What are the key points of application for thermal gas mass flowmeters? In what occasions is it mainly applied?

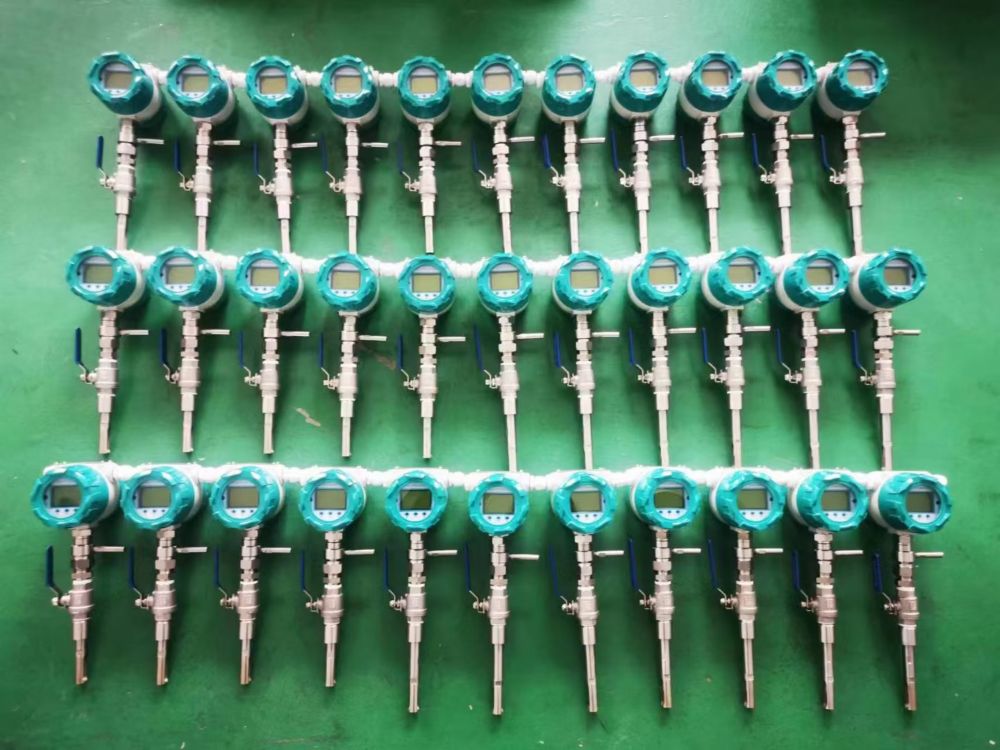

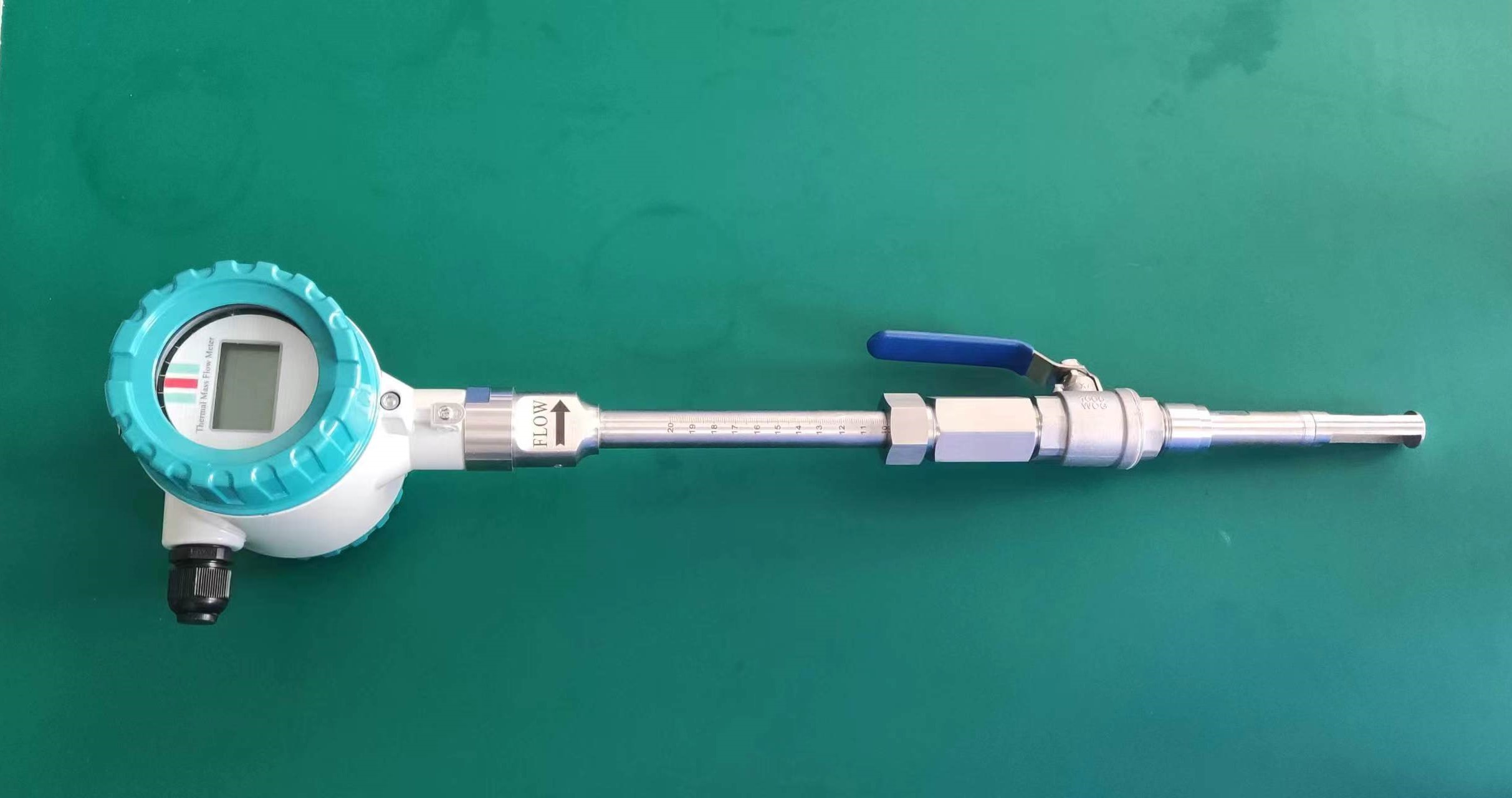

