Sewage flow meter selection introduction

The shortage of water resources and the impact of sewage on the environment are the two major problems facing the solution of water resources. In the process of solving these problems, the flowmeter has a role that cannot be ignored. Choosing a good sewage flowmeter plays a crucial role in solving the problem.

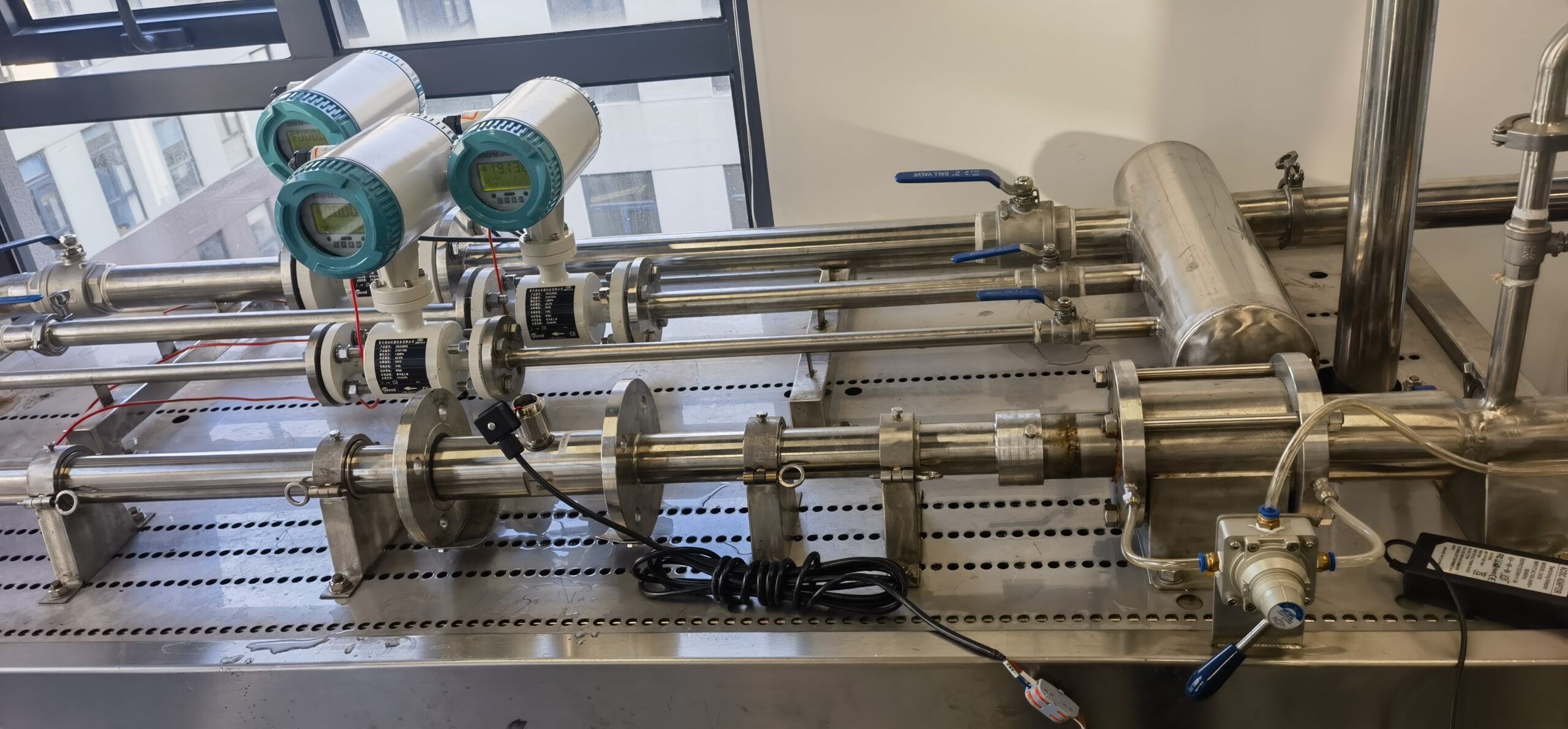

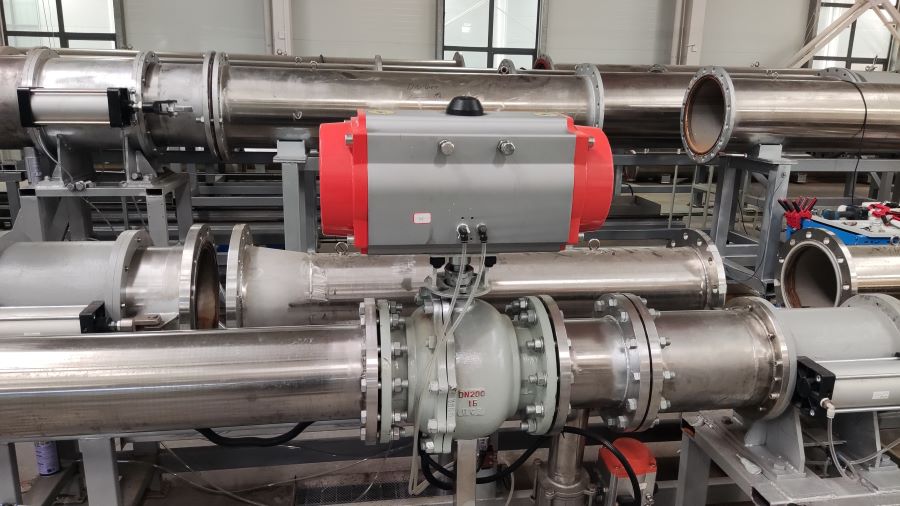

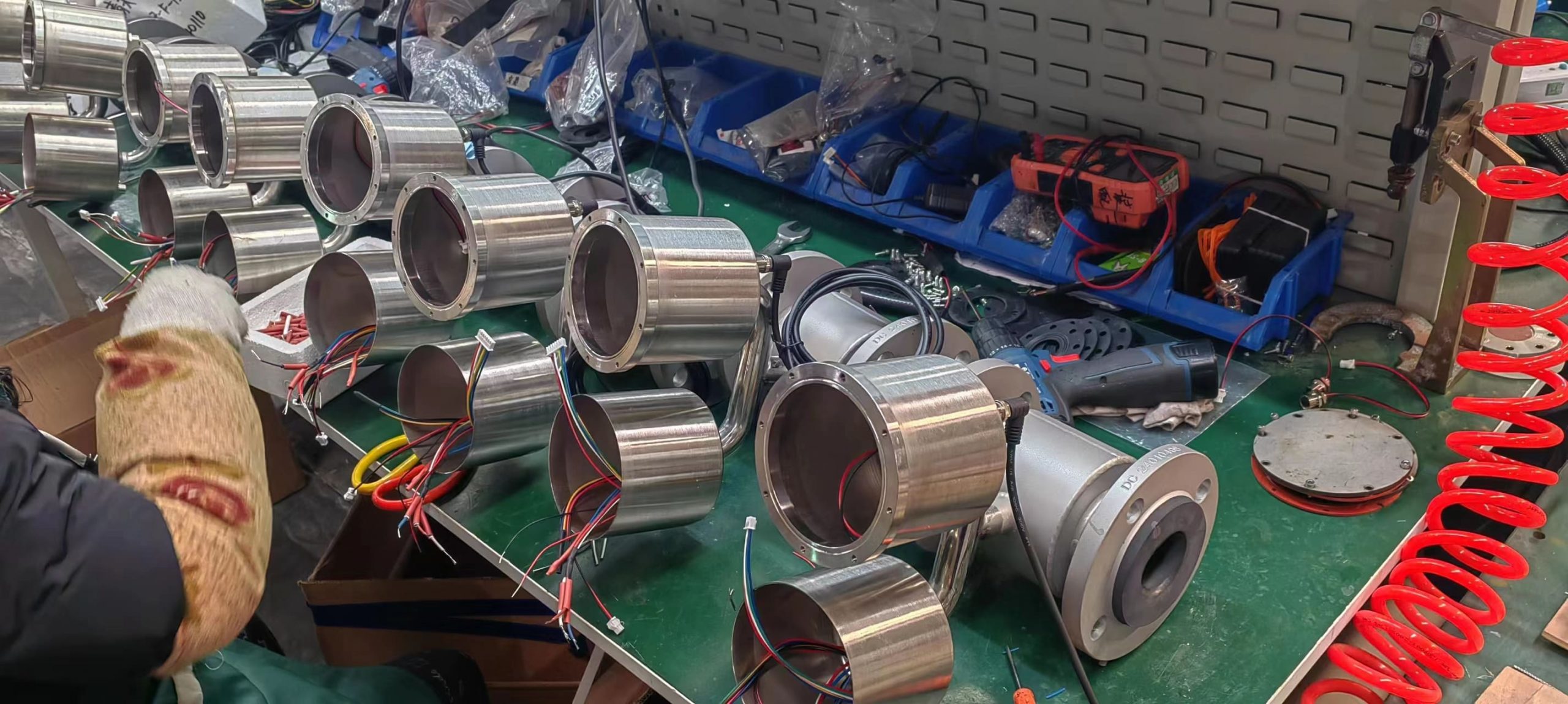

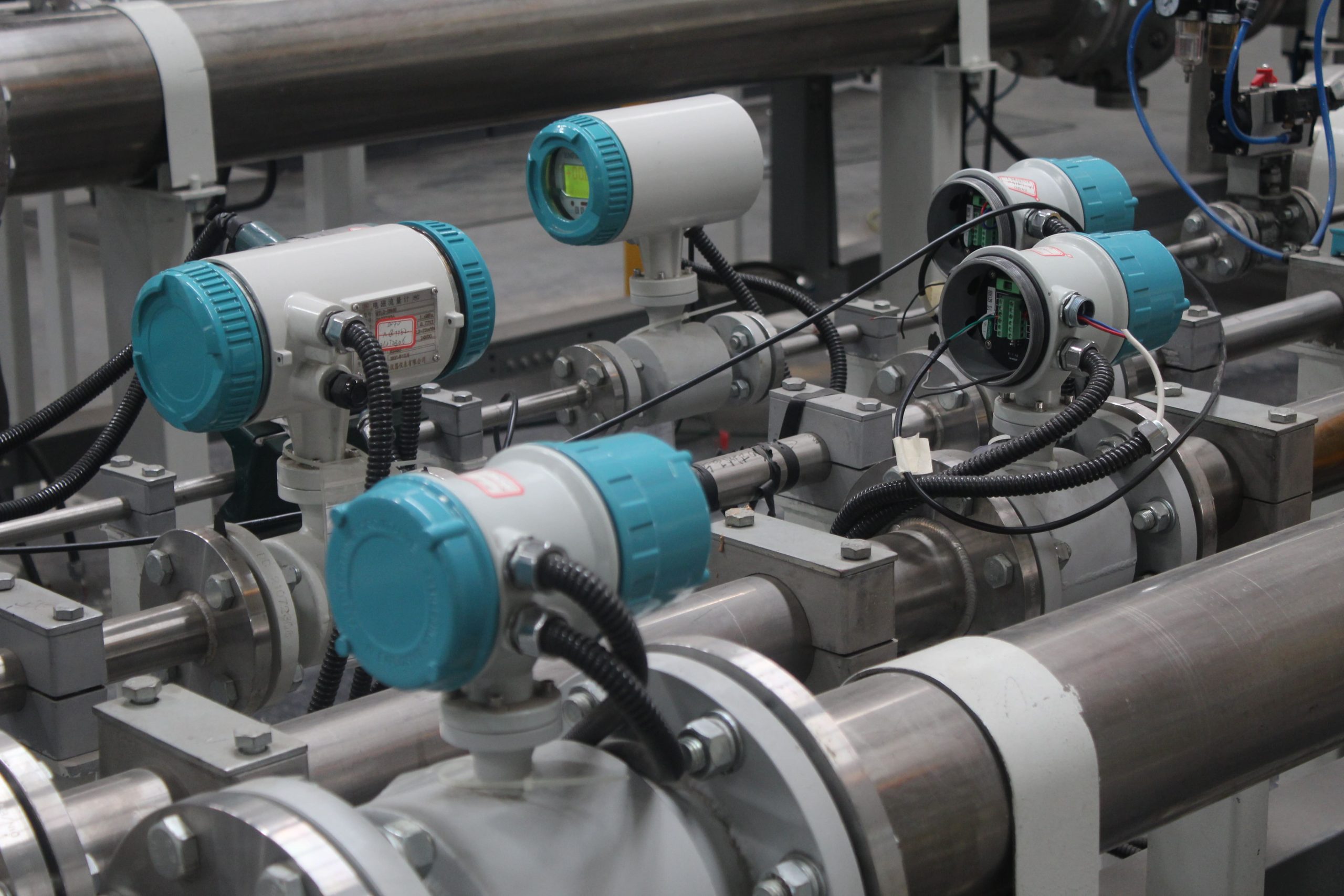

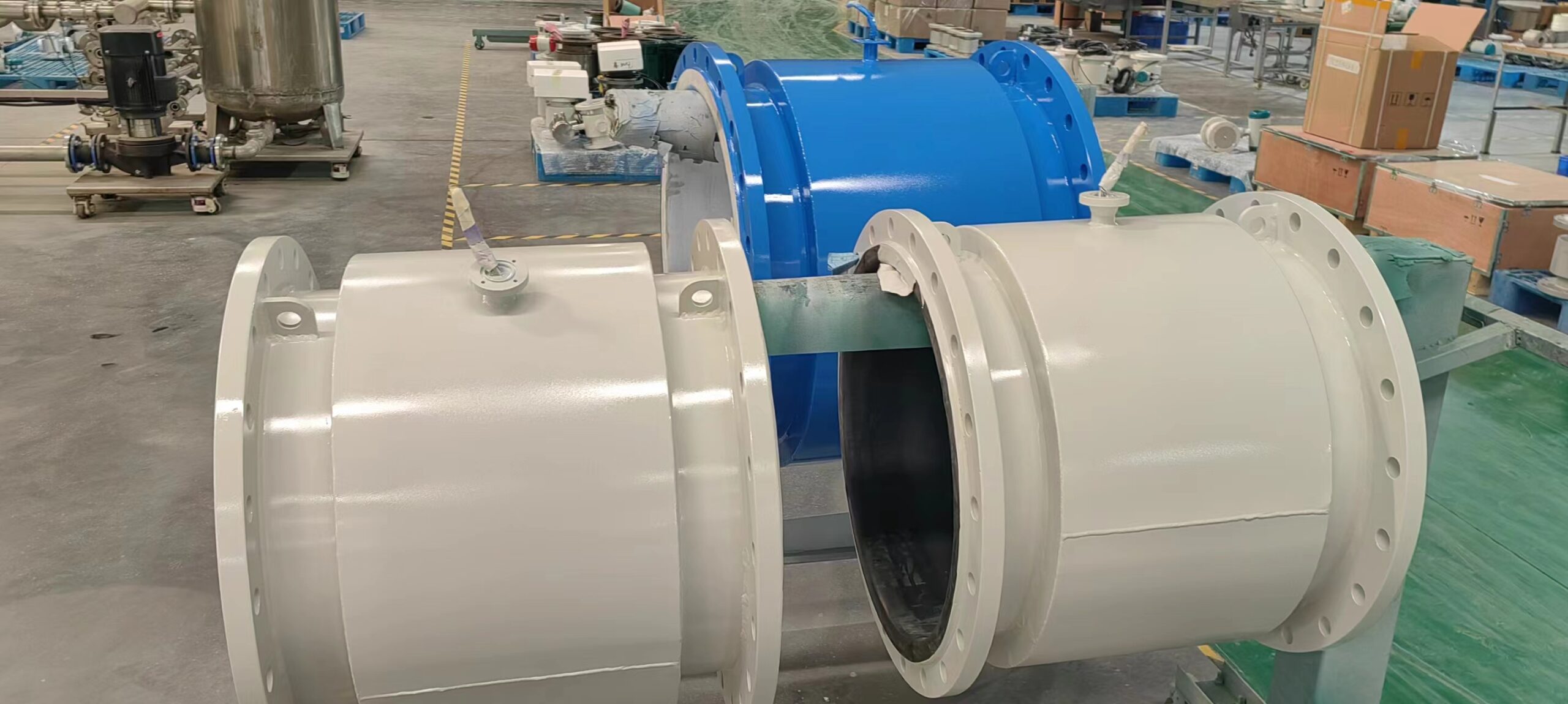

