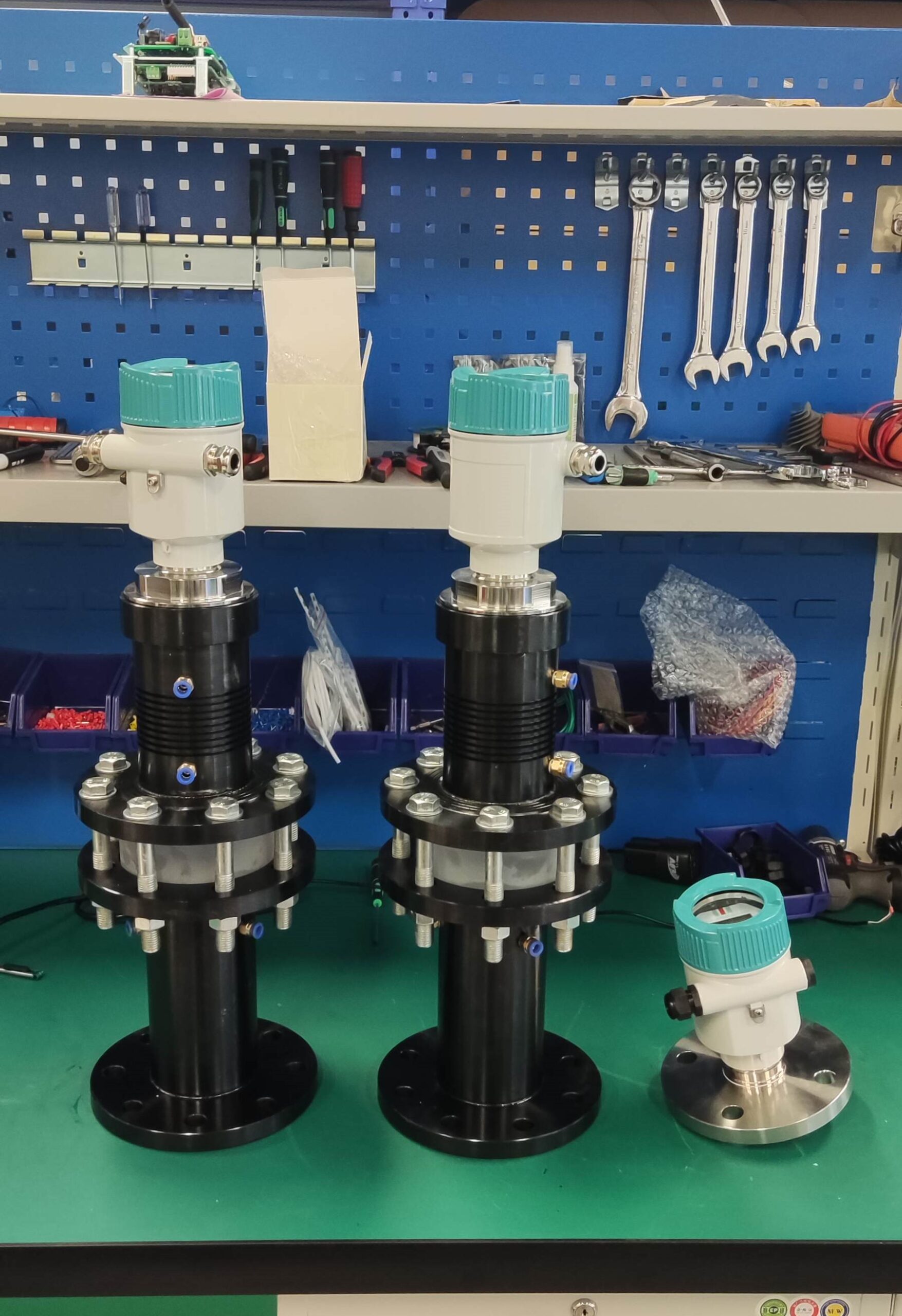

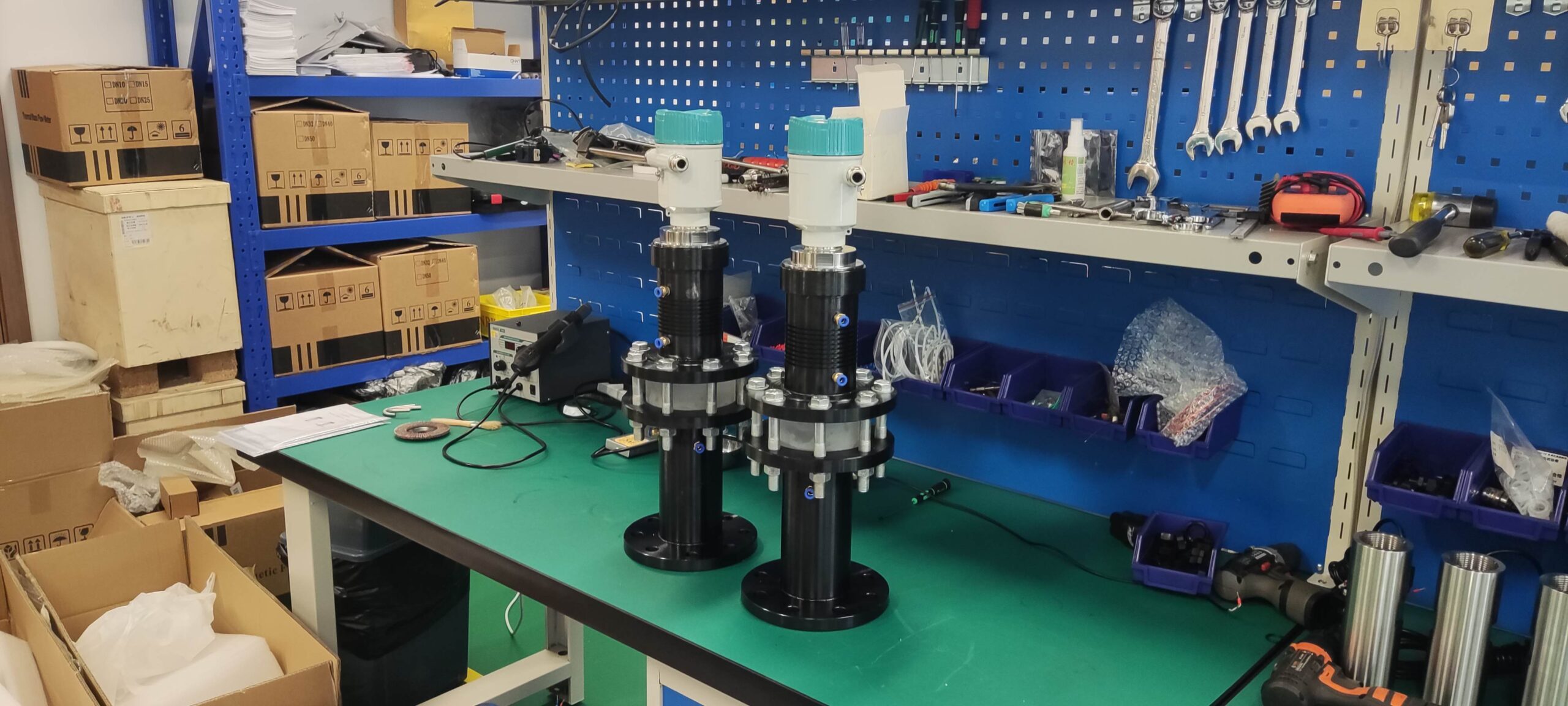

The application of radar level gauges in coating preparation tanks

In the chemical products, coatings and coating industries, the accurate measurement of liquid raw materials is particularly important. With the advancement of technology, radar level gauges, as a non-contact liquid level measurement technology, have been widely applied in various liquid level measurement scenarios due to their high precision and reliability.