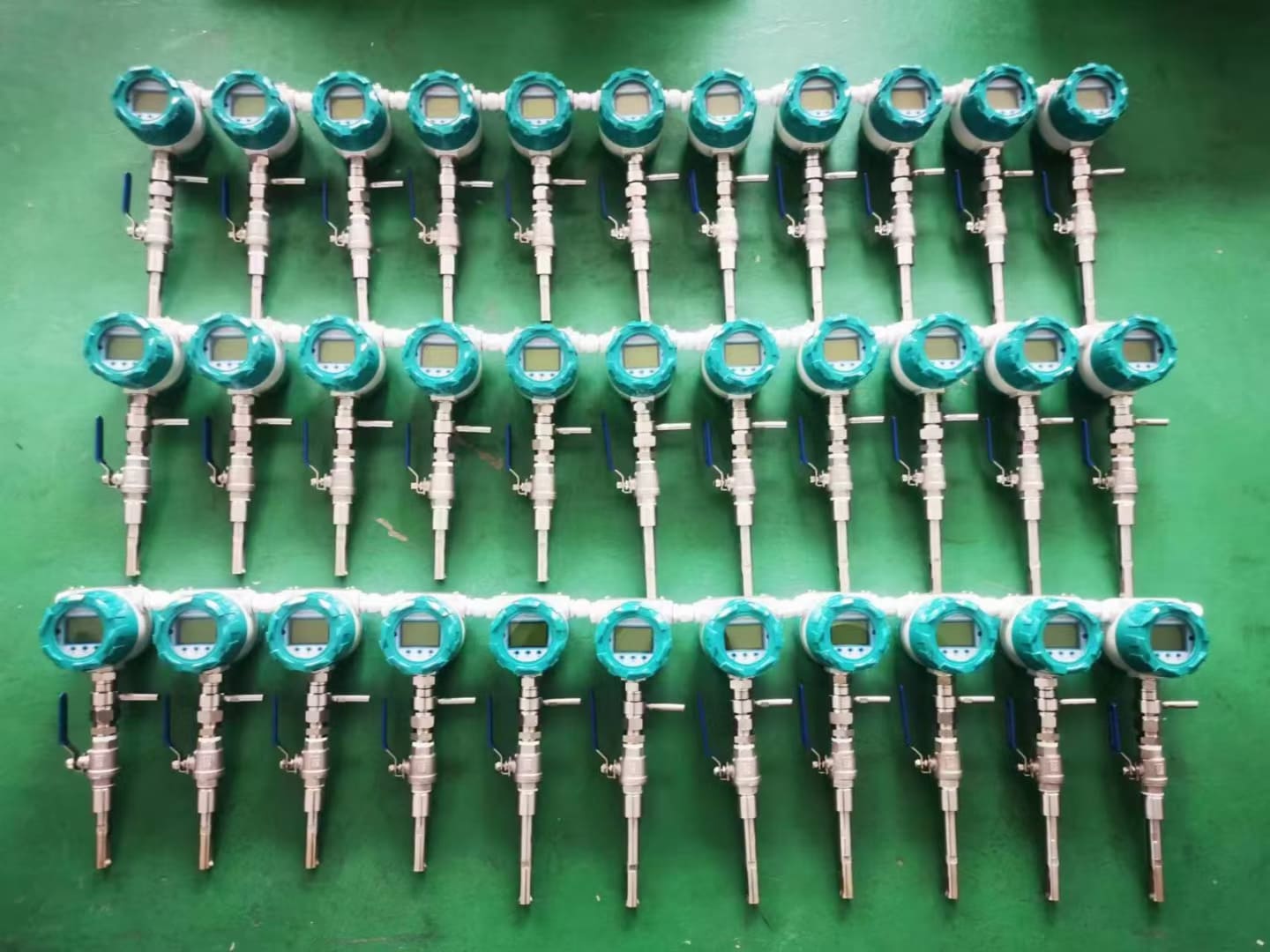

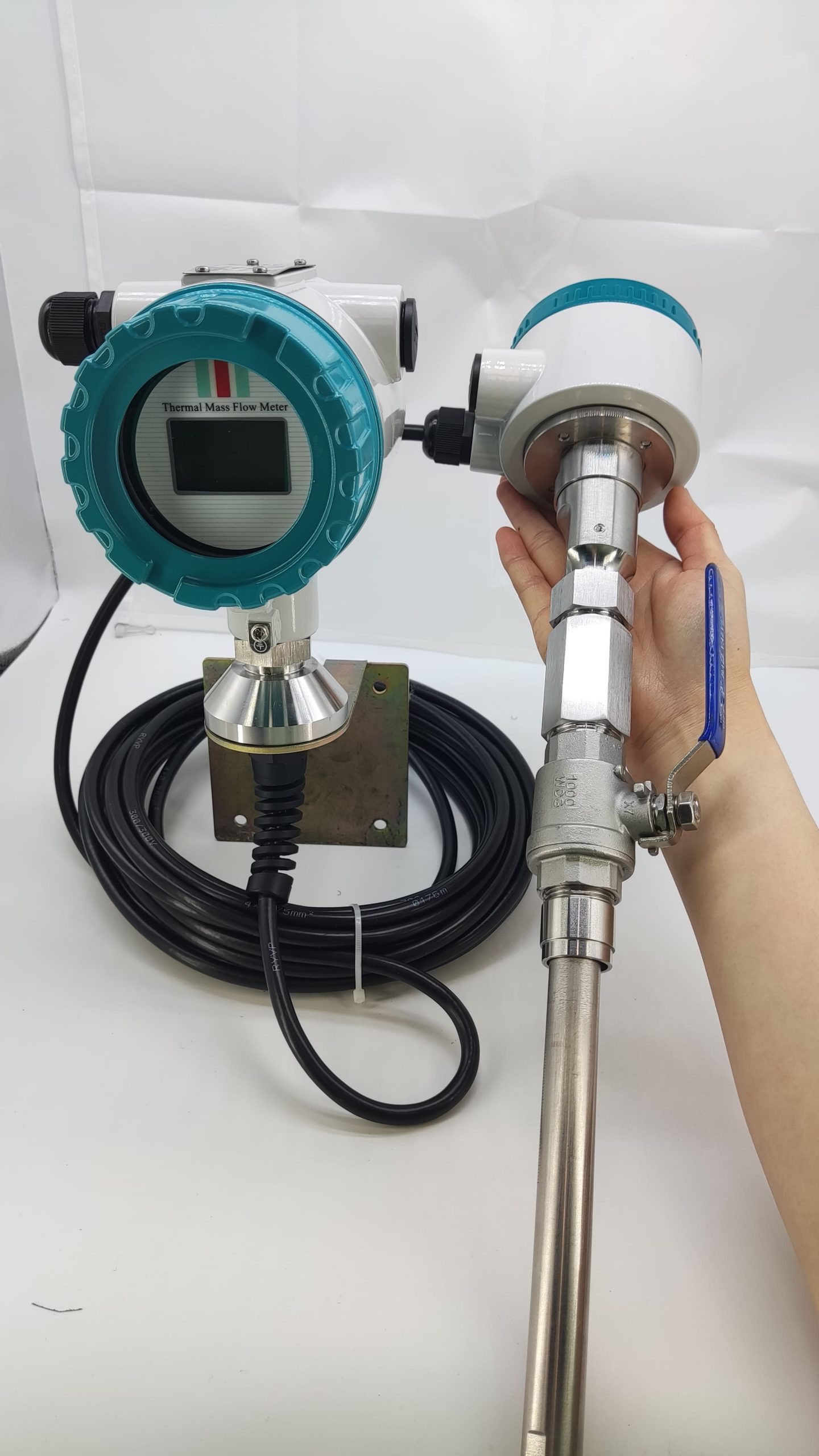

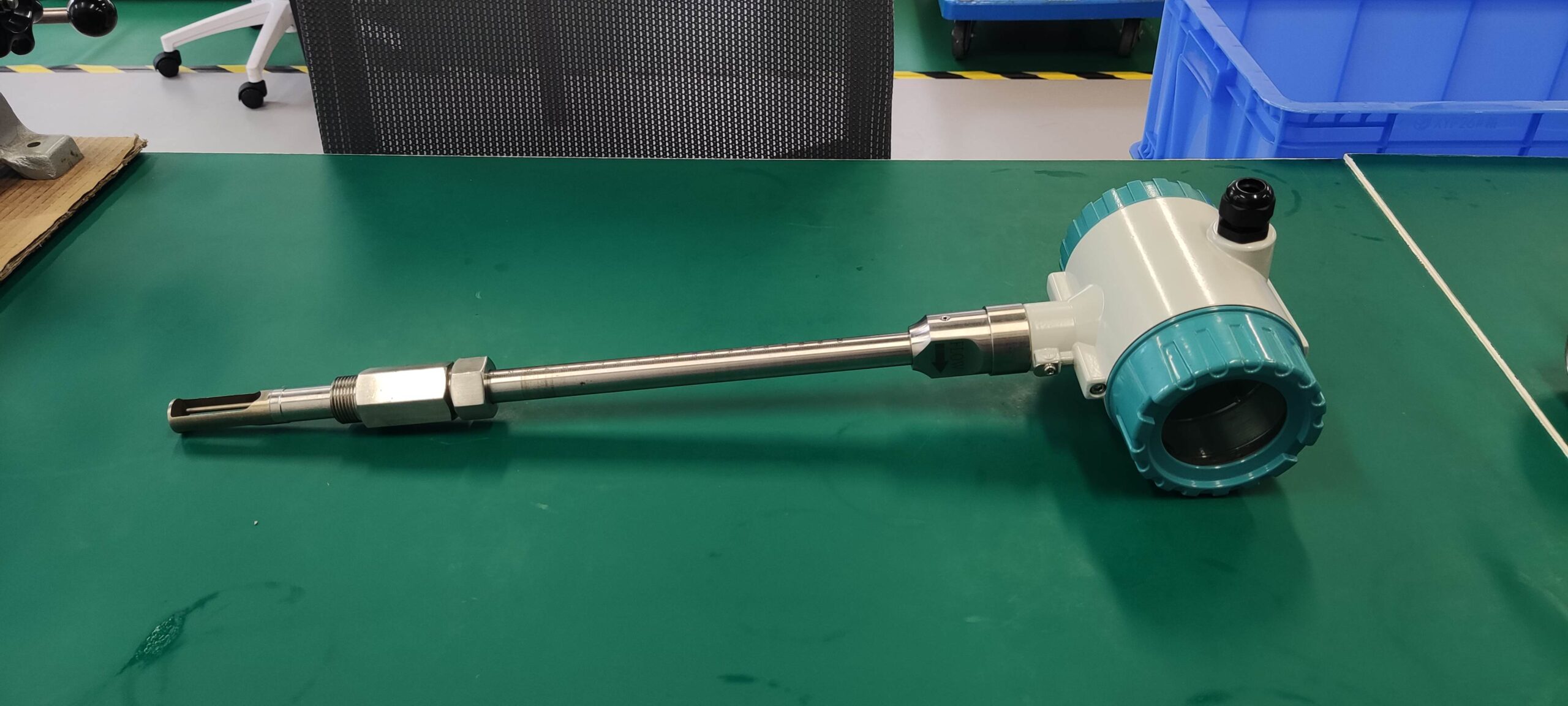

Thermal gas mass flowmeters have become well-known to many people in recent years. Those who have not come into contact with this type of gas flowmeter must be very curious about how it is applied. In what occasions is it applied? Today, the editor of Aister Instrument, a flowmeter manufacturer, will take you to learn about it!

