The application of turbine flowmeters in viscous liquids

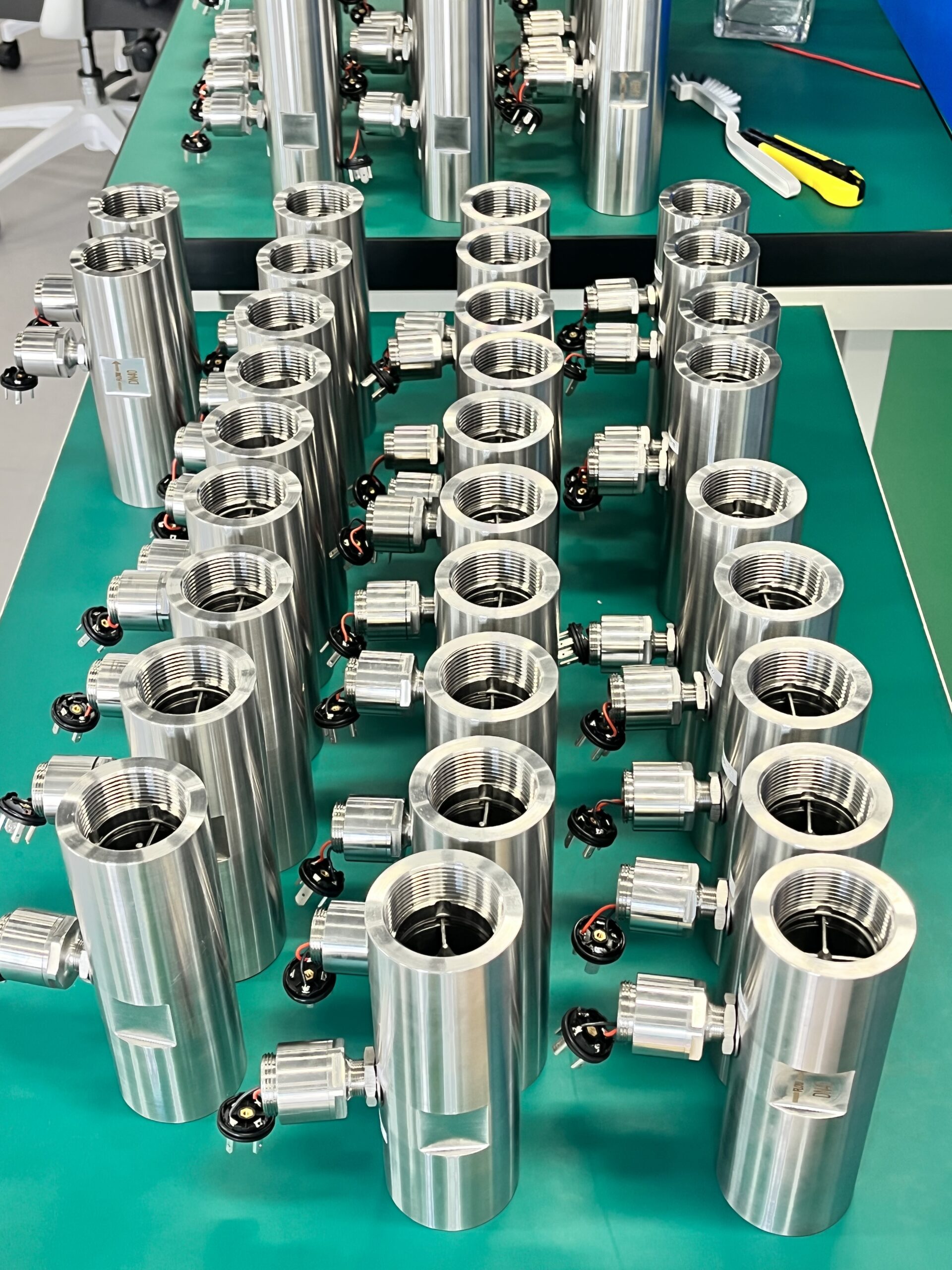

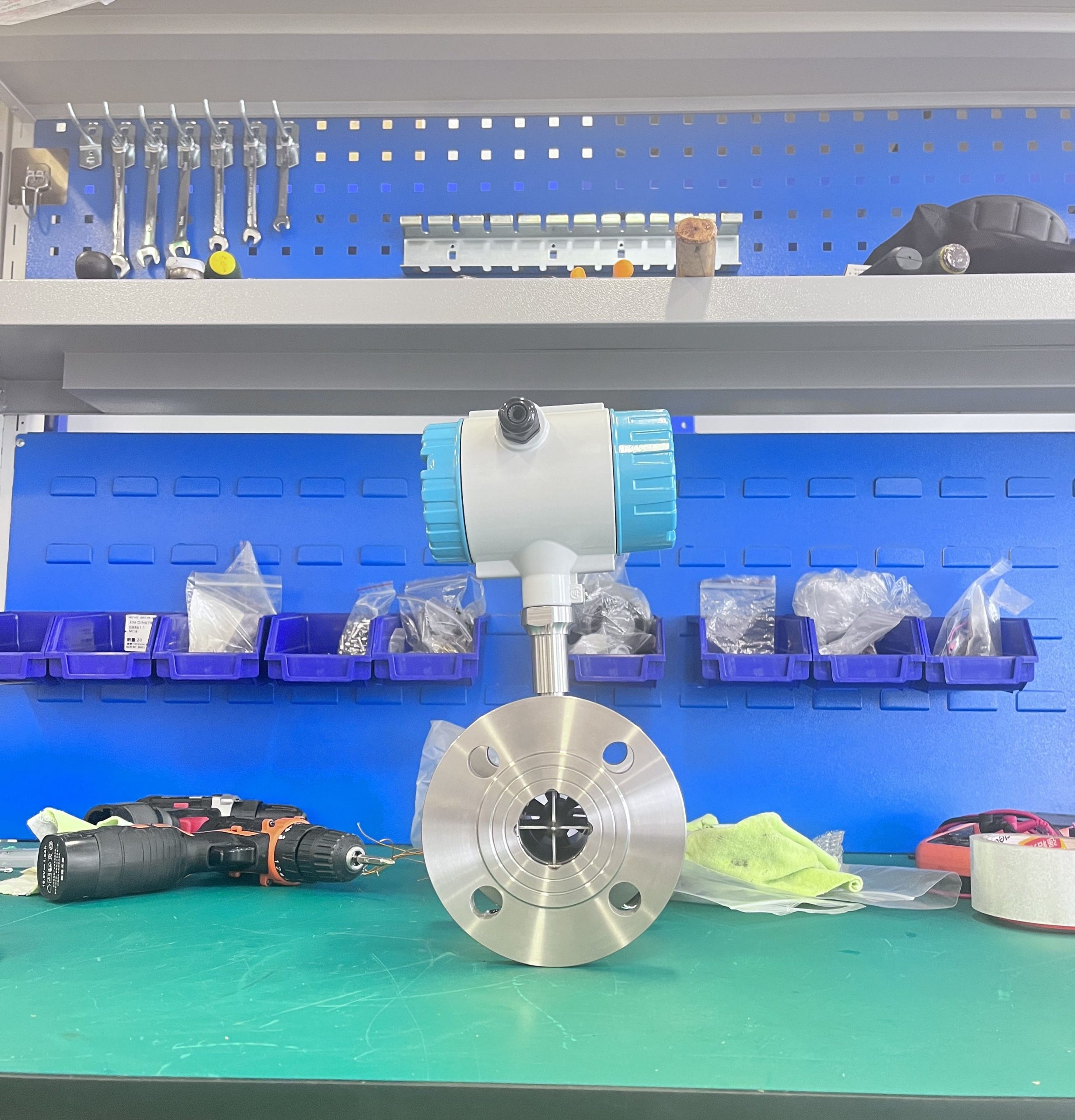

The liquid turbine flowmeter is a volumetric instrument that measures the total flow of liquid through a pipeline. It is mainly used to measure the cumulative flow of expensive media such as oil or other high-viscosity media. Its shell and gears are made of Ocr17N i12Mo2 stainless steel, which has the advantages of hygiene, cleanliness, acid resistance and corrosion resistance. It is widely used in occasions requiring hygiene and cleanliness such as liquid beverages, daily cosmetic liquids and medicine, as well as in the measurement of corrosive solutions in industrial sectors such as metallurgy and chemical engineering. Output pulse signal, 12VDC power supply, three-wire system.

