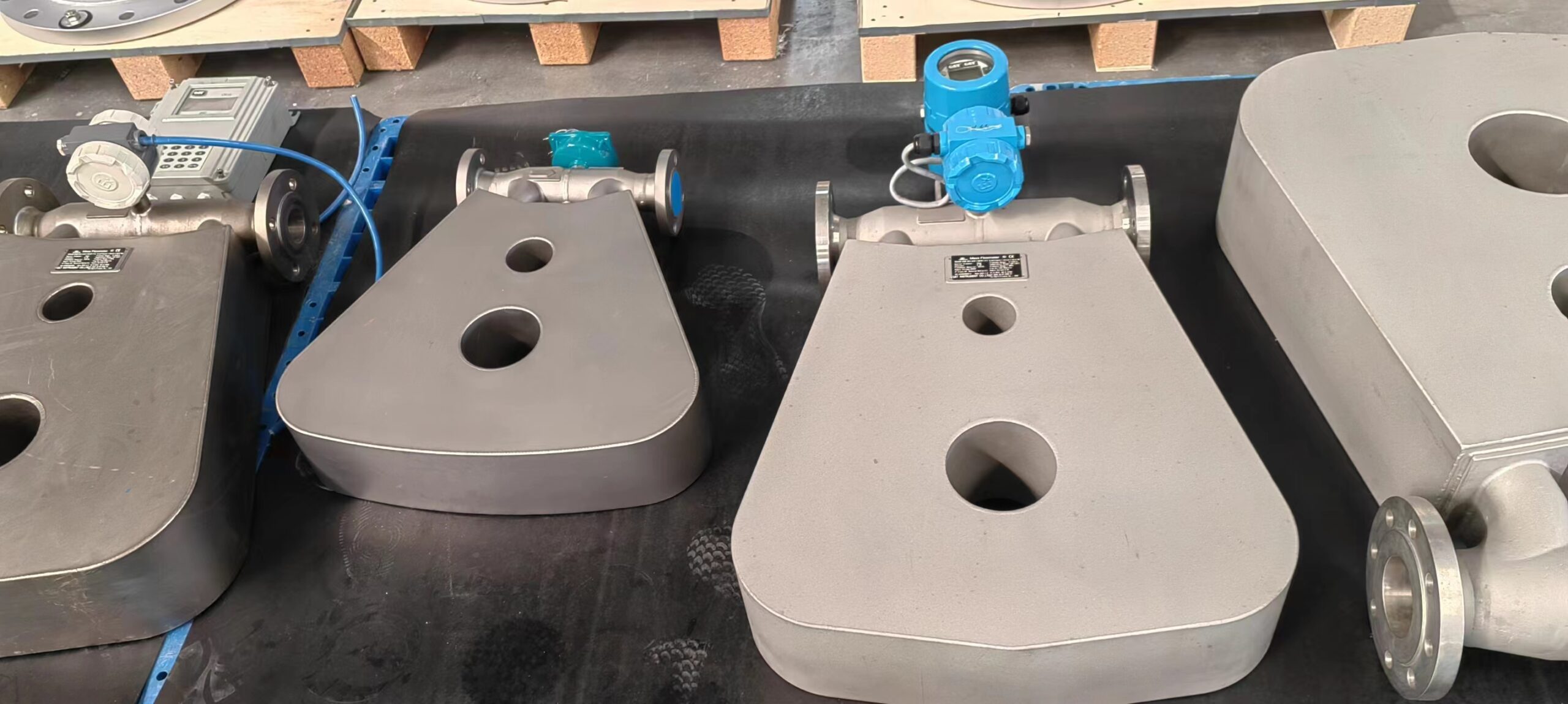

4. The direction of installation of the mass flowmeter

No matter what the flow direction is, the flow sensor can accurately measure the flow. Generally, arrows are used on sensors to indicate the normal flow direction of the fluid.

5. Gas-liquid two-phase flow

If the process medium generates gas-liquid two-phase flow, the sensor housing should be installed downward or on a vertical pipe. This installation method can effectively prevent the gas in the medium from accumulating in the flow pipe.

When installing a Coriolis mass flowmeter, the installation direction is very important. The installation direction is determined by the position of the process pipelines arranged on site. Only reasonable installation can ensure the long-term stable operation of the Coriolis mass flowmeter.