Let’s first take a look at the several major advantages of thermal gas mass flowmeters:

1. Special traffic data model algorithm; Fuzzy theory control algorithm for temperature and humidity

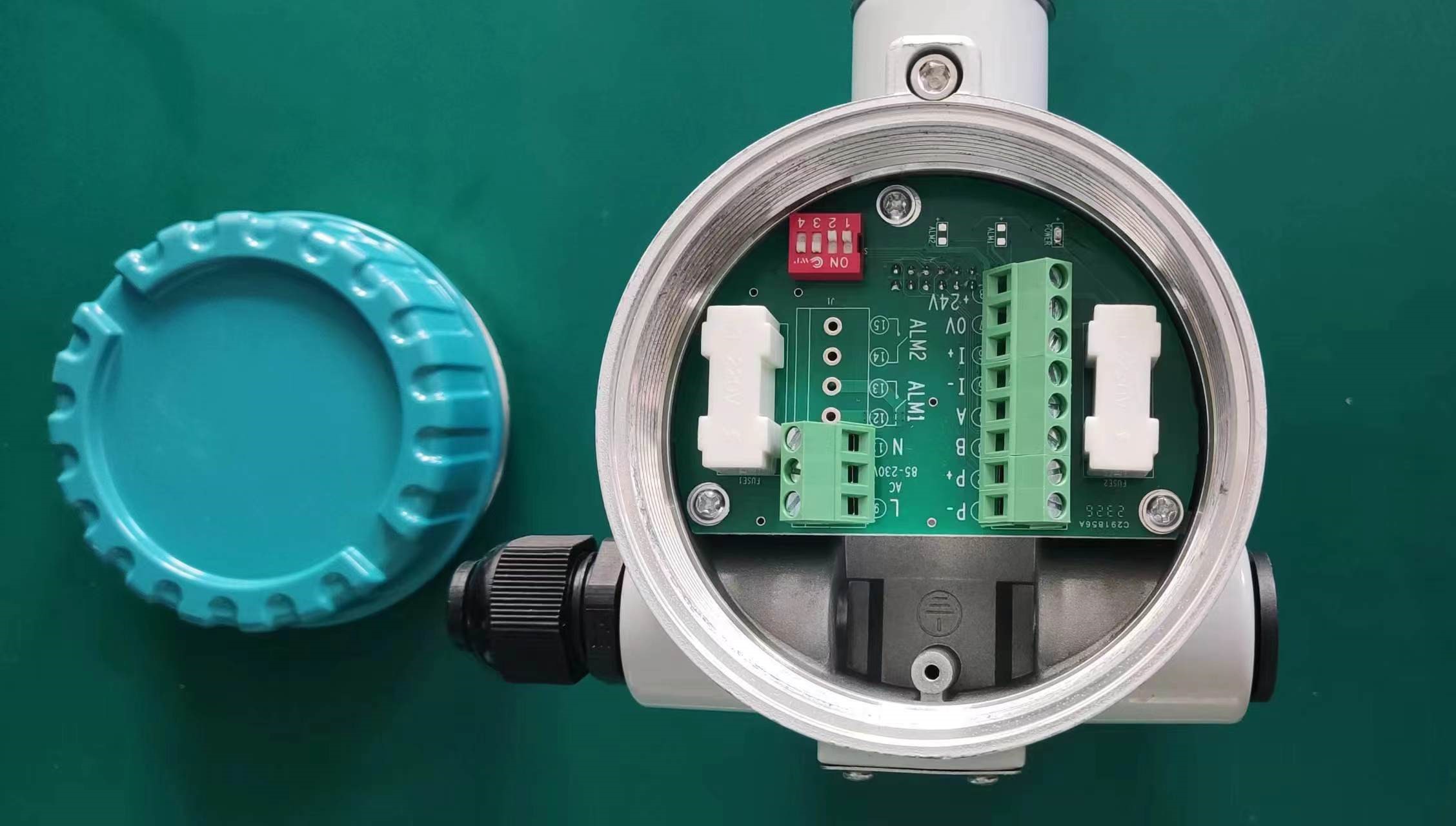

2. Develop high-performance intelligent microprocessors and analog-to-digital and digital-to-analog conversion circuit chips;

