What are the installation steps for the insertable thermal gas mass flowmeter

Three parts instrumentation, seven parts installation. The correct selection of the installation point and the proper installation of the thermal gas mass flowmeter are both very important steps. If there is a mistake in the installation process, it may not only affect the measurement accuracy but also shorten the service life of the flowmeter or even damage it.

Whether the flowmeter is installed vertically or horizontally, it should always be kept in a horizontal position.

2. In situations where unexpected gas outages are not allowed or where unexpected gas outages may cause significant irreparable losses, a bypass must be set up.

3. There should be at least a 10D straight pipe section in front of the flowmeter and at least a 5D (D is the pipe diameter) straight pipe section behind it.

4. If the instrument is installed outdoors, a sunshade should be added to prevent it from being exposed to direct sunlight and rain.

5. It should be confirmed that there are no strong magnetic fields, strong electric fields or intense mechanical vibrations near the flowmeter.

6. The static grounding of the flowmeter should be reliable, but it must not be shared with the strong current grounding.

7. Keep the direction of gas flow consistent with the arrow direction on the flowmeter.

8. Welding operations are strictly prohibited in explosive environments.

9. For environments with special requirements for welding, operations should be carried out in accordance with relevant requirements.

It is strictly prohibited to install the flowmeter at the low point in the pipeline, otherwise water and other impurities are likely to accumulate.

