Selection of materials for fluid contact parts of electromagnetic flowmeters

Encounter electromagnetic flowmeters, I believe that many users have encountered difficulties in selection, such as according to the flow of caliber, material selection for the medium, coupled with some auxiliary functions, the need to access the computer or secondary table, these are more technical problems, which involve some calculation formulas and chemical knowledge and so on. Today, we will talk about the aspects that need to be paid attention to in the selection of electromagnetic flowmeter materials.

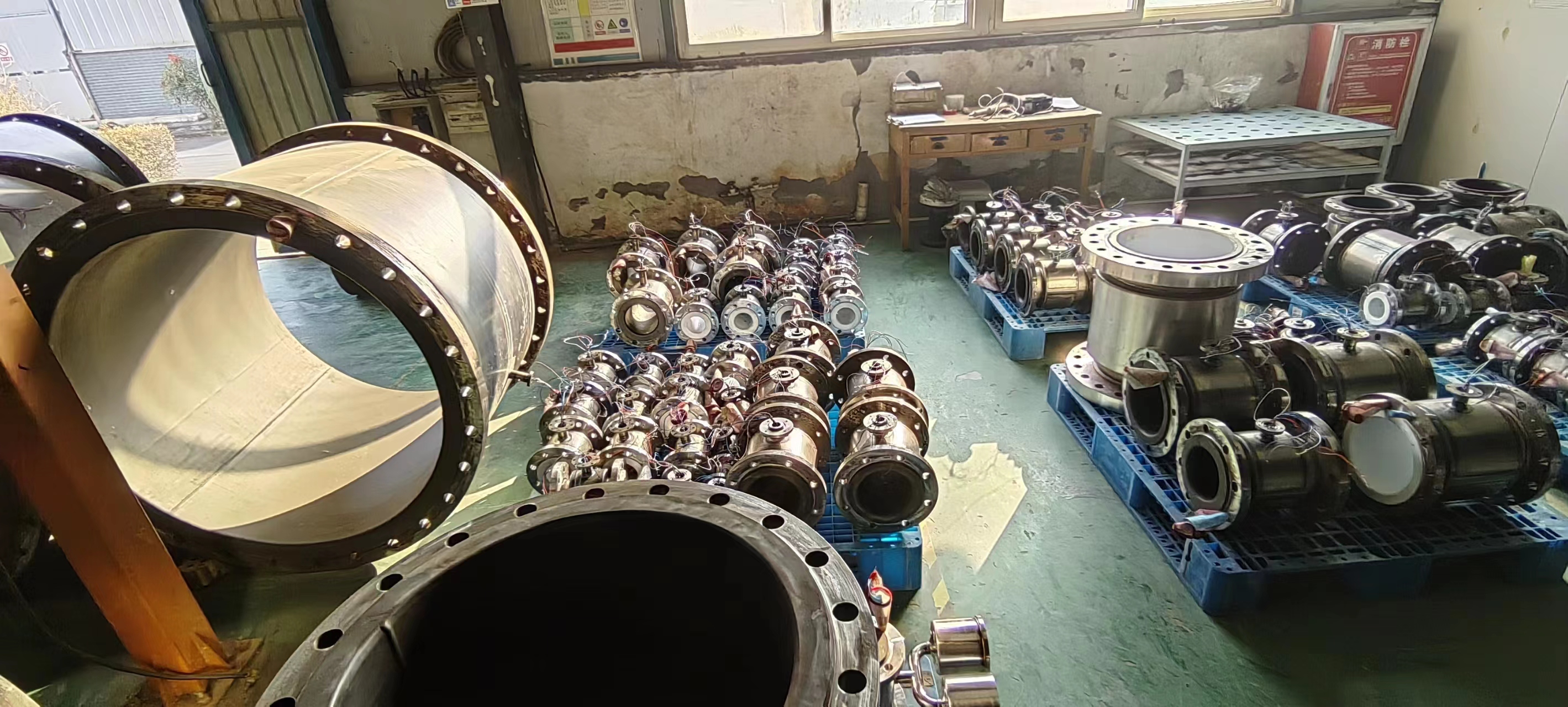

Because the electromagnetic flowmeter has fewer parts, simple shape and flexible material selection, the electromagnetic flowmeter can adapt to a variety of fluids. However, in the material to be selected, the sensor parts in contact with the fluid, such as the lining of the measurement tube, electrodes, ground rings and sealing gaskets, the corrosion resistance, wear resistance and use temperature of various materials must be understood clearly to adapt to different media.

