Five core advantages of thermal gas mass flowmeters in measuring air

In fields such as industrial process control, HVAC systems, compressed air monitoring, and environmental emission detection, the precise measurement of air flow is of vital importance. Thermal gas mass flowmeters, with their unique working principle and excellent performance, have become the ideal choice for air flow measurement. The following is an analysis of its five core advantages:

Directly measure the mass flow rate without the need for temperature and pressure compensation

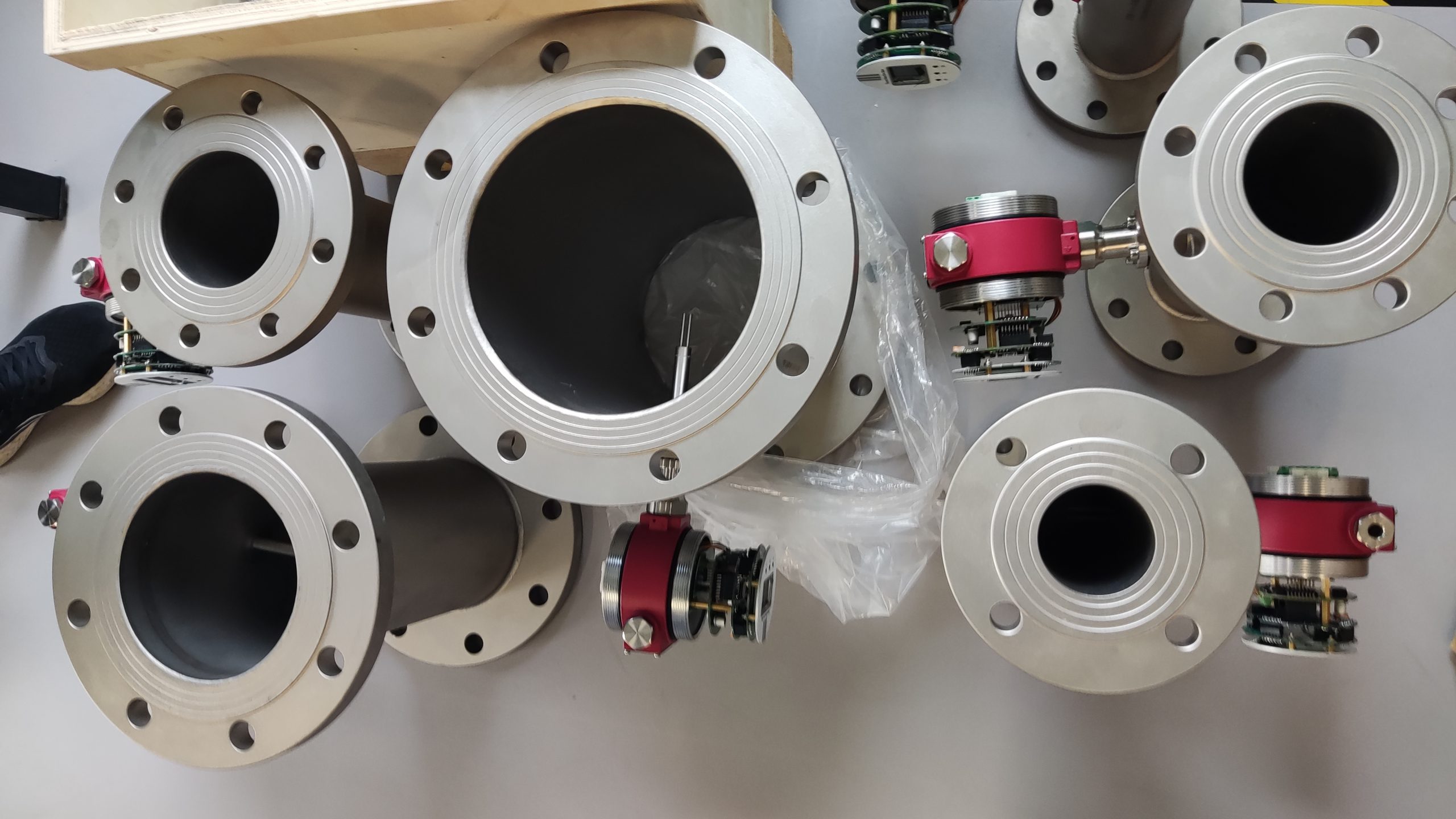

Traditional flowmeters (such as vortex and orifice plate) measure volumetric flow, which requires additional temperature and pressure sensors for compensation calculation. In contrast, thermal gas mass flowmeters directly output mass flow (such as kg/h, Nm³/min), eliminating the need for complex conversions and providing more accurate and reliable data. It is especially suitable for scenarios with strict requirements for gas mass and flow rate, such as compressed air and combustion control.