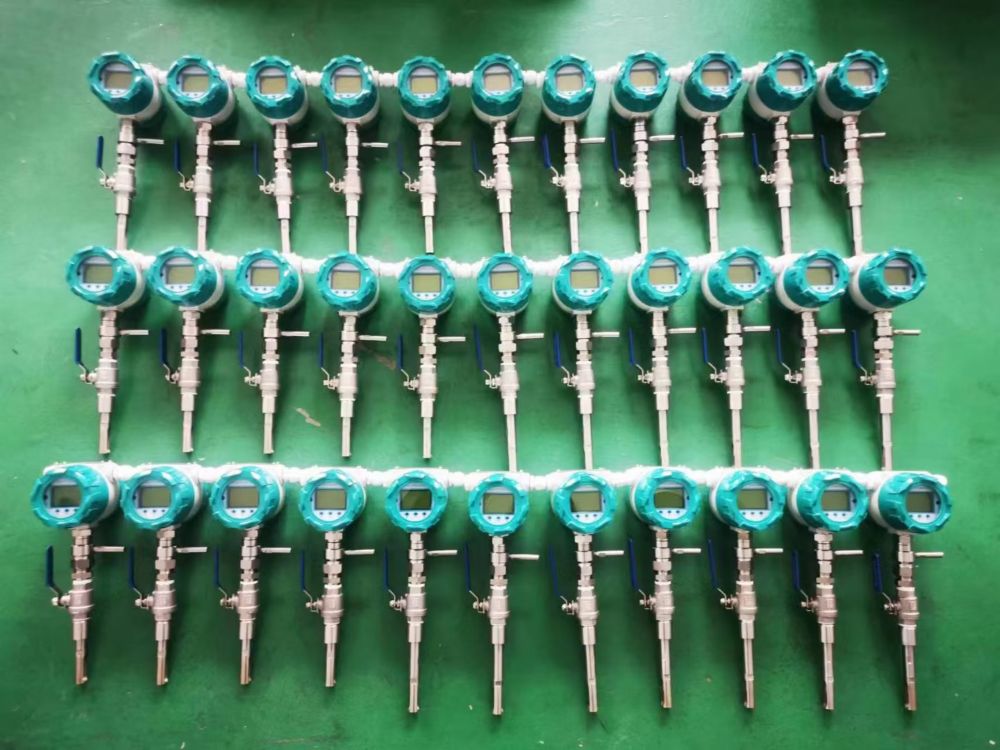

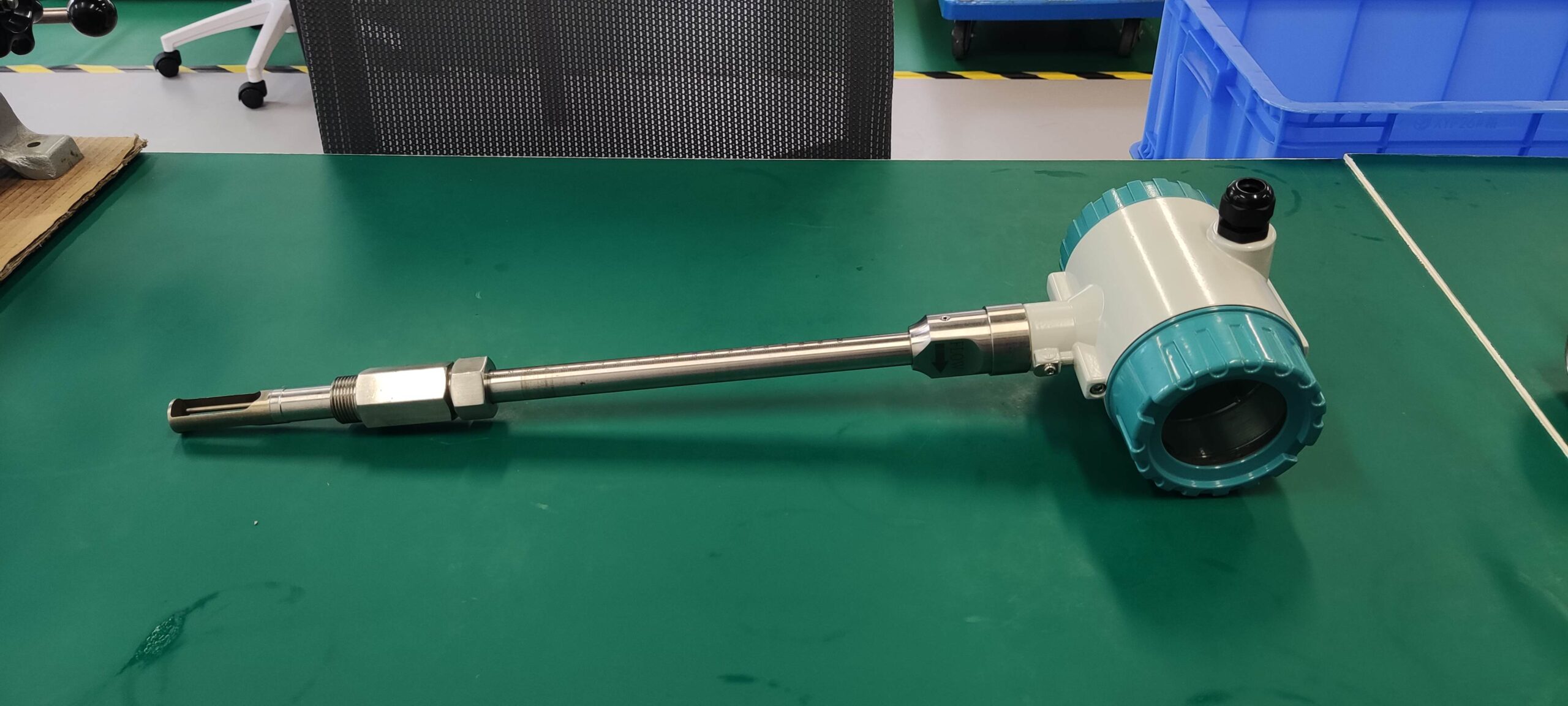

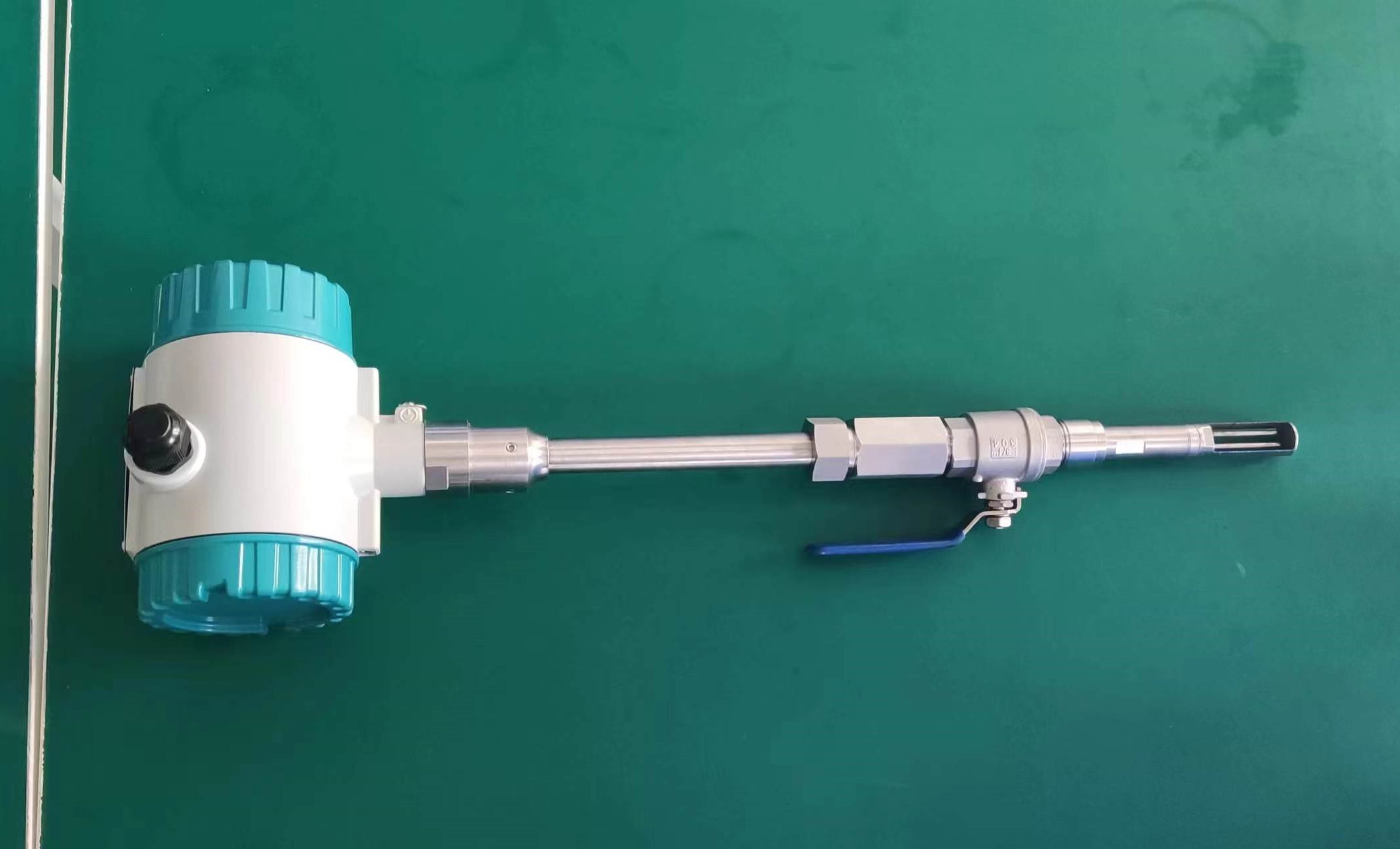

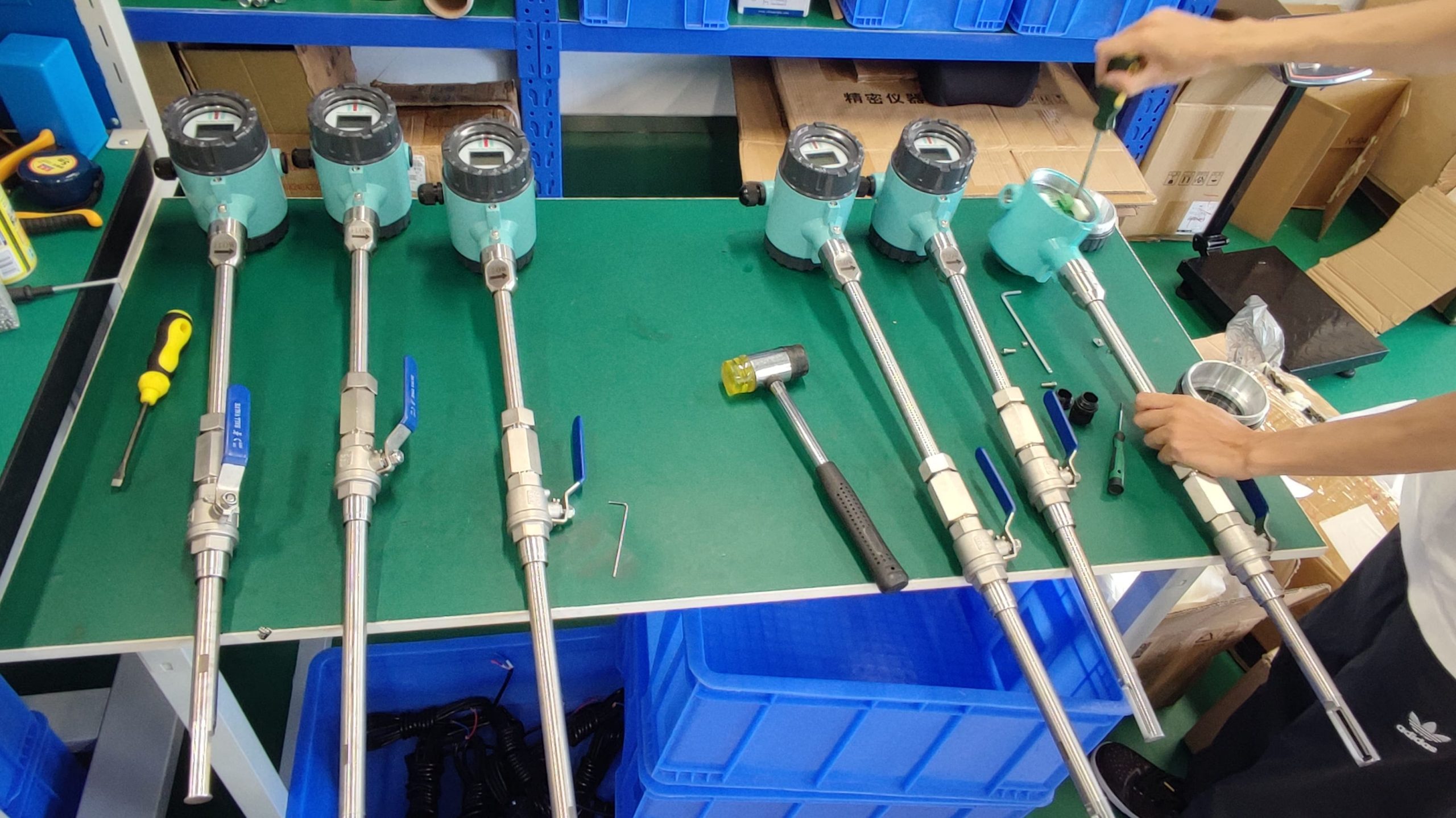

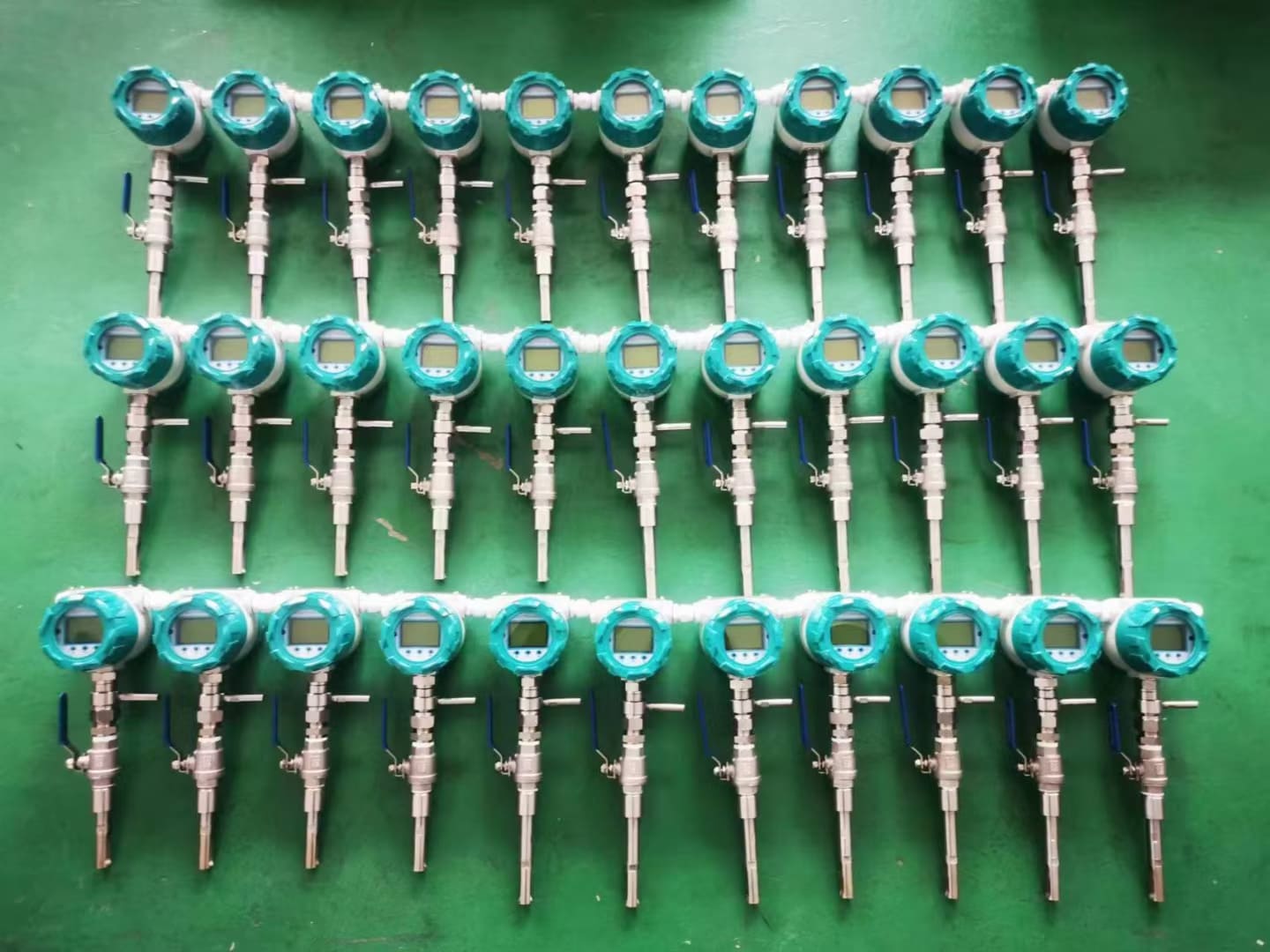

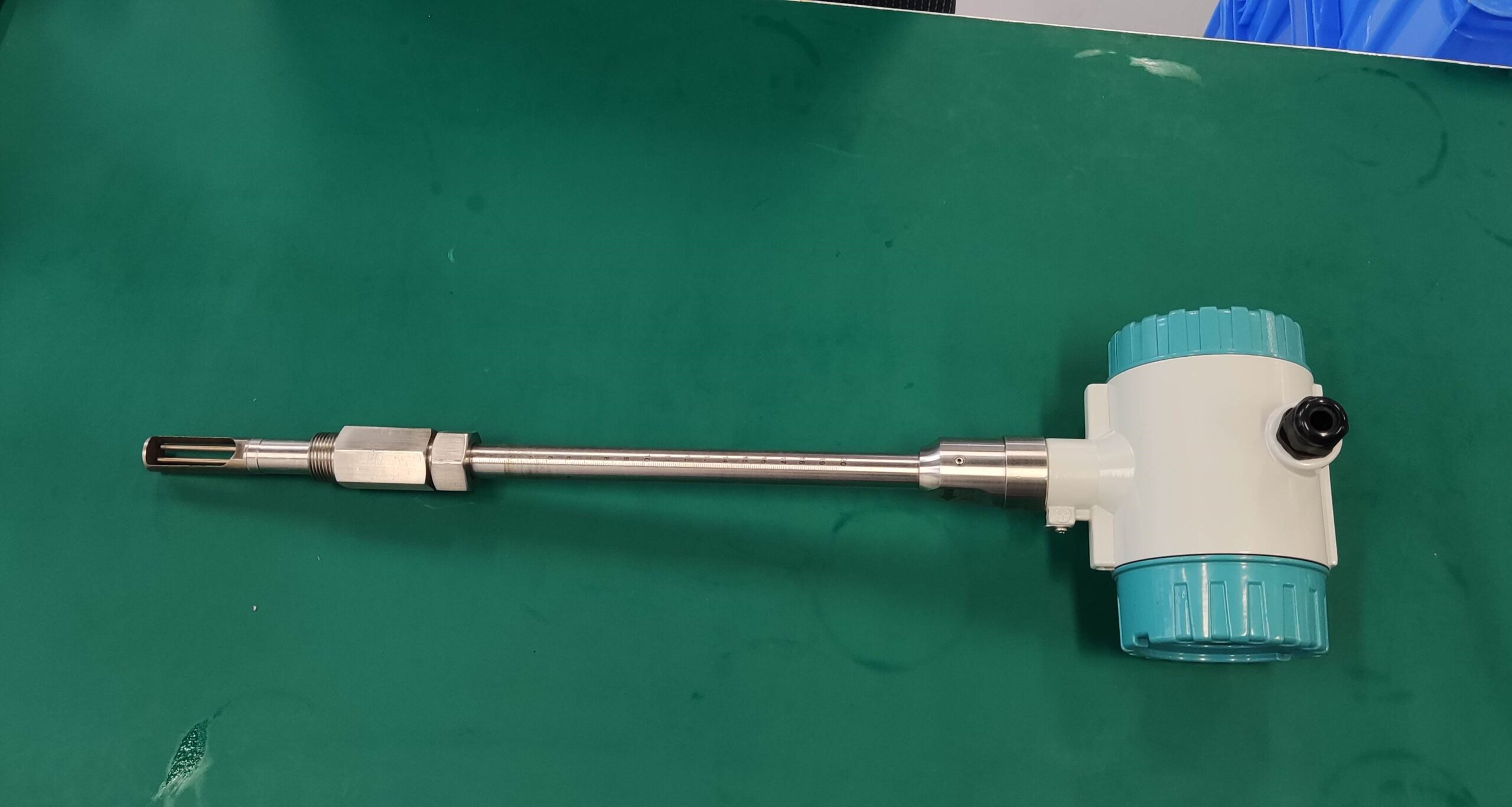

The thermal gas mass flowmeter is an instrument that measures the flow rate of fluids