How should the installation direction of a thermal gas mass flowmeter be selected

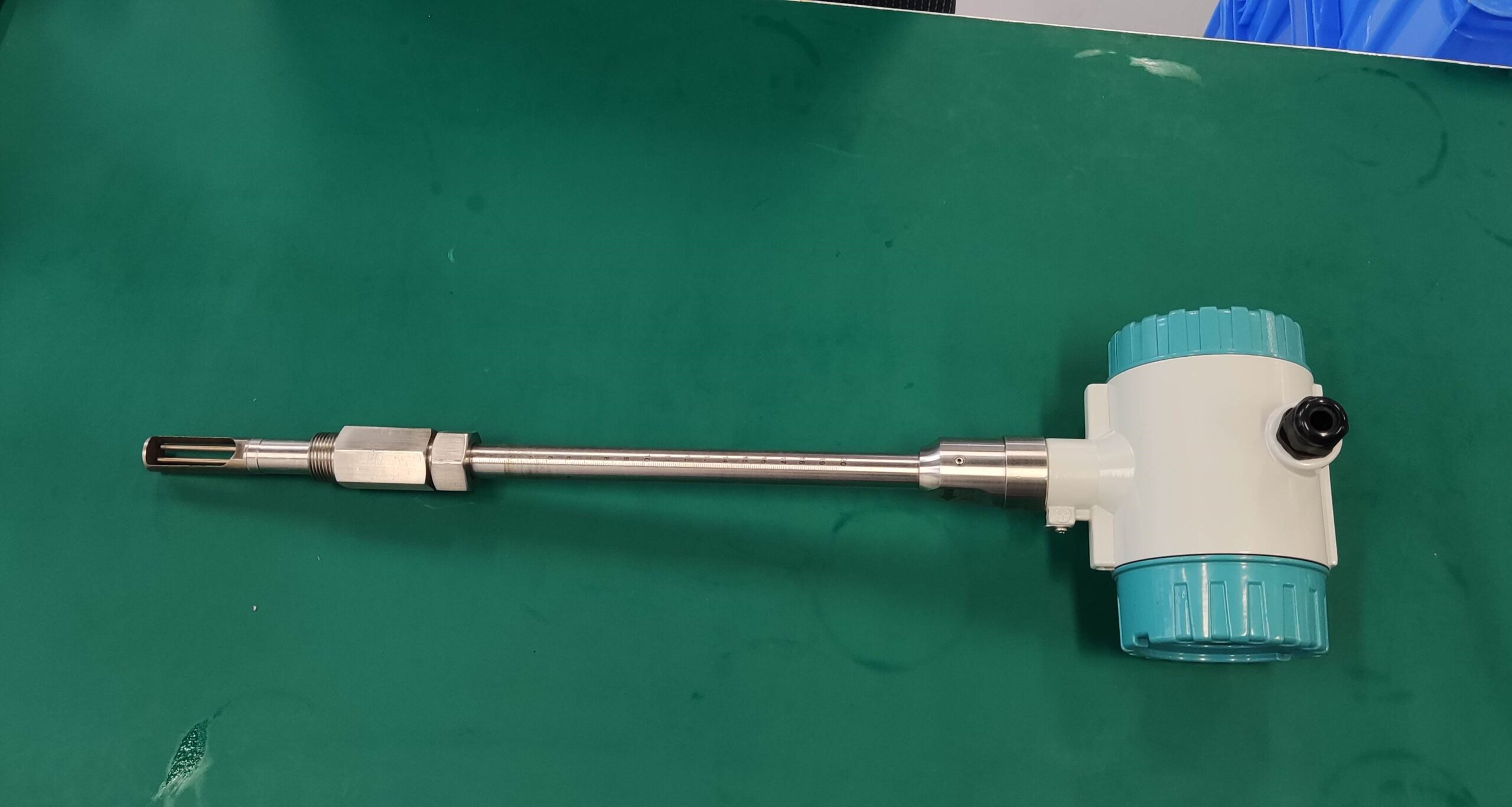

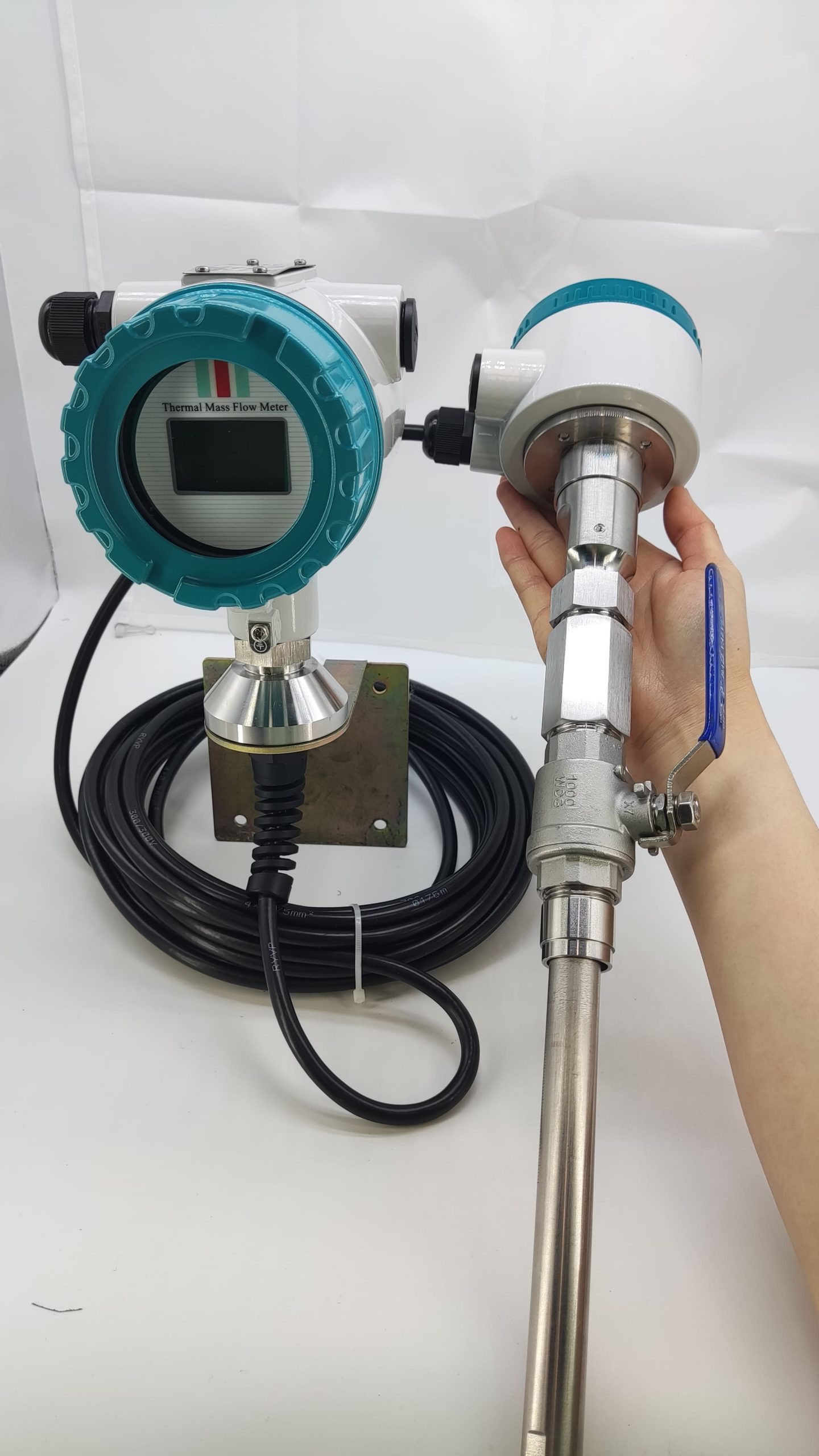

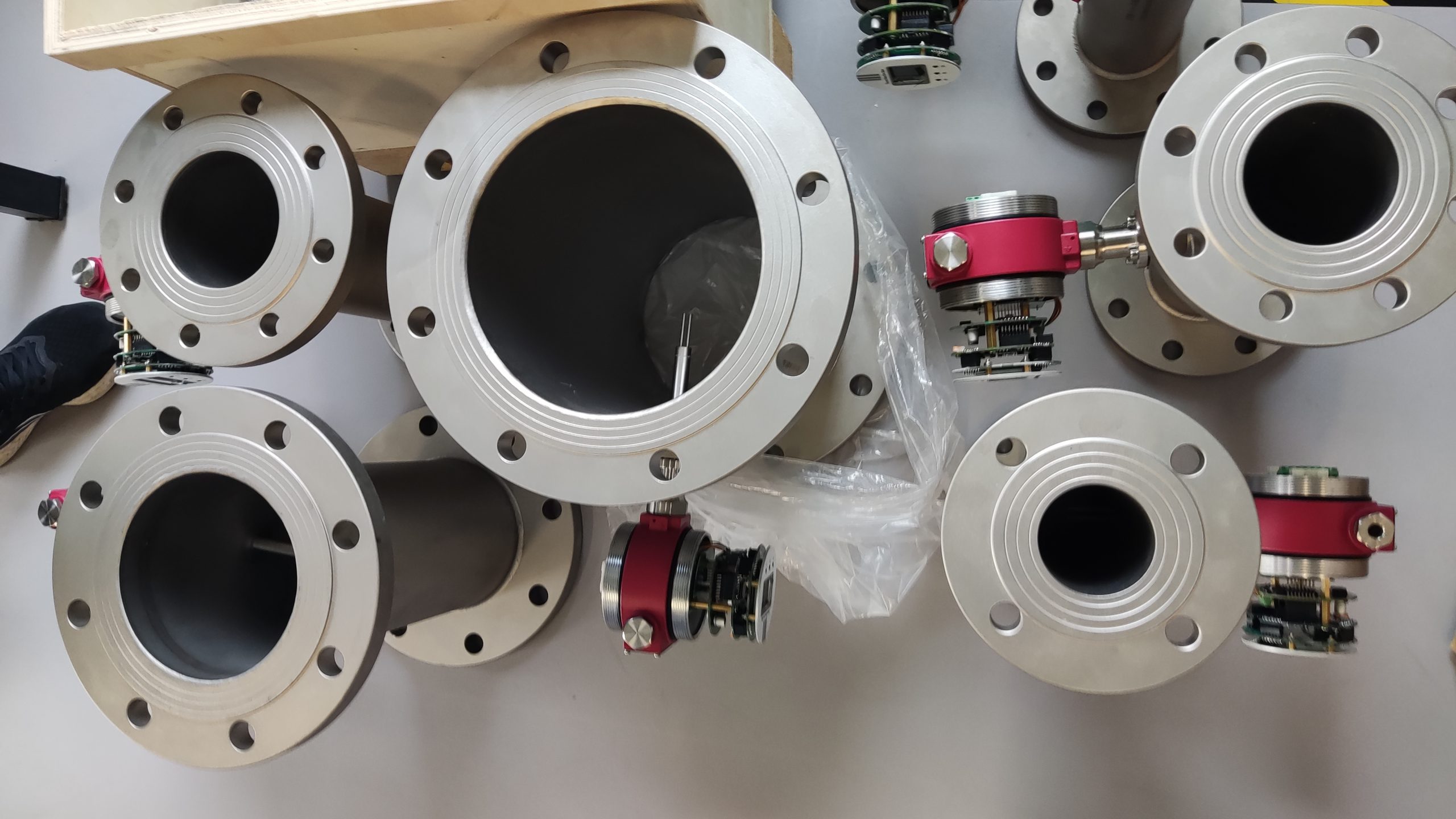

Thermal gas mass flowmeters measure gas flow based on the principle of thermal diffusion and transmit electrical signals to computers and other conversion devices through sensors. To ensure the accuracy of thermal gas mass flowmeter measurement, in addition to the quality of the product being up to standard, the installation direction must also be correct; otherwise, it will also affect the measurement accuracy of the thermal gas mass flowmeter. Today, the editor of Aister Instrument, a flowmeter manufacturer, will talk to you about how to choose the installation direction.