2. Wide range ratio, suitable for high and low flow rates

The range ratio of thermal flowmeters can typically reach 100:1 or even higher. They can not only detect extremely low flow rates (such as 0.1m /s) but also handle high-speed airflows (such as 50m /s), meeting the wide dynamic range requirements of air compressor energy-saving monitoring and ventilation system regulation. In contrast, the accuracy of turbine or orifice plate flowmeters drops significantly at low flow rates.

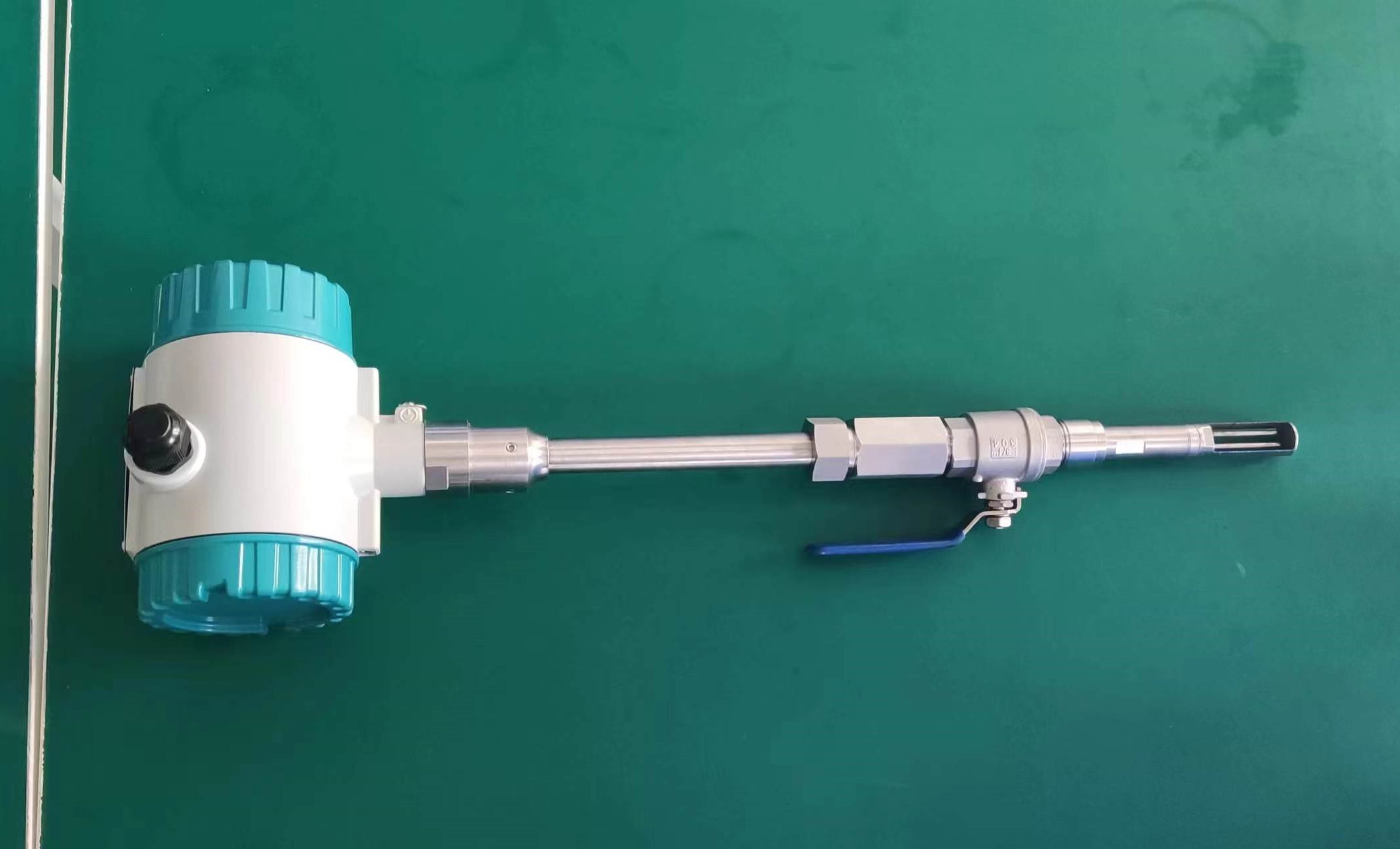

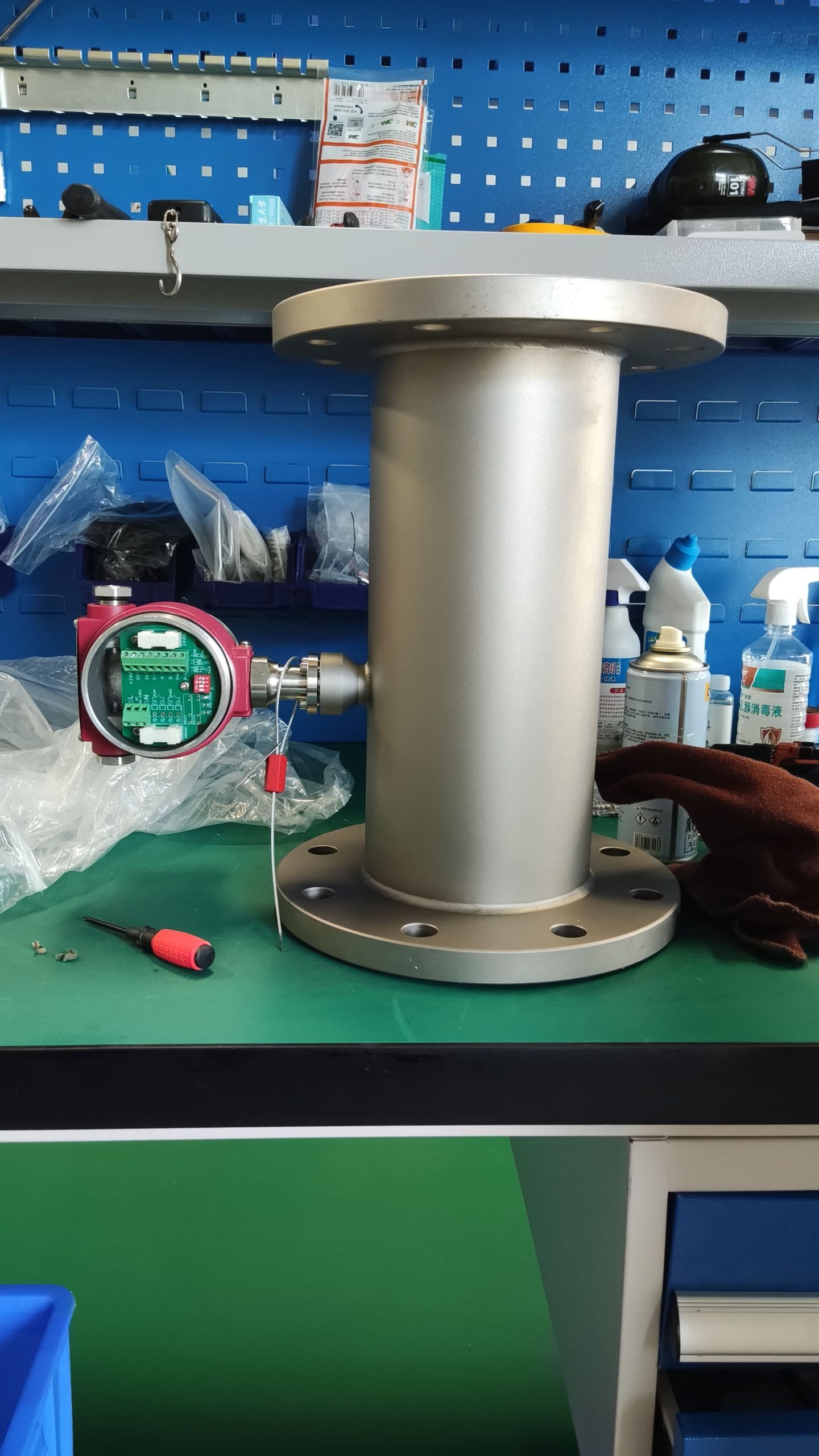

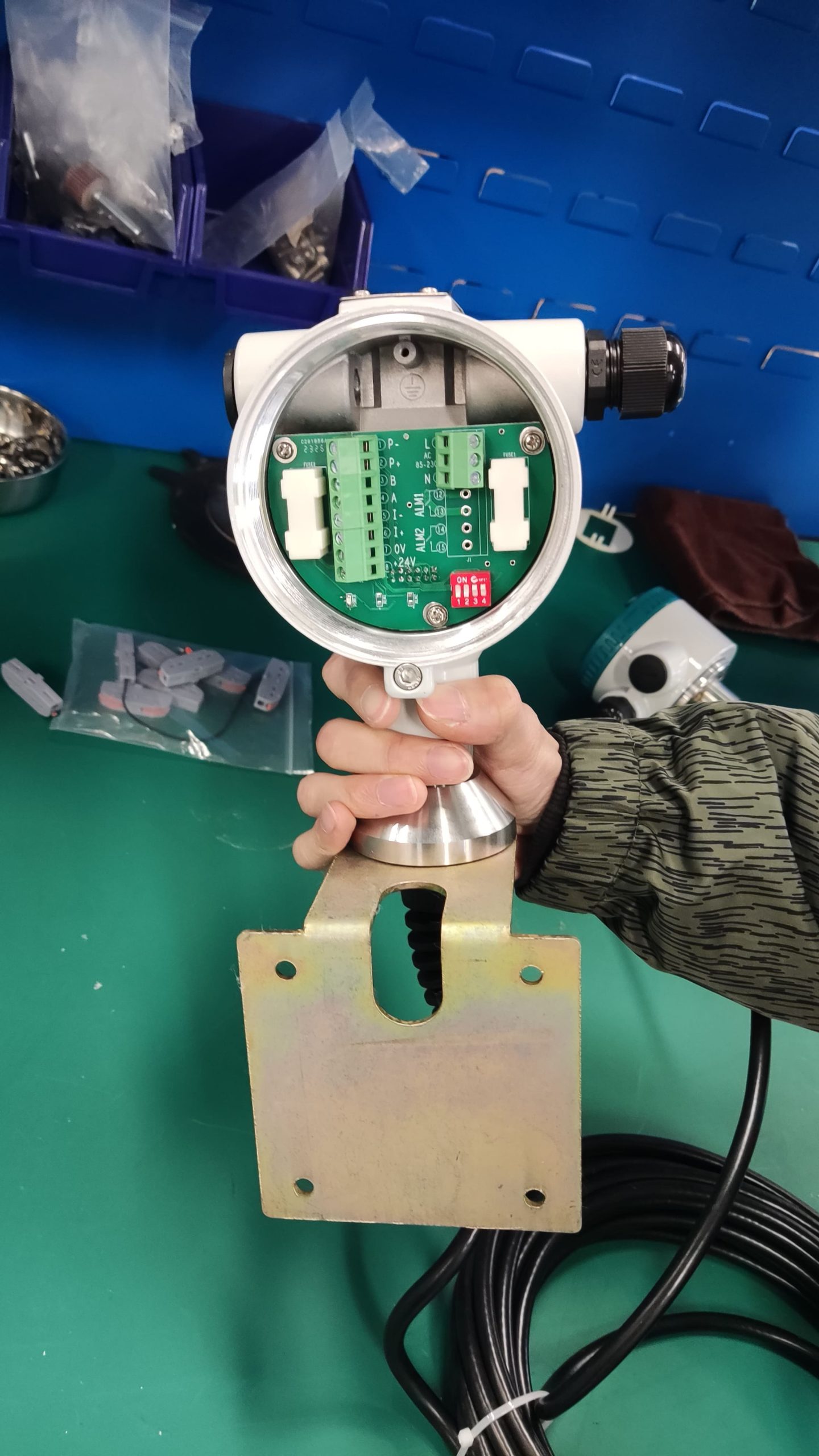