by using the principle of heat conduction. This instrument accurately measures the mass flow of gas by using the constant temperature difference method. It has the advantages of small size, high degree of digitalization, easy installation and accurate measurement.

Select the installation point

When choosing a horizontal straight pipe section for installation, the requirements for the straight pipe section at the installation point are as follows: the distance between the throttling element upstream of the installation point and the pipe diameter must be greater than 10 times that of the installation point, and the distance between the throttling element downstream of the installation point and the pipe diameter must be greater than 5 times that of the installation point. If conditions permit, it is recommended to make the straight pipe sections before and after as long as possible.

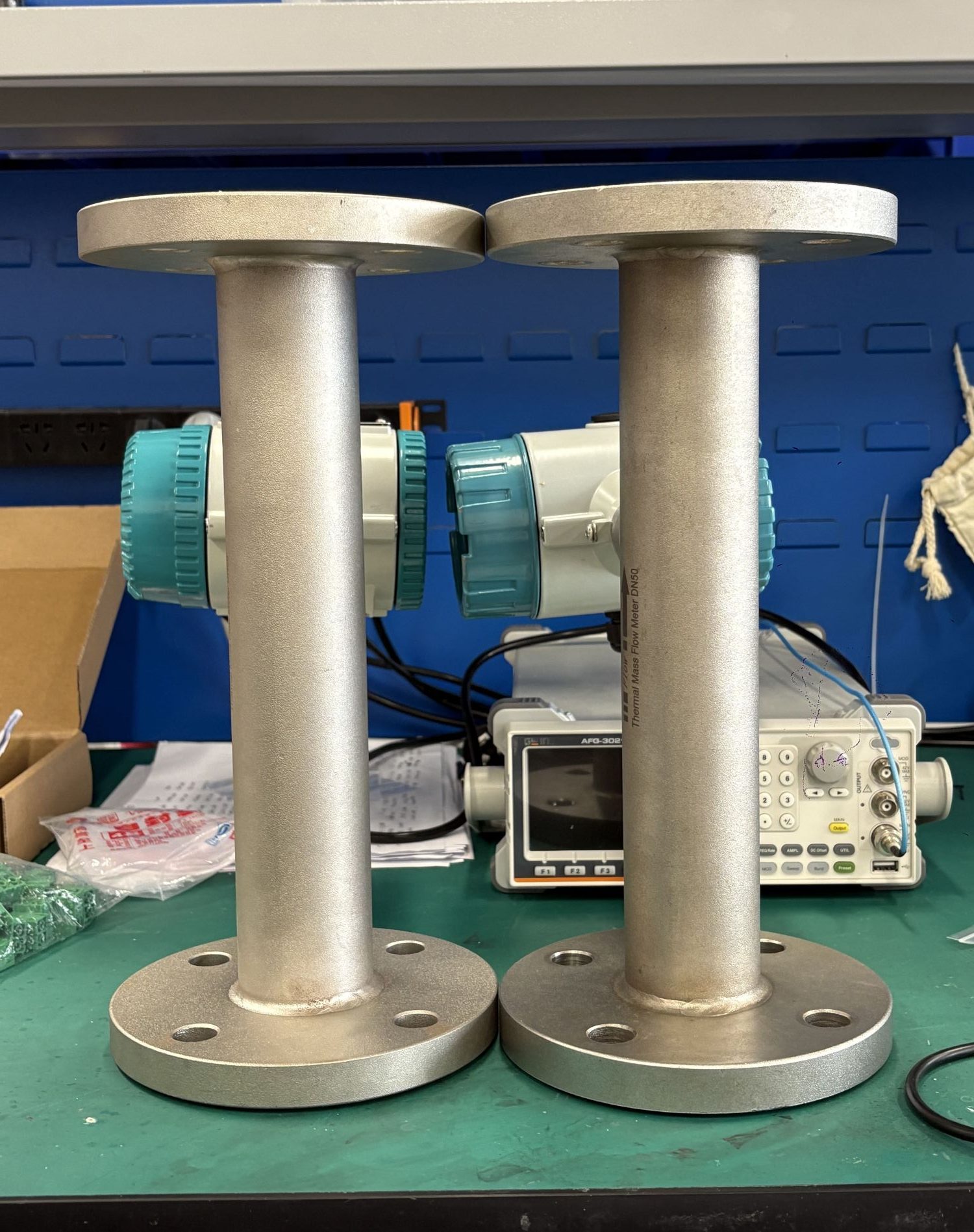

Install the base

Welding operations are prohibited in explosive environments.

