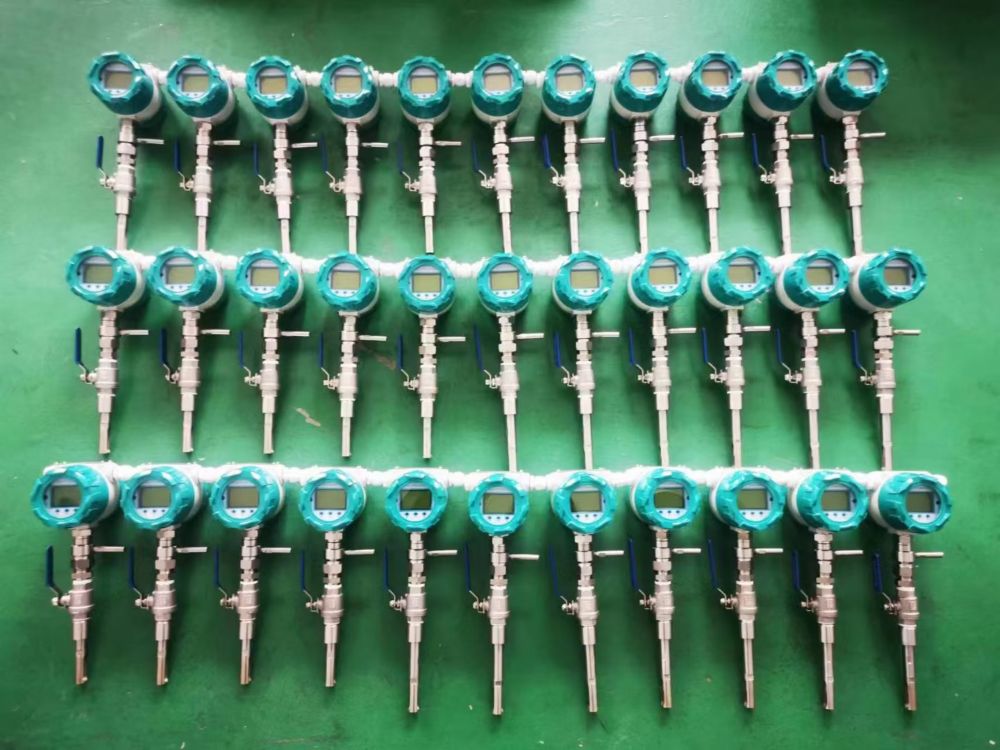

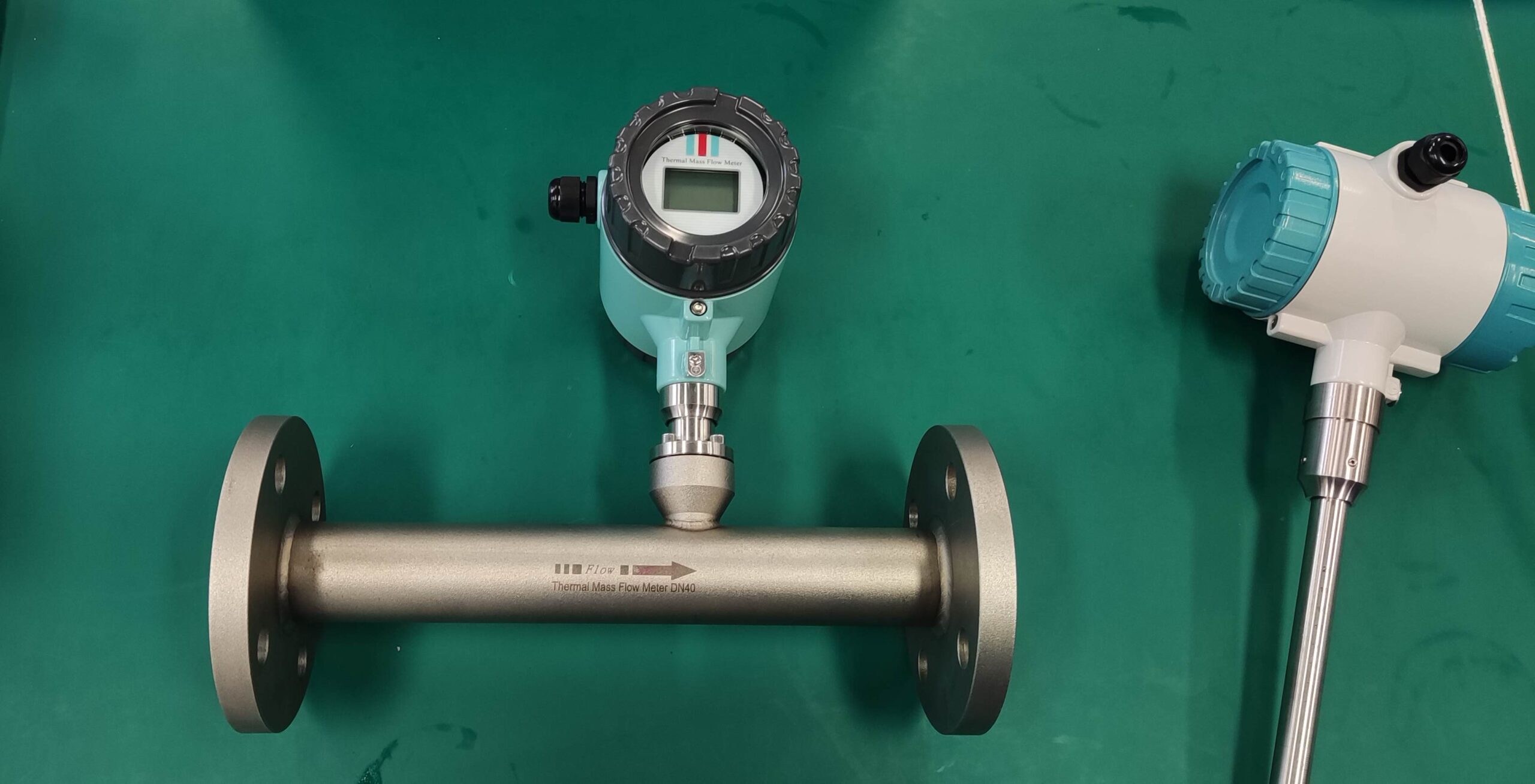

Thermal gas mass flowmeter: The intelligent choice for precise gas flow measurement

In fields such as industrial production, energy management, and environmental monitoring, the measurement of gas flow directly affects process control, energy consumption optimization, and safe operation. Traditional mechanical flowmeters are often limited by factors such as pressure and temperature changes when measuring gas flow, resulting in insufficient accuracy. The thermal gas mass flowmeter, with its unique working principle and technical advantages, is becoming the new industry standard for gas flow measurement.

In fields such as industrial production, energy management, and environmental monitoring, the measurement of gas flow directly affects process control, energy consumption optimization, and safe operation. Traditional mechanical flowmeters are often limited by factors such as pressure and temperature changes when measuring gas flow, resulting in insufficient accuracy. The thermal gas mass flowmeter, with its unique working principle and technical advantages, is becoming the new industry standard for gas flow measurement.