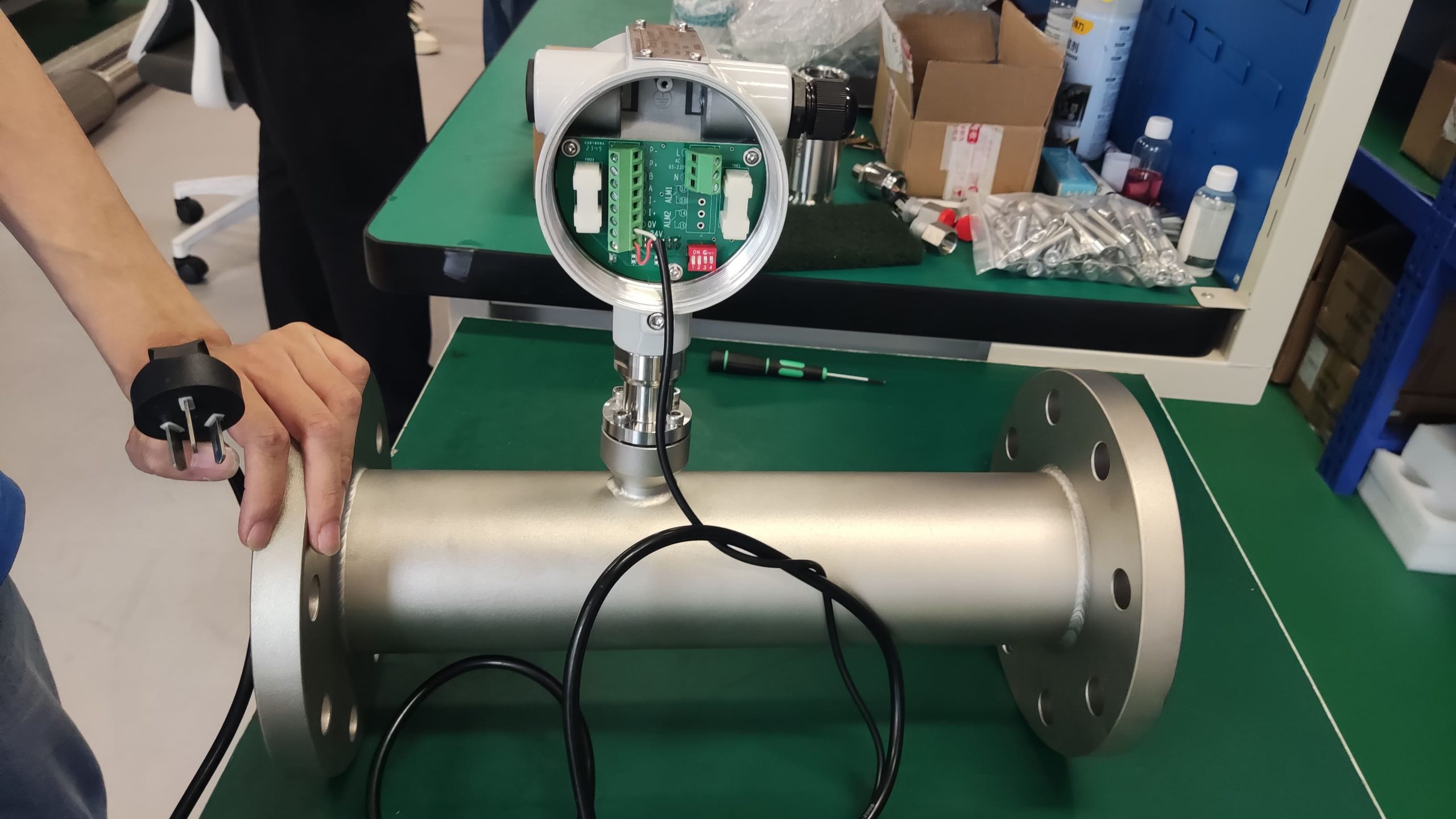

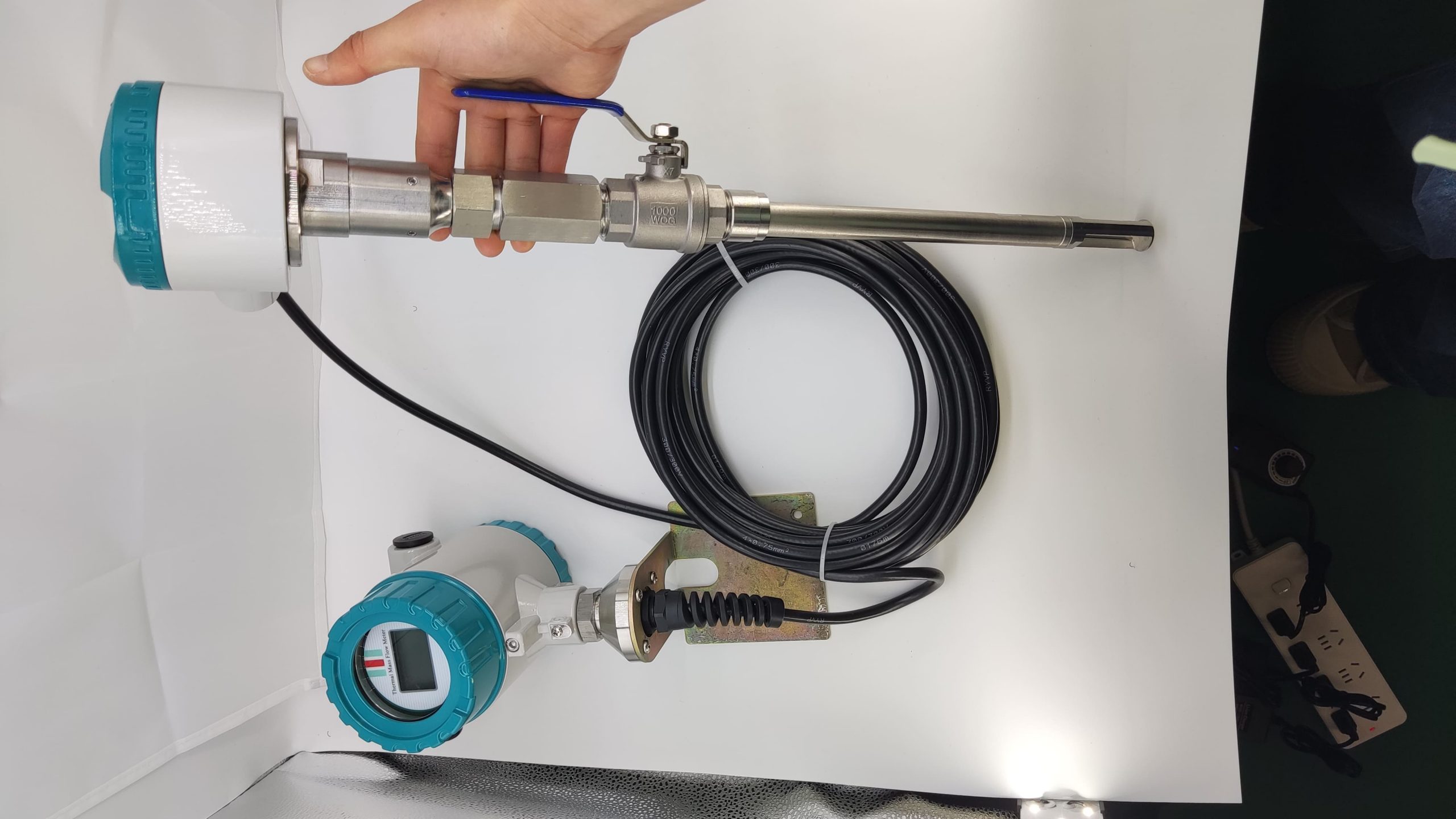

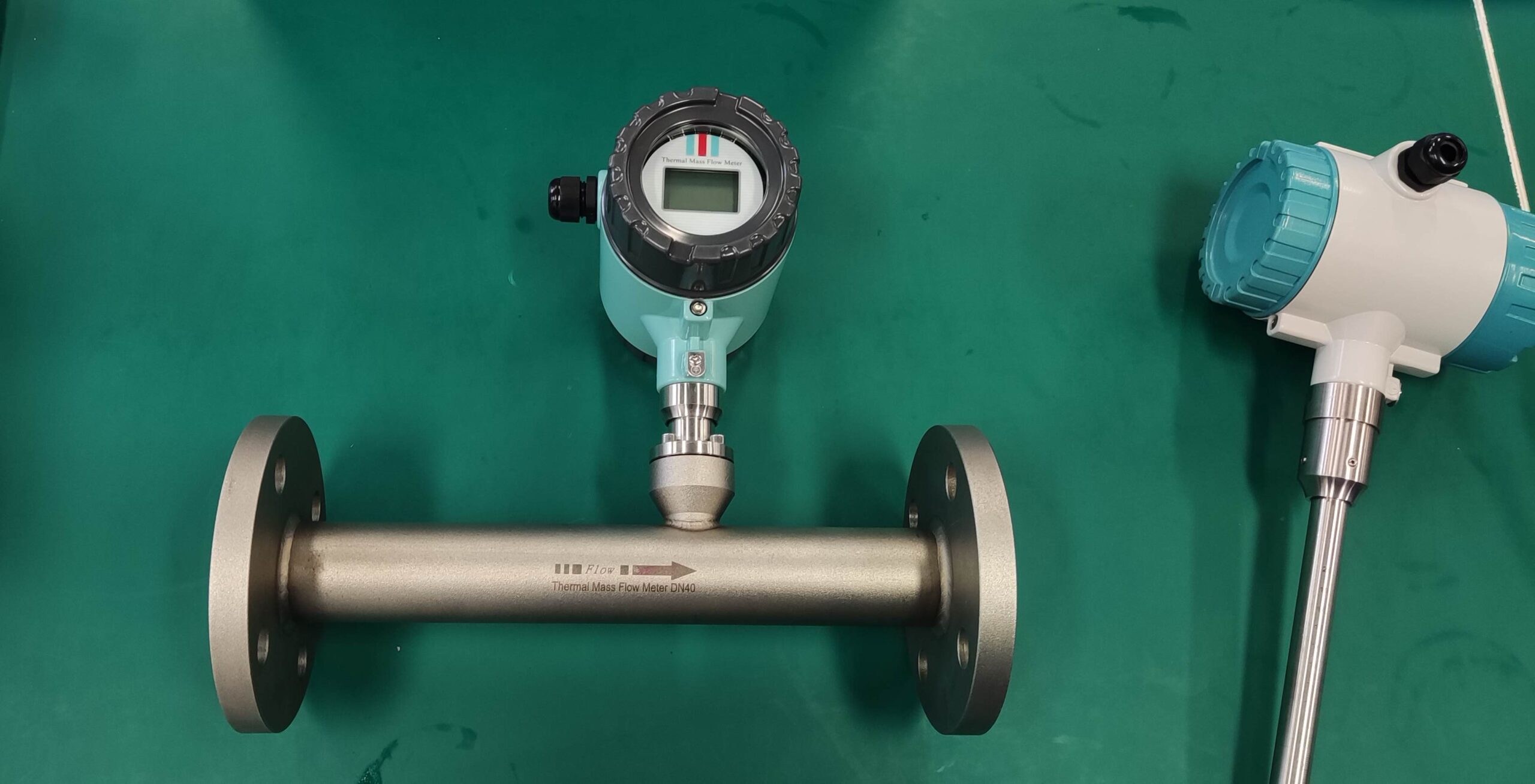

3. No moving parts, maintenance-free and long service life

Thermal flowmeters operate on the principle of thermal diffusion. The sensor has no mechanical moving parts and will not wear or get stuck due to dust, humidity or vibration. It is particularly suitable for measuring compressed air containing trace amounts of oil mist and water vapor. It has high long-term stability and significantly reduces maintenance costs.

4. Low voltage loss, energy-saving and highly efficient

Compared with orifice plate, vortex and other throttling flowmeters, thermal flowmeters have almost no pressure loss, which can reduce the energy consumption of air compressors or fans. They are especially suitable for energy-saving audits of compressed air systems and help enterprises reduce operating costs.

5. High precision and rapid response

The accuracy can reach ±1% FS, and for some high-end models, it can reach ±0.5%, meeting the requirements of trade settlement or process control.

The response time is less than 1 second, and it can monitor airflow fluctuations in real time. It is suitable for dynamic applications such as leakage detection and combustion control.