In environments with special requirements for welding, operations should be carried out in accordance with relevant requirements.

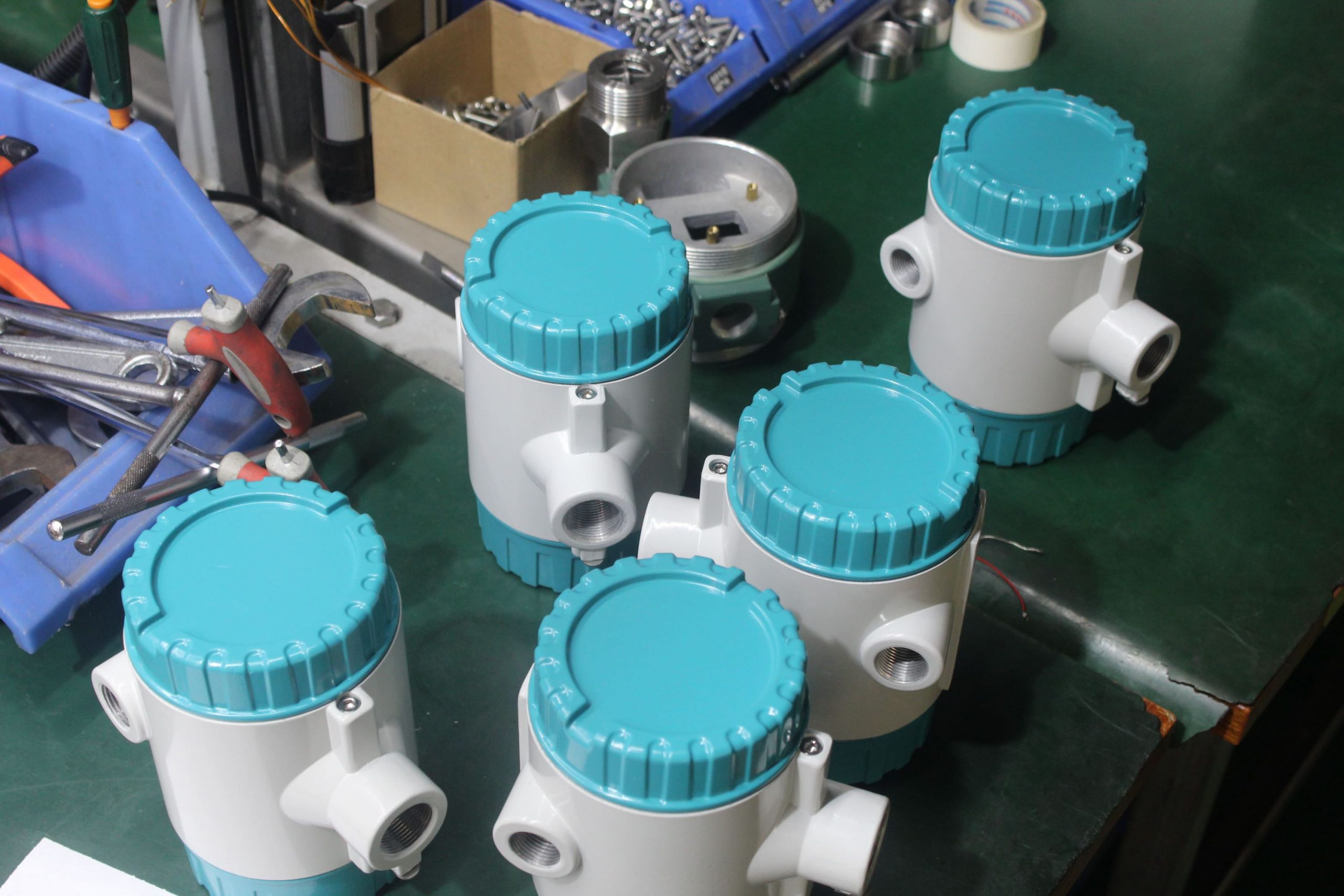

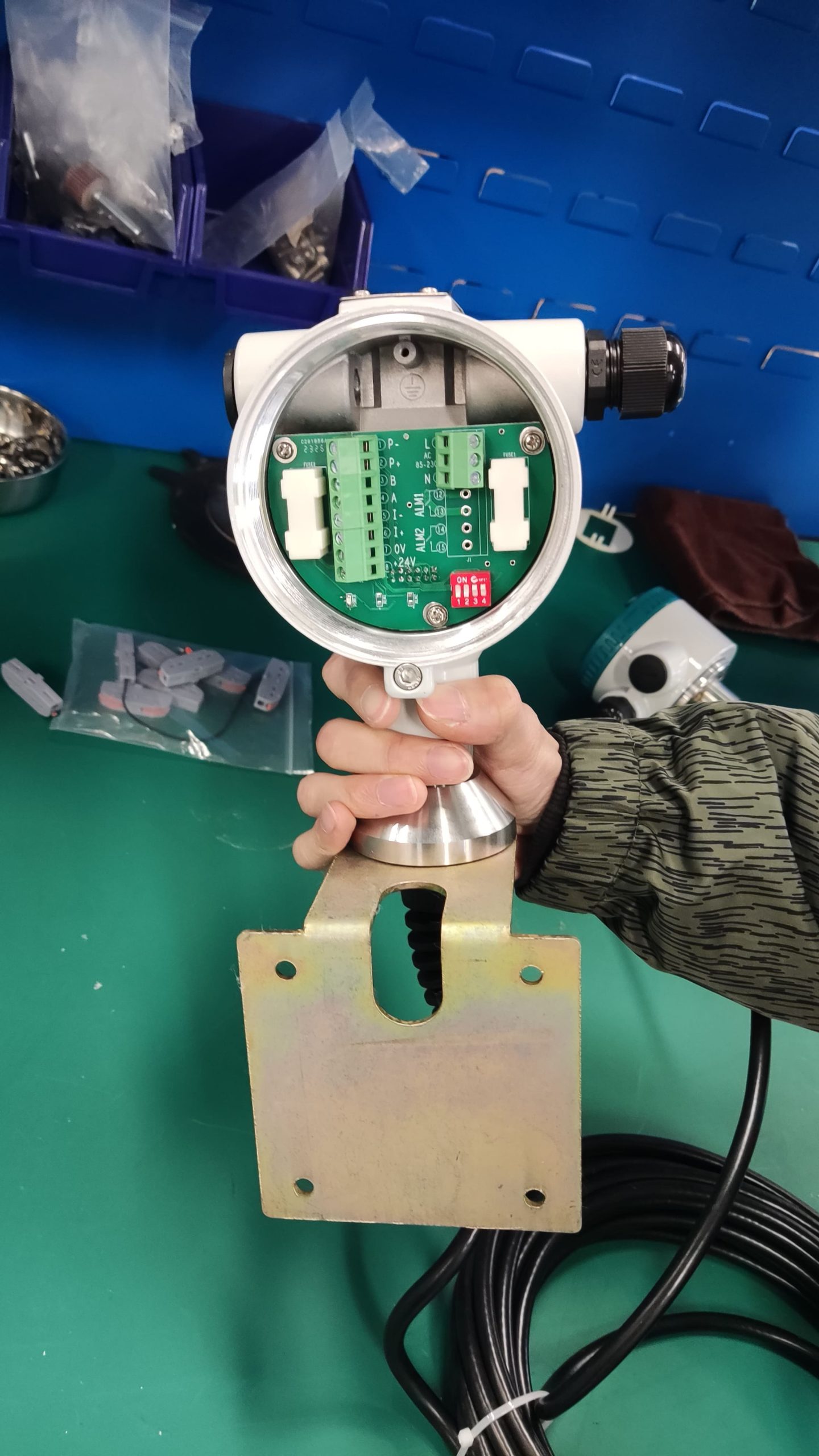

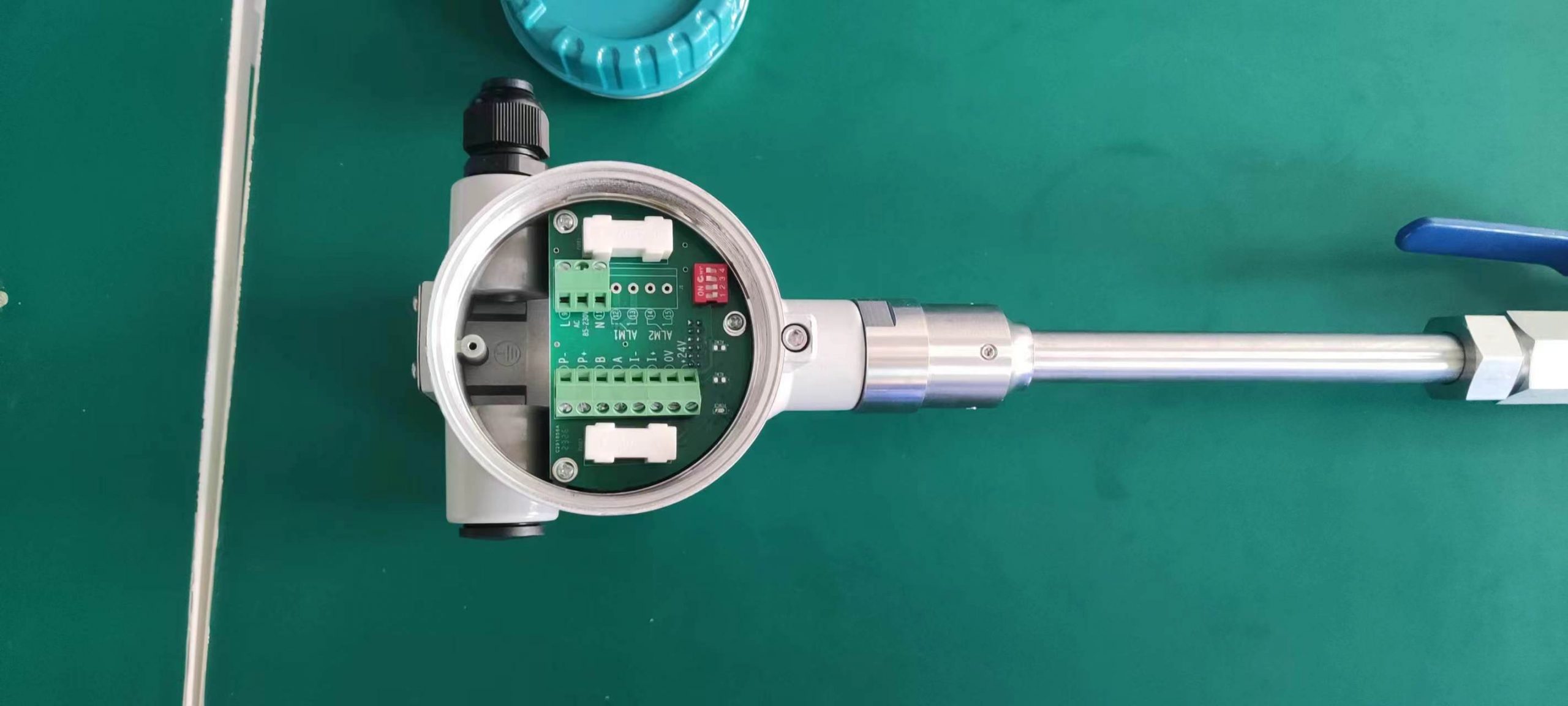

The base is divided into two types according to different installation methods: welded and snap-on. When installing, the base should be located at the vertex of the cross-section direction of the pipe, and the axis of the through hole on the base should be perpendicular to the axis of the pipe. The installation effect drawing