The liquid turbine flowmeter has the following features:

1. Adopt contactless messaging technology;

2. High precision and less affected by changes in liquid viscosity;

3. No straight pipe section needs to be installed before the meter.

4. Intrinsically safe explosion-proof, explosion-proof mark: ExdIICT6Gb

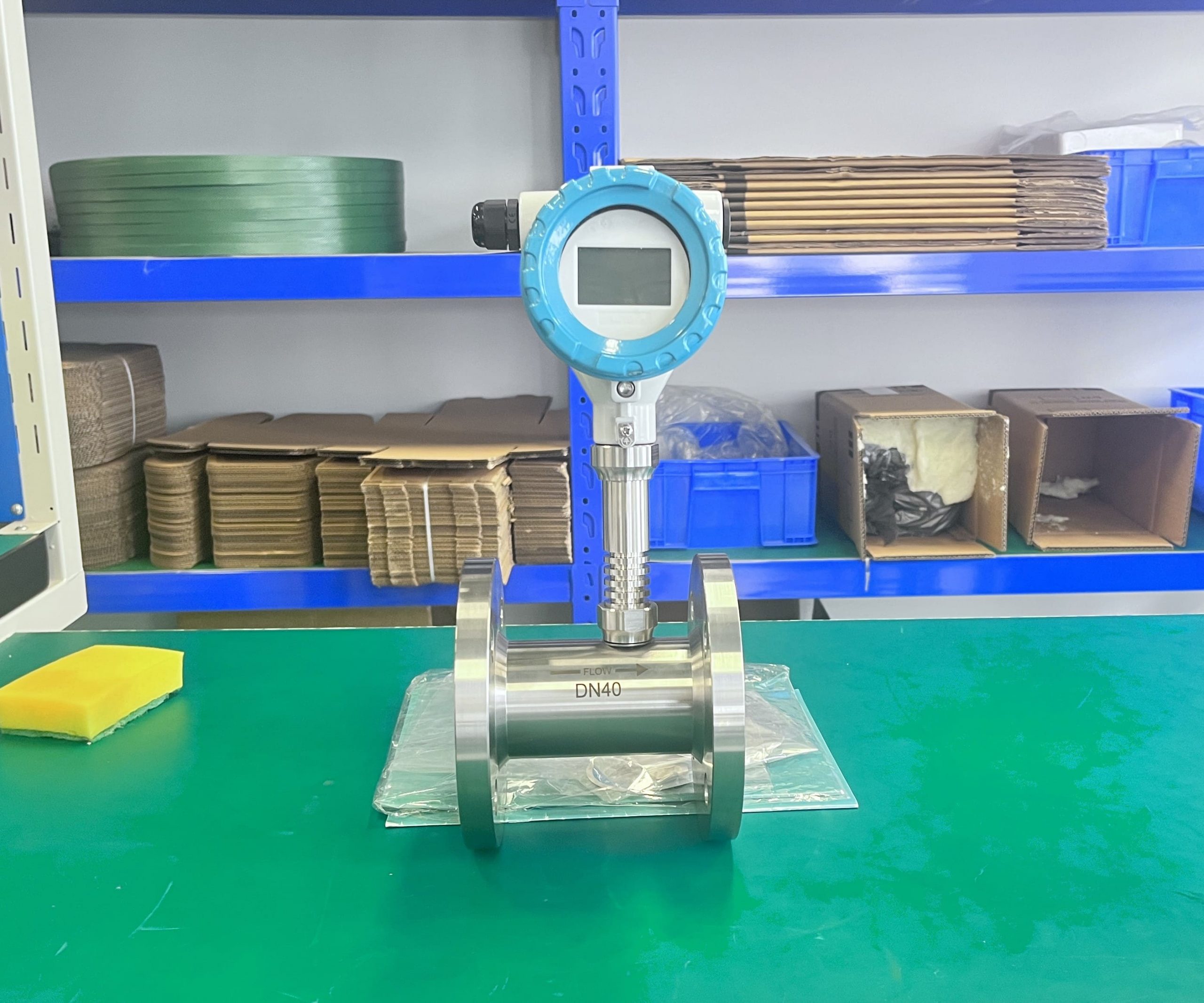

Installation and Use of liquid turbine flowmeters

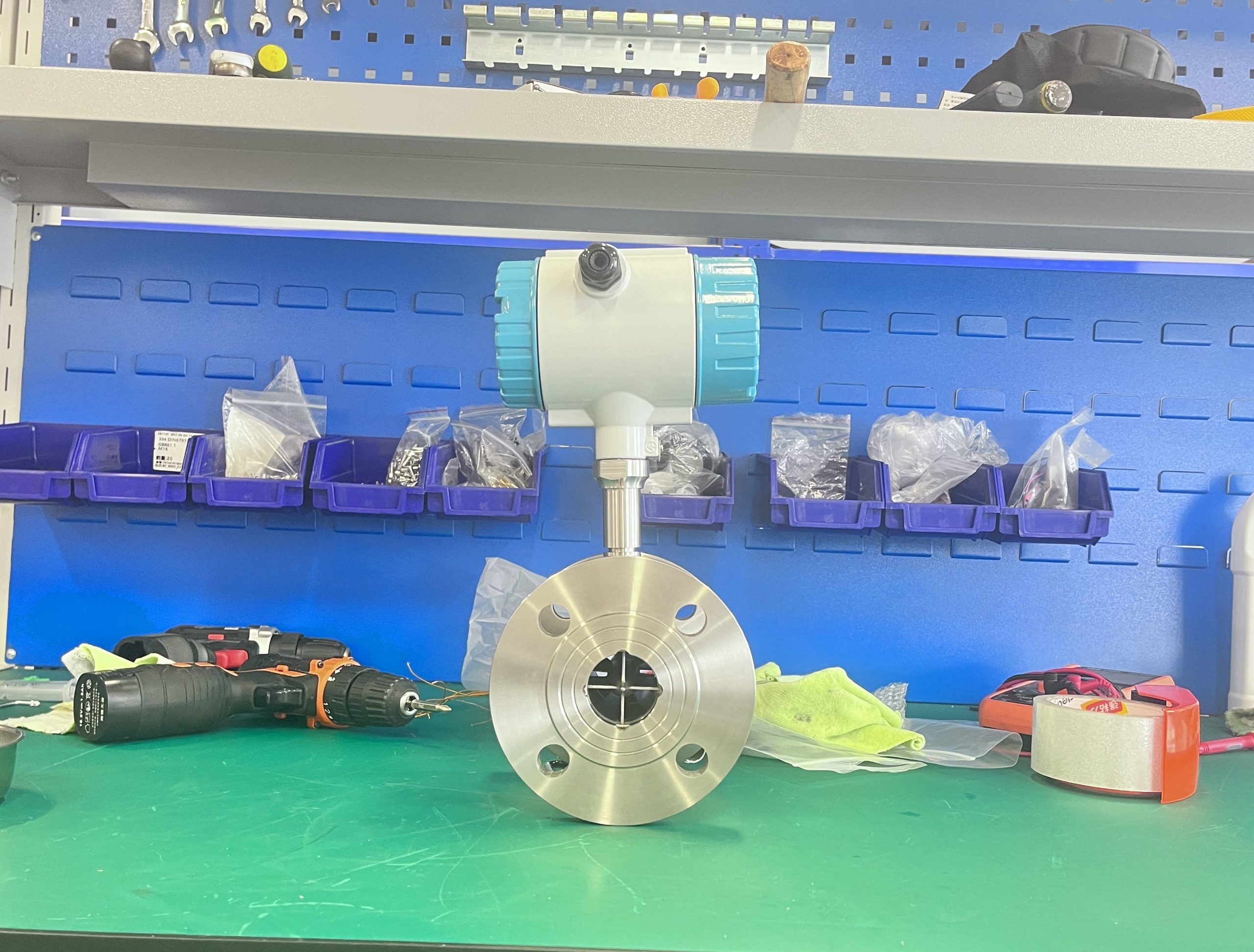

