What are the key points for maintaining high-frequency radar level gauges

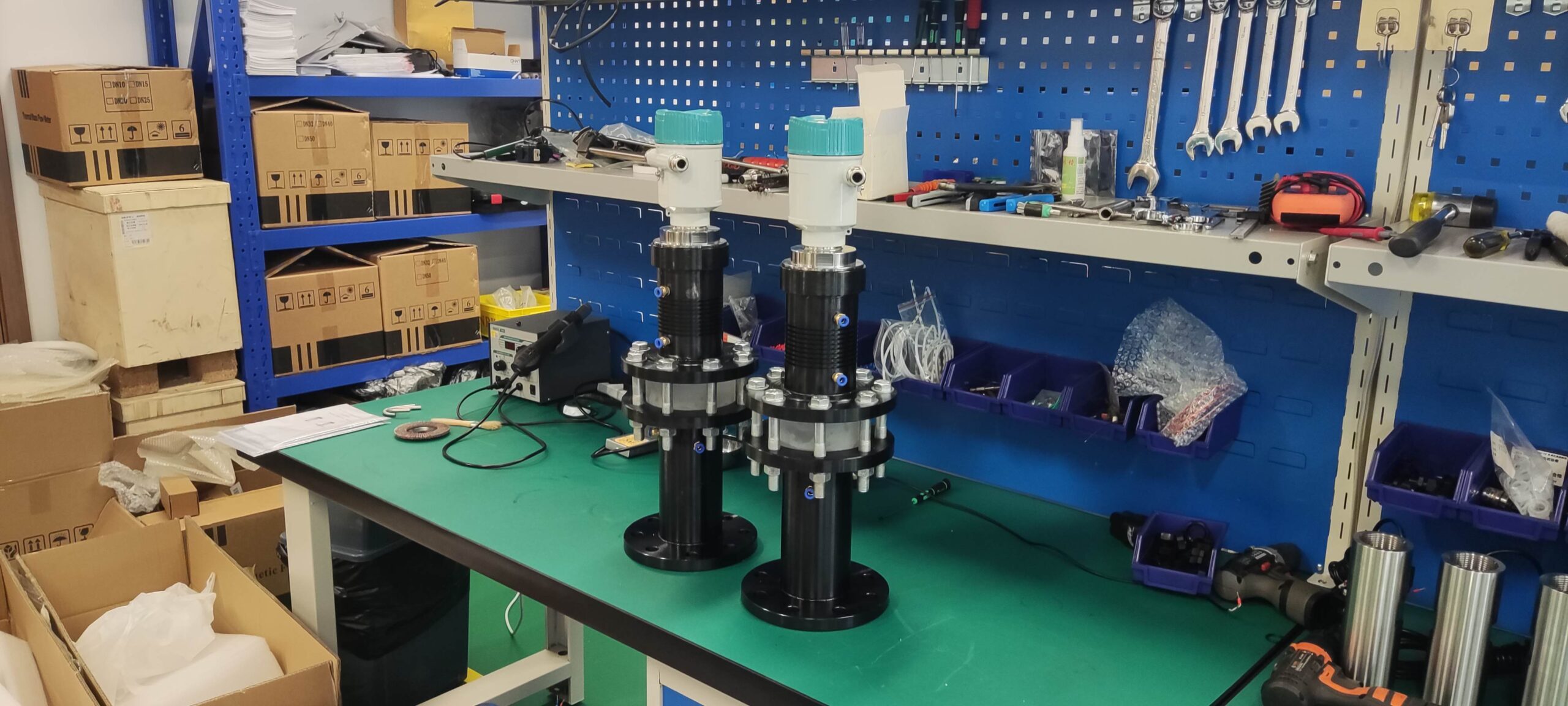

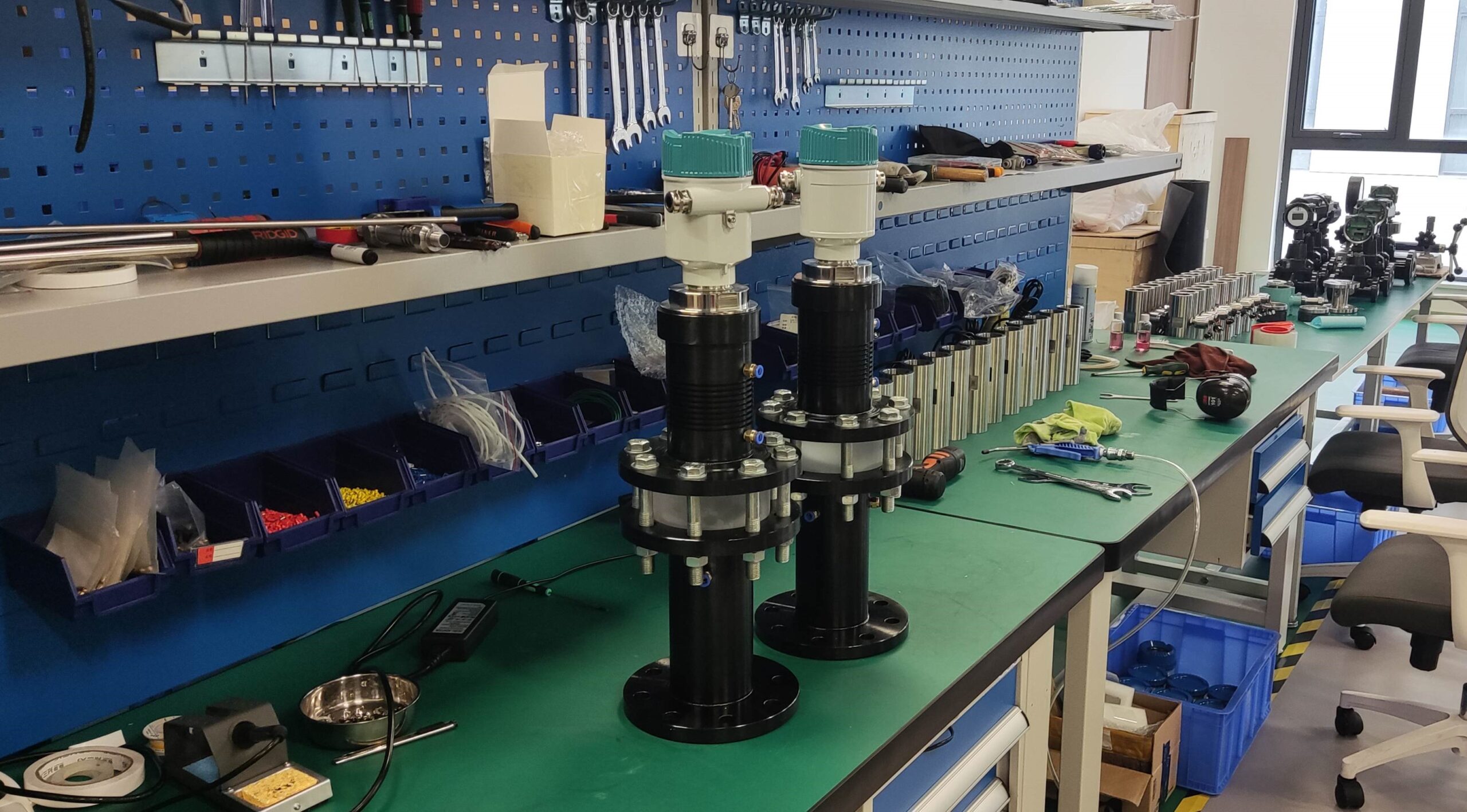

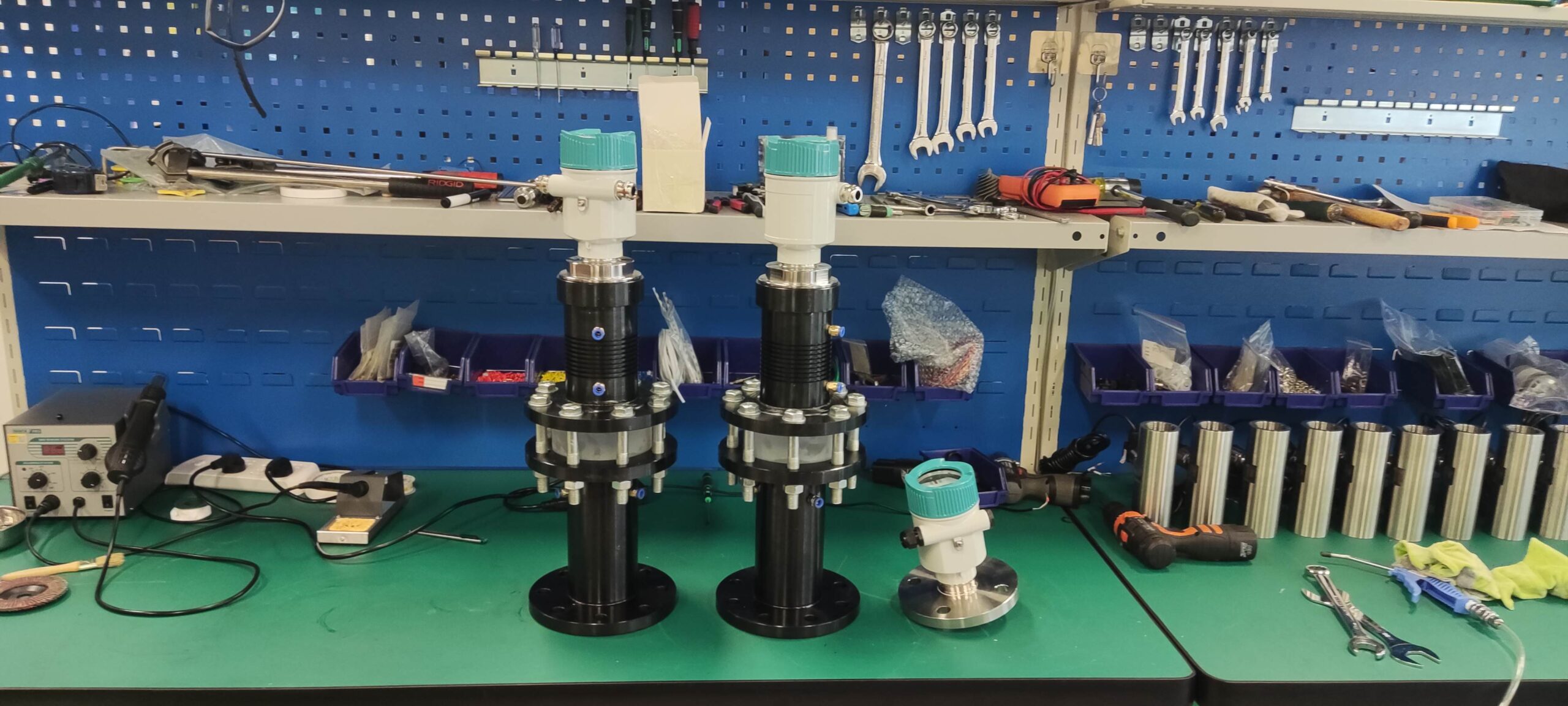

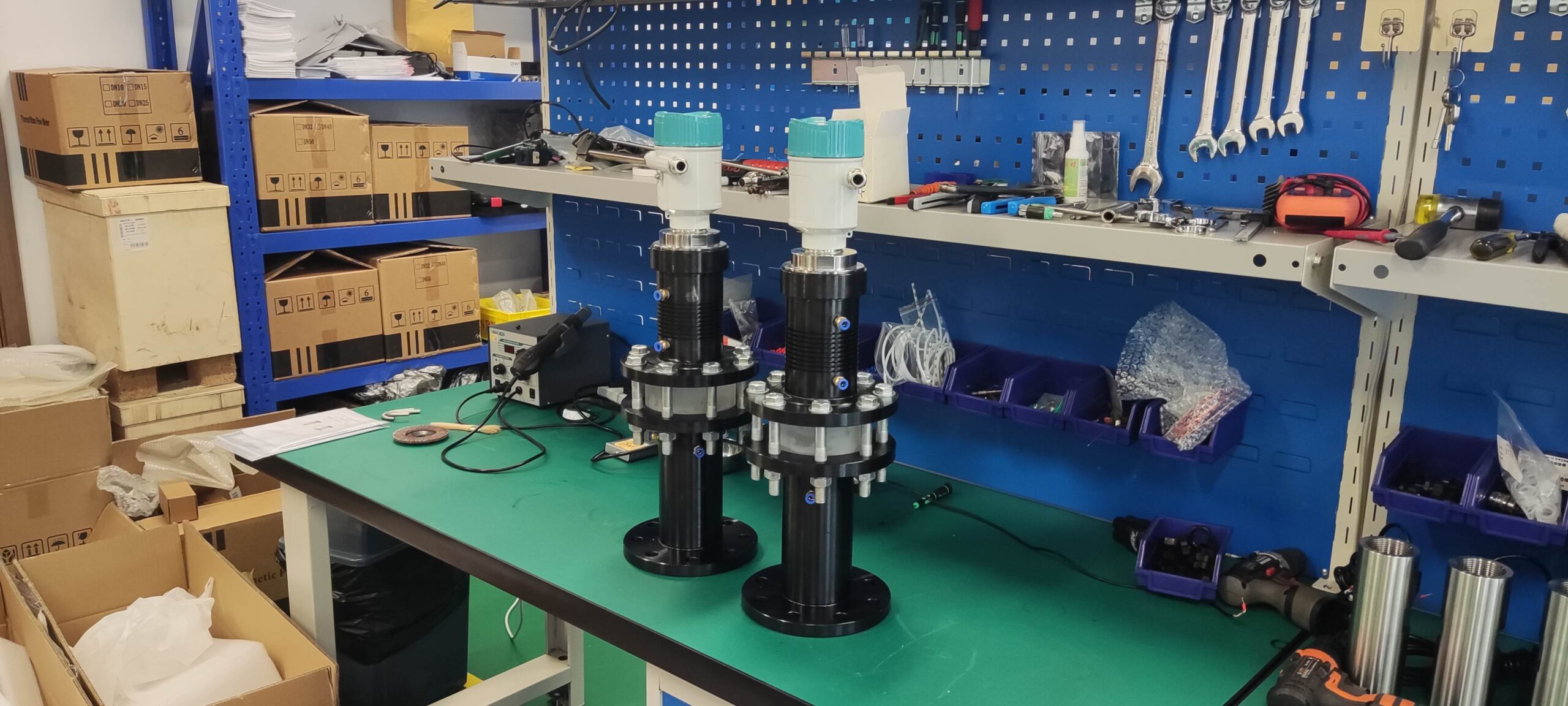

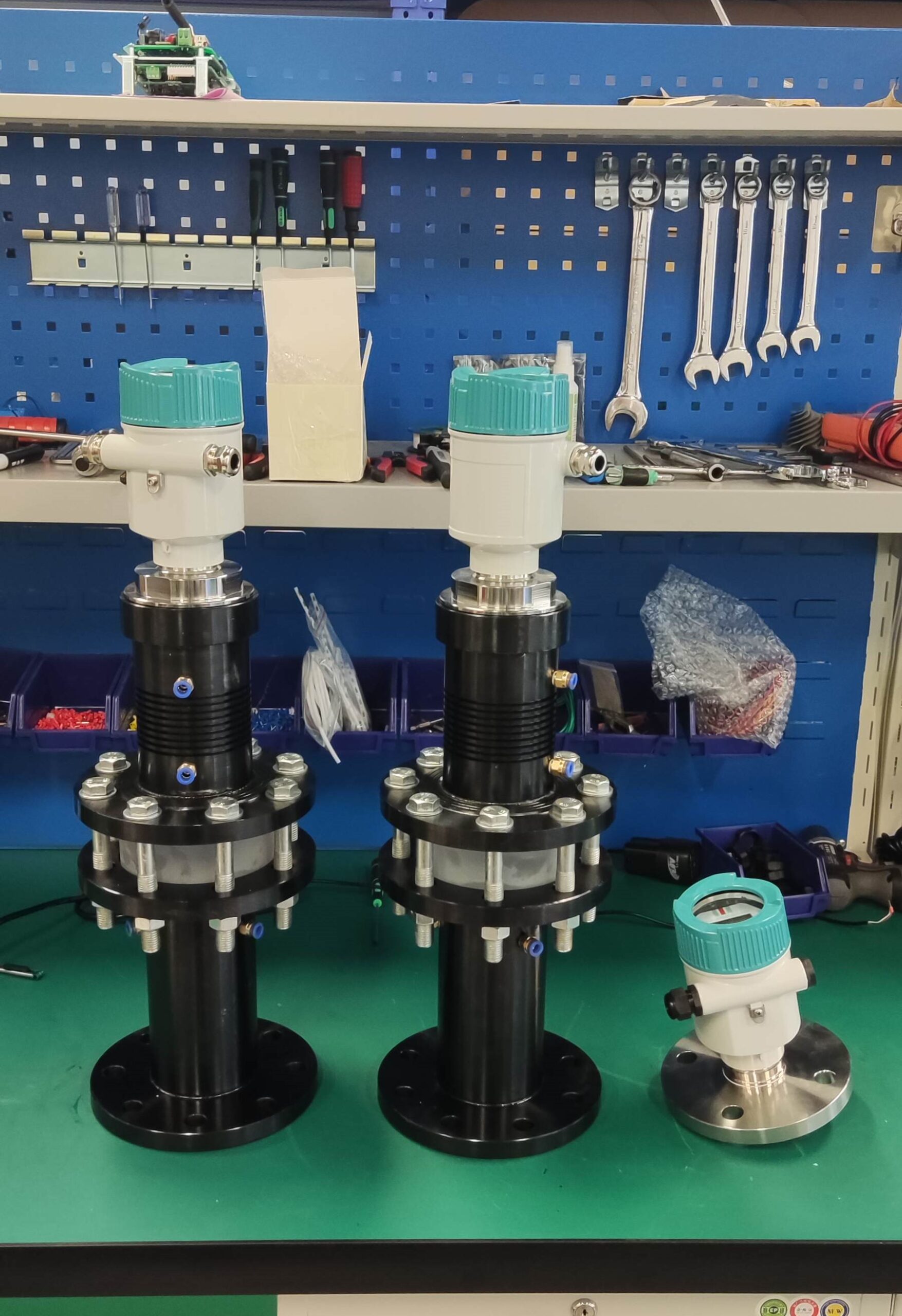