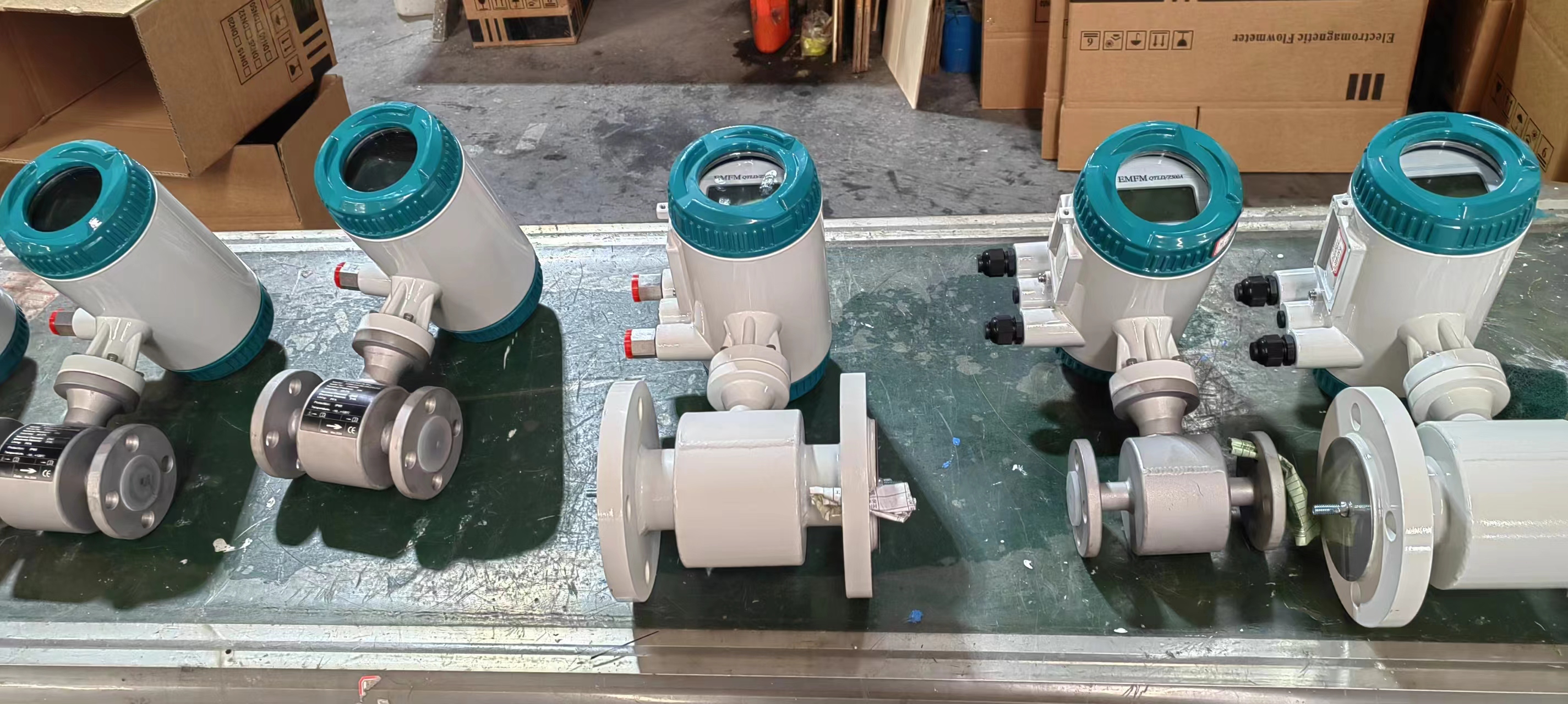

1, electromagnetic flowmeter

Advantages: The electromagnetic flowmeter has a simple structure, and there are no moving parts and choke parts inside the pipeline, which will not cause additional pressure loss when the medium flows through; Liquid-solid two-phase flow medium with measurable suspension; The measurement results are not affected by fluid density, viscosity, temperature, pressure and conductivity.

Disadvantages: If the medium contains gas, the measurement results will be affected to some extent.

2, ultrasonic flowmeter

Advantages: Non-contact measurement can be achieved, non-conductive liquid can be measured, no pressure loss.

Disadvantages: Can only measure clean liquid, if the medium contains acrobatics, not recommended.

-.jpg)