Can electromagnetic wave flowmeters be installed on PE pipes

Electromagnetic flowmeters (usually referring to electromagnetic flowmeters, as electromagnetic itself is not directly used for flow measurement) can be installed on PE (polyethylene) pipes, but the following points should be noted to ensure their normal operation and measurement accuracy:

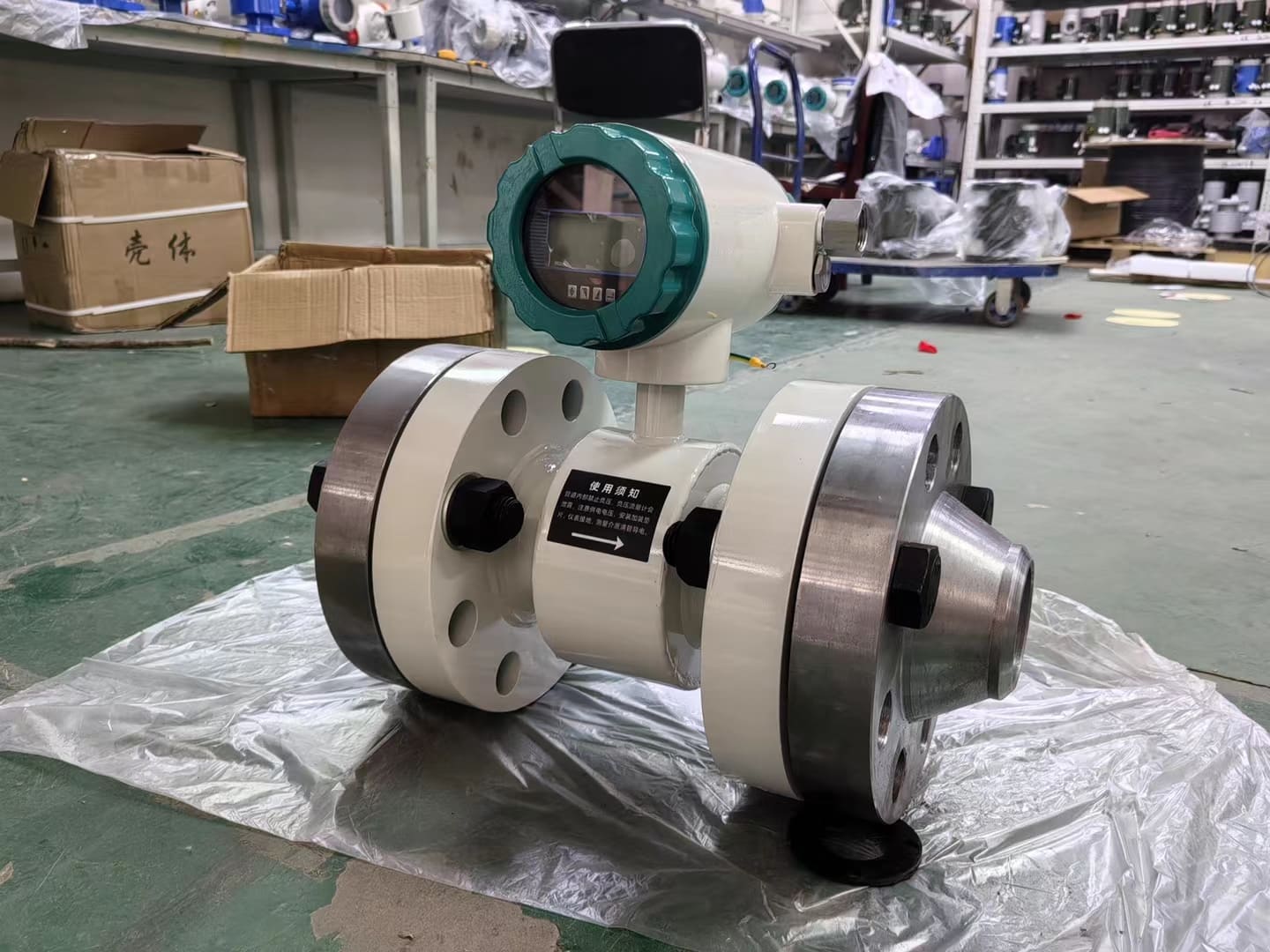

1. The working principle of electromagnetic flowmeters

Electromagnetic flowmeters measure flow based on Faraday’s law of electromagnetic induction. When a conductive liquid flows through an electromagnetic flowmeter, an electromotive force is induced in the magnetic field perpendicular to the fluid’s flow direction. By measuring this electromotive force, the flow rate of the fluid can be calculated.