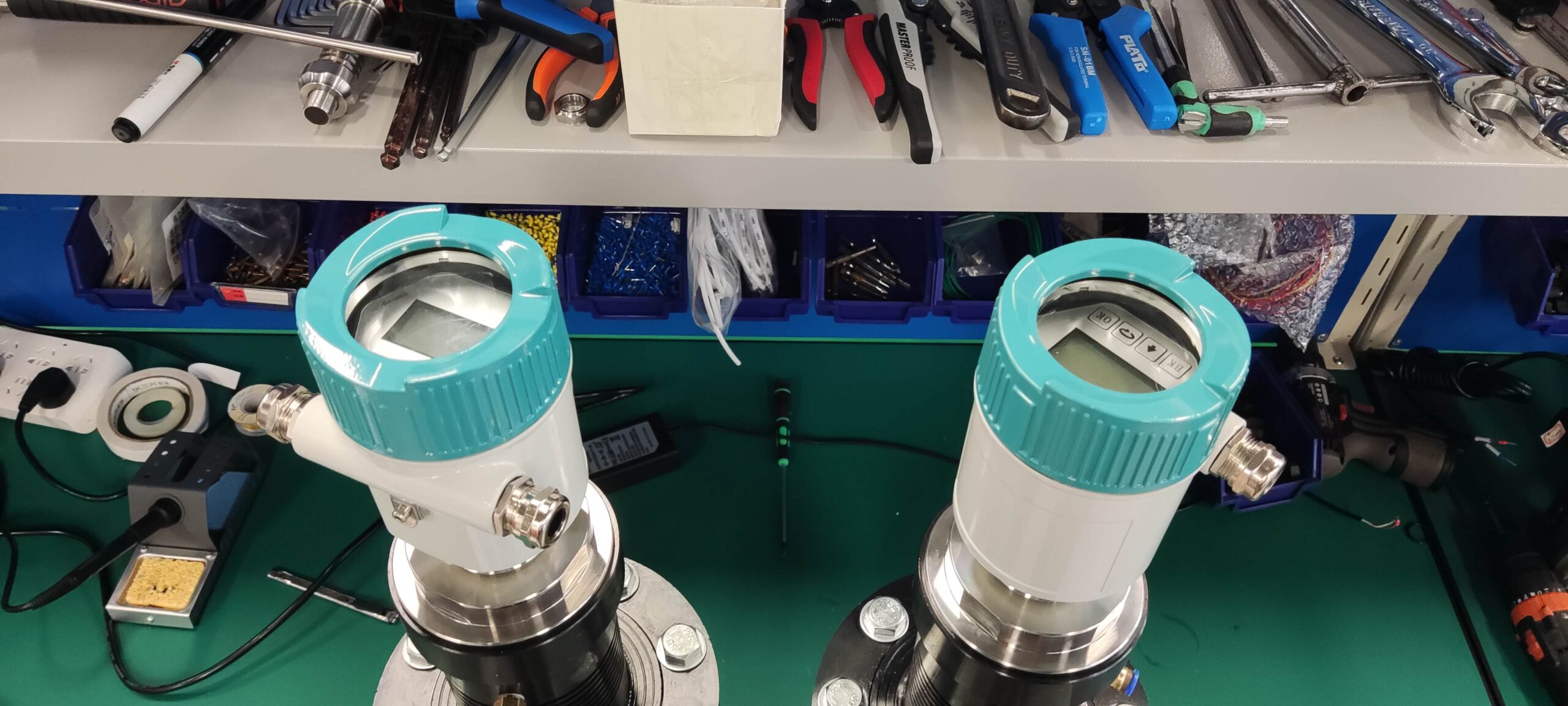

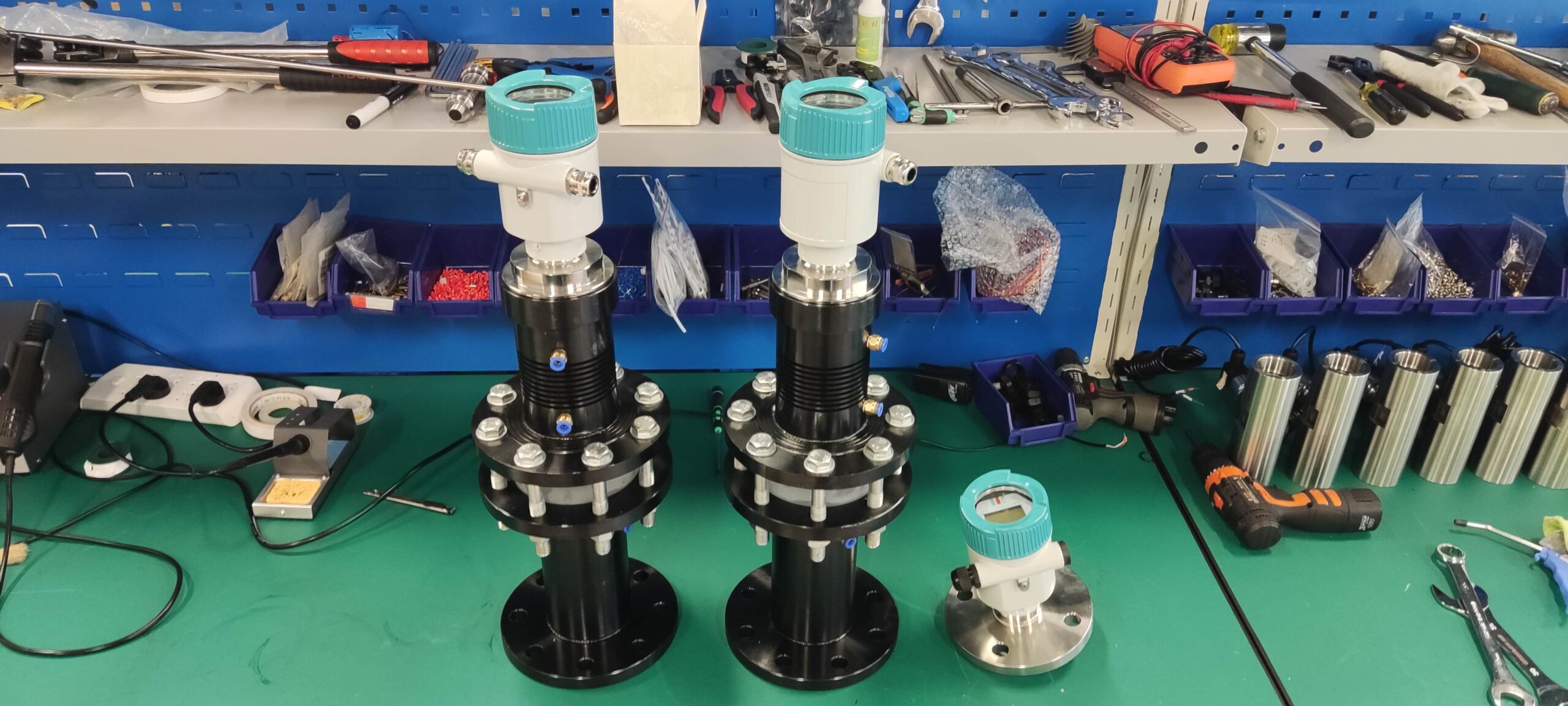

The high-frequency radar level gauge is a radar-type level measurement instrument with a measurement distance of up to 70 meters. The antenna has been further optimized and processed.

The high-frequency radar level gauge is a radar-type level measurement instrument with a measurement distance of up to 70 meters. The antenna has been further optimized and processed. A new type of fast microprocessor can perform signal analysis and processing at a higher rate, enabling the instrument to be used for various strongly corrosive liquids. The antenna of the radar emits relatively narrow microwave pulses, which are transmitted through the antenna. When the microwaves come into contact with the surface of the medium being measured, they are reflected. The antenna of the radar then receives this microwave signal and transmits it to the electronic circuit section. The electronic circuit section automatically analyzes the signal and converts it into a level signal. Due to the extremely fast propagation speed of electromagnetic waves, this process is almost instantaneous.