of the welded base is completed (the welding position has been treated for rust prevention).

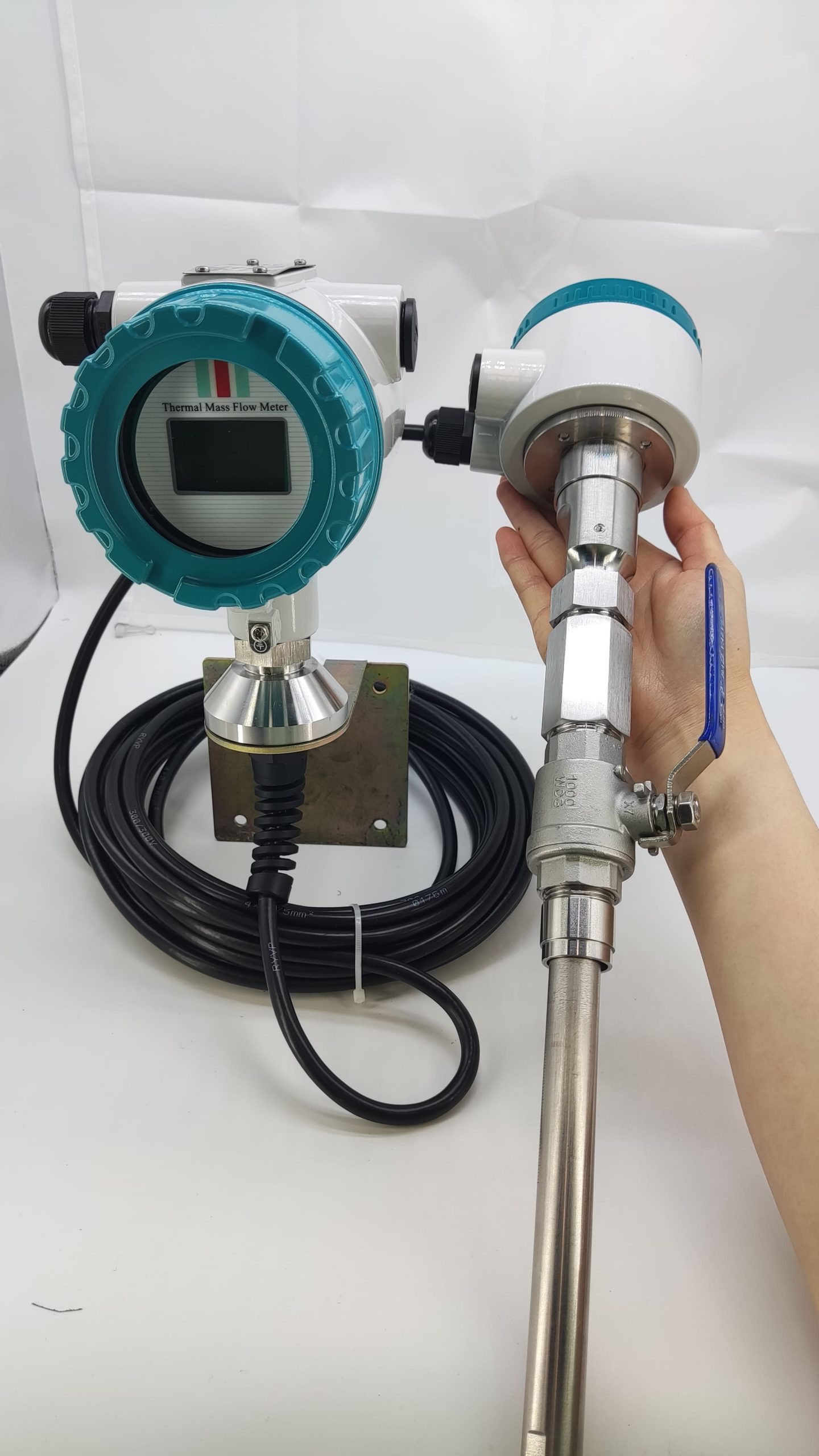

Install the ball valve

Fasten the stainless steel special valve to the base. Use a sealing gasket on the crimping contact surface (nylon material is used when the medium temperature is below 100℃, and copper material is used when the temperature is above 100℃).

Drilling holes

Before drilling, carefully confirm the on-site environment to ensure the safety of the operation.

After the drilling is completed, the valve should be closed in time to prevent air leakage.

3. In situations where online drilling and installation are permitted, dedicated drilling tools can be used to achieve online drilling and installation without production interruption. For the usage method of the dedicated tools, please refer to the relevant instructions. When drilling during production suspension, various methods can be adopted. It is necessary to ensure that the axis of the hole is concentric with the axis of the hole on the base. If the hole is made by gas cutting, the drilling operation should be arranged before the welding of the base.