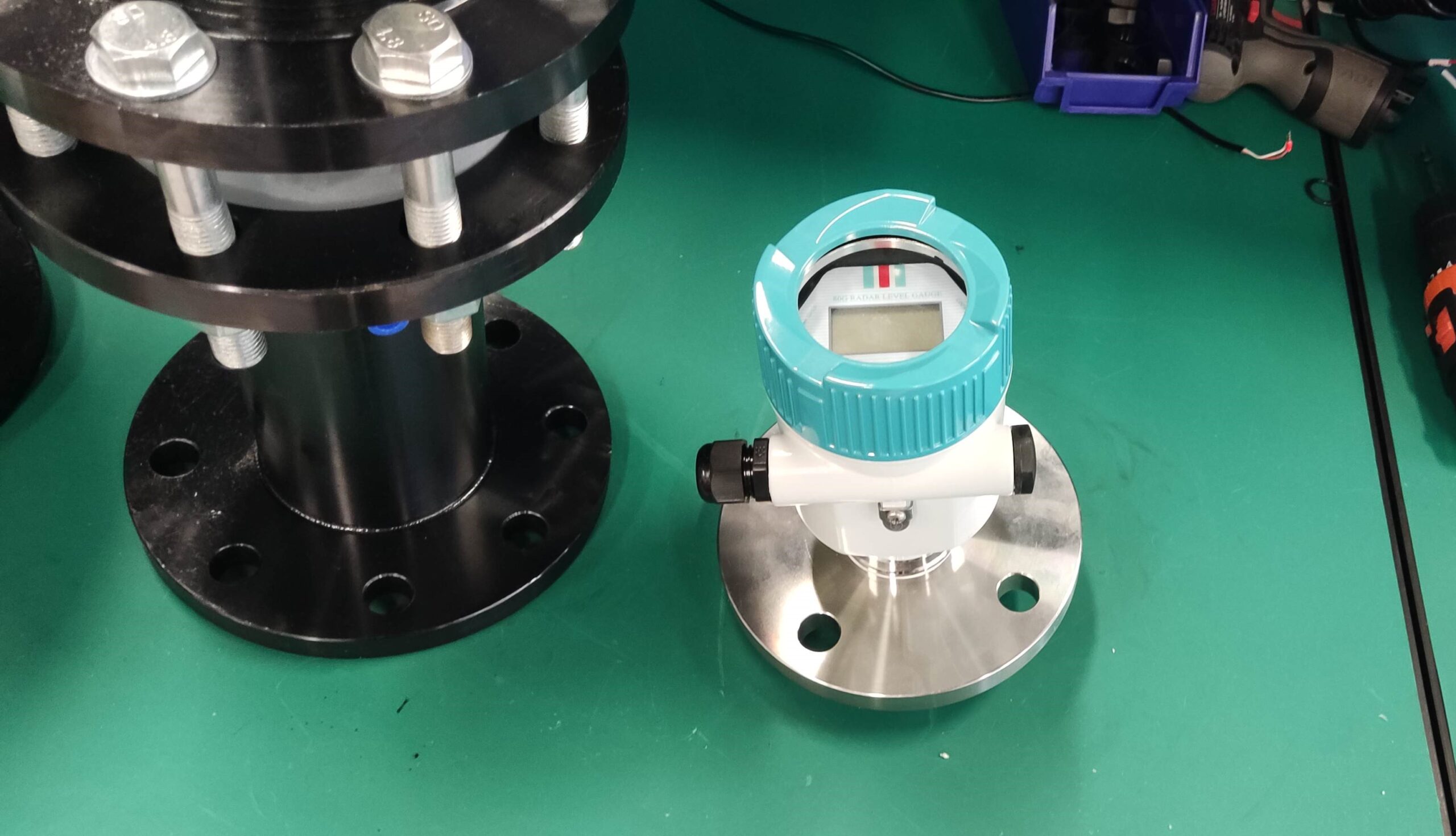

Coating preparation tanks usually contain liquids with high viscosity, easy caking, suspended particles or bubbles and other characteristics. These characteristics may have an impact on the measurement accuracy of radar level gauges. For instance, high-viscosity liquids may cause unclear reflection of microwave signals on the liquid surface, while suspended particles or bubbles may lead to signal scattering, thereby affecting the measurement results.