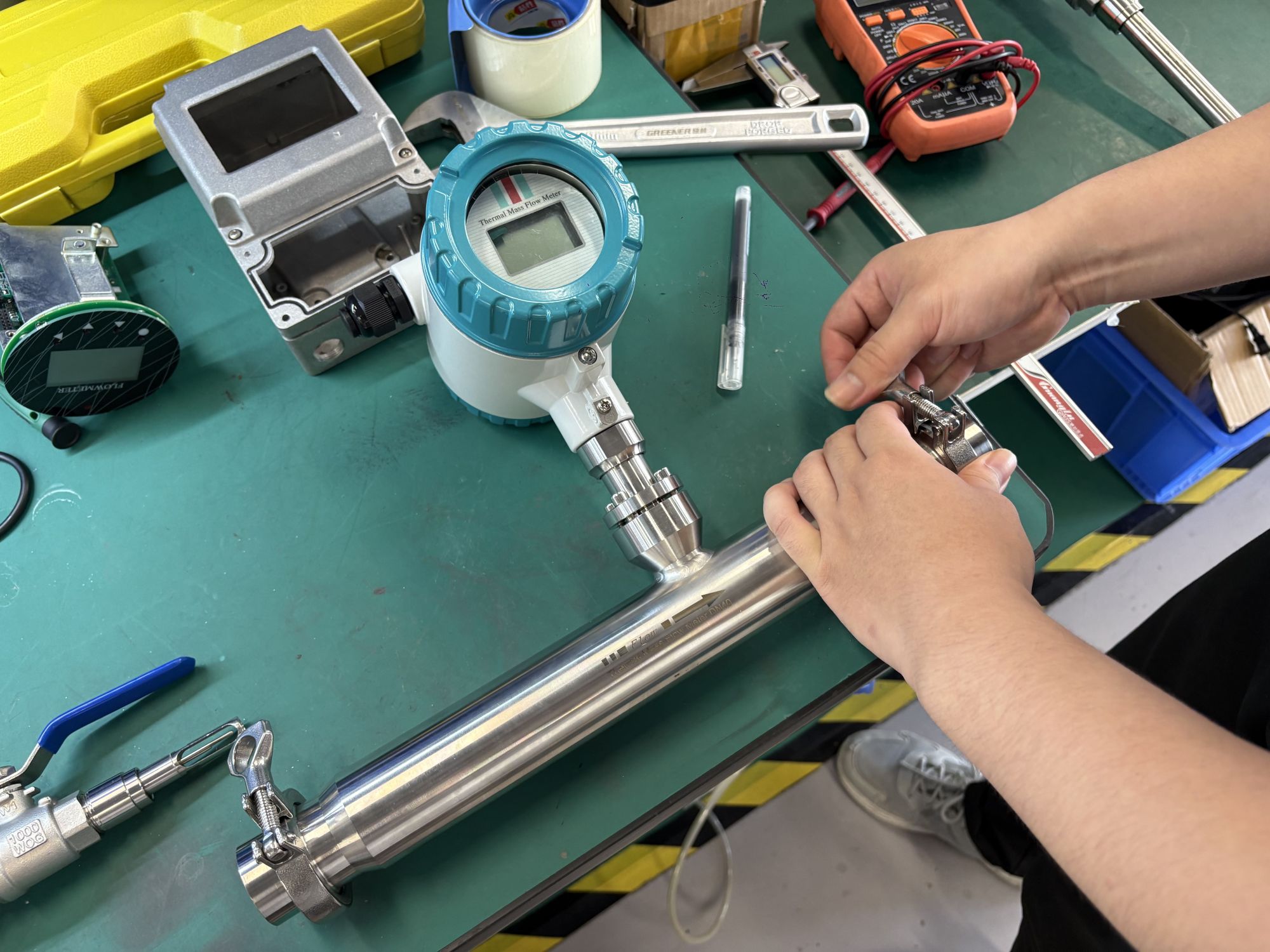

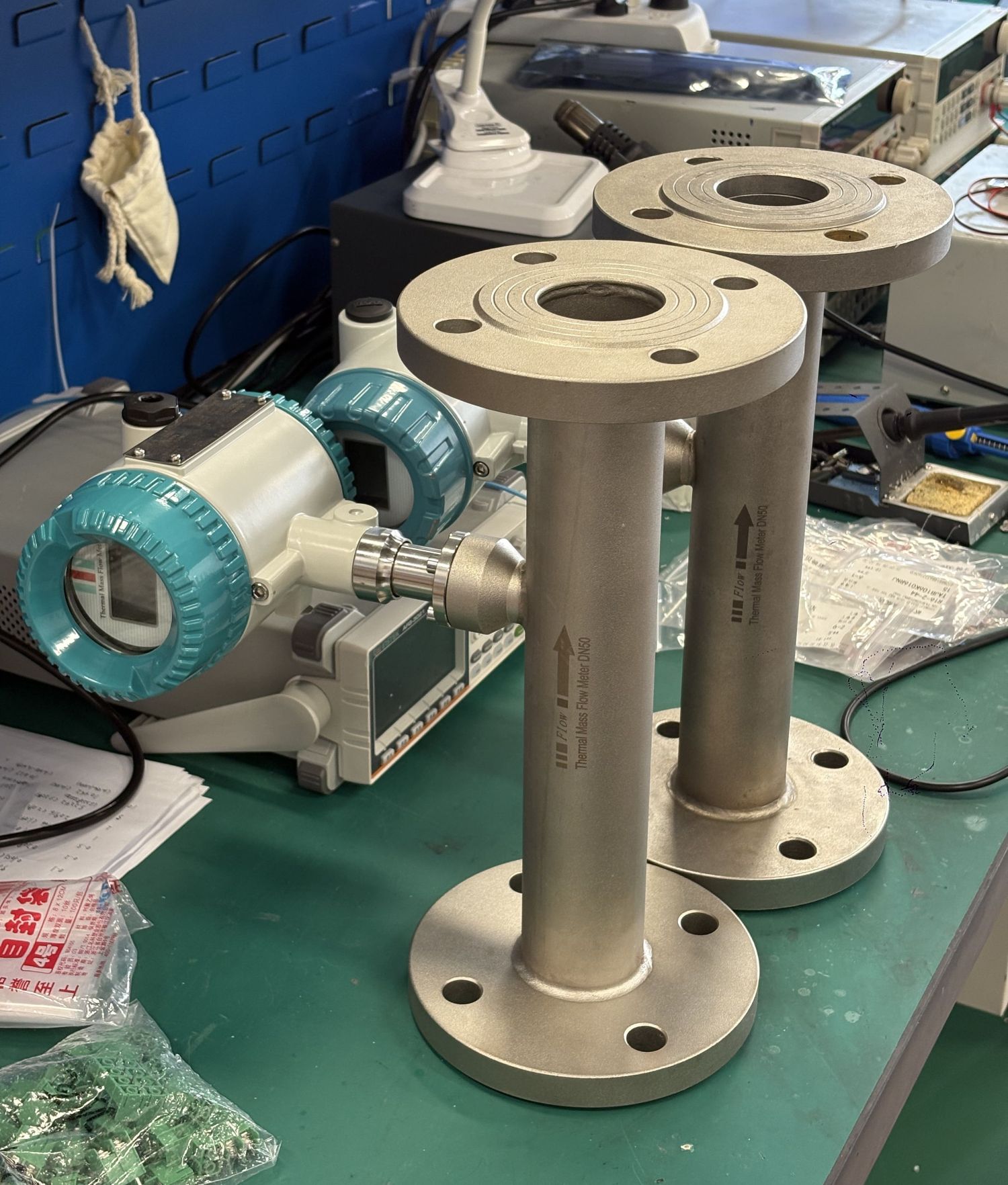

The installation direction must definitely be consistent with the flow direction of the measured gas. Therefore, whether purchasing a finished product or customizing a thermal gas mass flowmeter, it is necessary to first understand in which direction the gas is flowing in the equipment to be measured, as well as the flow speed, generated pressure, etc. All these data should also be statistically recorded and organized.

So, how exactly should the installation direction of a thermal gas mass flowmeter be selected?

