How does a radar level gauge measure the oil level in a fuel tank

As an important facility for storing fuel, the accurate measurement of oil level in fuel tanks is directly related to energy management and safety guarantee. Therefore, adopting high-precision and reliable measurement technologies to monitor the oil level in fuel tanks is a crucial link in ensuring the continuity and security of energy supply. Among various liquid level measurement technologies, radar level gauges have become the preferred equipment for measuring the oil level in fuel tanks due to their advantages such as non-contact measurement, high precision and strong stability.

The characteristics of the oil level in the fuel tank mainly include: the dielectric constant of the fuel is relatively high, which has a certain impact on the propagation of electromagnetic waves; There may be interfering factors such as steam and foam inside the fuel tank, which may affect the measurement accuracy. The volatility and flammability of fuel oil require that the measuring equipment must have good explosion-proof performance.

In view of these characteristics, radar level gauges can provide effective solutions. The working principle of the radar level gauge is based on microwave pulse propagation time (TOF) or frequency modulated continuous wave (FMCW) technology. It emits microwave signals. When the signals encounter the liquid surface and are reflected back, the liquid level height is calculated based on the change in the time or frequency of the echo.

Because microwaves can penetrate most media, including steam and foam, radar level gauges can work stably in harsh environments and provide accurate measurement results.