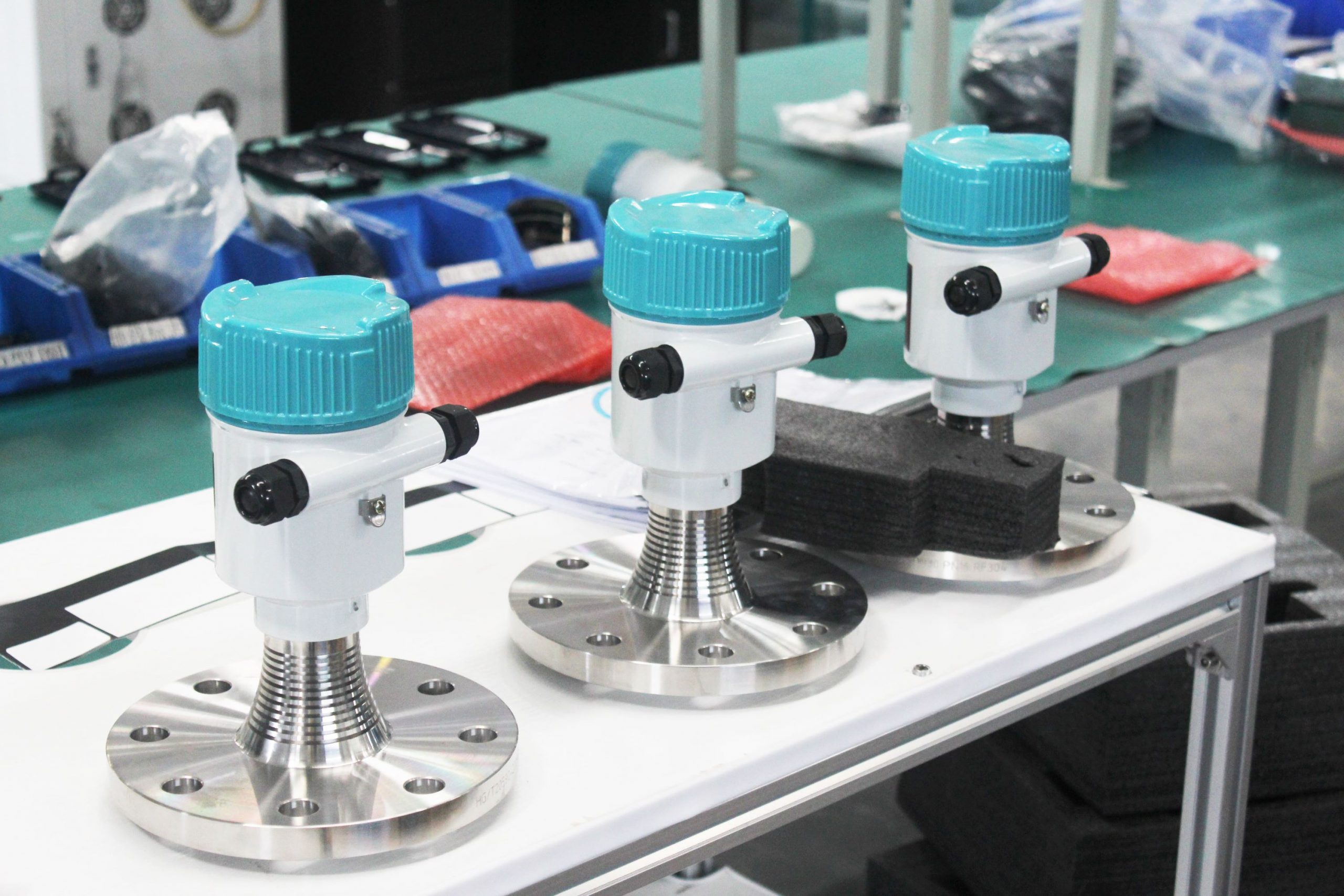

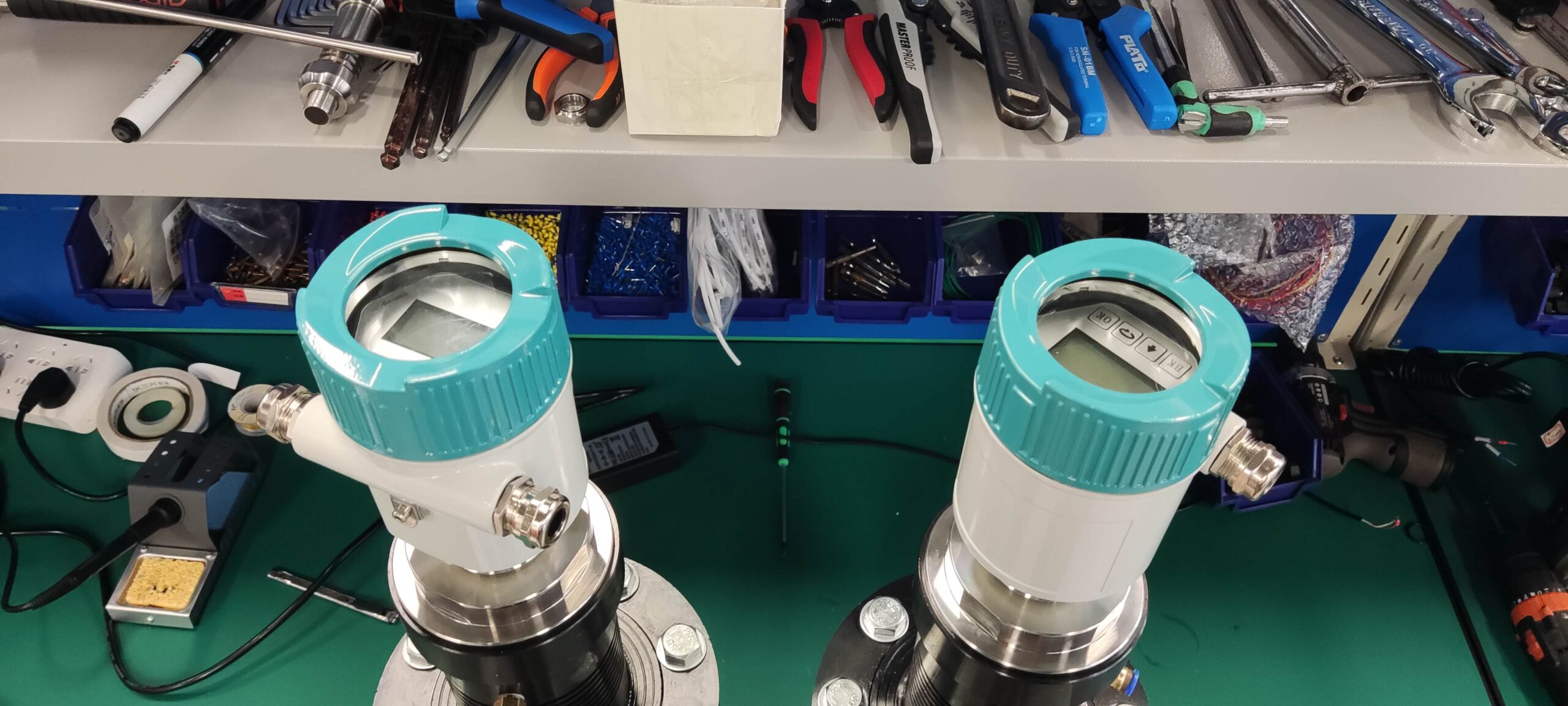

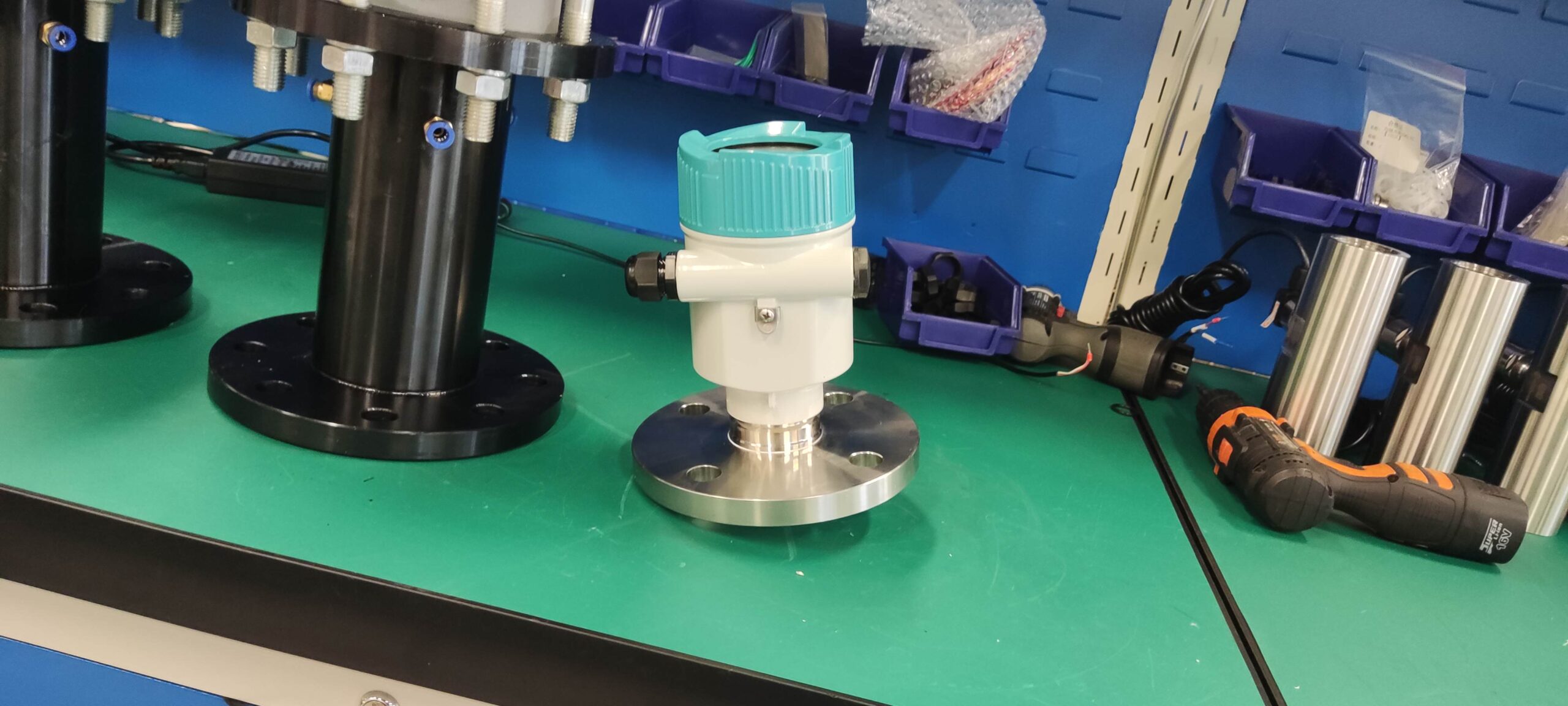

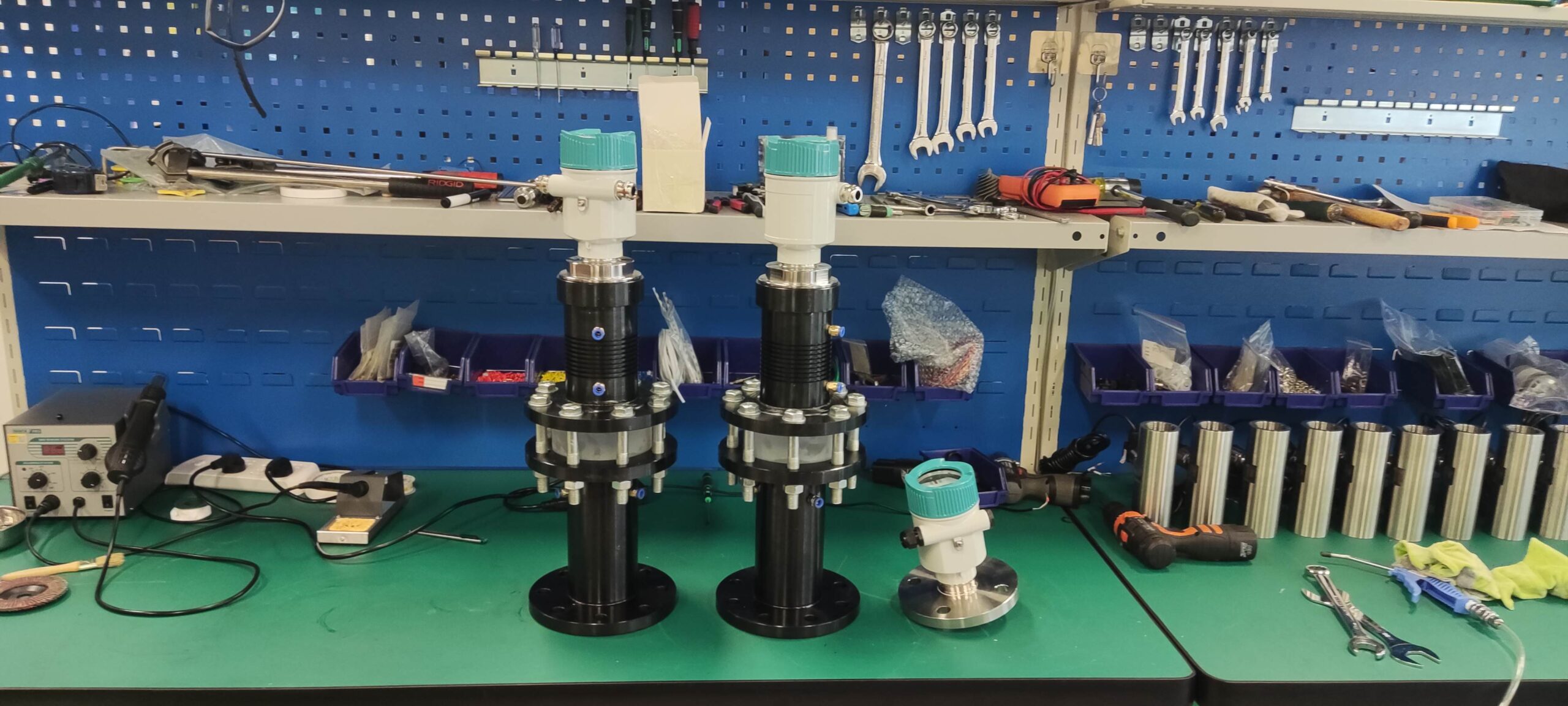

Radar level gauges typically employ microwave pulse or frequency-modulated continuous wave (FMCW) technology. By emitting microwave signals and receiving the signals reflected back from the liquid surface, they determine the liquid level height based on time differences or frequency changes. The advantage of this technology lies in that it is not affected by the chemical properties, temperature, pressure of the medium or the shape of the container, and thus is suitable for liquid level measurement in a variety of complex environments.