What are the key points for the installation and maintenance of high-frequency radar level gauges?

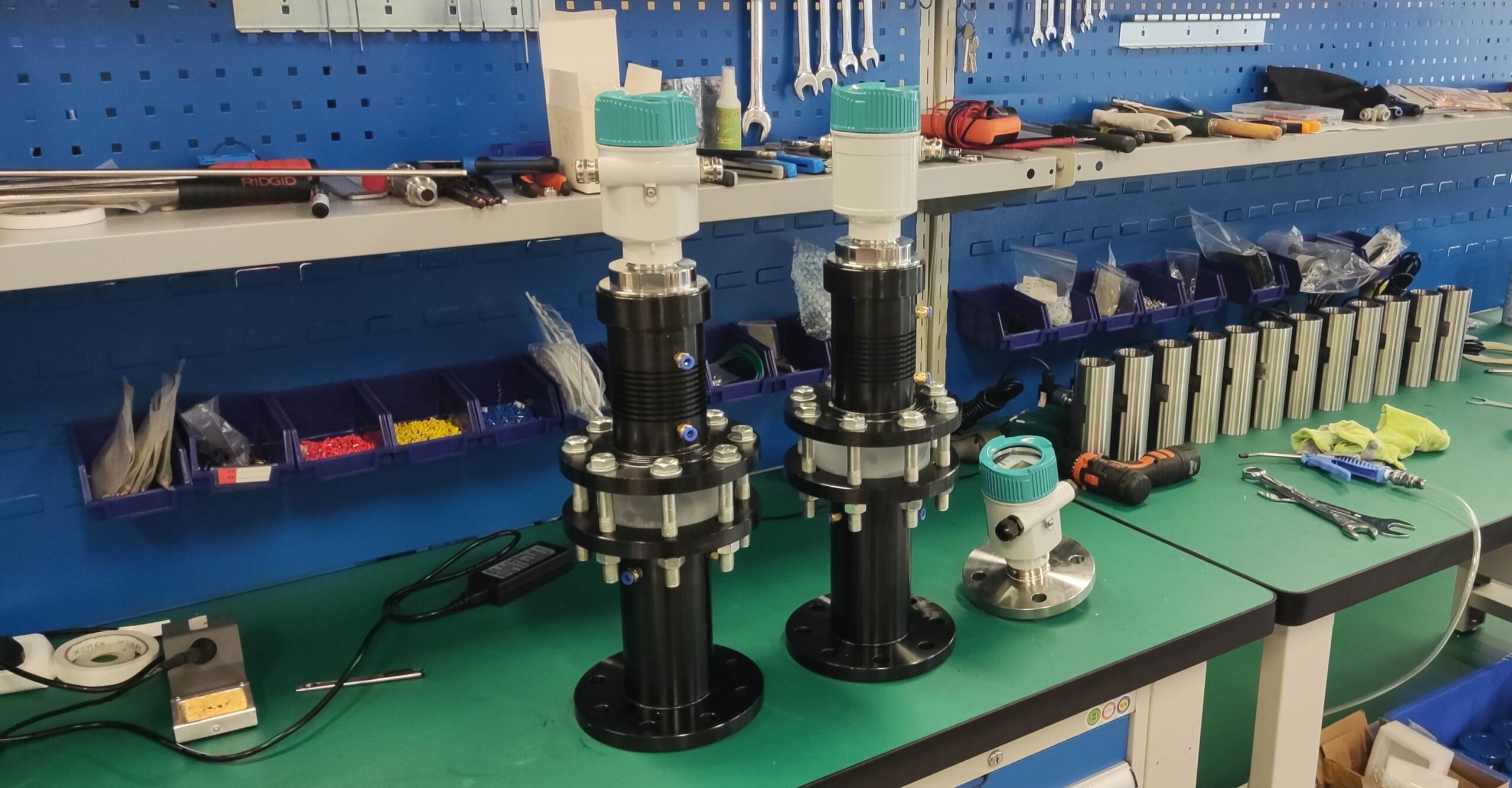

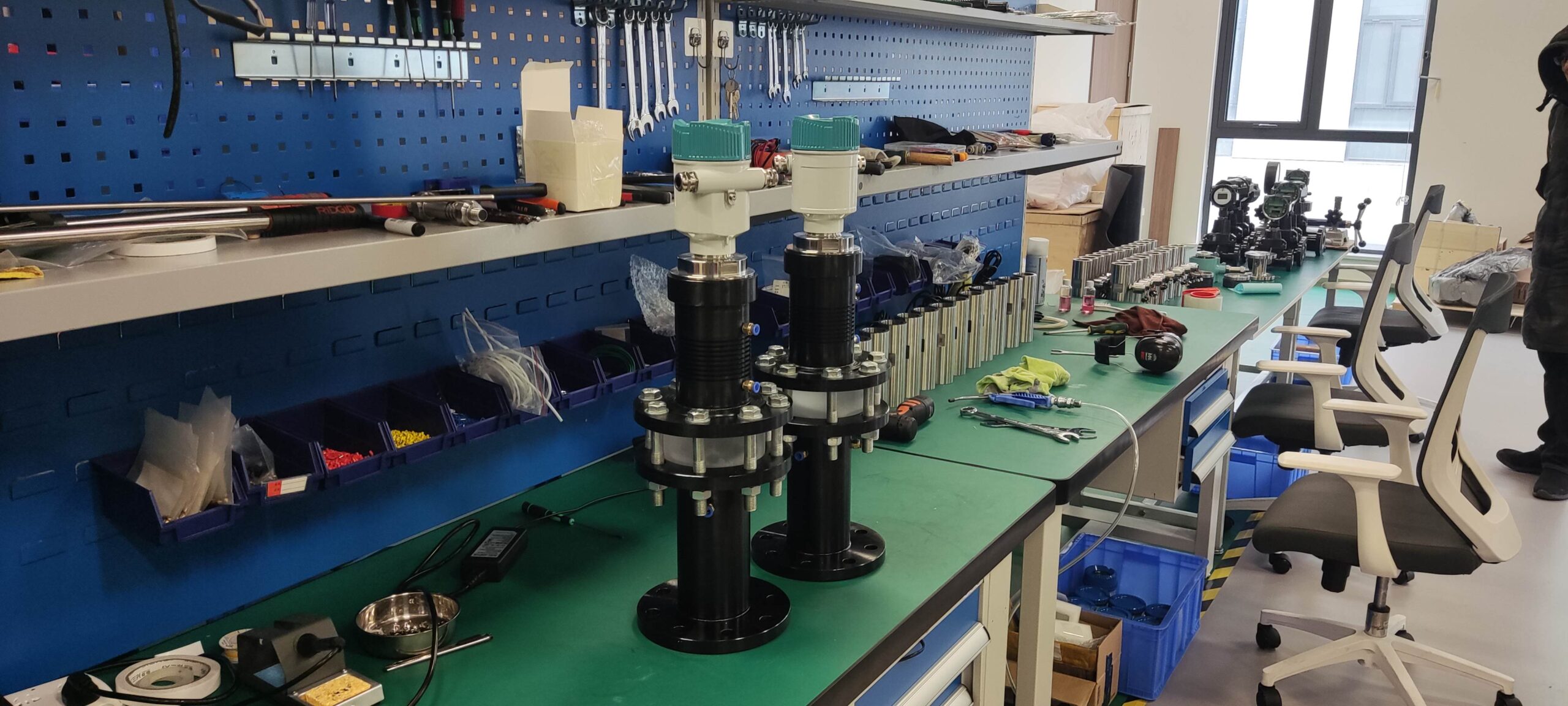

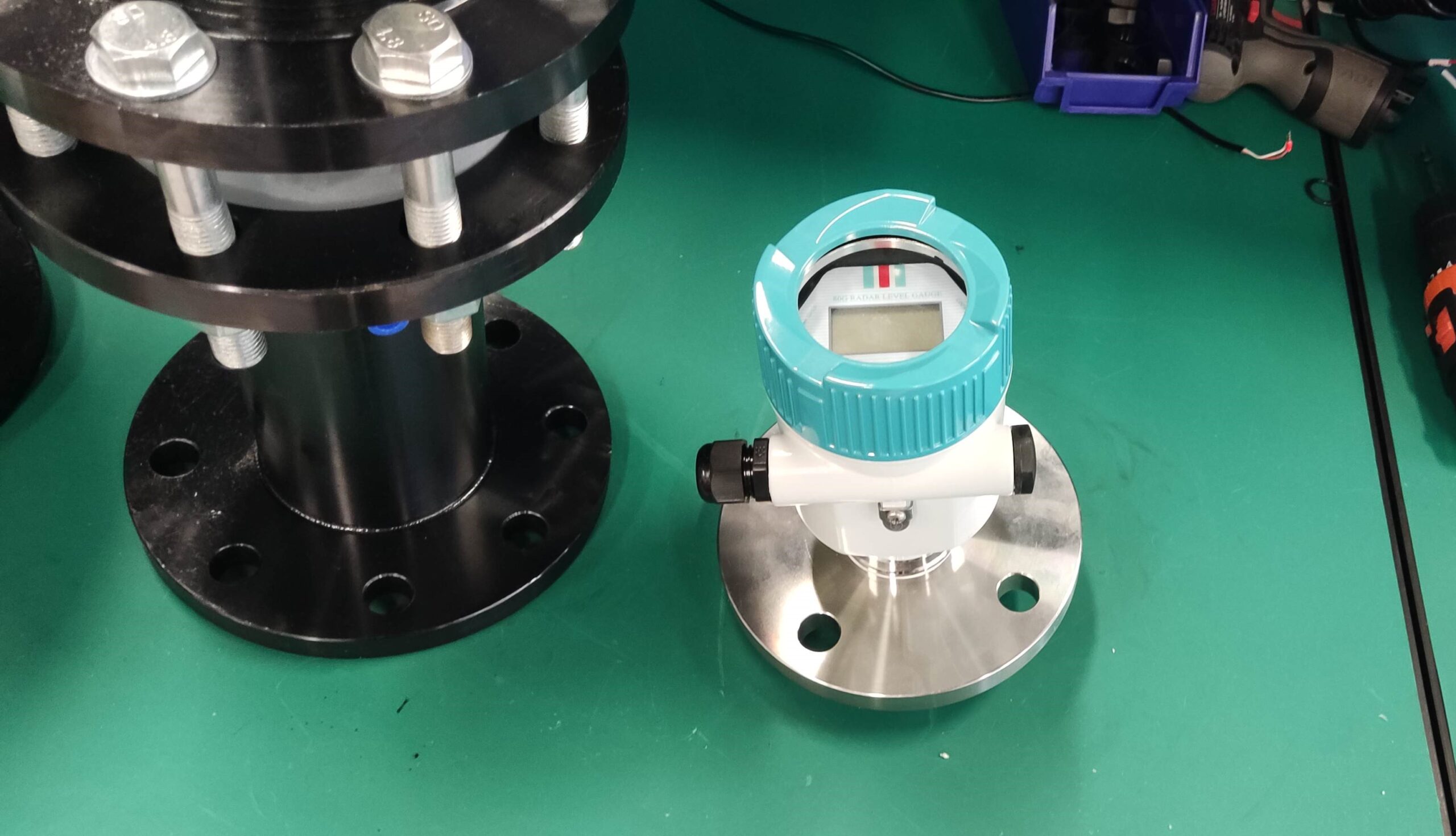

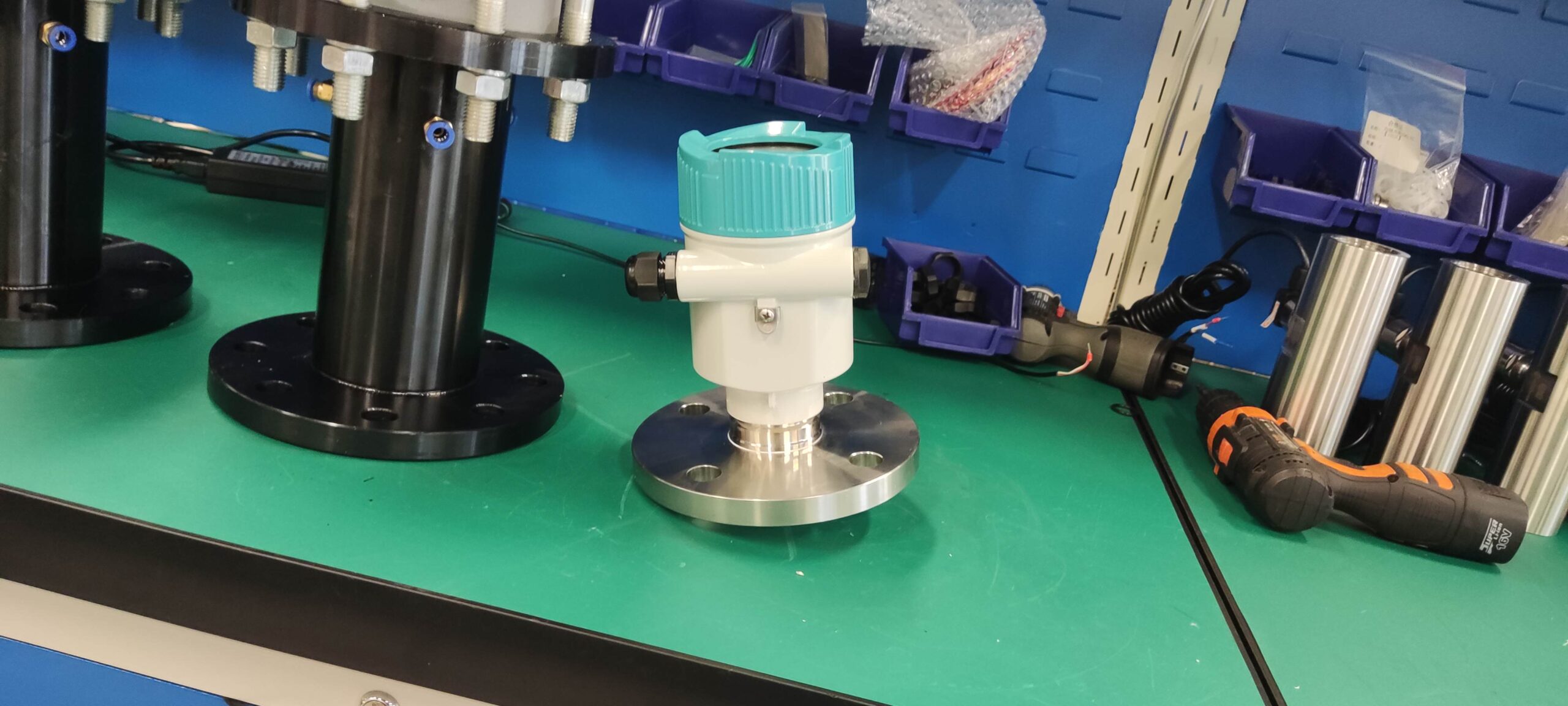

Choosing an appropriate installation location is of vital importance. The liquid level gauge should be installed at a position that can accurately reflect the changes in liquid level, while avoiding the influence of mechanical damage and overheating. In addition, ensure that the installation process follows the guidelines and suggestions provided by the manufacturer, including the correct installation Angle and fixation method.

When maintaining a liquid level gauge, it is necessary to regularly check its working condition and performance. The inspection includes observing whether the indication of the liquid level gauge is accurate and whether there is any leakage or other abnormal conditions. In addition, regularly cleaning the liquid level gauge to remove accumulated dirt and dust is also an important step in maintaining its performance.

3. Using appropriate tools and materials is also a key to maintaining the liquid level gauge. Make sure to use sealing materials that comply with the specifications and follow the correct operating procedures. During the maintenance process, if any problems or malfunctions are found, professional technical support or maintenance personnel should be contacted in a timely manner.