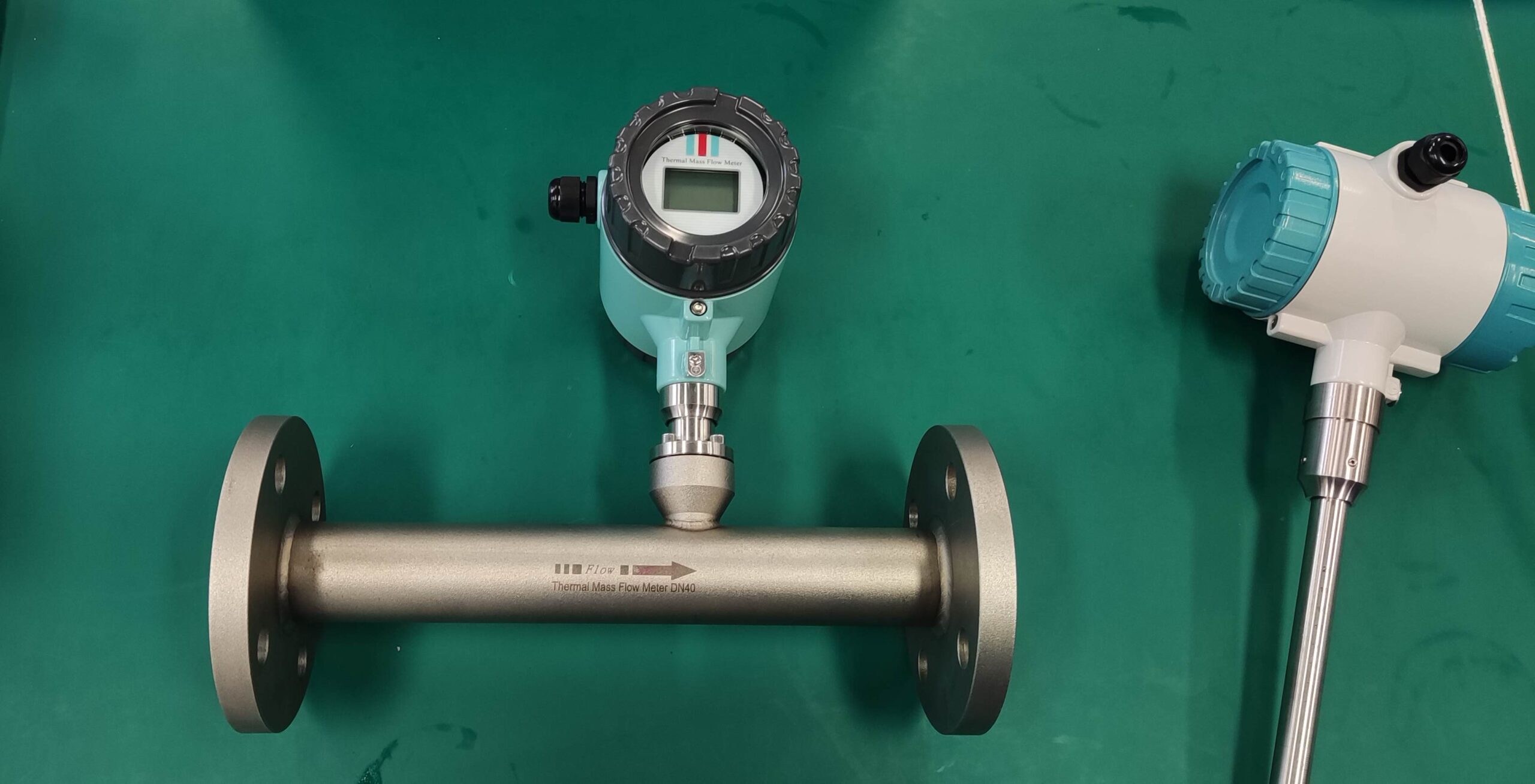

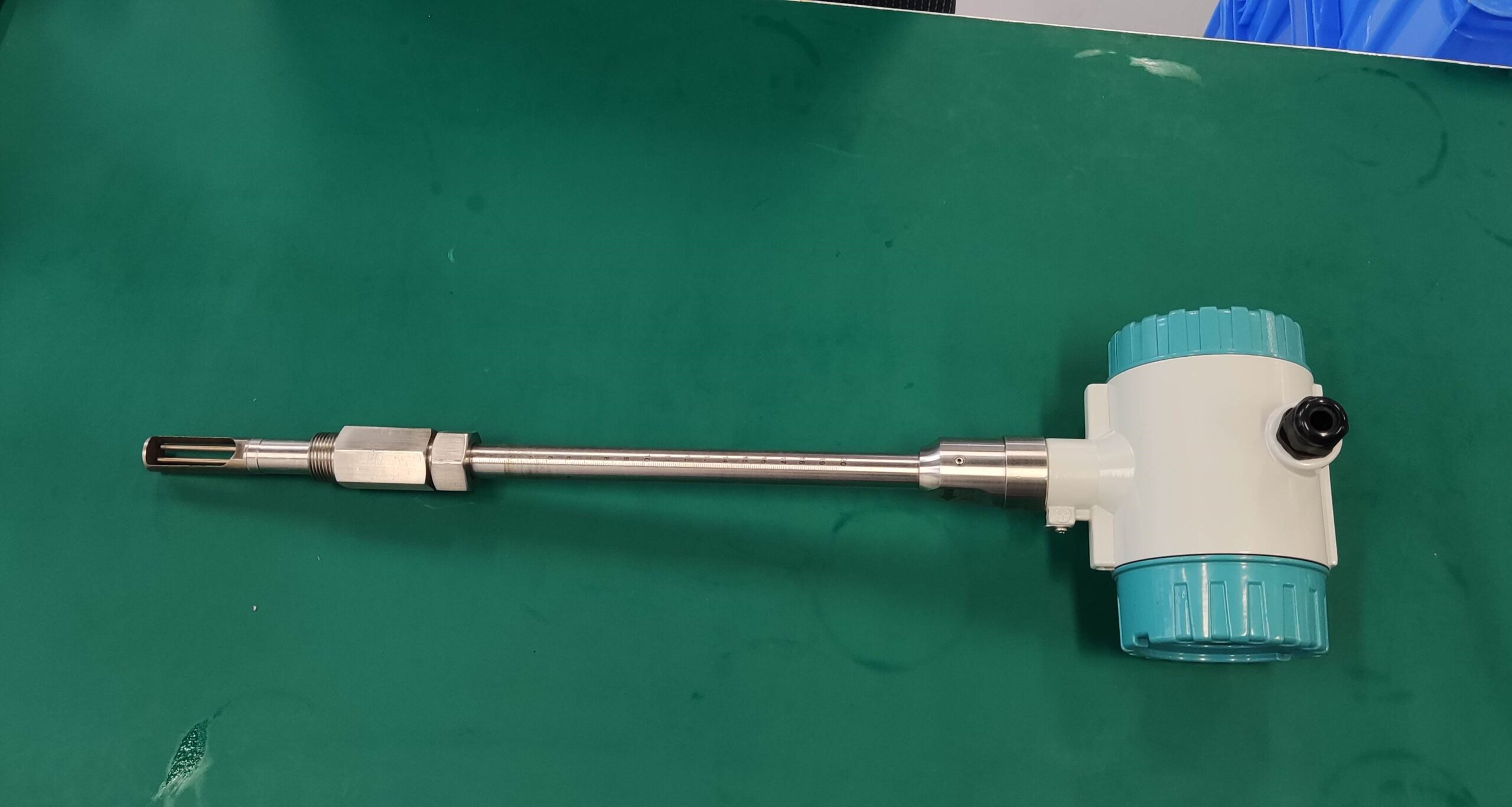

3. Wide range ratio: 1000:1; Large diameter, low flow rate, and negligible pressure loss;

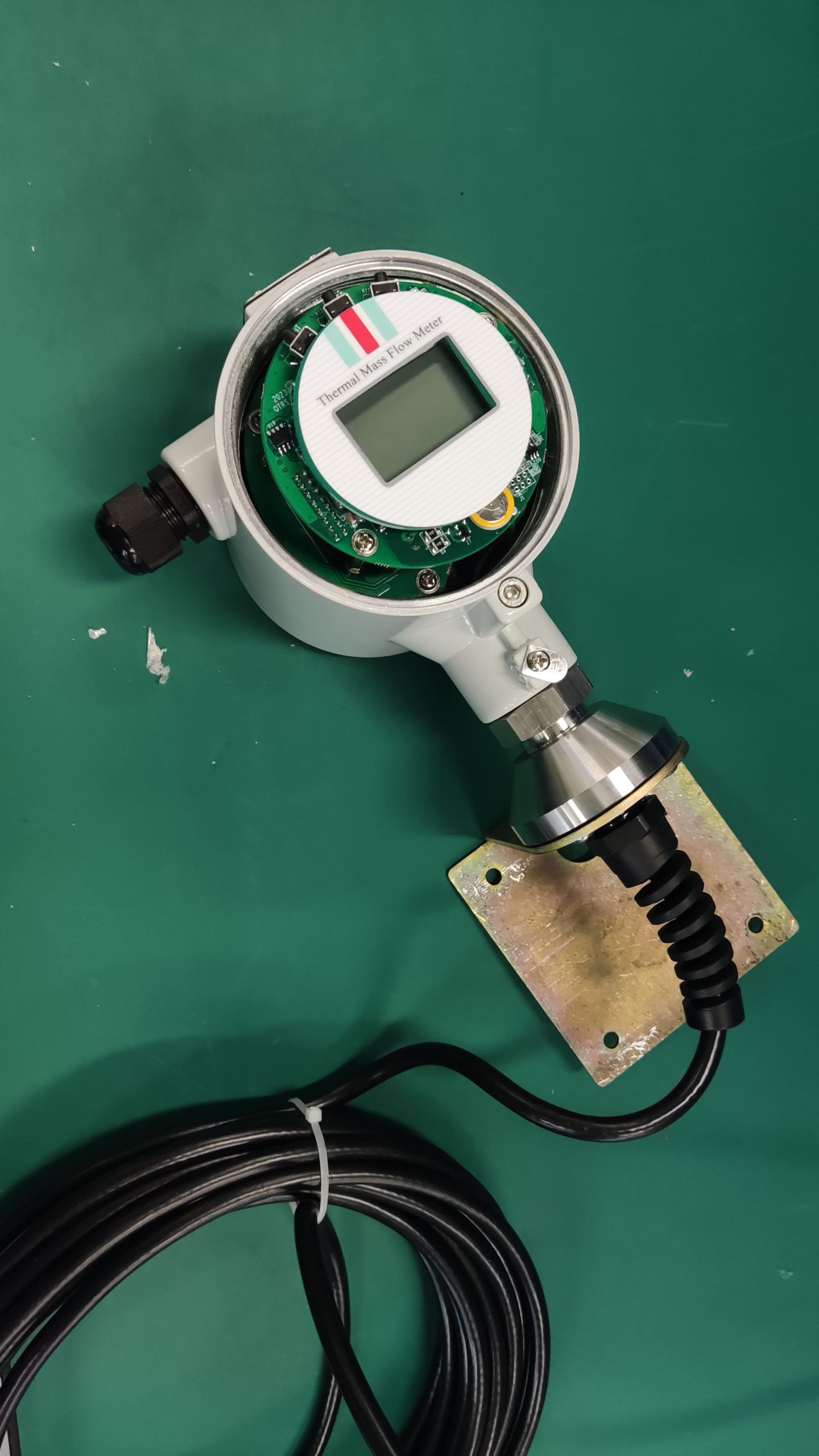

4. Direct measurement of mass flow rate without temperature and pressure compensation;

5. The measurement at low flow rates is extremely sensitive.

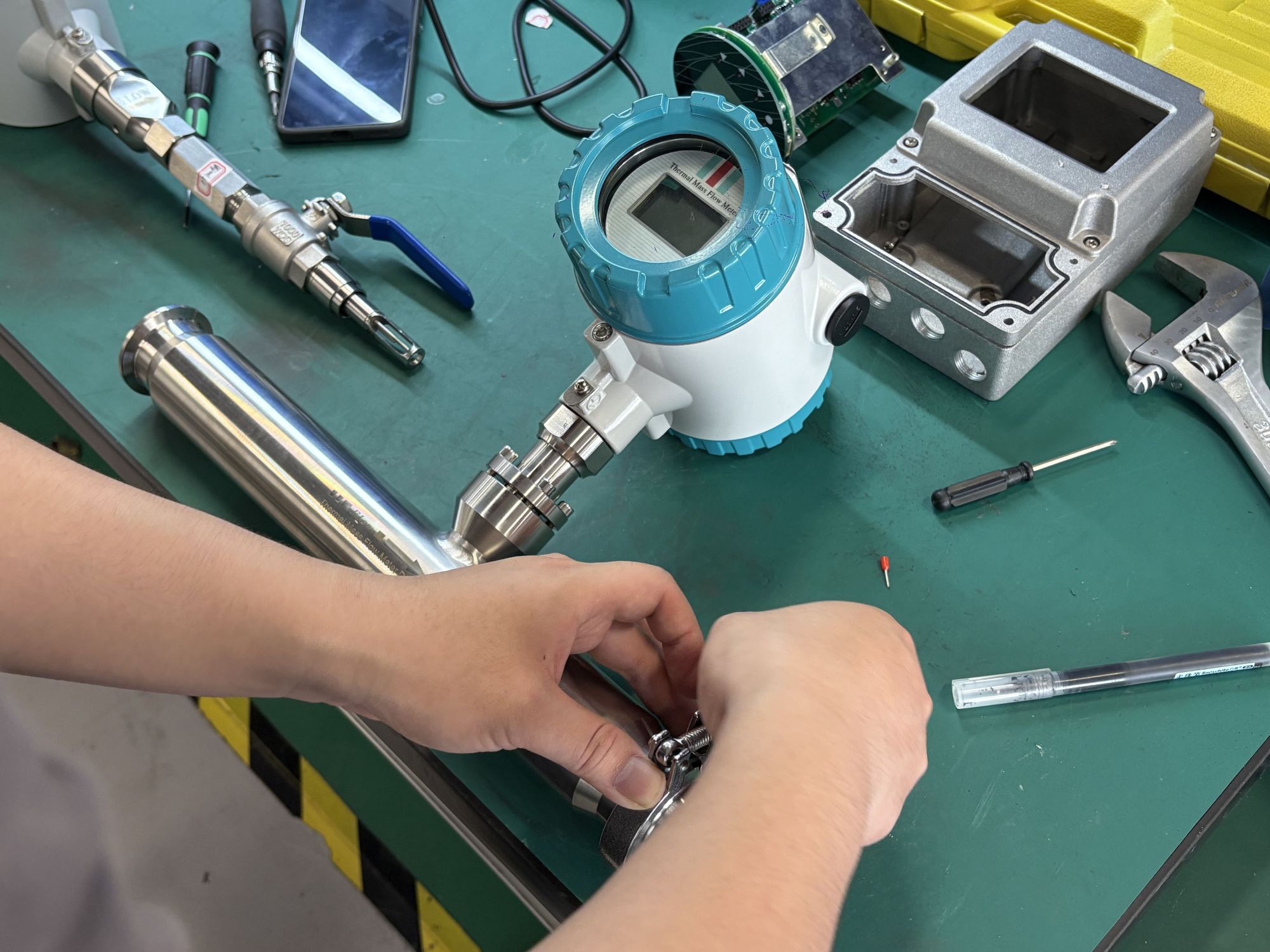

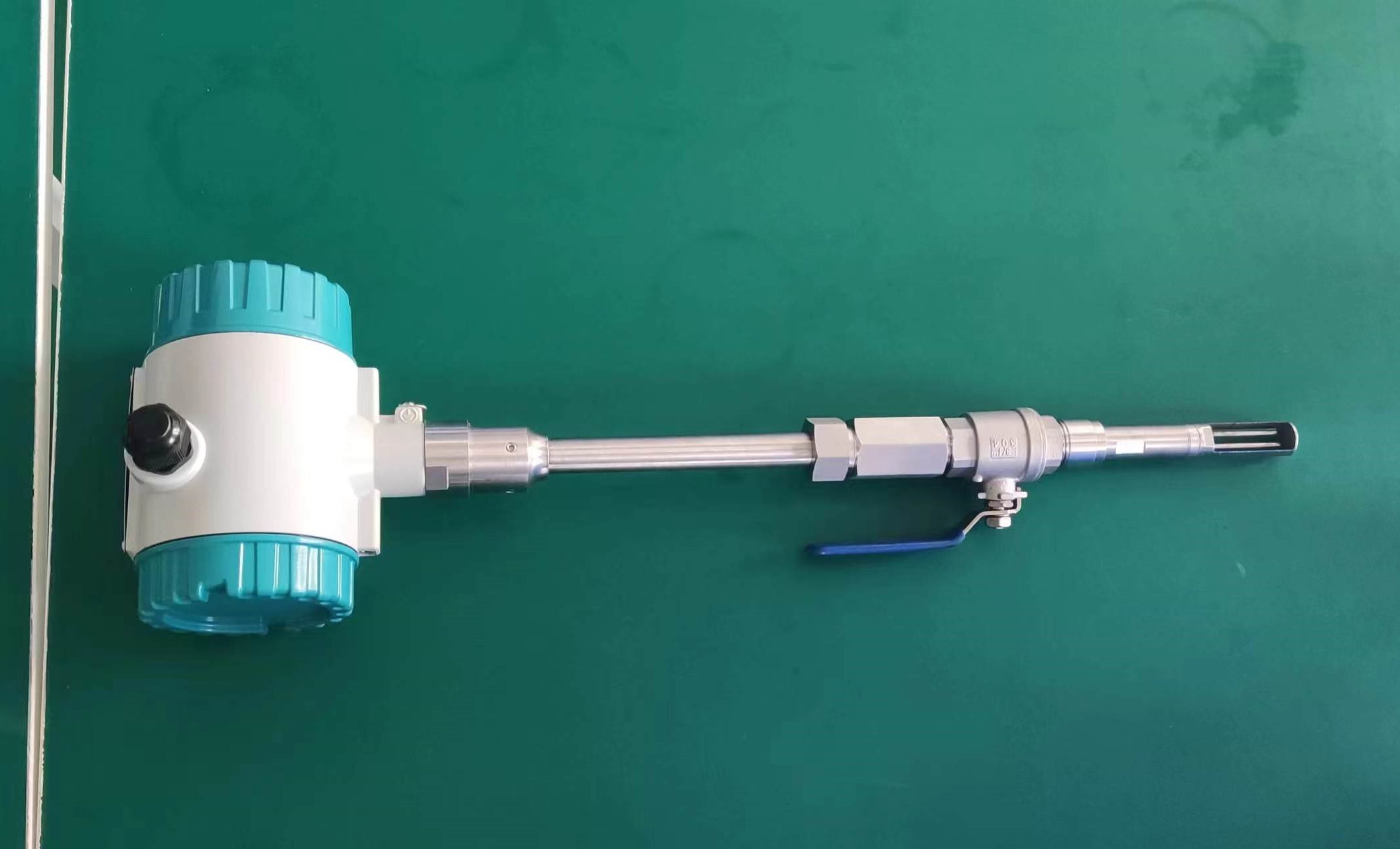

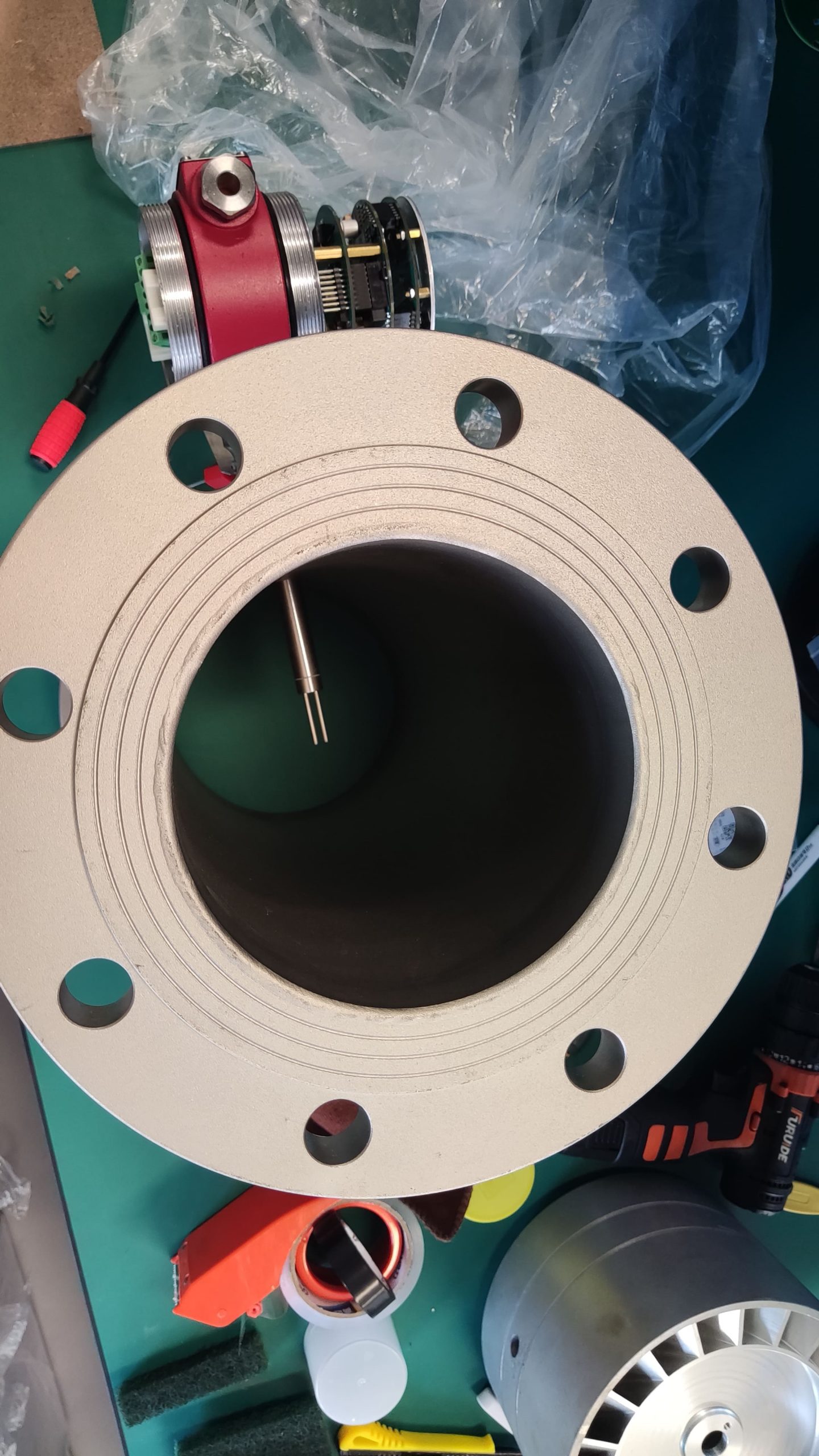

6. It is convenient for design and selection, and easy to install and use.

7. Suitable for flow measurement of various single or mixed gases.

Application scenarios of thermal gas mass flowmeters

Public construction projects – monitoring of electricity, gas and water treatment, as well as gas in pipelines; General Information System Biogas Gas; Natural gas; Liquefied gas; The boiler is preheated to treat the air