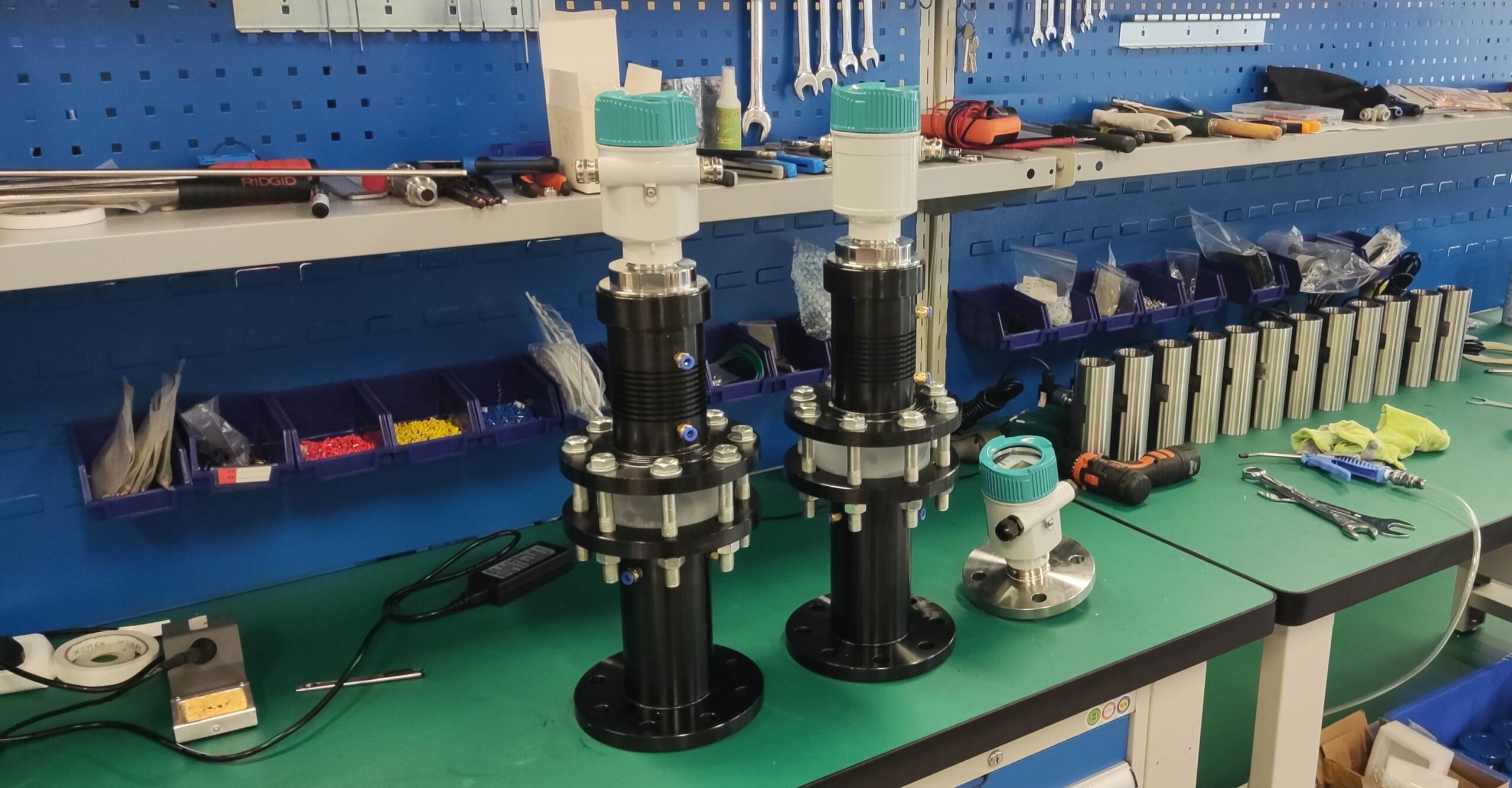

To enhance the accuracy and reliability of measurement, other types of sensors or measurement technologies, such as capacitive, ultrasonic or optical level gauges, can be combined to achieve the integration and complementarity of multiple technologies. By comparing the performance of different technologies in specific applications, a more comprehensive solution can be provided for the liquid level measurement of coating preparation tanks.

