Solutions to common problems encountered in the application of radar level gauges

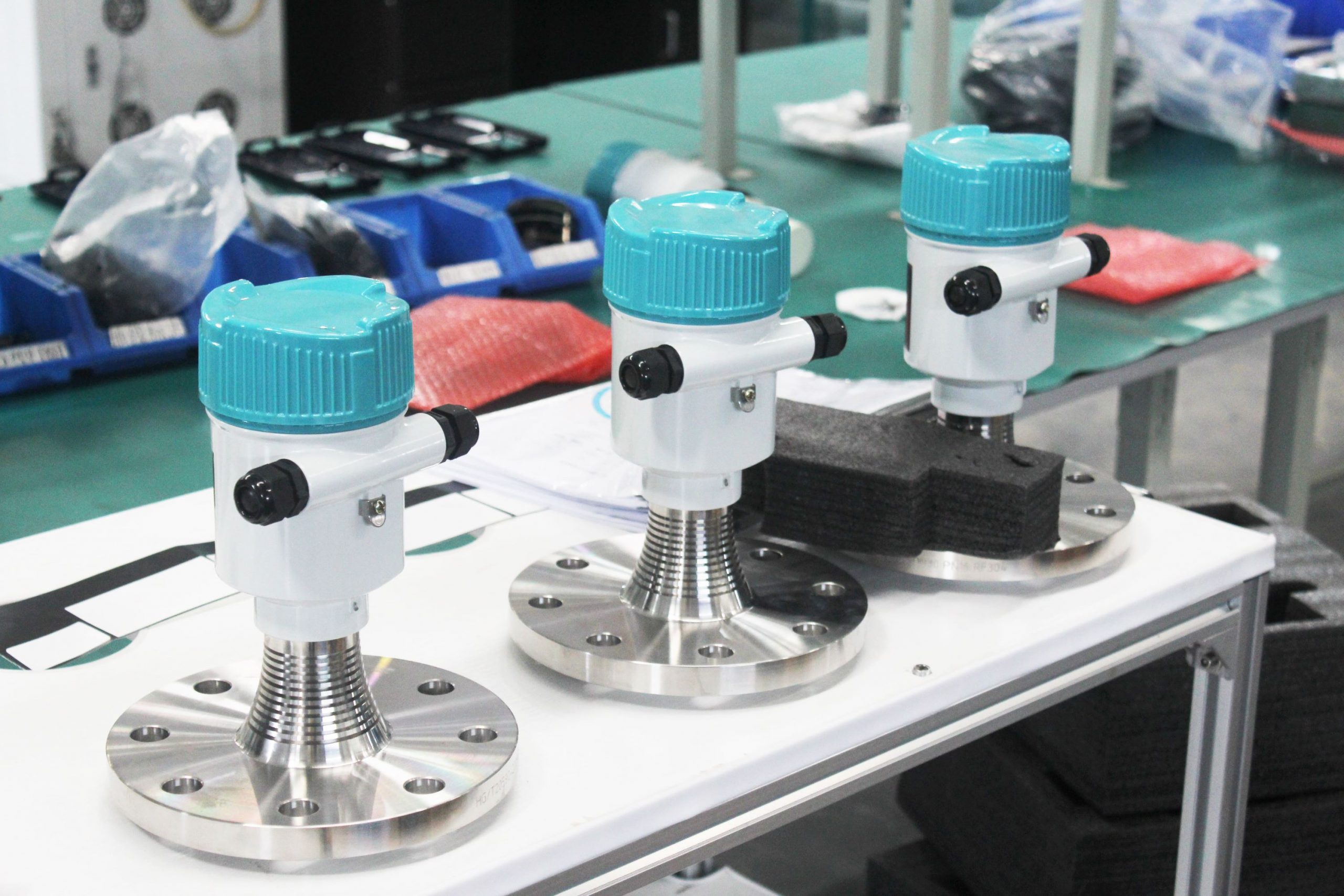

Radar level gauges are widely used in environmental protection, power, petroleum, chemical, steel and other industries. This is inseparable from the fact that radar waves can reliably measure liquid levels without being affected by changes in the density, dielectric constant, conductivity of the measured medium, as well as foam, smoke, steam and other media. Although radar level gauges have many advantages, due to the complexity of the measured policies and working conditions, defects are inevitable in the application process of radar level gauges, which affects accurate measurement.

There are many reasons for the unreliable measurement of radar level gauges, but the common ones mainly include the following points

1. The equipment position of the radar level gauge. Radar level gauges measure based on the time travel or frequency difference of microwaves during the process of transmission, reflection and reception. Therefore, it is an ideal application condition for microwaves to reach the liquid surface of the measured medium without any disturbance. However, due to the constraints of the installation position of the radar level gauge, this requirement is difficult to meet in practical applications.

2. Pressure and temperature

1) The influence of pressure on the reliable measurement of radar level gauges. The radar level gauge is not affected by air density when transmitting microwave signals, so it can operate normally under both vacuum and pressure conditions. However, due to the structural constraints of the radar detector, when the operating pressure inside the container reaches a certain level, the radar level gauge will have significant measurement errors. Therefore, during actual measurement, it is necessary to be careful not to exceed the pressure value allowed by the manufacturer at the time of factory delivery to ensure the reliability of the radar level gauge’s measurement.

2) The influence of temperature on the reliable measurement of radar level gauges. The radar level gauge emits microwaves without using air as the transmission medium, so the change in medium temperature has a negligible impact on the transmission speed of microwaves. However, the sensor and antenna parts of the radar level gauge are not heat-resistant. If the temperature of these parts is too high, it will affect the reliable measurement and normal operation of the radar level gauge.

3. Process characteristics. Take the operation of alumina as an example. Since all the slurries in the alumina process are carried by water, their dielectric constant is relatively large, and they have a better ability to reflect microwaves. Moreover, the tanks using radar level gauges are mostly at normal pressure, allowing for maintenance without stopping. However, the particularity of the process also brings many unfavorable factors to the measurement:

1) Multiple discharge ports;

2) Many slurries are viscous and prone to scarring. When there are thick and wet scarring on the production line, it will cause intense reflection of microwaves, keeping the surface measurement value at a stable high liquid level. When “Near-field Control” is turned on, the “lost wave” error or system crashes occurs again due to the surface not receiving useful measurement echoes.

3) To prevent the slurry from accumulating and hardening, there is often stirring in the tank, and the stirring causes the liquid surface to tremble. Sometimes, foam and vortices may also be produced.