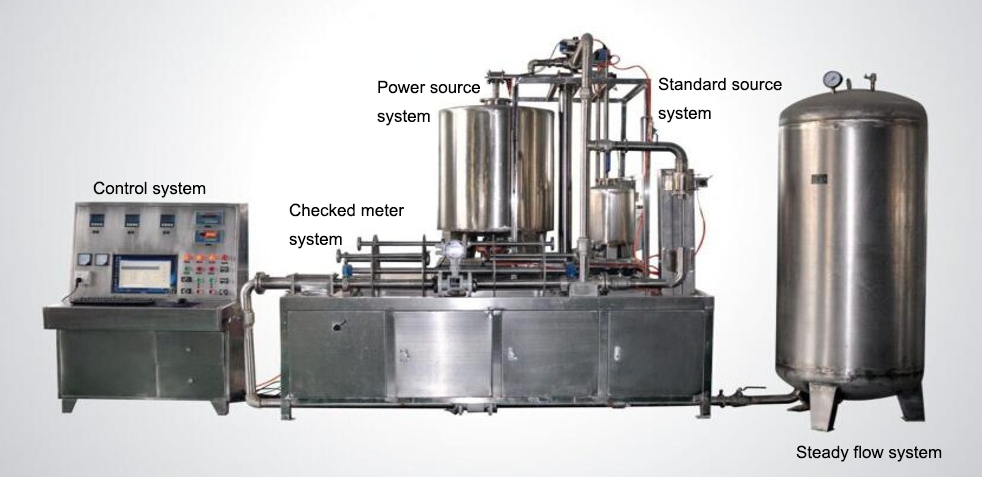

Water Flow Calibration Device

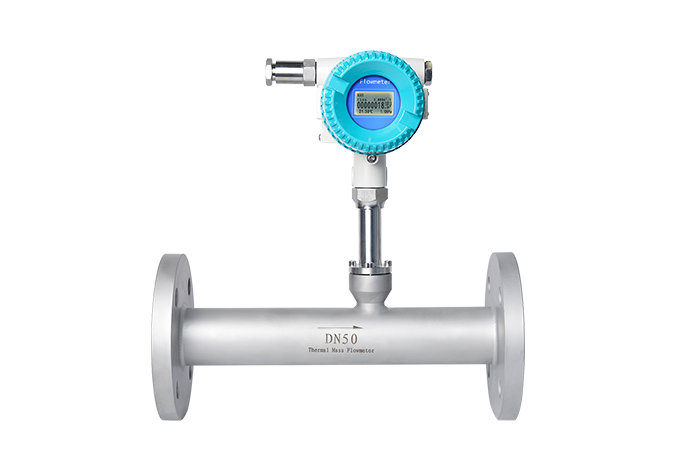

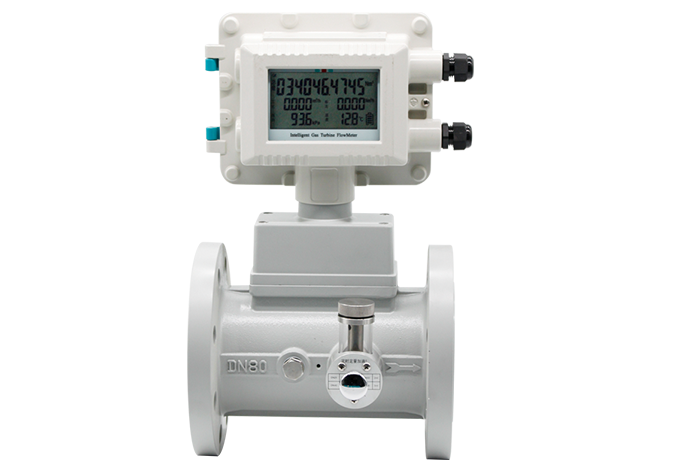

Types of flowmeters that can be detected:

Electromagnetic flow meters, Turbine flow meters, Metal tube float flow meters, Vortex flow meters, etc., can be verified as one type or multiple types simultaneously

The diameter of the detectable instrument:

Standard version DN10/25/50 (Optional range: DN10-DN800)

Comprehensive accuracy:

0.20%

Pressure range:

0~0.6MPa

Aister Instrument Factory has many years of independent research and development, design and production experience in water flow standard devices. It can precisely calibrate various velocity flowmeters, volumetric flowmeters, mass flowmeters, etc. with diameters ranging from DN10 to DN800.