2. Characteristics of PE pipes

PE pipes have many advantages, such as good temperature resistance, strong corrosion resistance, good flexibility and strong pressure resistance. These characteristics enable PE pipes to be widely used in a variety of application scenarios, including fluid transportation systems.

3. Precautions for installation on PE pipes

Conductivity requirements:

Electromagnetic flowmeters require that the measured fluid has a certain degree of electrical conductivity (generally, the electrical conductivity is required to be ≥5μs/cm). If the fluid’s conductivity is insufficient, it may affect the measurement accuracy.

For PE pipes, they themselves are not conductive. However, if the fluid (such as water, sewage, etc.) is conductive, it will not affect the use of electromagnetic flowmeters.

Installation environment:

It is necessary to ensure that there is no vibration or strong electromagnetic field around the installation site to avoid affecting the measurement of the electromagnetic flowmeter.

If installed outdoors, it should be protected from rain, water accumulation and direct sunlight, and corresponding moisture-proof and sun-proof measures should be taken.

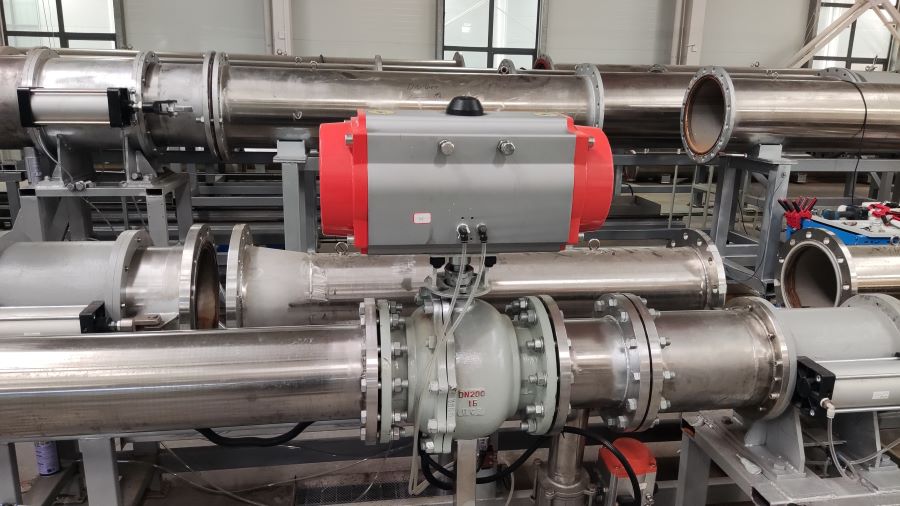

Requirements for straight pipe sections:

To improve the influence of vortices and flow field distortion, there are certain requirements for the lengths of the straight pipe sections before and after the installation of the flowmeter (the inlet should be ≥10×DN, and the outlet should be ≥5×DN). If the requirements of the straight pipe section cannot be met, a rectifier can be installed.

Grounding and shielding

The casing of the electromagnetic flowmeter should be grounded as much as possible to reduce electromagnetic interference.

Select shielded cables to reduce the electromagnetic radiation and coupling of the cables.

Installation location:

It is recommended to choose vertical installation. For horizontal installation, it should be installed at a lower position and not at the top of the pipe to ensure full pipe measurement and prevent bubble interference.