Typical application scenarios

✅ Compressed air system: Monitor gas consumption and optimize energy-saving management

✅ HVAC ventilation: Adjust the ratio of fresh air to exhaust air to enhance energy efficiency

✅ Industrial combustion control: Precisely control combustion-supporting air to enhance combustion efficiency

✅ environmental emission monitoring: Measure the flow of flue gas and exhaust gas to ensure compliance

Selection suggestions

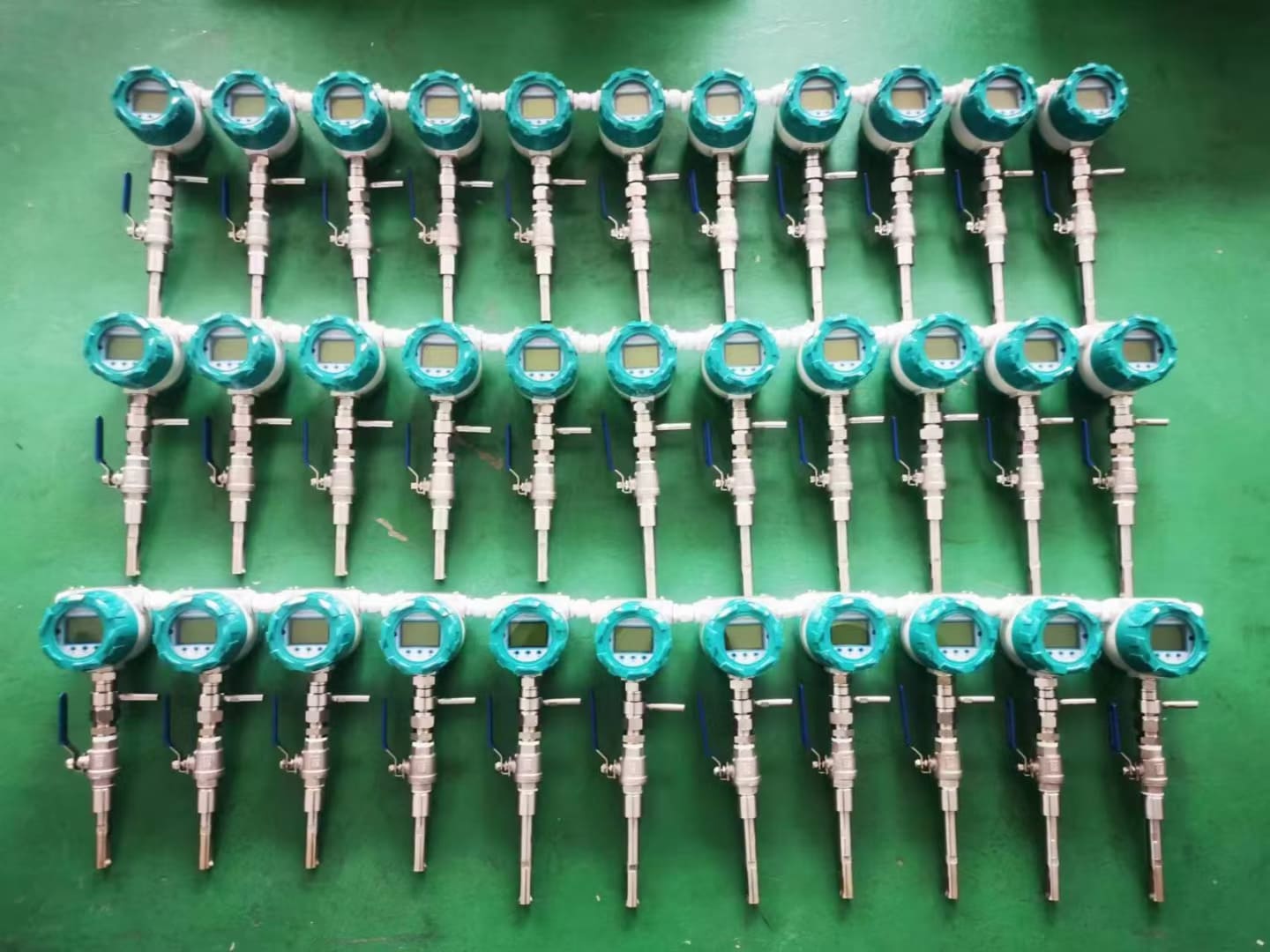

General air/compressed air: Standard thermal flowmeter

High-temperature gas (≤200°C) : Select high-temperature type sensors

Damp or oily environments: Anti-corrosion coating or online self-cleaning function