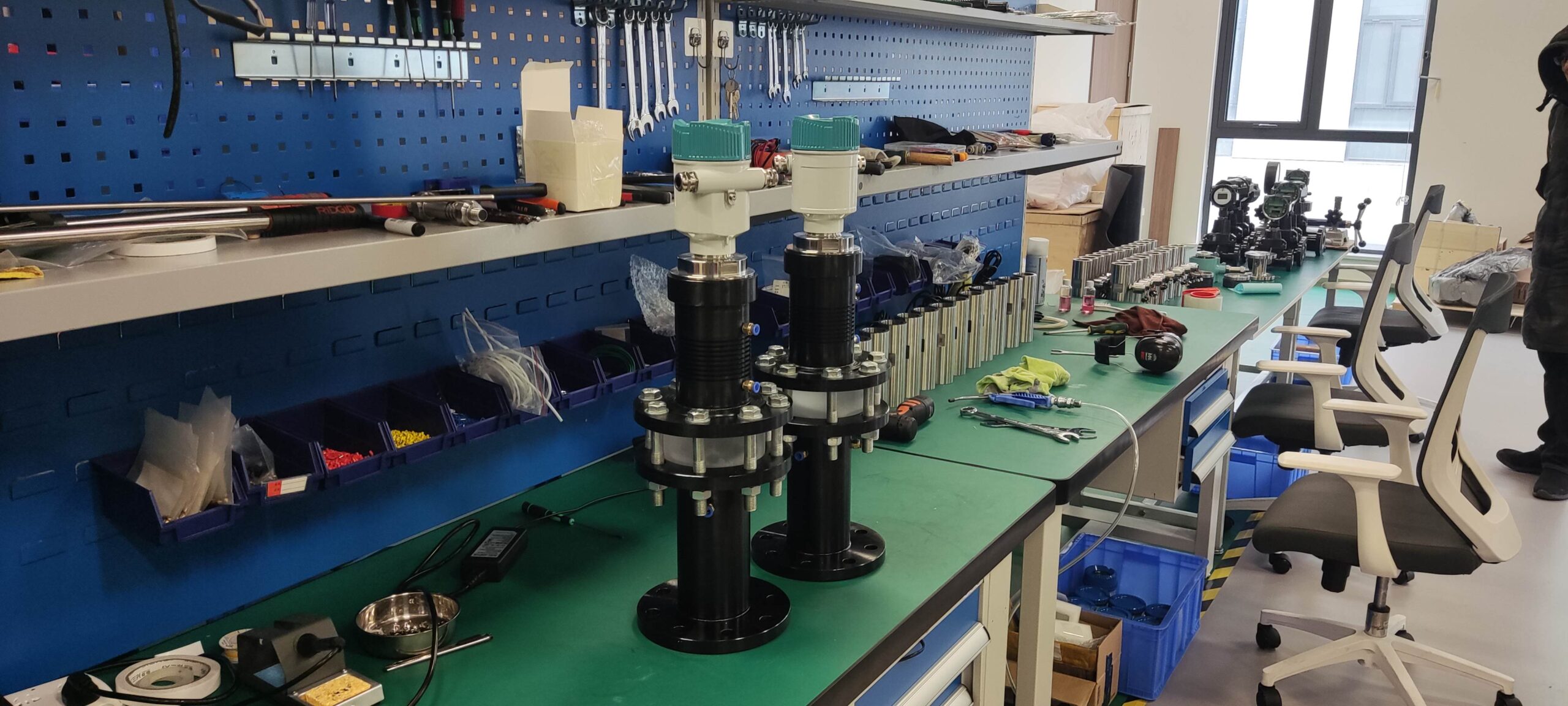

Although the special properties of coating preparation tanks pose challenges to liquid level measurement, the application of radar level gauges in the liquid level measurement of coating preparation tanks is feasible through scientific experimental design, parameter optimization and multi-technology integration.