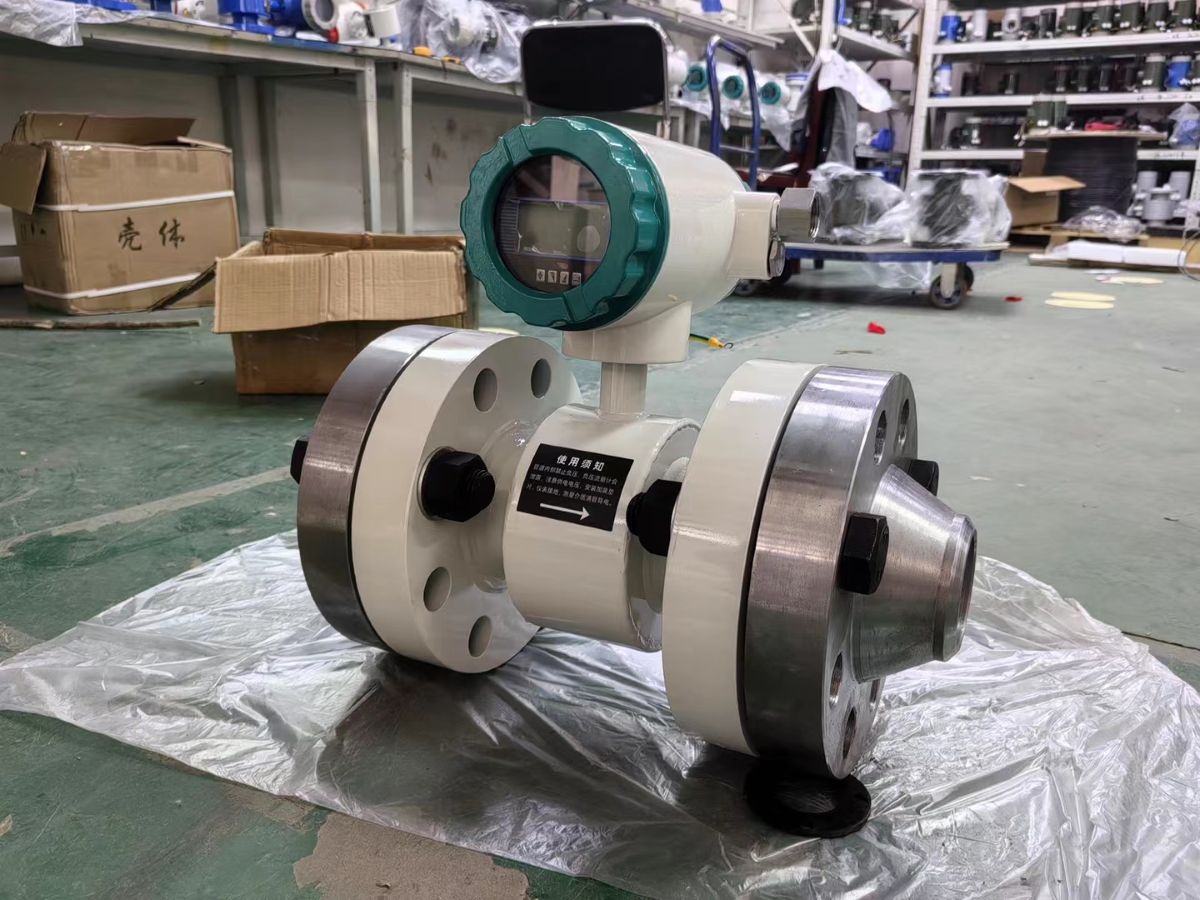

1. Selection of lining material

Commonly used lining materials are fluorine plastic, rubber and polyurethane. Rubber is suitable for non-corrosive or weakly corrosive liquids, such as industrial water, sewage and weak acid and alkali. Fluorine plastic, that is, tetrafluoride lining, has excellent chemical resistance, but poor wear resistance, can not be used to measure ore slurry. Polyurethane has excellent wear resistance, but the corrosion resistance of acid and alkali is poor, its wear resistance is equivalent to 10 times that of natural rubber, suitable for coal slurry, pulp, etc., but the medium temperature is lower than 40-70 degrees Celsius.

2. Electrode and grounding ring material selection

Measuring the corrosion resistance of the medium, the influence on the electrode is the first factor to be considered. Commonly used metal materials, Ha B, Ha C, titanium, tantalum, platinum-iridium alloy, can cover almost all chemical liquids. In principle, the choice of electrode material should be determined by the user based on the actual application of the medium in other devices and previous experience. Sometimes necessary experiments should be done, such as taking liquid samples in the field and doing corrosion tests on the materials to be used in the laboratory.

