What are the requirements for pipeline installation of liquid turbine flowmeters

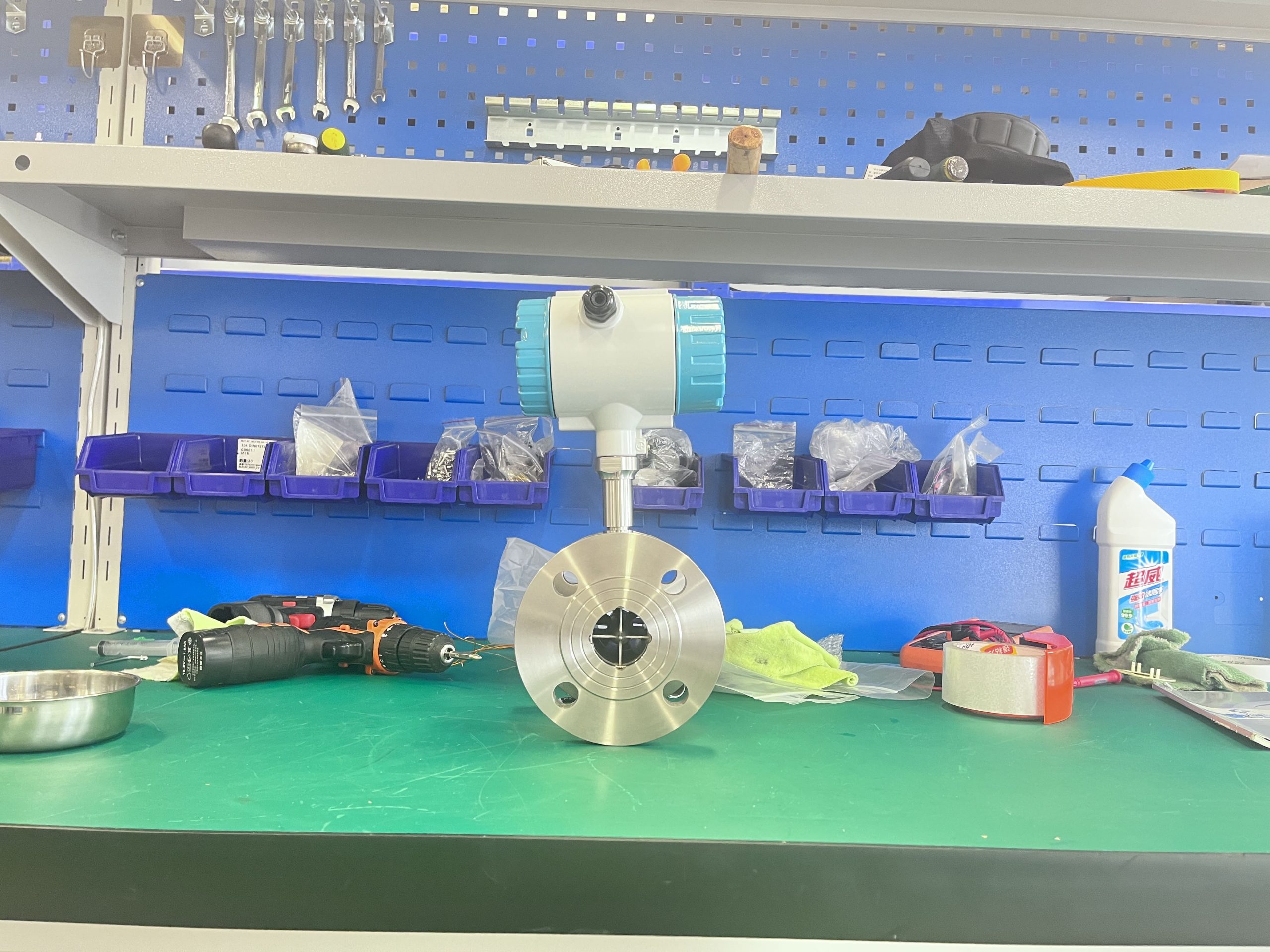

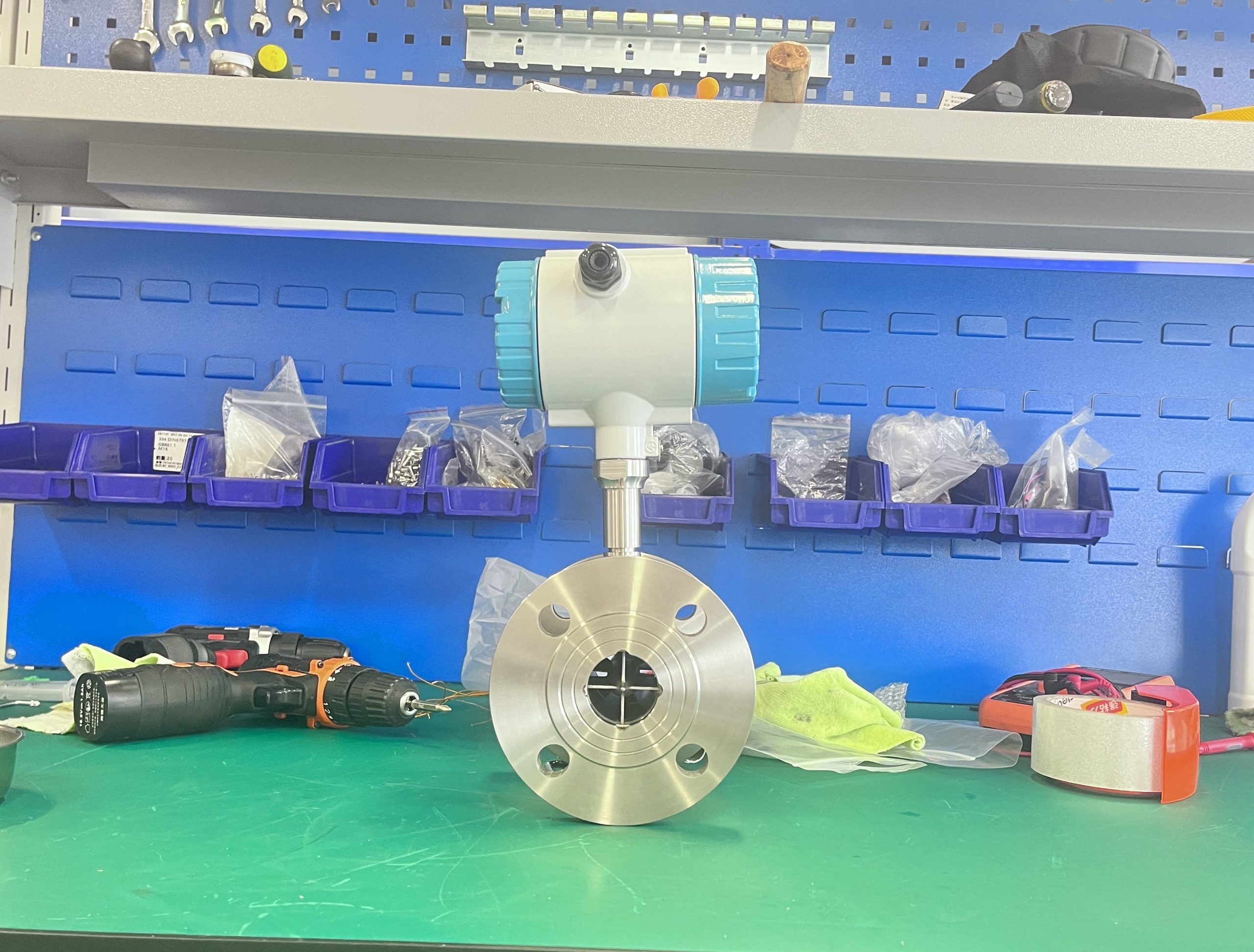

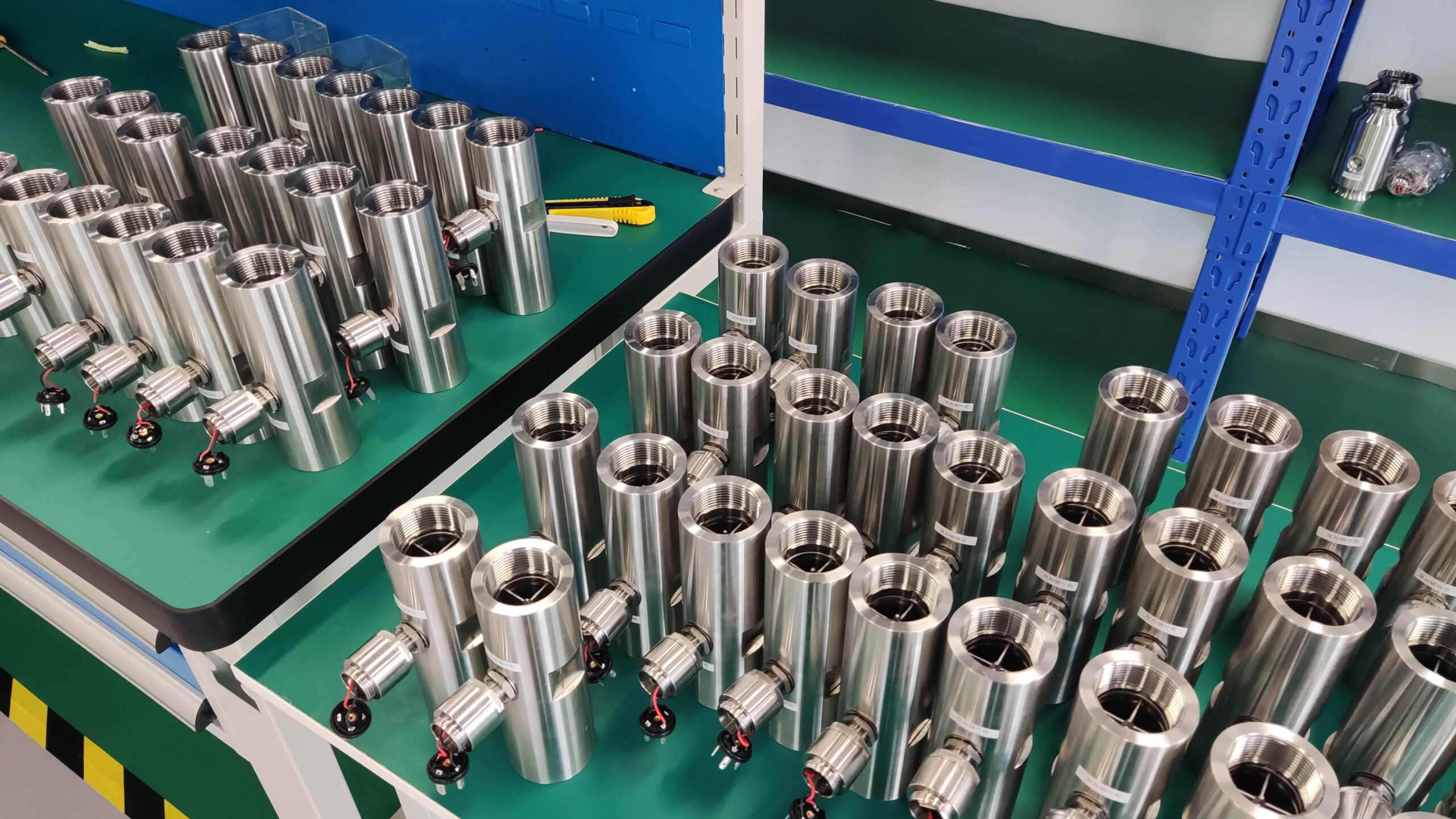

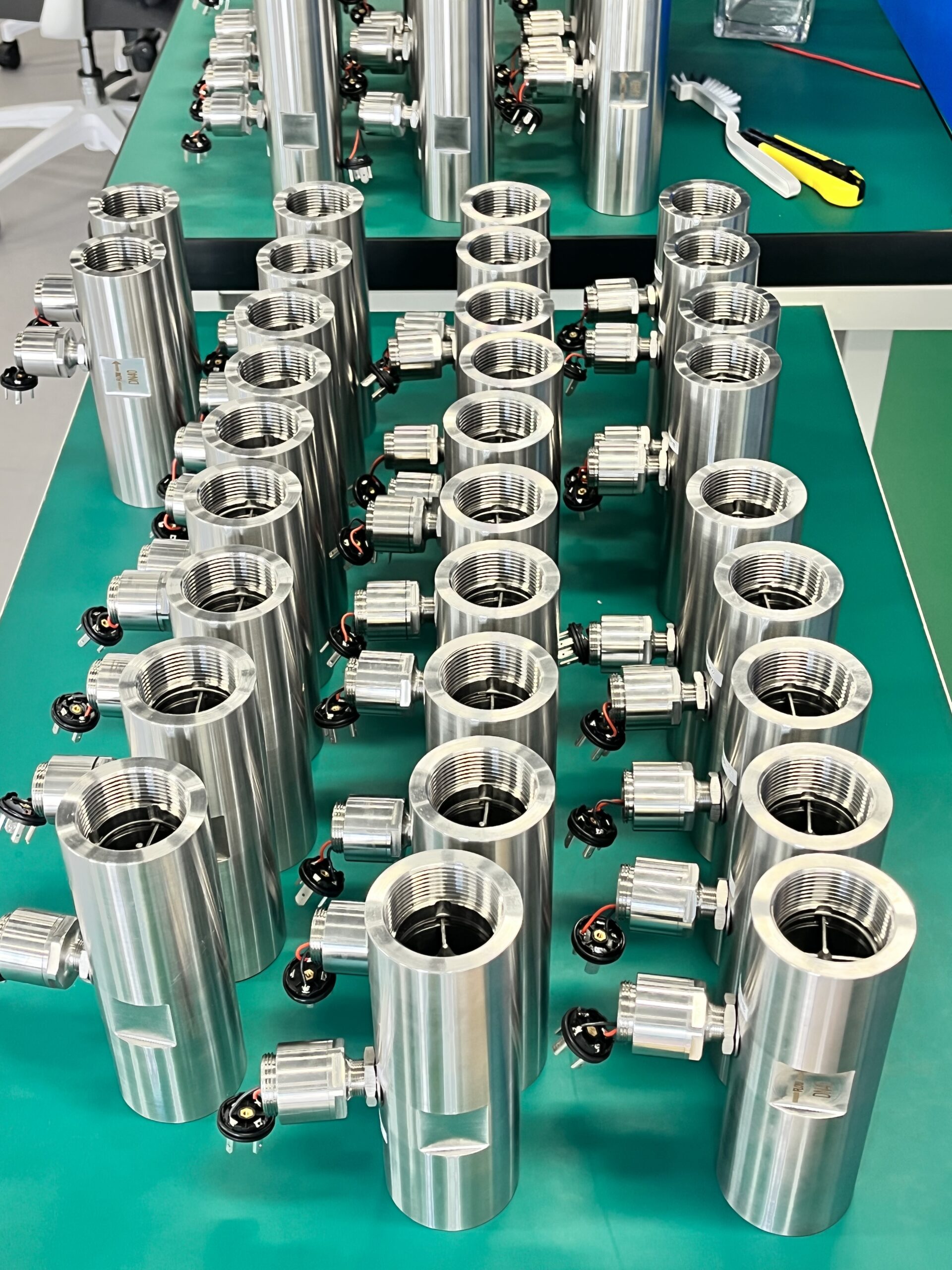

The turbine flowmeter is composed of a turbine flow sensor and a display instrument, and it is a type of flowmeter that is more suitable for liquid flow. The flowmeter features a simple structure, high precision, and convenient installation, maintenance and use. Turbine flowmeters are widely used in fields such as petroleum, chemical engineering, metallurgy, water supply, papermaking, environmental protection, and food. They are suitable for measuring liquids in closed pipelines that do not corrode stainless steel 1Cr18Ni9Ti, 2Cr13, corundum Al2O3, and hard alloys, and have no fibers, particles or other impurities. If used in conjunction with display instruments with special functions, it can be used for automatic quantitative control, over-limit alarm and other purposes.