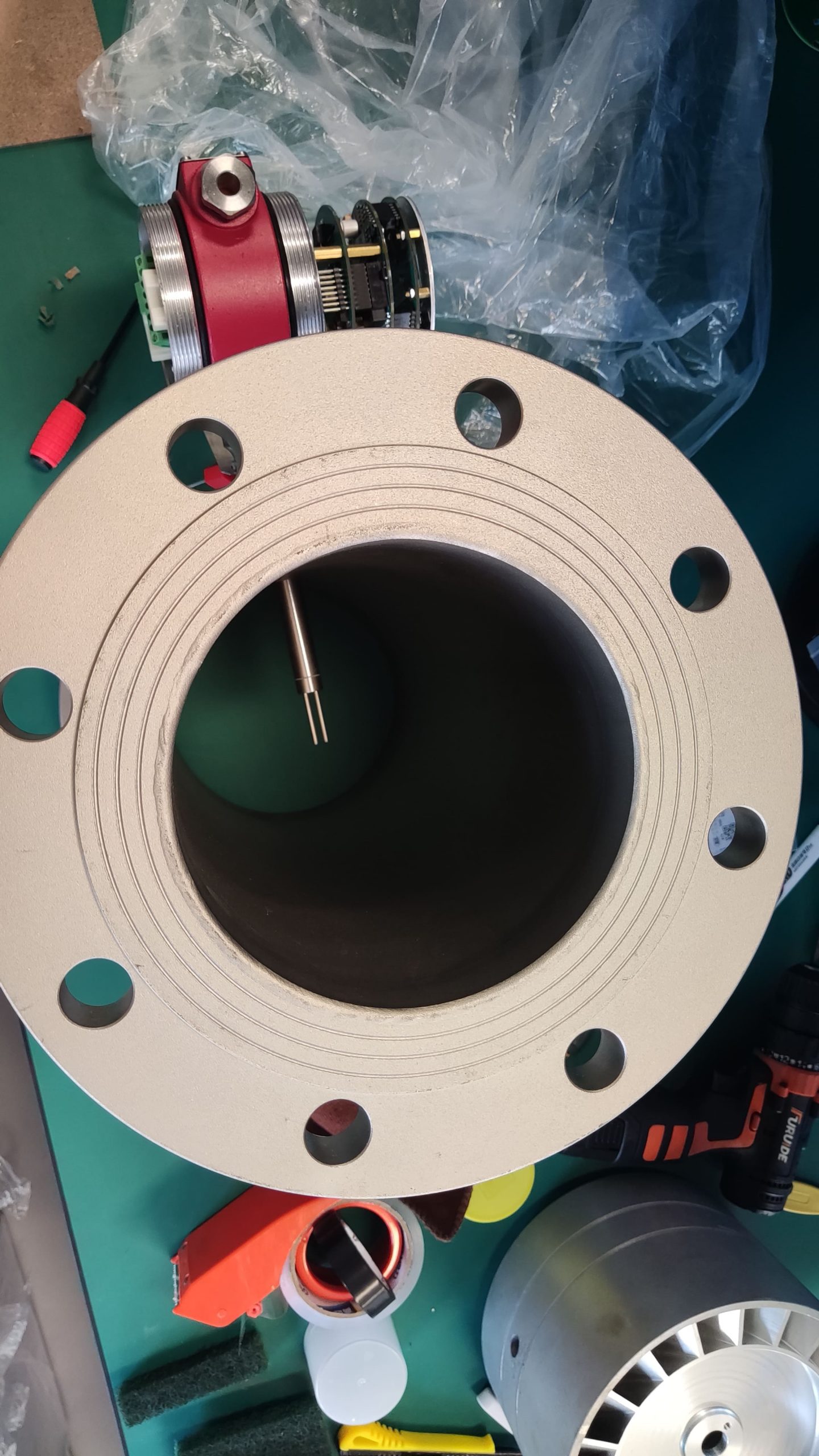

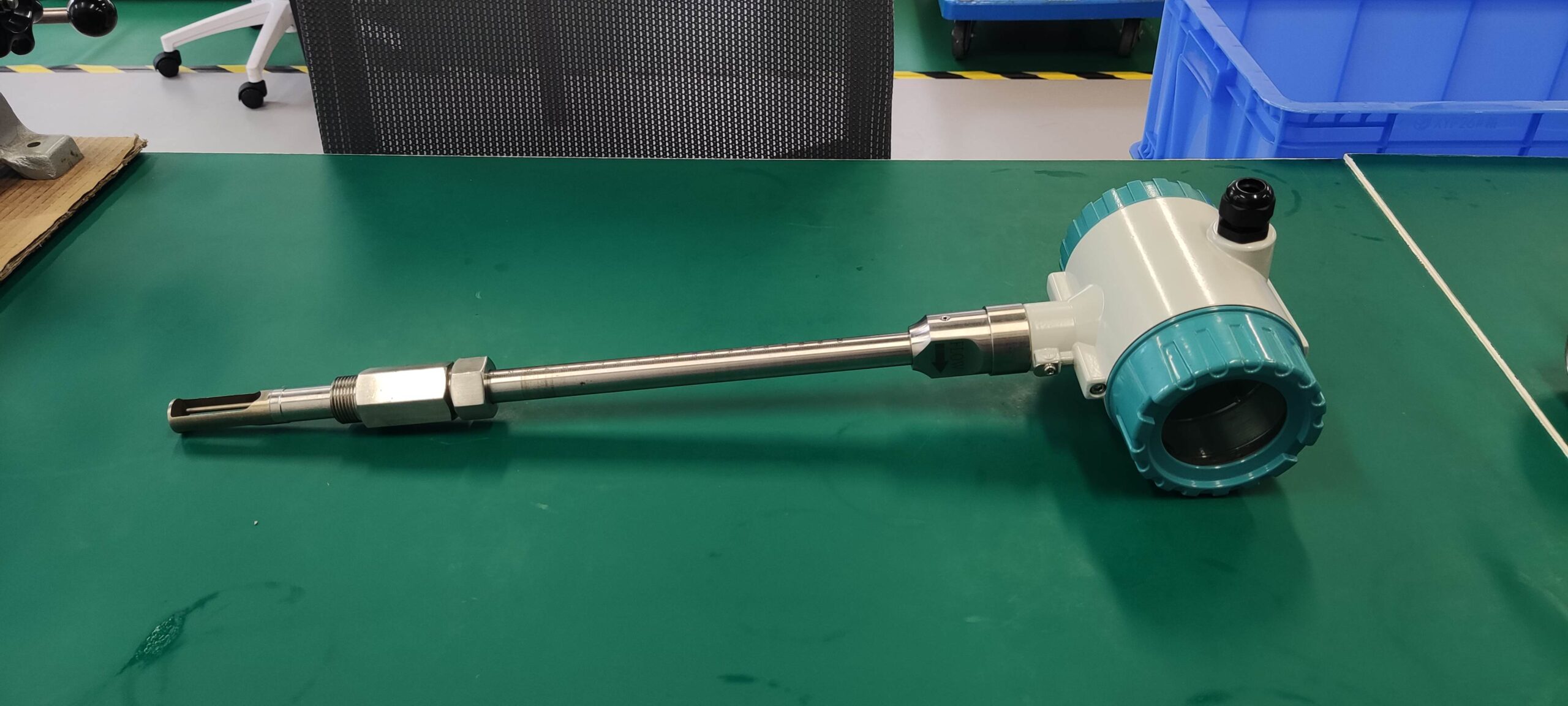

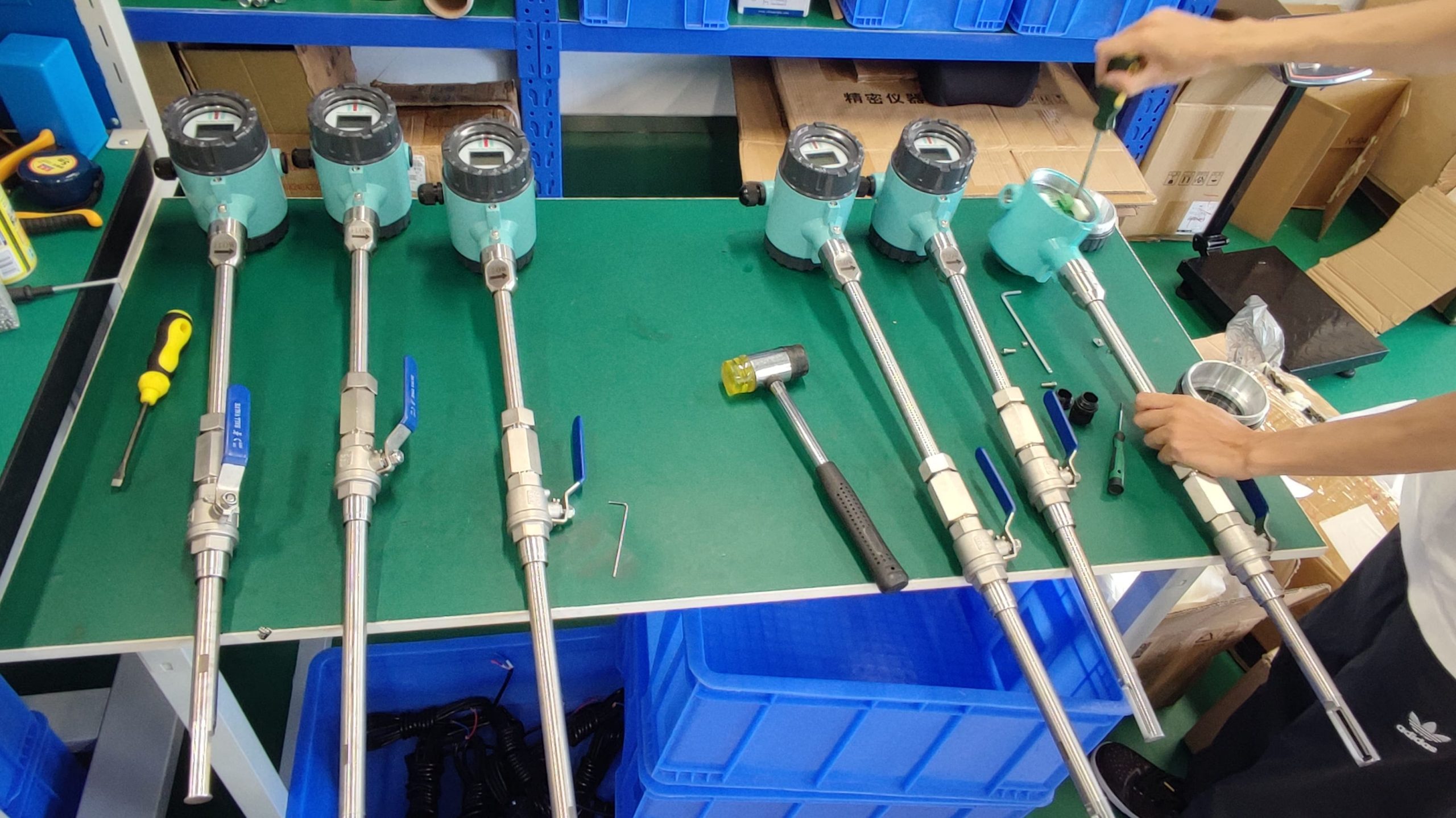

At present, there are two mainstream installation methods that are suitable for the installation of most equipment, namely horizontal installation and vertical installation. Horizontal installation can measure gases or steam. It should be noted that if the medium to be measured contains liquid, the position for horizontal installation should be selected at a higher place.

Vertical installation is relatively more demanding. When the gas composition is pure and there is no liquid, the flow direction is not restricted. Just keep the vertical Angle within a reasonable range. If the gas contains a small amount of liquid, it should be installed from bottom to top. If it is for measuring liquid, it should be installed from bottom to top. This is done to reduce errors.

However, regardless of the direction, vibration and mechanical collision should be avoided during installation. If the vibration is too strong, anti-vibration measures need to be added. After installation, maintenance and care in the later stage are also indispensable.