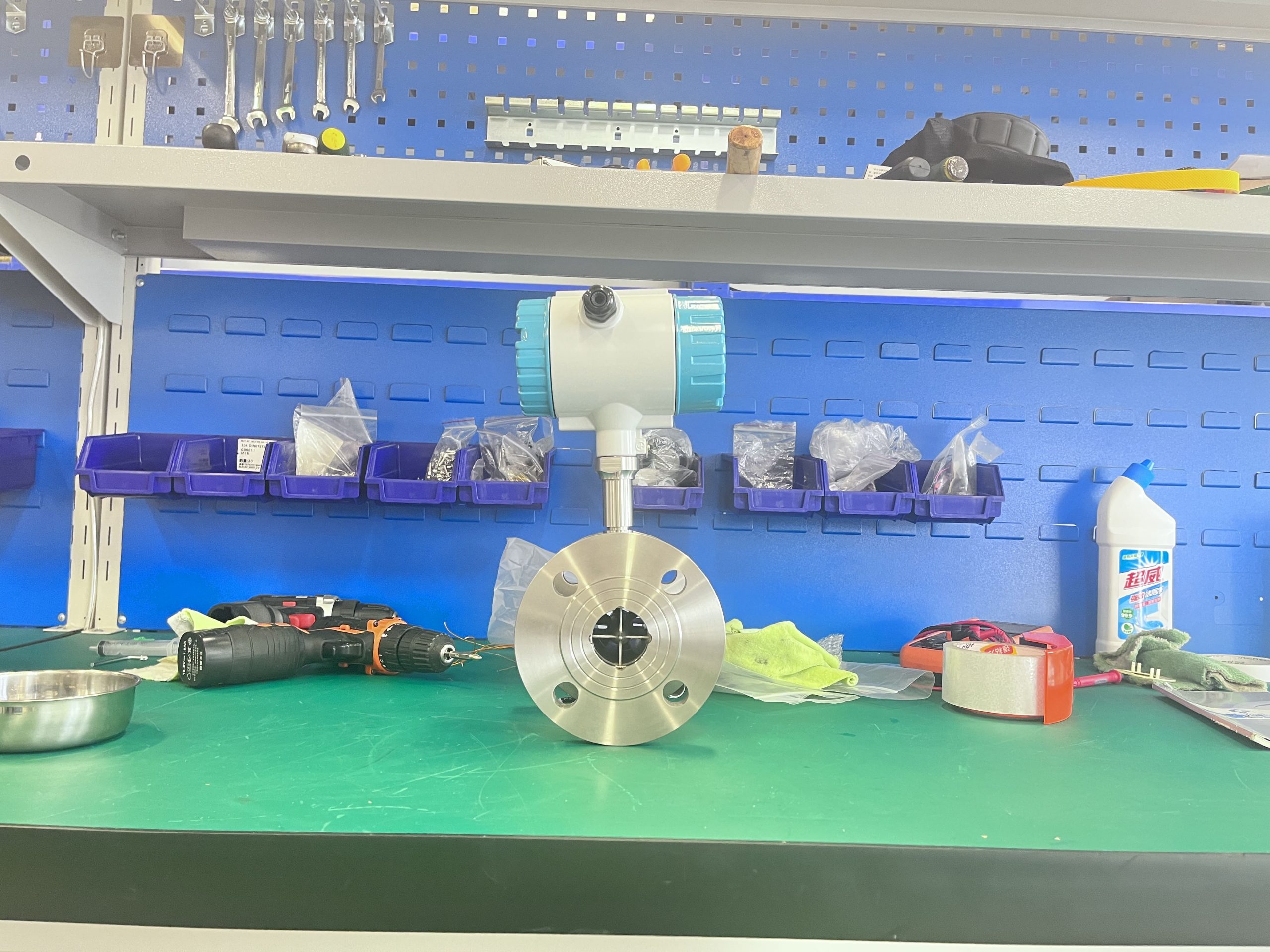

Before installing the transmitter, all debris on the surface of the pipeline should be carefully removed. When installing the transmitter, it is necessary to prevent debris from falling into the pipeline. The elliptical gear should be installed in a horizontal position as much as possible.

2. A filter should be installed before the transmitter to prevent it from being blocked by debris and getting stuck in the pipeline. The filter should be cleaned regularly.

3. The transmitter should be installed at the output end of the pump; otherwise, it will also cause an increase in instrument error.

4. There should be no strong magnetic fields around the transmitter that could affect the operation of the instrument.

When the transmitter is in use, the meter should be filled with liquid. The liquid to be tested should not be mixed with gas; otherwise, a gas separator should be installed.