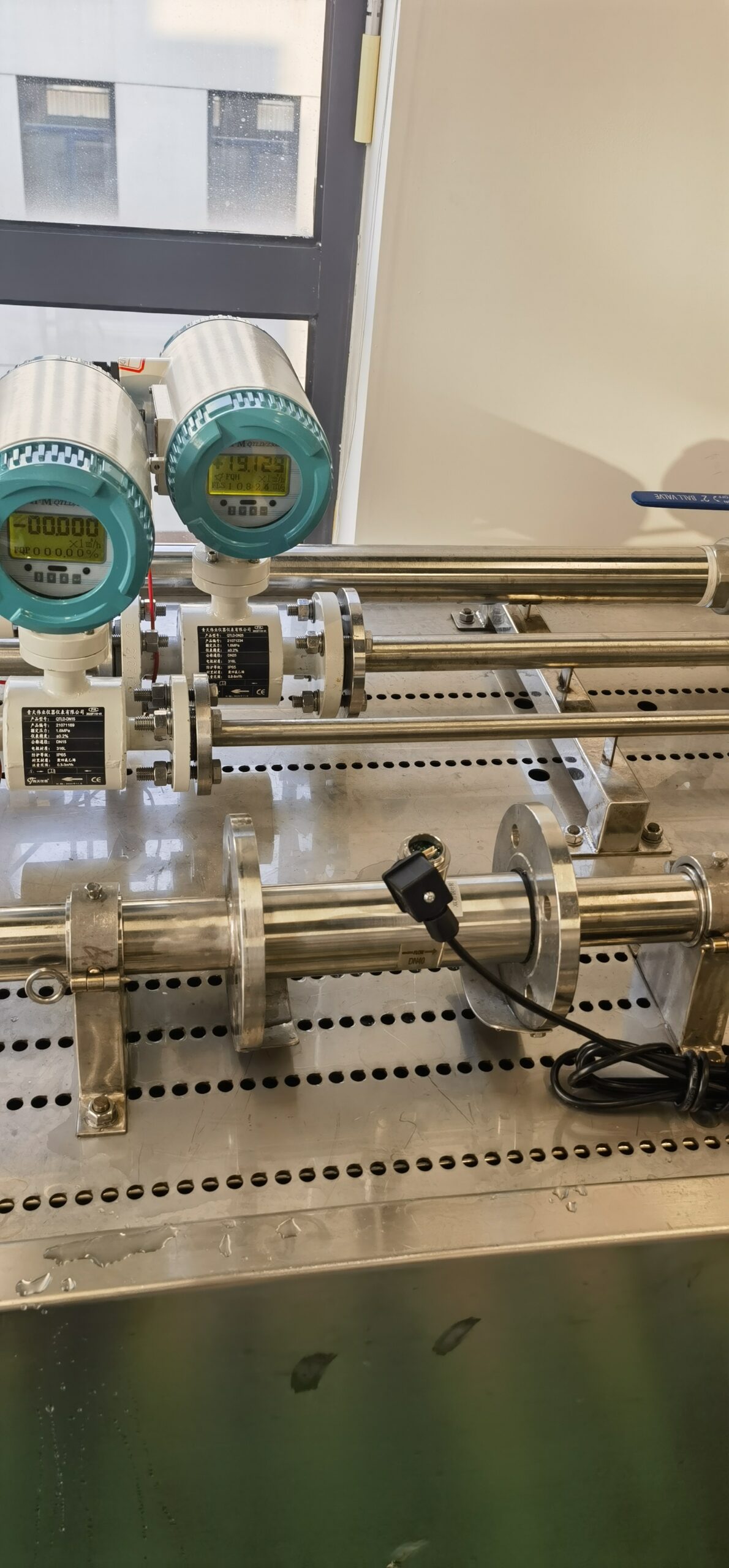

Installation matters of turbine flowmeter pipeline

The sensor should be installed in a place that is convenient for maintenance, where the pipeline is free from vibration, strong electromagnetic interference and thermal radiation influence.

For horizontal installation of sensors, the pipeline should not have a perceptible tilt (generally within 5°), and for vertical installation of sensors, the verticality deviation of the pipeline should also be less than 5°. In places where flow cannot be stopped, bypass pipes and reliable stop valves should be installed. When measuring, it is necessary to ensure that there is no leakage in the bypass pipe.

At the position where the sensor is to be installed on the newly laid pipeline, first connect a short pipe to replace the sensor. After the “line sweeping” work is completed and it is confirmed that the pipeline is thoroughly cleaned, then officially connect the sensor.

If the fluid contains impurities, a filter should be installed on the upstream side of the sensor, and the settled impurities in the pipeline should be regularly cleaned and discharged. If the liquid being measured contains gas, a degasser should be installed on the upstream side of the sensor. The drain and deaeration ports of the filter and deaerator should lead to a safe place.

When the turbine flowmeter sensor is installed outdoors, measures should be taken to avoid direct sunlight and rain.