Energy exchange in the oil and gas industry Gas recovery Gas measurement Gas mass analysis Air leakage detection Natural gas metering Flare gas monitoring

Gas measurement during the gas distribution process in the fuel management system of the power enterprise industry development; Measurement of various gases in boilers and auxiliary information systems; Gas measurement in gas furnaces Hydrogen measurement Measurement of primary and secondary air in blast furnaces of power plants

Chemical flue gas circulation monitoring Gas flow measurement of the sampling system; Measurement of gas flow of the induced draft fan Ammonia measurement in fertilizer plants Measurement of various gas flow rates in battery factories

The metallurgical technology industry enters the gas filling measurement of steel plants. Measurement of gas production in blast furnaces of ironmaking plants Measurement of coke oven gas in coking plants Control of the measurement system for gas (such as blast furnace gas, coking enterprise gas, natural gas, etc.) in the heating furnace of the rolling mill; Control of gases such as hydrogen, oxygen and nitrogen in heat treatment quenching furnaces, etc

Measurement of gases in the wastewater treatment system of the papermaking industry Flue flow monitoring Recover secondary/tertiary air from the boiler; Measure the gas and air supply from the boiler

The addition of fresh air in the processing technology operations of food and pharmaceutical enterprises. The carbon dioxide in breweries can be treated. The flow rate of hot air in the bottle sterilizer; Measurement of gas flow data generated during the thermal oxidation process; Ventilation management system Quality control of boiler intake, exhaust gas and process

Gas measurement in the process of environmental protection biogas utilization; Chlorine gas measurement in the chlorine gas treatment process; Gas measurement in the aeration tank during the sewage treatment process; Monitor the emissions of SO2 and NOx from chimney flue gas

For the measurement of compressed air quality in other related industry enterprises and factories, Aister Instruments has been manufacturing thermal gas mass flowmeters for many years. If you have any other questions during the use of this flowmeter, you can contact us online or by phone at any time.