The core advantages of thermal gas mass flowmeters

Directly measure the mass flow rate

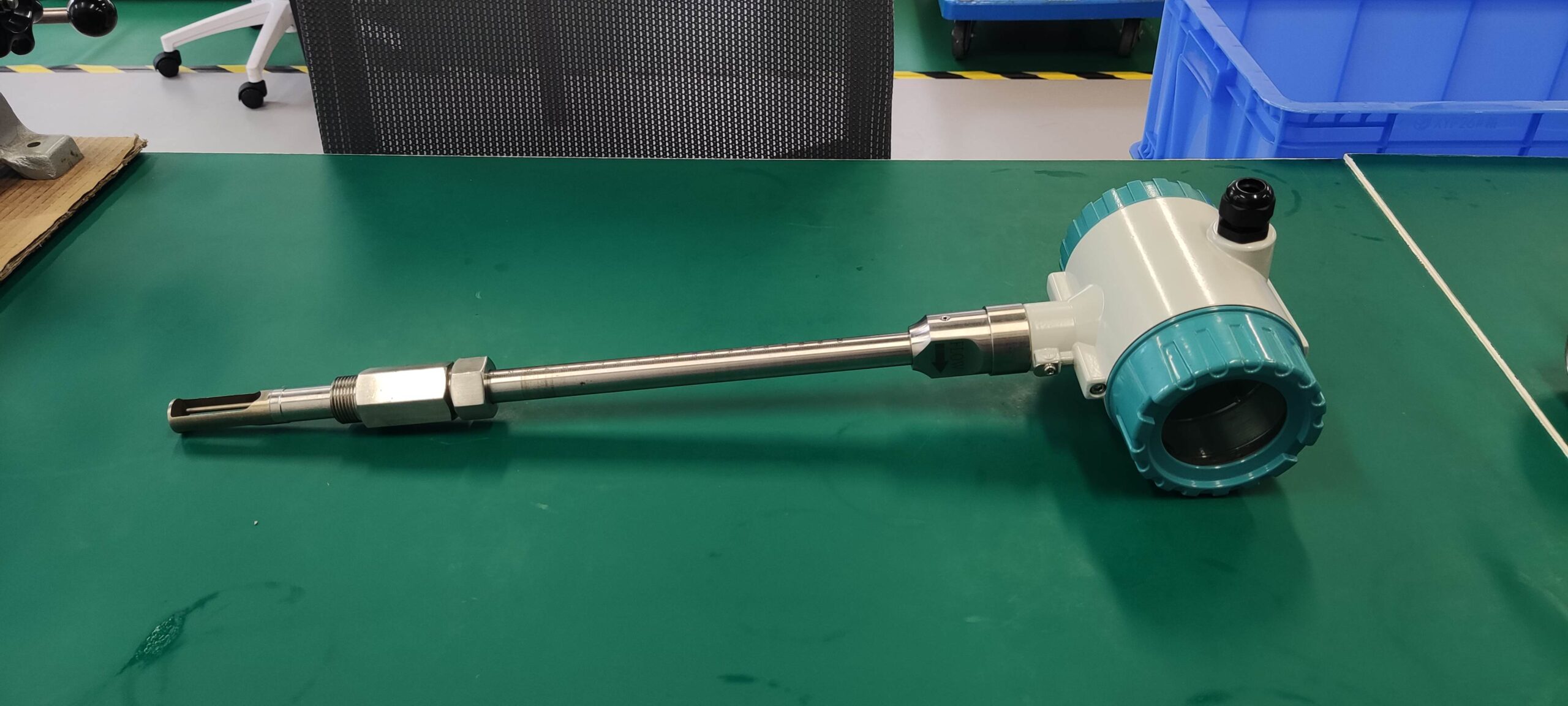

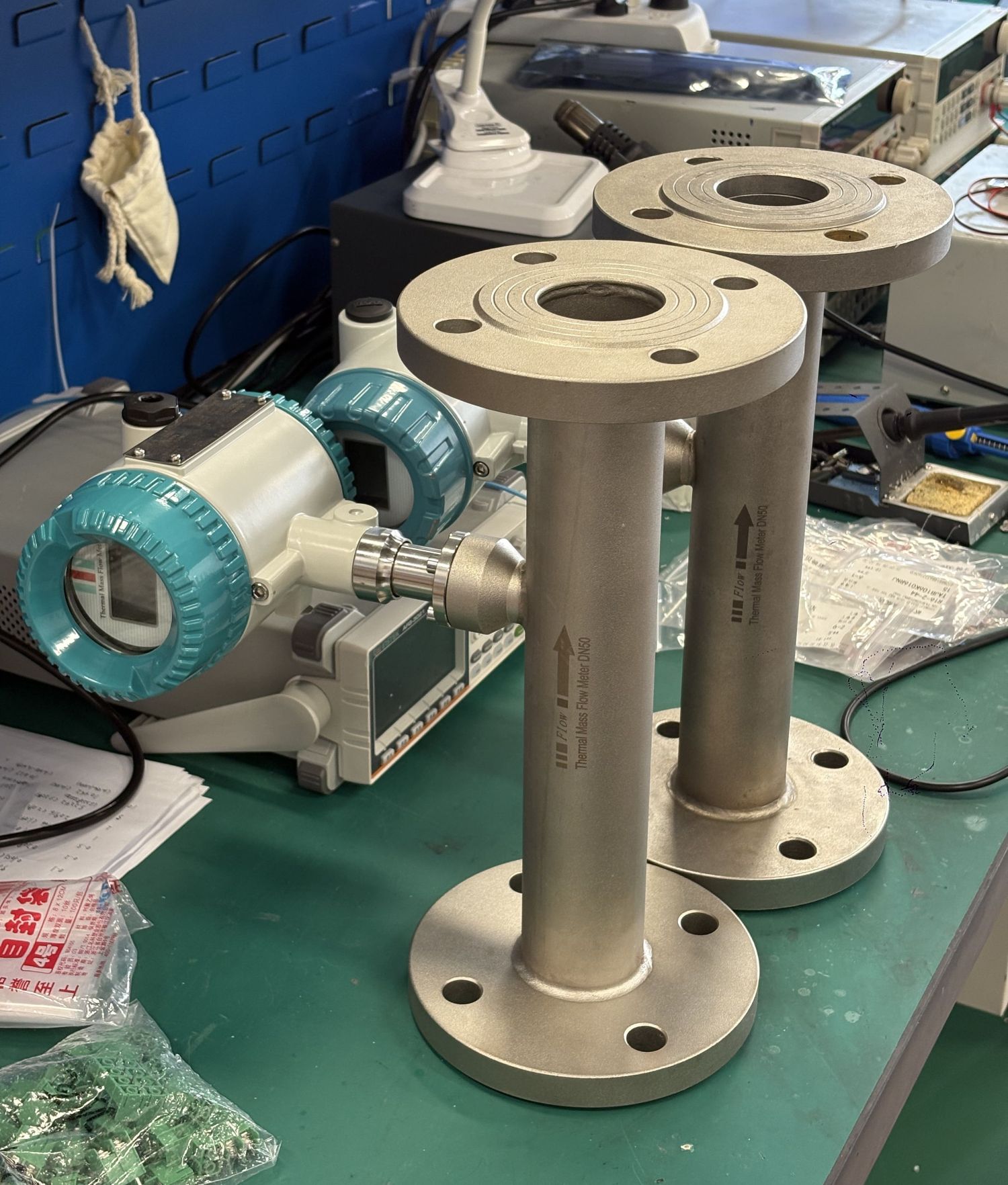

Based on the principle of thermal diffusion, it directly measures the mass flow rate of gases without the need for temperature and pressure compensation, providing more accurate and reliable data. It is particularly suitable for the measurement of gases such as compressed air, natural gas, and biogas.