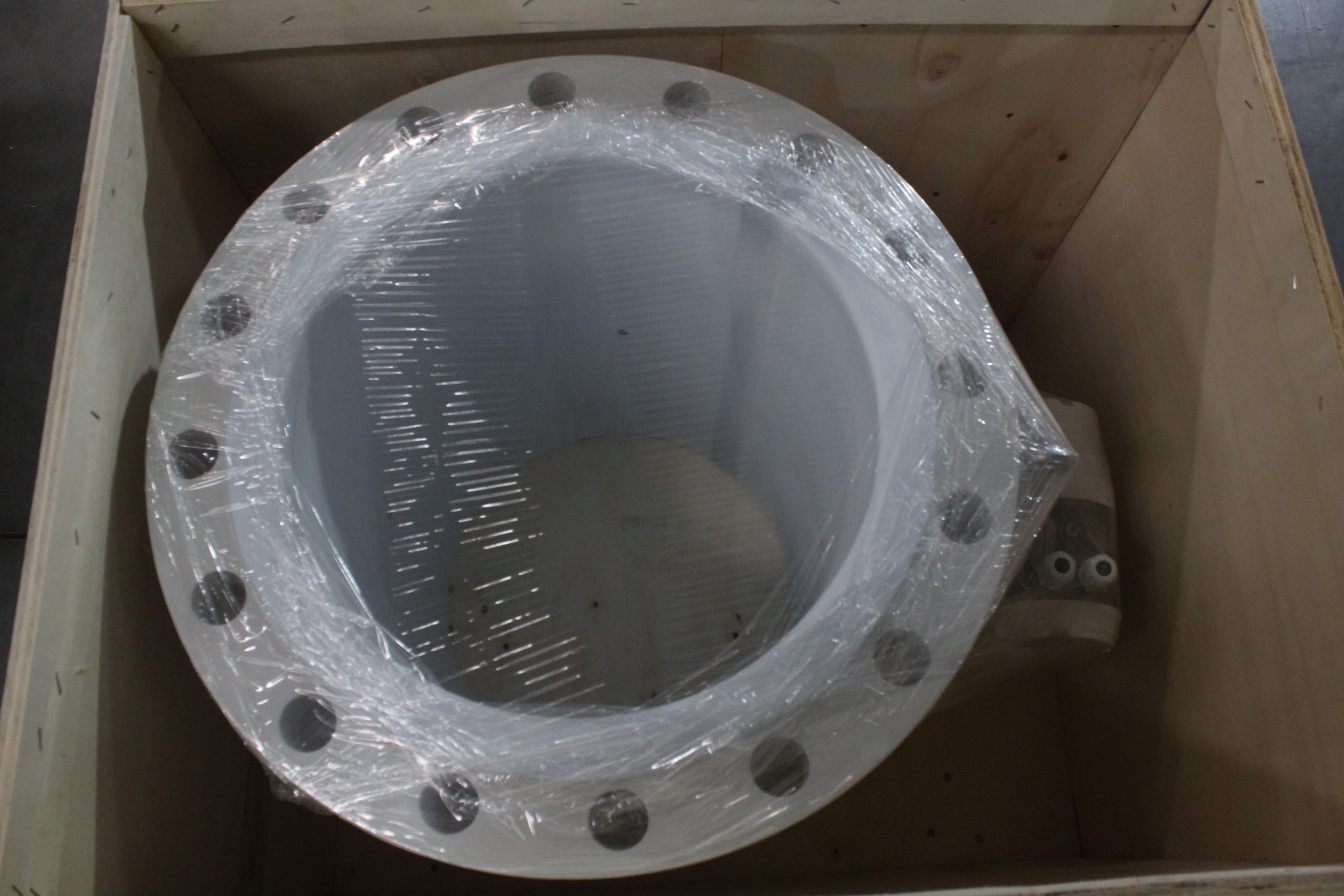

Pipe connection:

Ensure that the interface type and size of the electromagnetic flowmeter match those of the PE pipe to facilitate installation and maintenance.

Summary: Electromagnetic flowmeters can be installed on PE pipes, but factors such as conductivity requirements, installation environment, straight pipe section requirements, grounding and shielding, installation location, and pipe connection need to be taken into consideration. As long as the correct installation method and precautions are followed, electromagnetic flowmeters can also achieve accurate and reliable flow measurement on PE pipes.

-.jpg)

-.jpg)