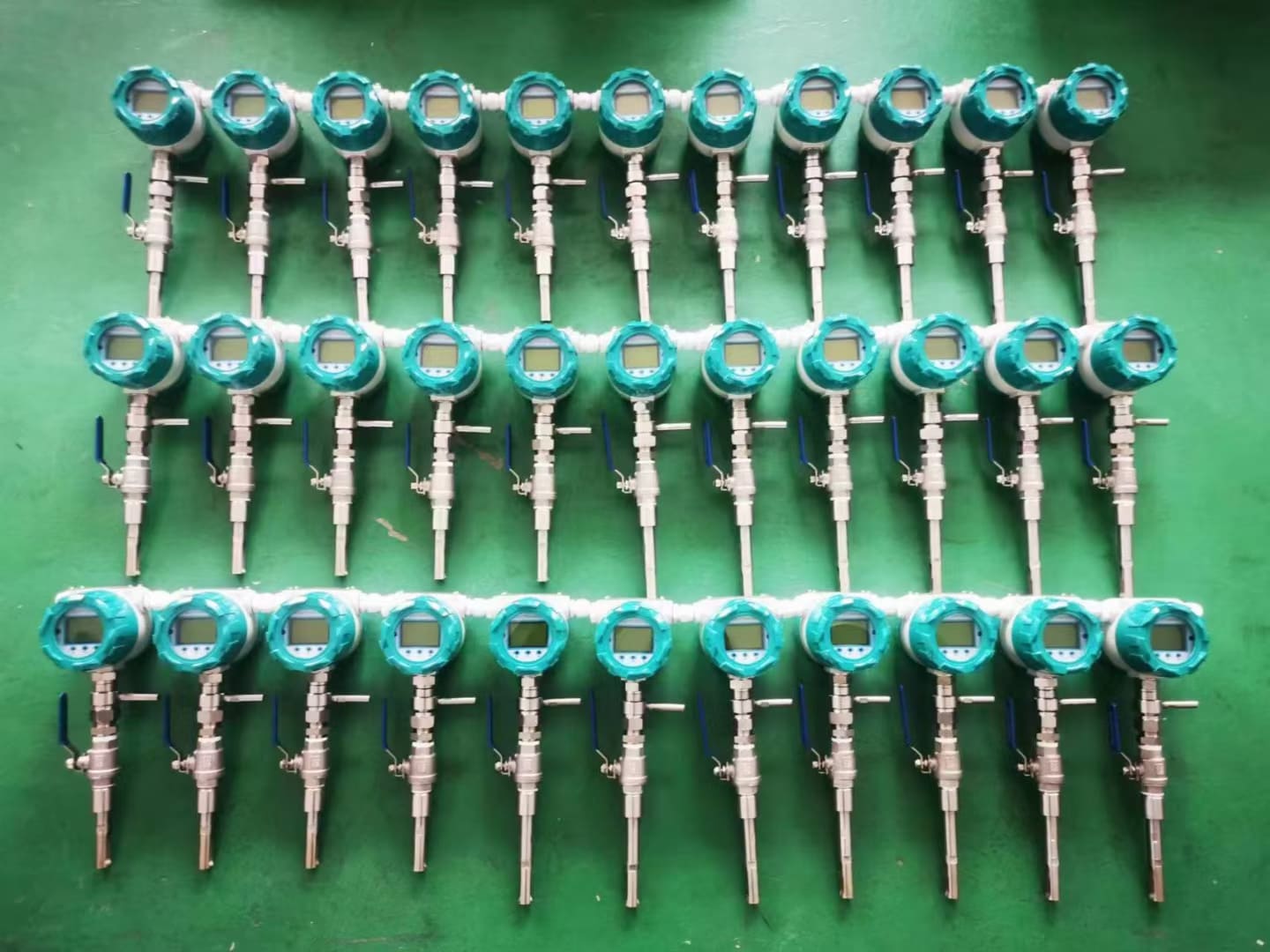

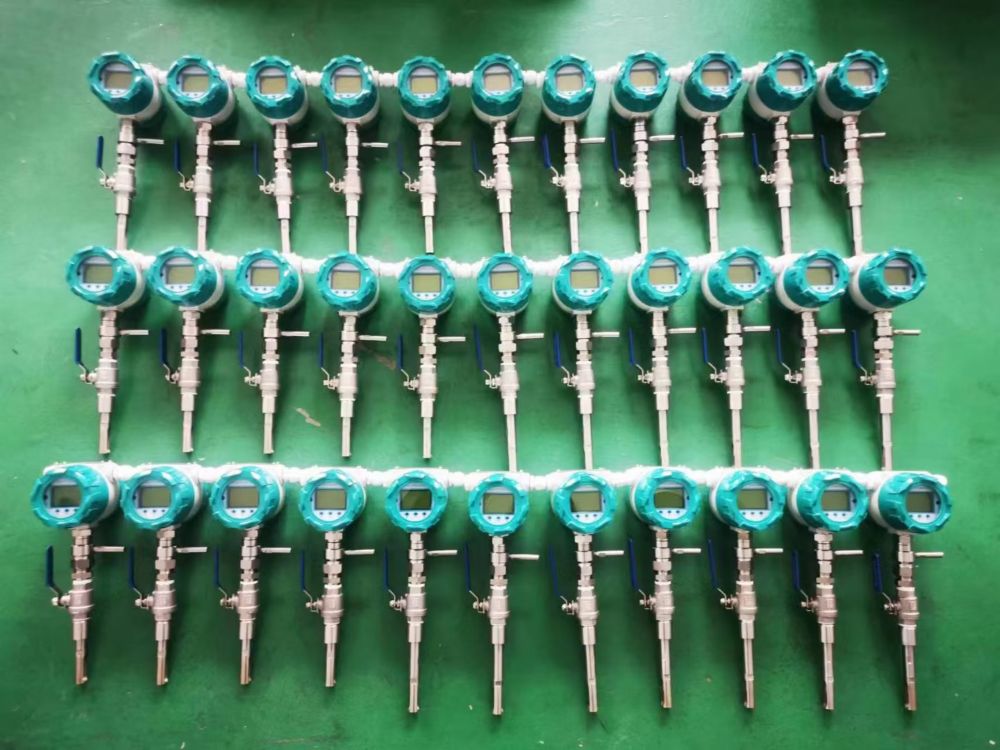

Aister instrument’s heat-generating gas mass flowmeter has been in use for many years. If you encounter any problems during the installation of this flowmeter, you can contact us online or by phone at any time.