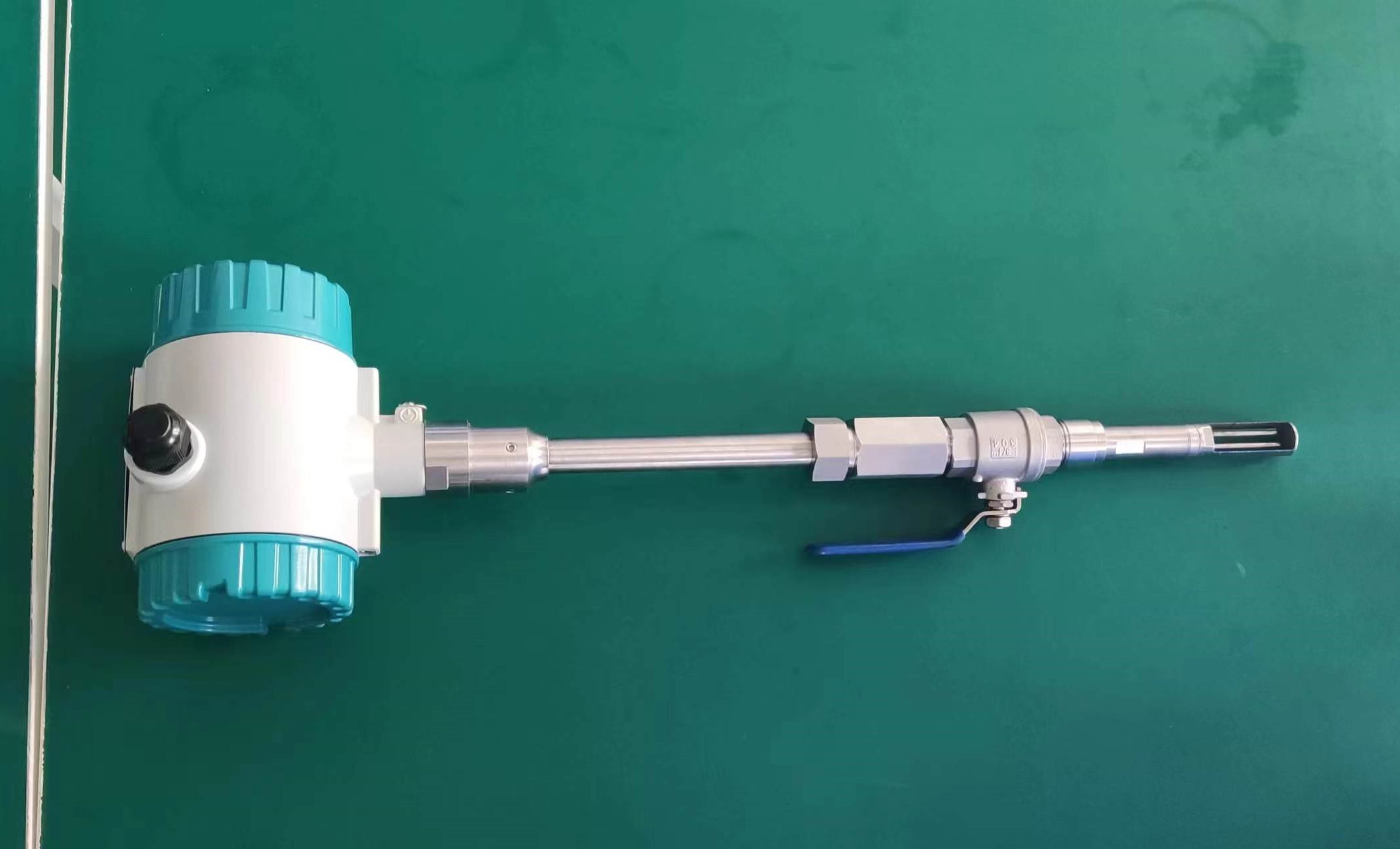

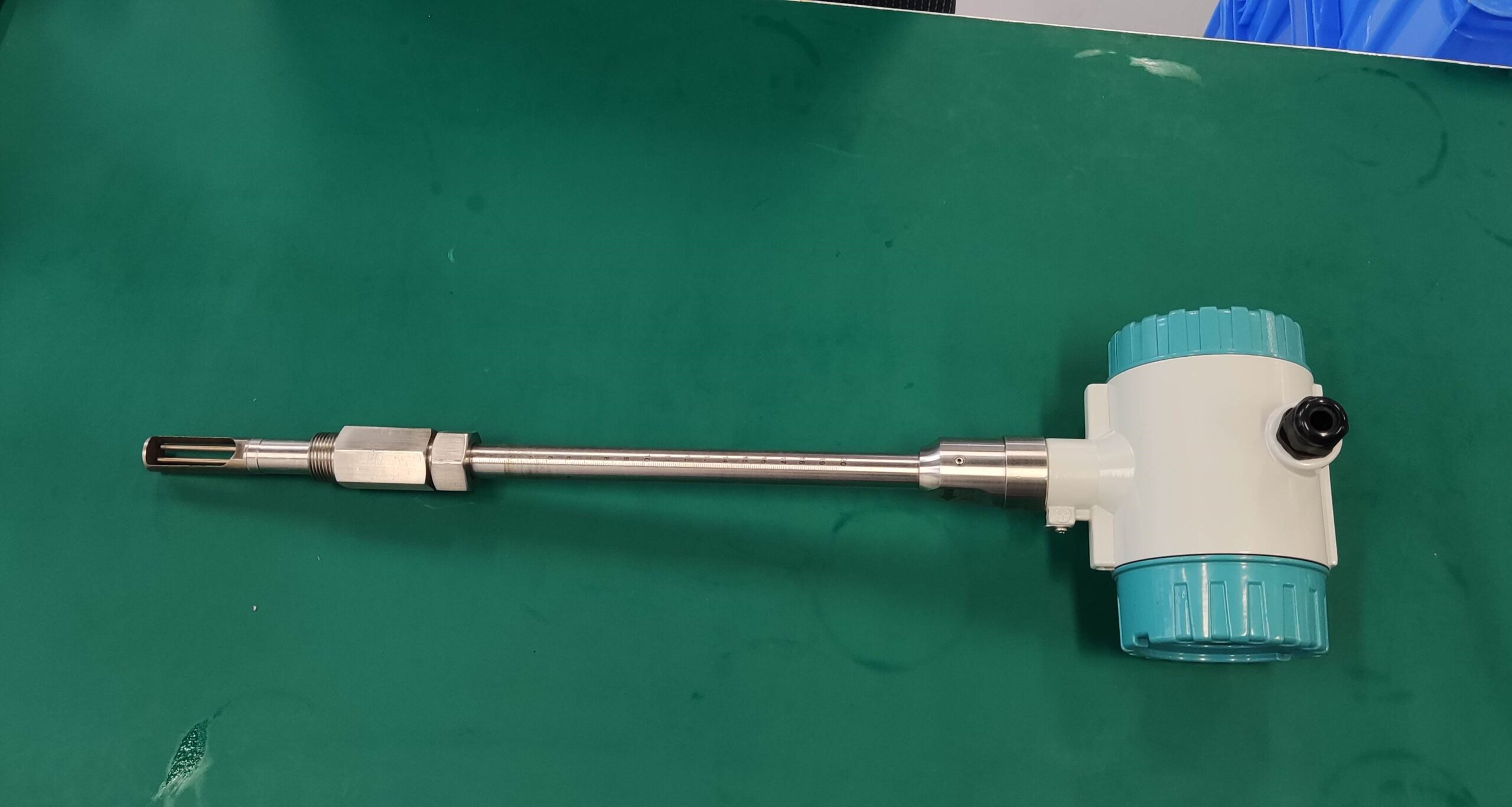

No moving parts and maintenance-free

The sensor has no mechanical moving parts and is not affected by vibration, dust and other environmental factors. It has high long-term stability and significantly reduces maintenance costs.

Wide range ratio, high sensitivity

It can measure extremely low flow rates (0.1m/s) to high-speed airflows (100m/s), is suitable for different working conditions, has a fast response speed and excellent dynamic performance.

Corrosion-resistant and adaptable to complex media

Made of special materials (such as 316L stainless steel, Hastelloy, etc.), it can measure corrosive gases (such as chlorine, ammonia) and high-purity gases.