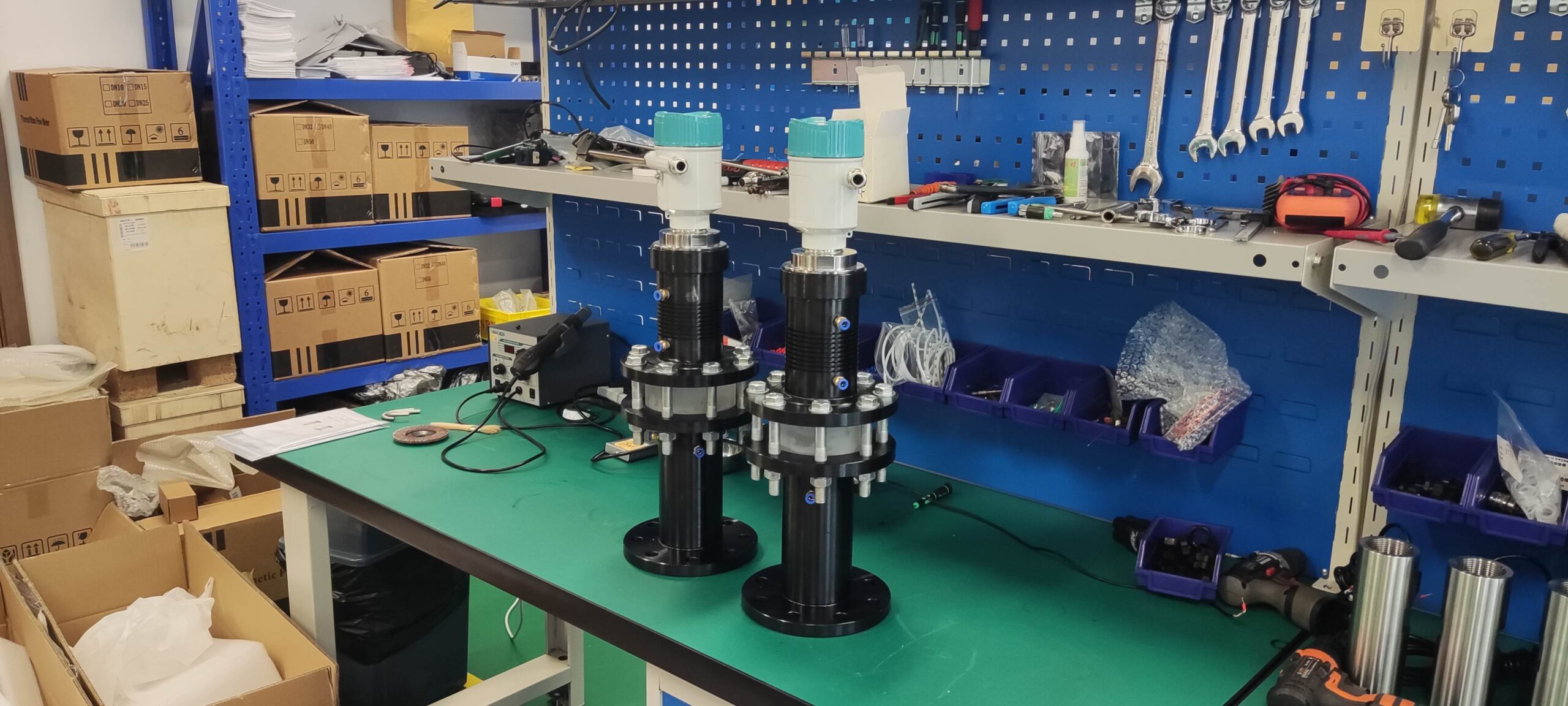

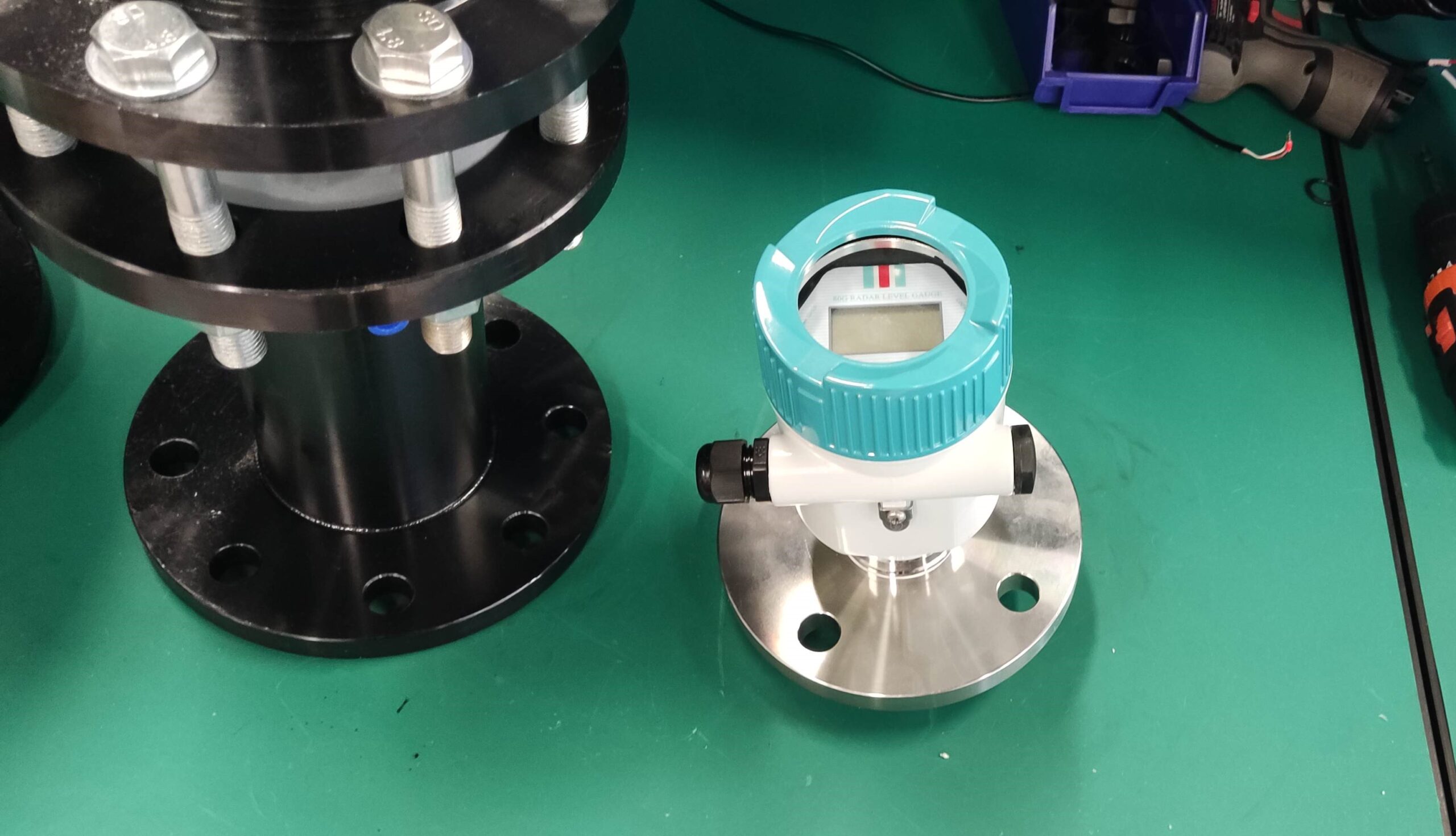

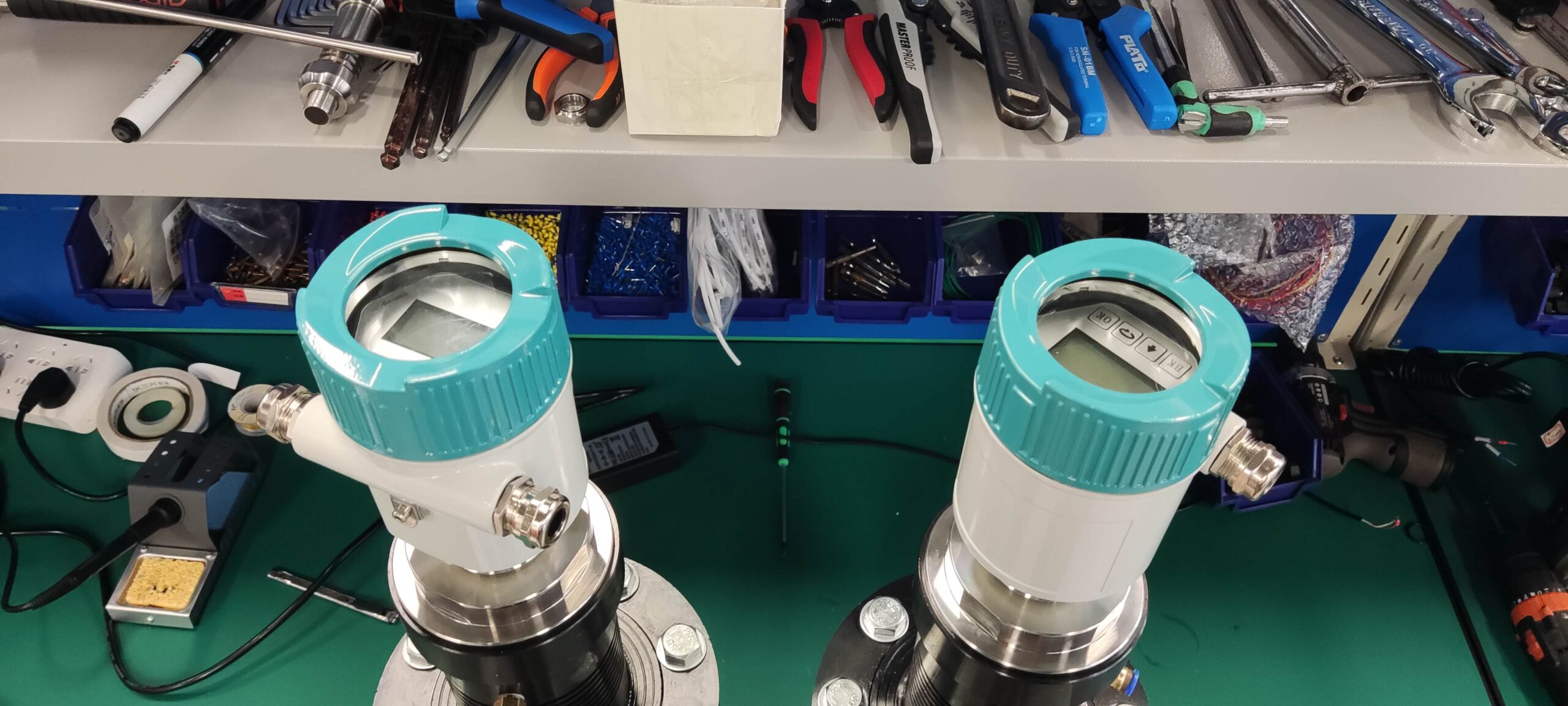

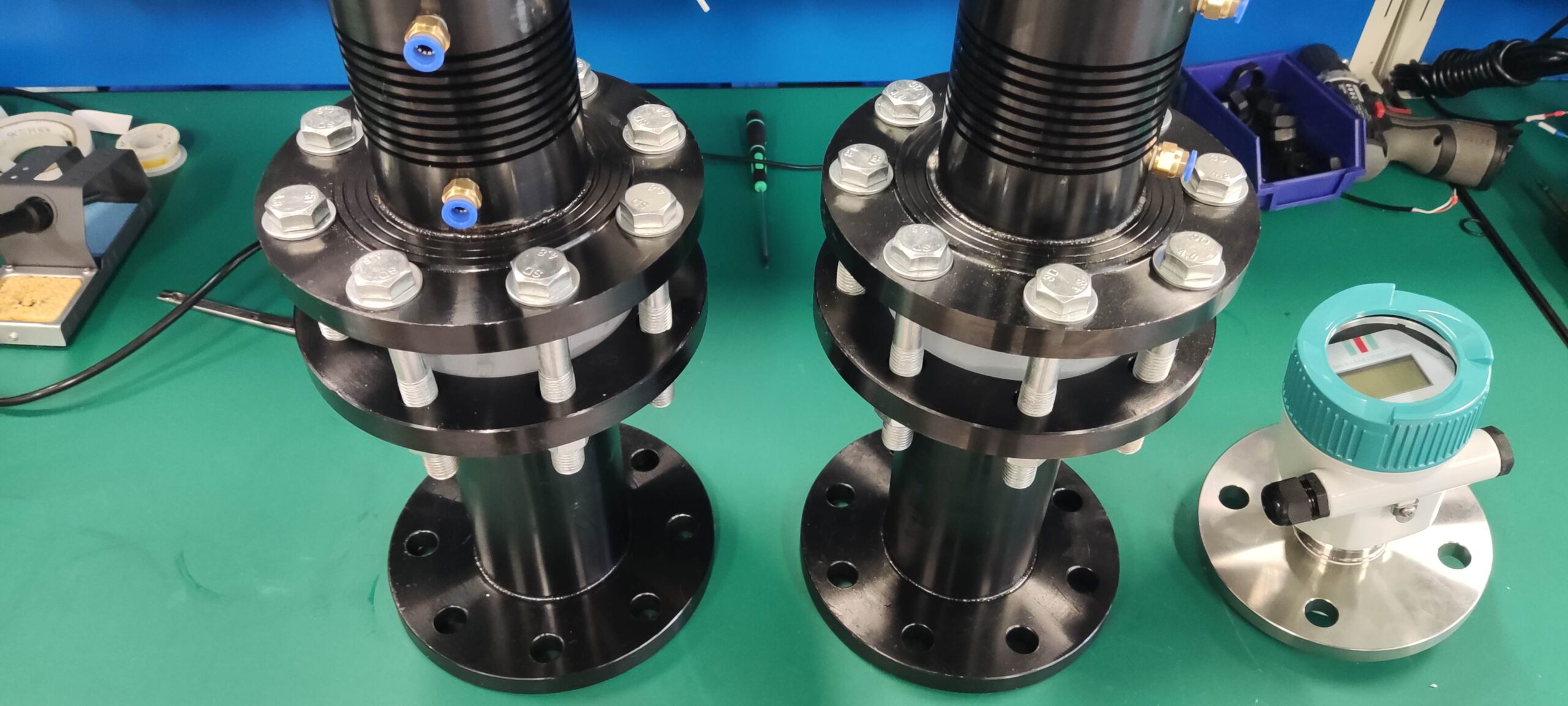

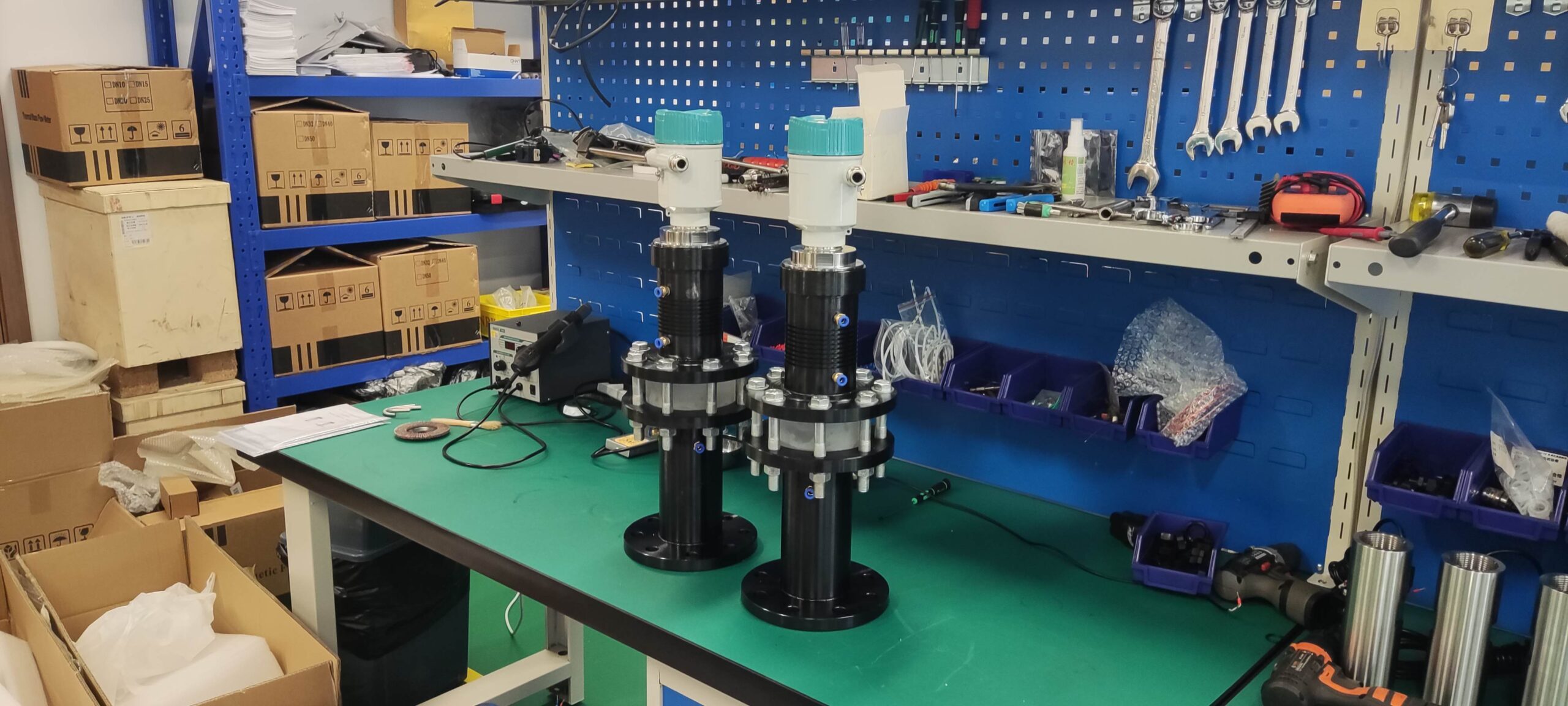

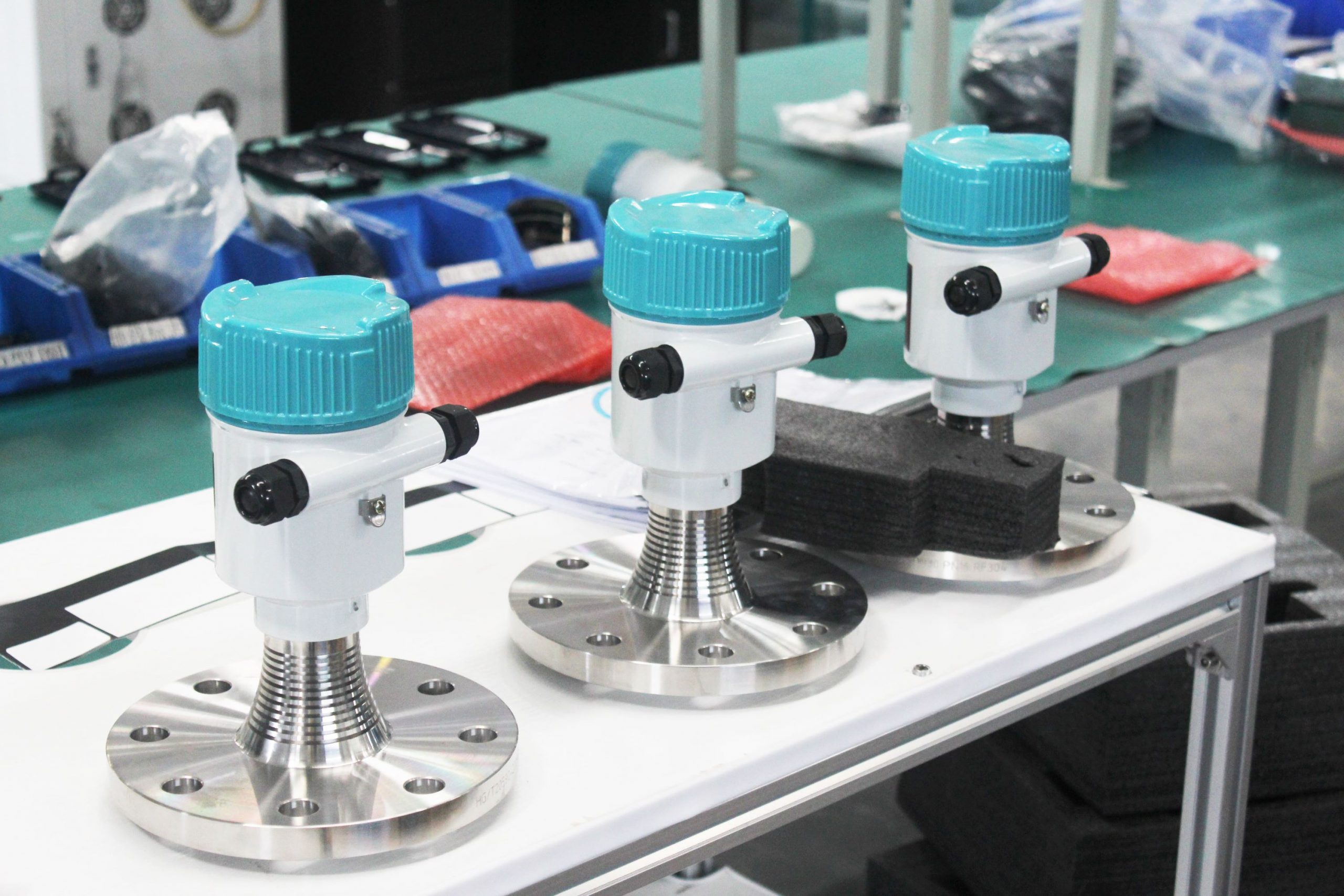