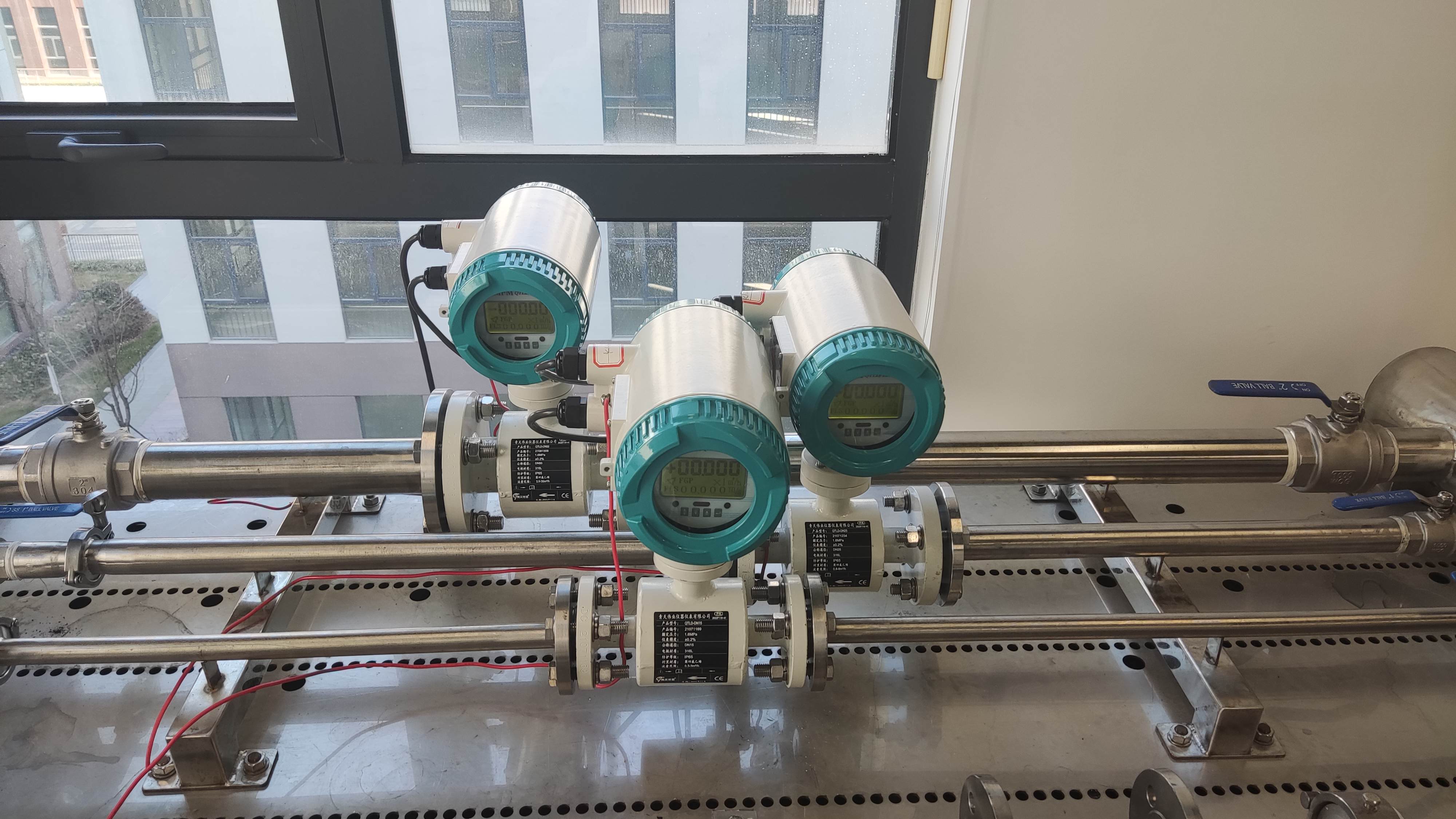

The ground ring is connected to both ends of the flow sensor of the pipeline, their corrosion resistance requirements are lower than the electrode, there is a certain corrosion, and it can be replaced regularly. Stainless steel and Hastelloy are usually used, and precious metals such as tantalum and platinum are less economically considered due to their large volume. If the process pipe is in contact with the fluid there is no need for a ground ring.

-.jpg)

-.jpg)