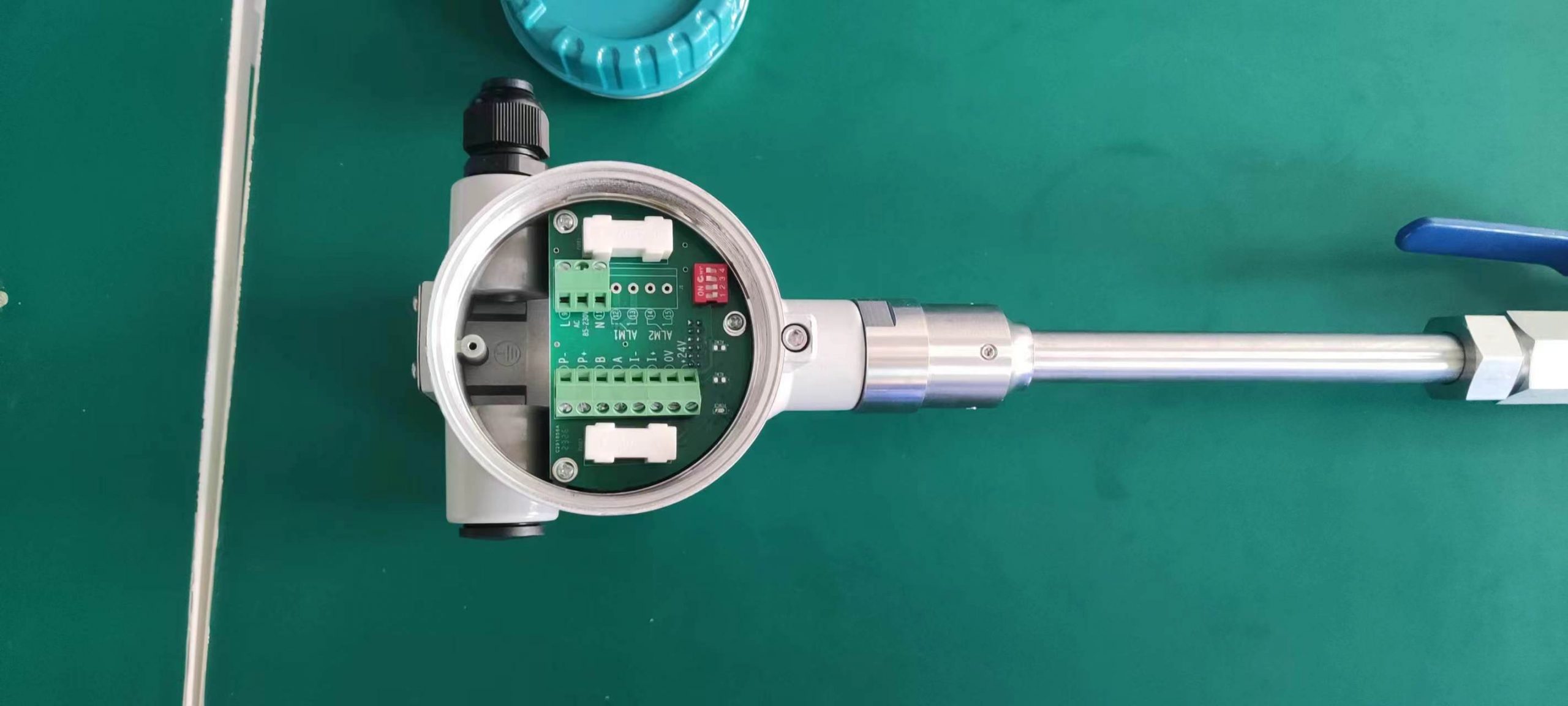

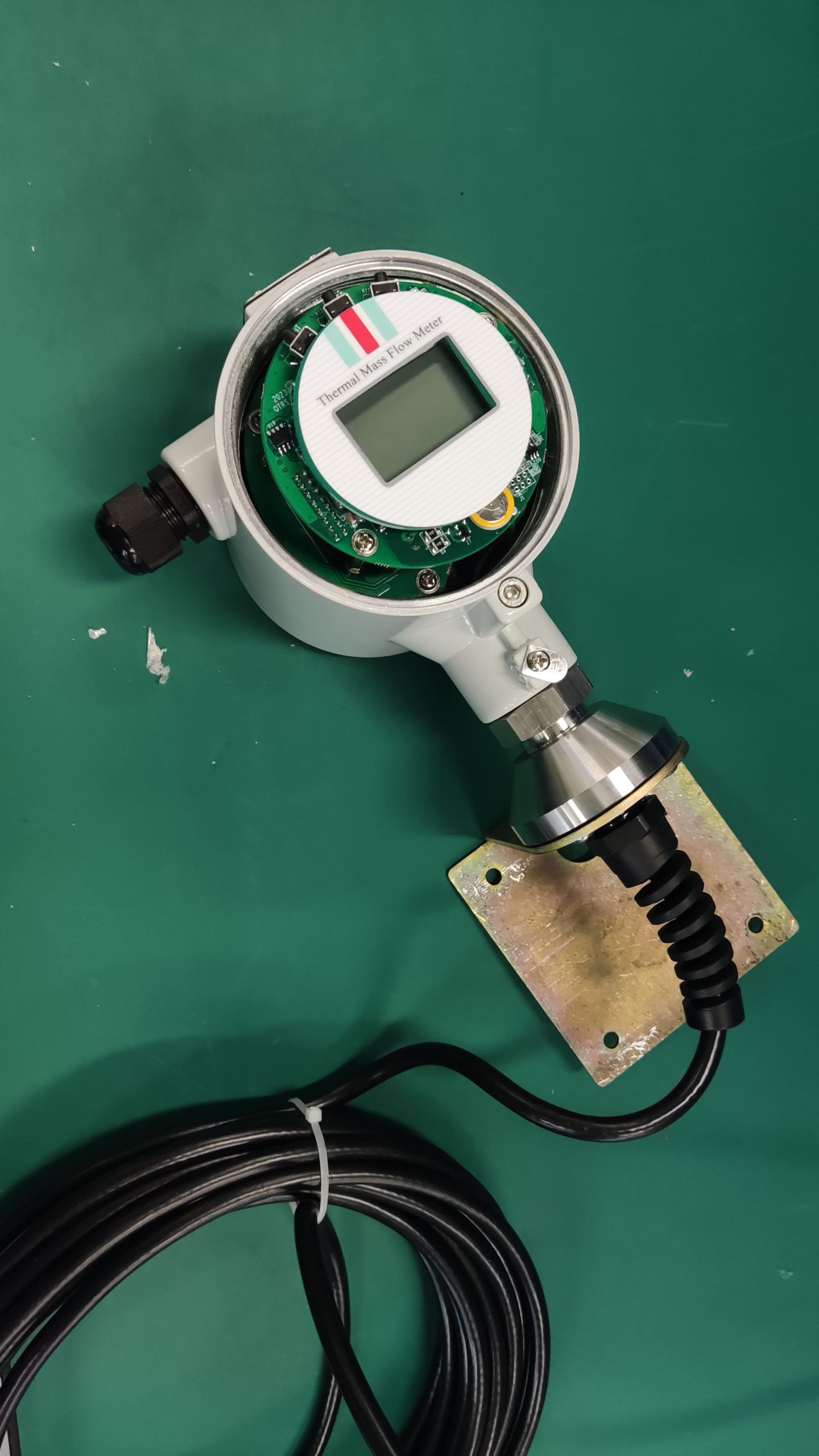

Intelligence and remote monitoring

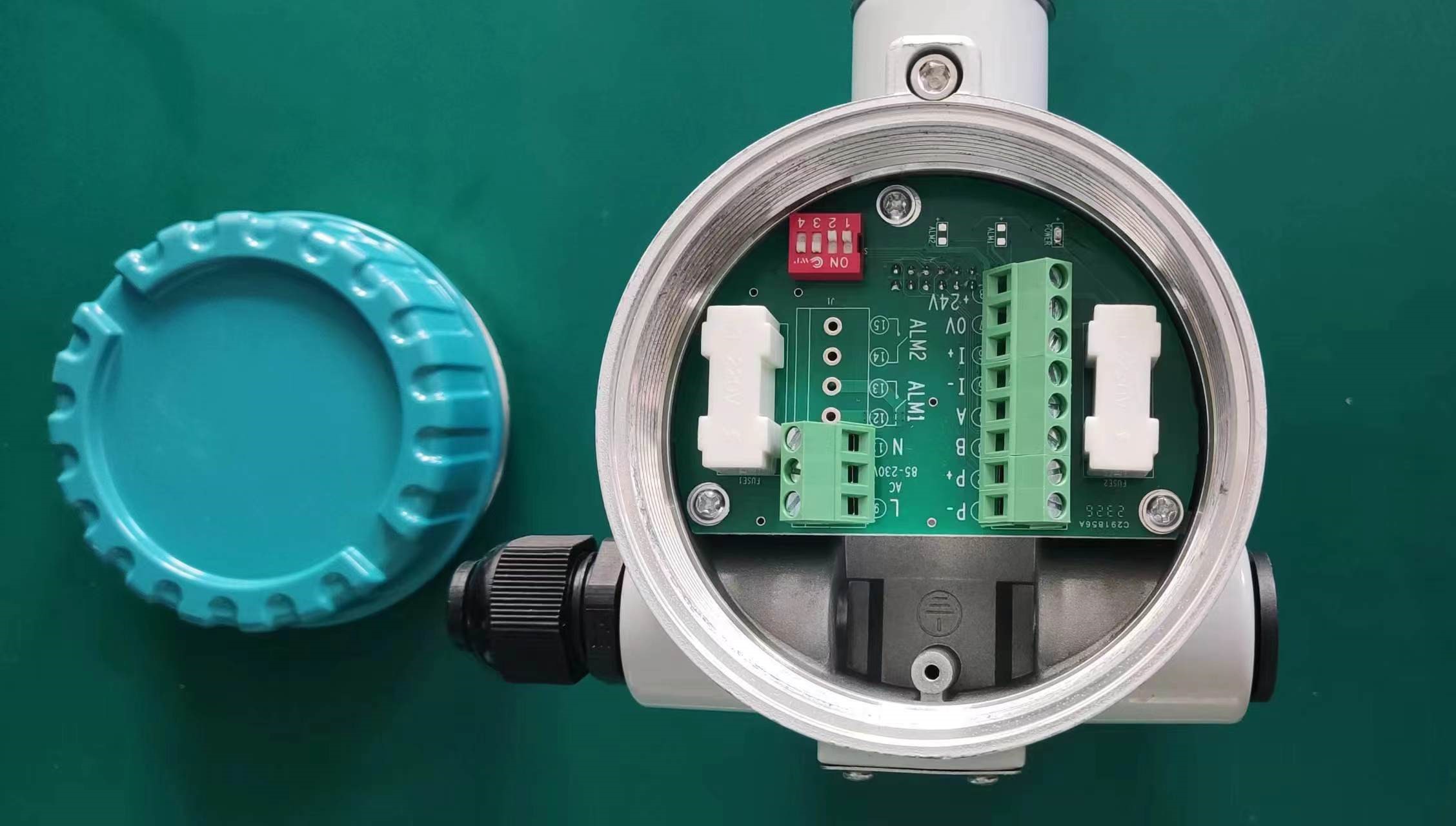

It supports communication protocols such as 4-20mA, RS485, and Modbus, and can be connected to PLC, DCS or cloud platforms to achieve remote data monitoring and intelligent analysis.