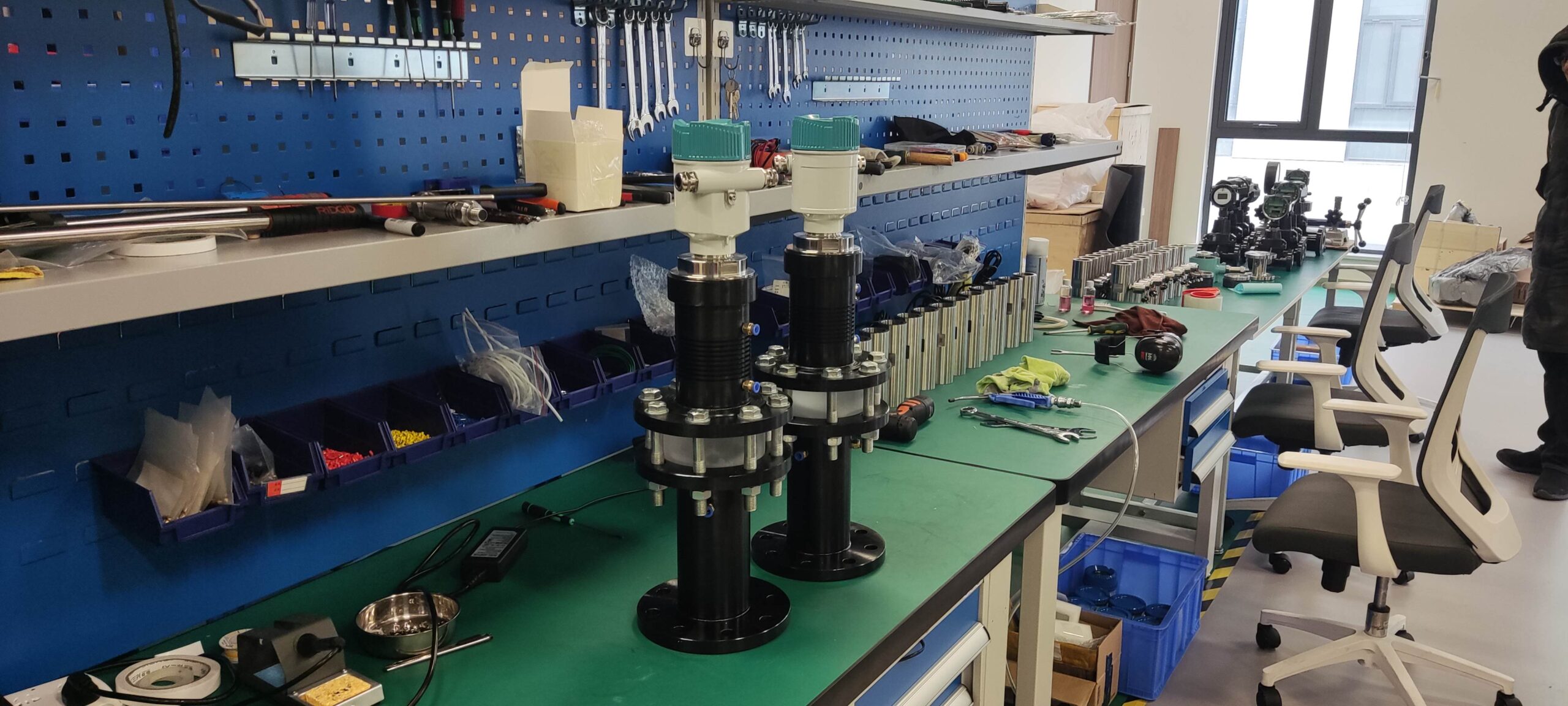

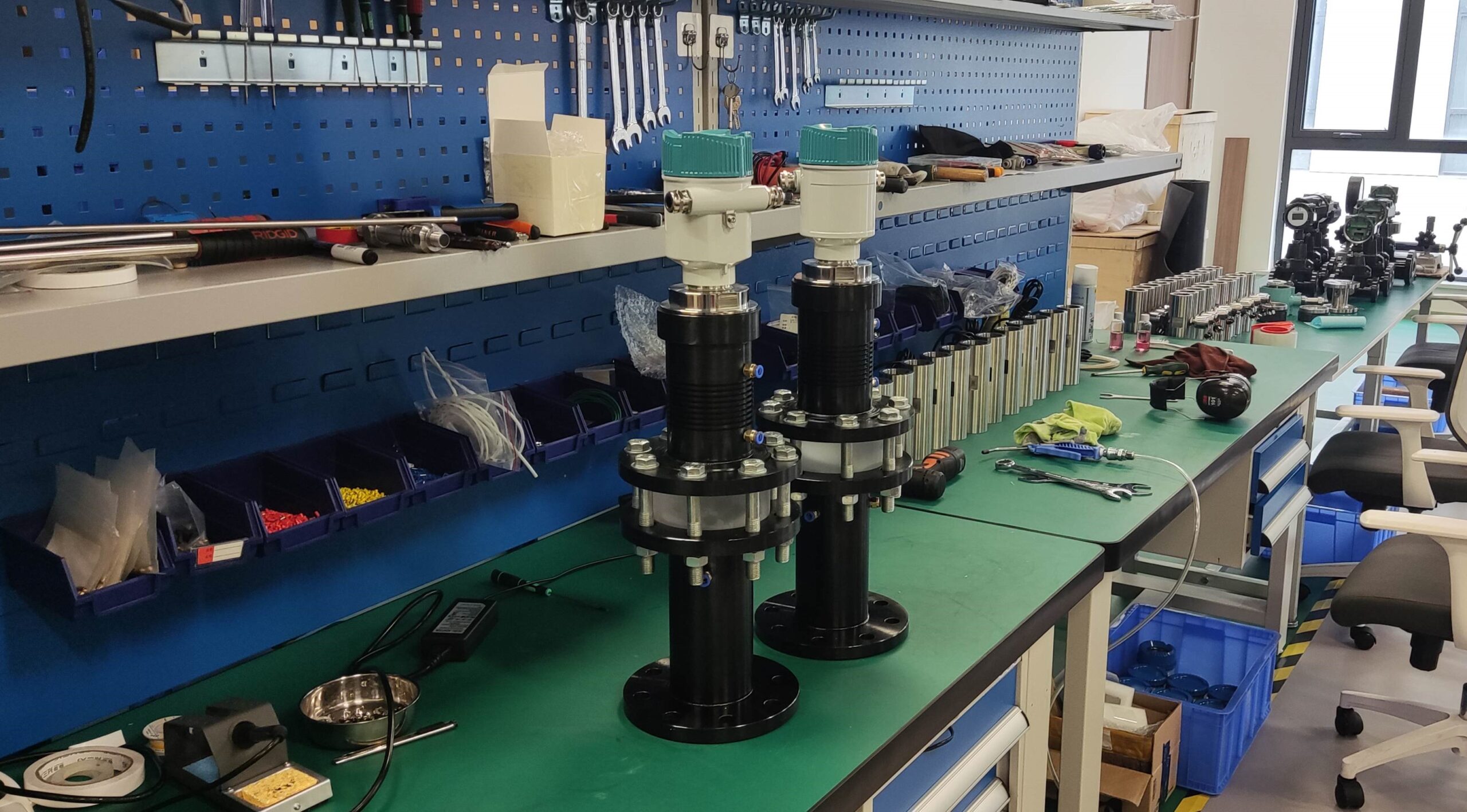

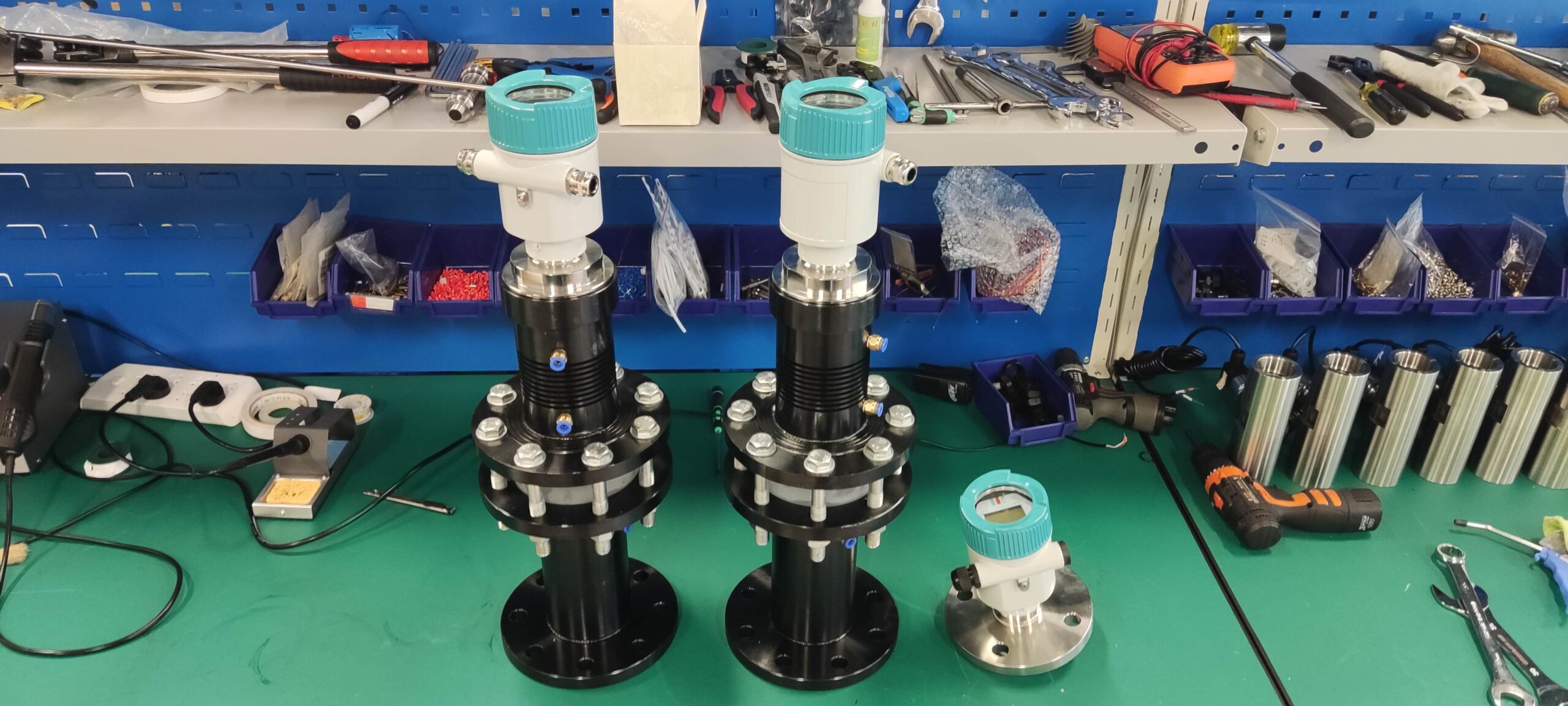

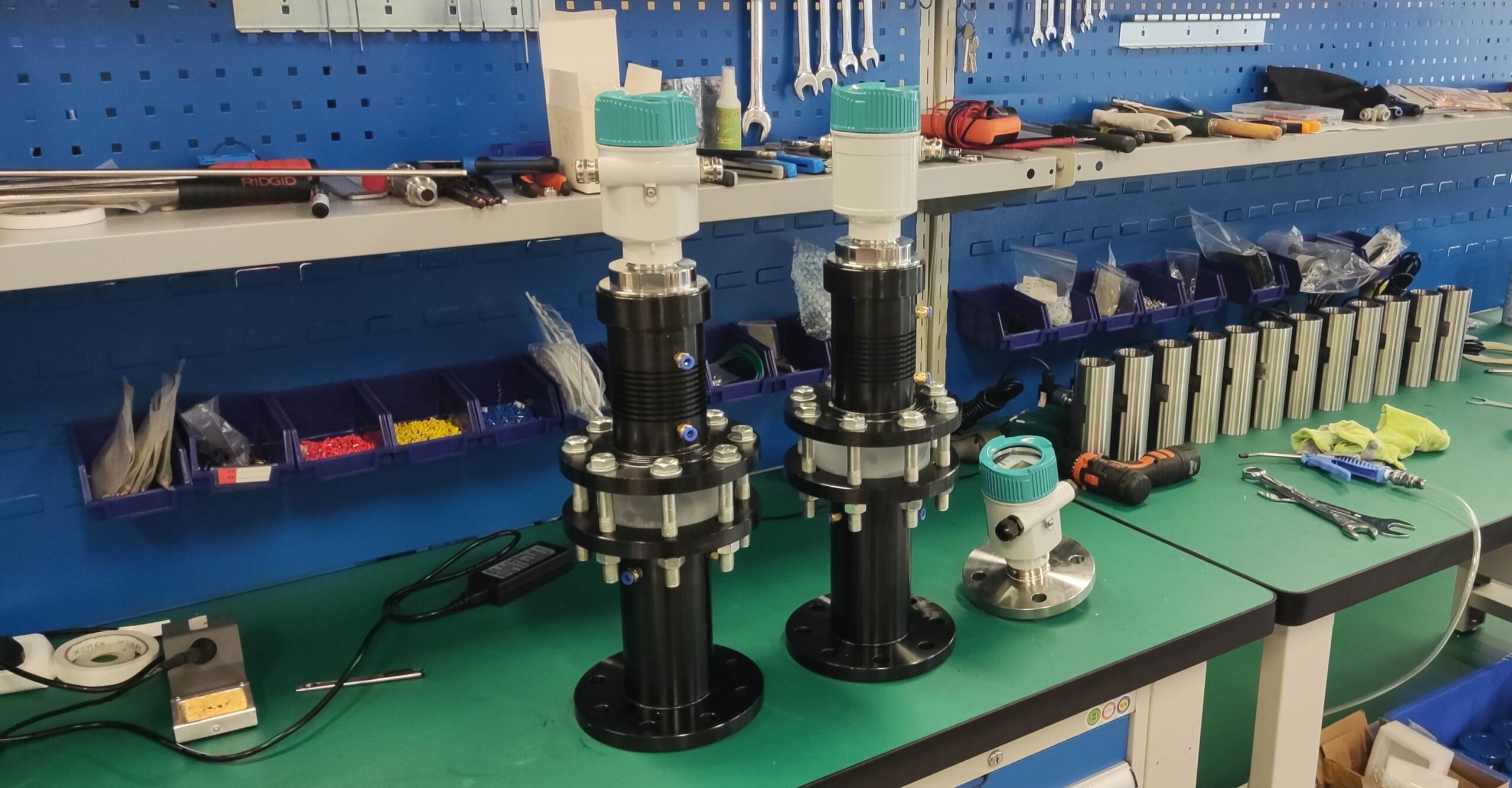

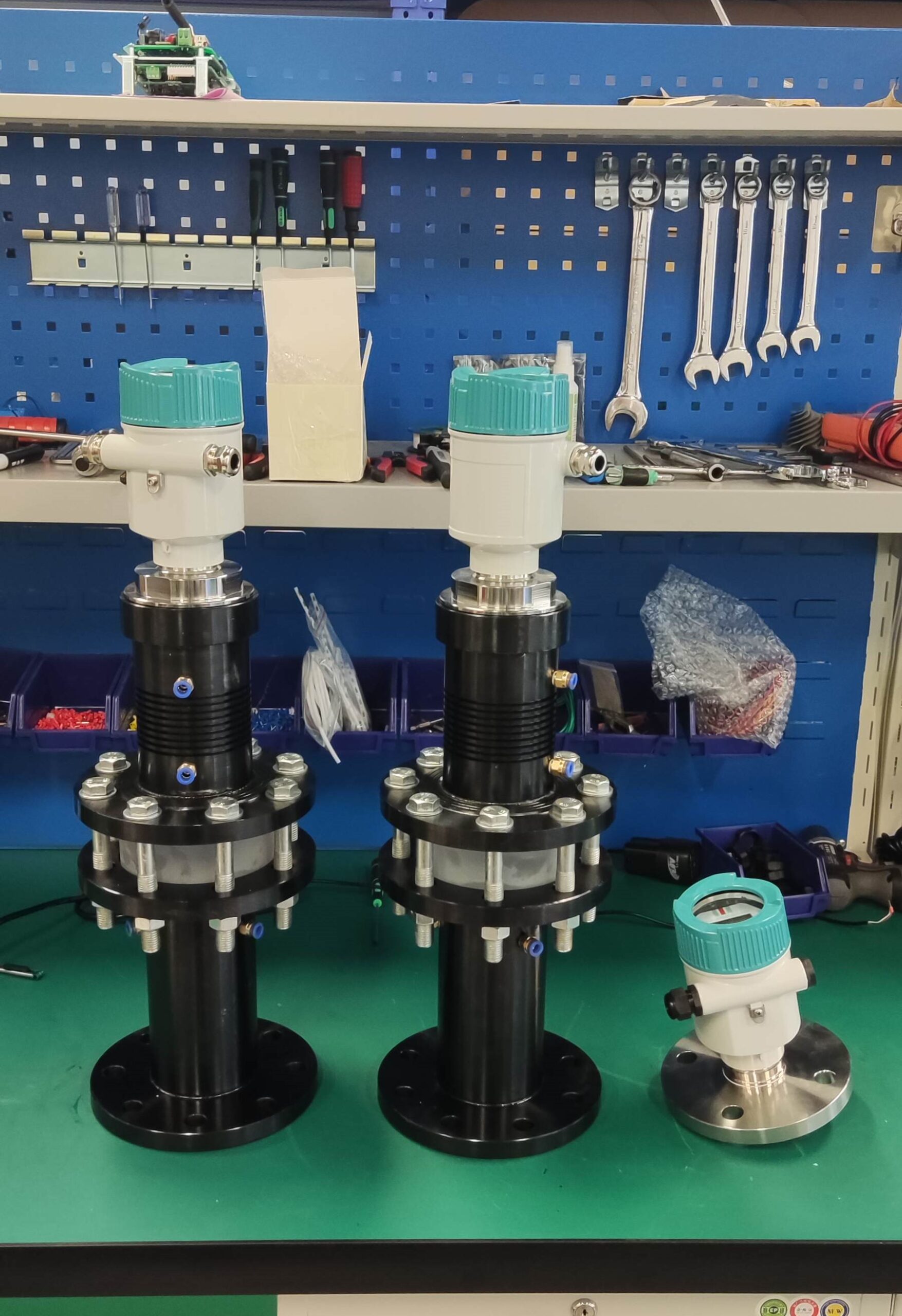

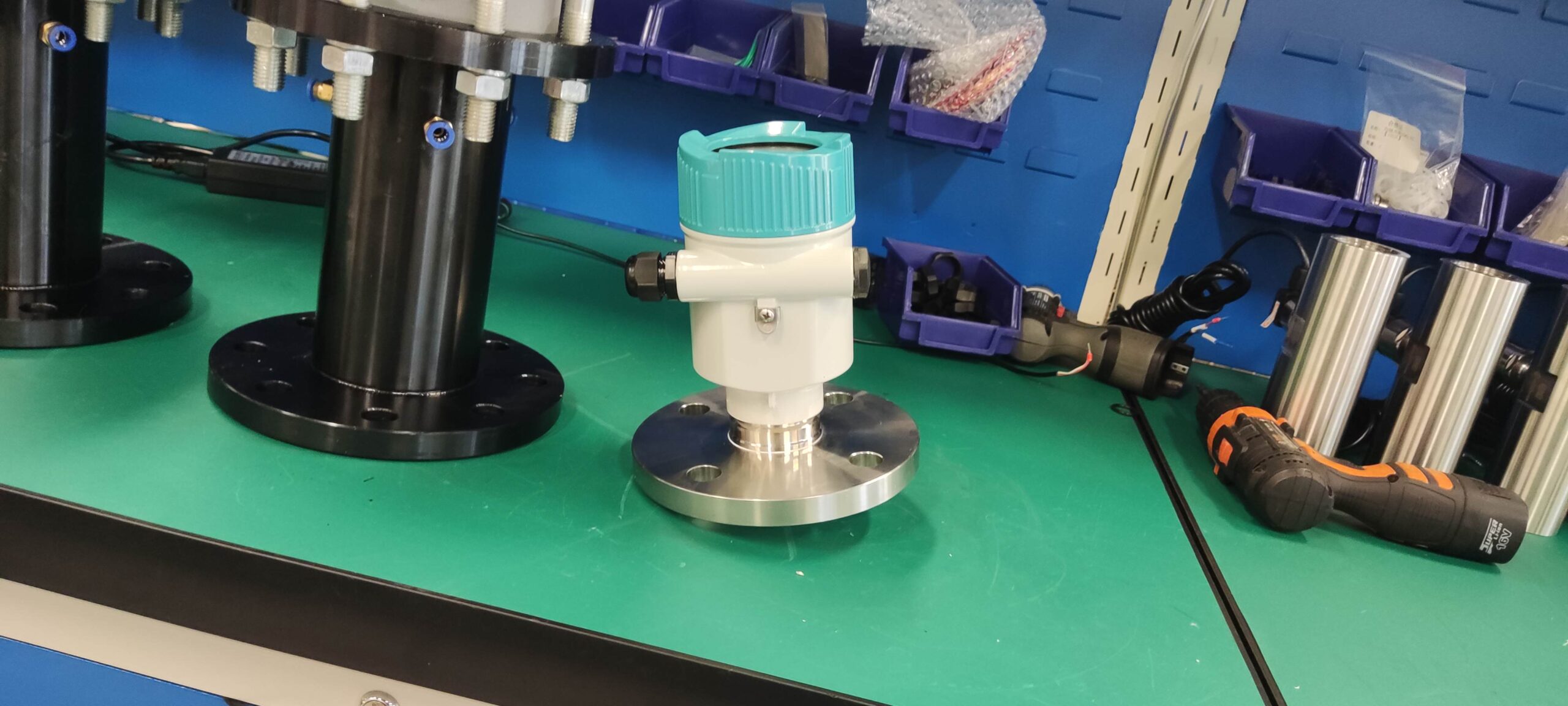

During the implementation of the radar level gauge, a detailed analysis of the fuel tank was first conducted. Considering the possible formation of steam and foam inside the tank, a radar level gauge suitable for high-temperature and high-pressure environments and with good penetration capability was selected. This liquid level gauge adopts high-frequency microwave signals, which can effectively penetrate the steam layer and reduce measurement errors. Meanwhile, the explosion-proof design of the equipment ensures its safe use in flammable and explosive environments.

When installing, the radar level gauge is placed at the center of the top of the fuel tank to ensure that the microwave signal is perpendicular to the liquid surface, thereby achieving the best measurement effect. During the commissioning stage, technicians precisely calibrated the liquid level gauge to ensure the accuracy of the measurement data.

After being put into use, the radar level gauge has demonstrated extremely high stability and reliability. Even when a thick layer of steam forms inside the tank, the liquid level gauge can accurately measure the change in oil level. In addition, by integrating with the automated control system, real-time monitoring and data analysis of oil levels have been achieved, significantly enhancing the efficiency and safety of fuel management.