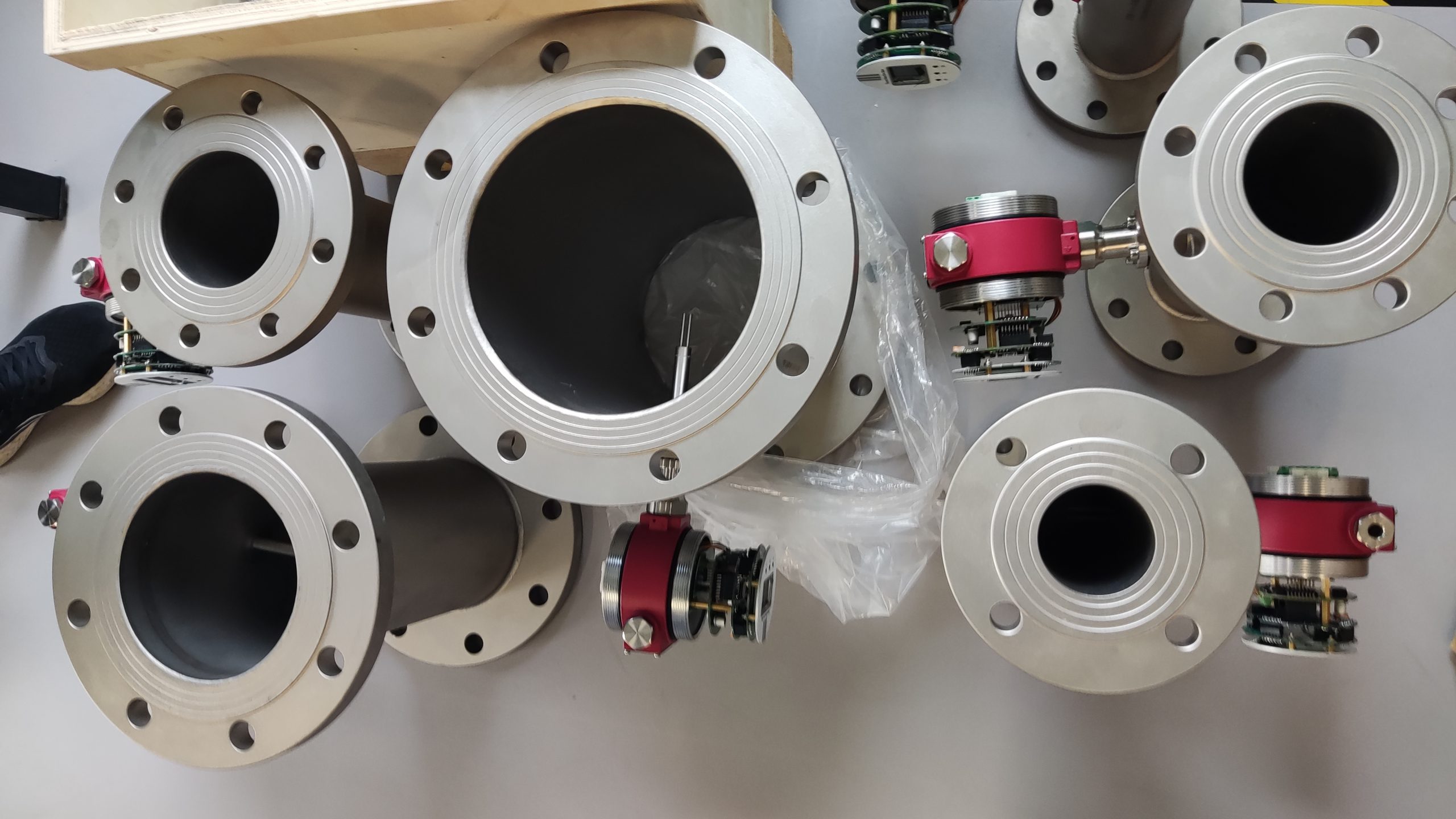

Typical application scenarios

Compressed air monitoring: Energy consumption management of factory compressed air systems, optimizing the efficiency of air source utilization.

Natural gas measurement: Trade settlement at gas transmission and distribution and refueling stations to ensure accurate measurement.

Environmental protection emission monitoring: Measurement of flue gas and waste gas flow, facilitating environmental compliance.

Semiconductor and pharmaceutical industries: Process control for high-purity gases (such as nitrogen and argon).

Biogas utilization: biogas power generation, landfill gas flow monitoring.