A detailed description of the thermal gas mass flowmeter

A detailed description of the thermal gas mass flowmeter

1. Principle of thermal gas mass flowmeter

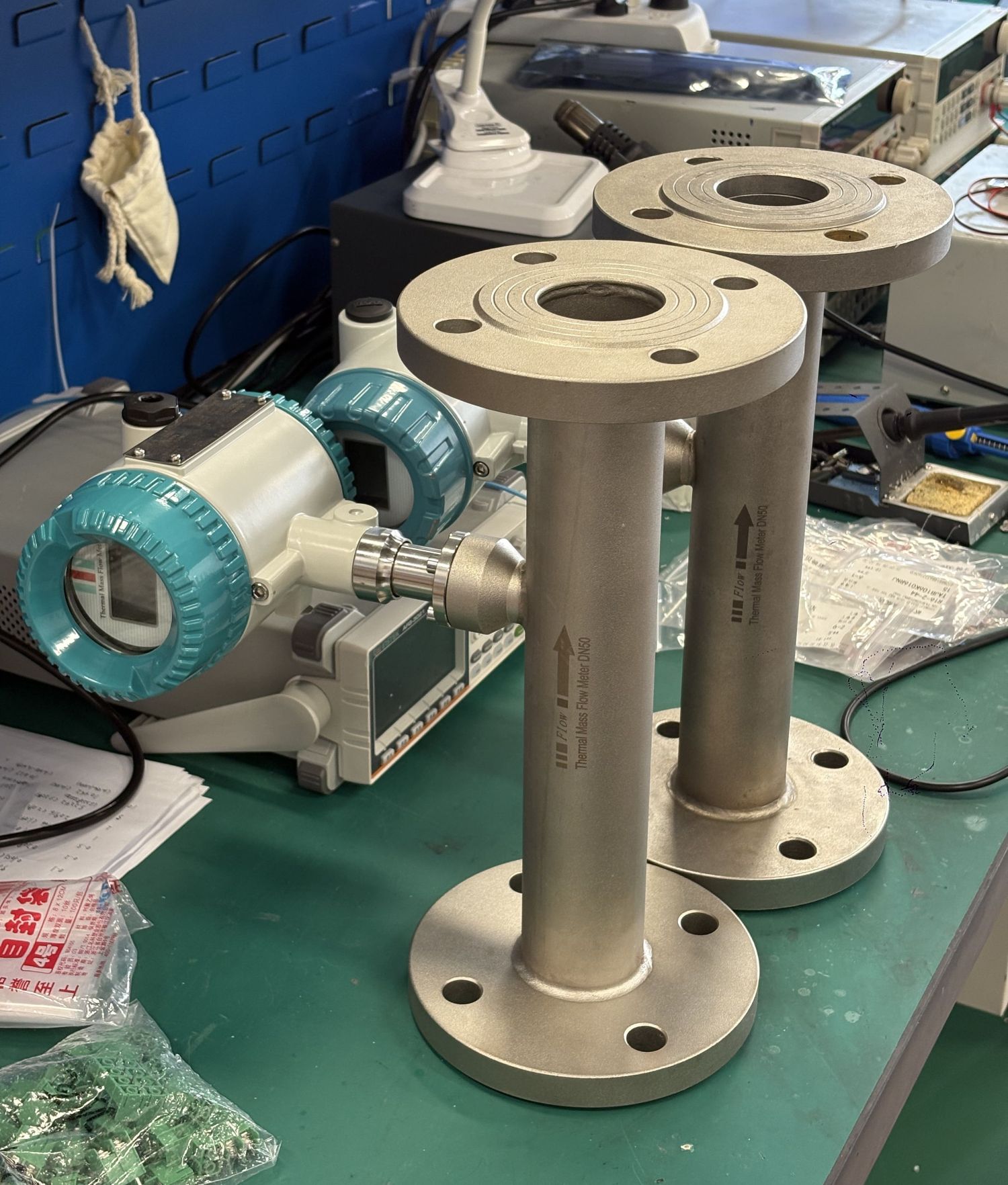

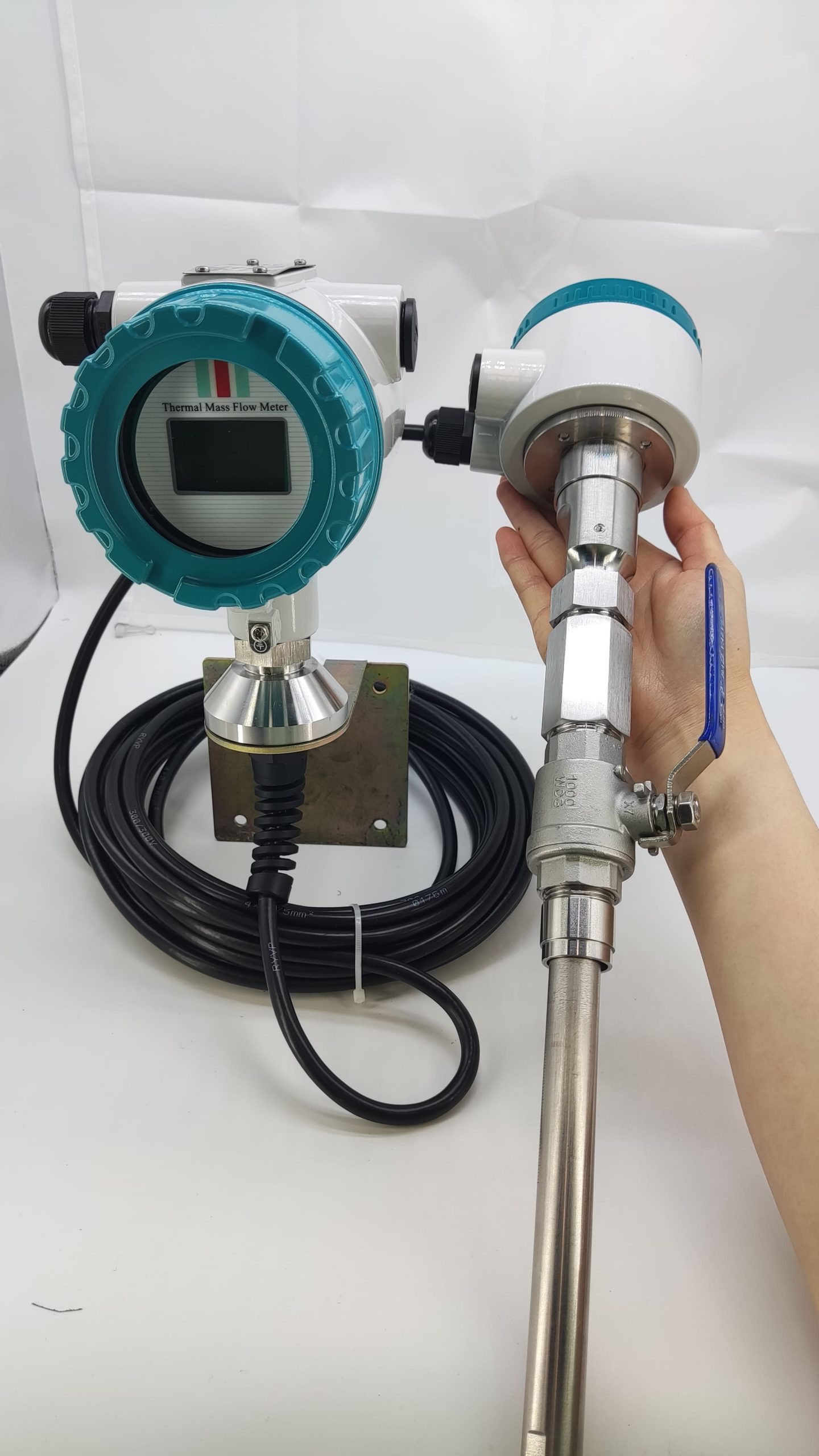

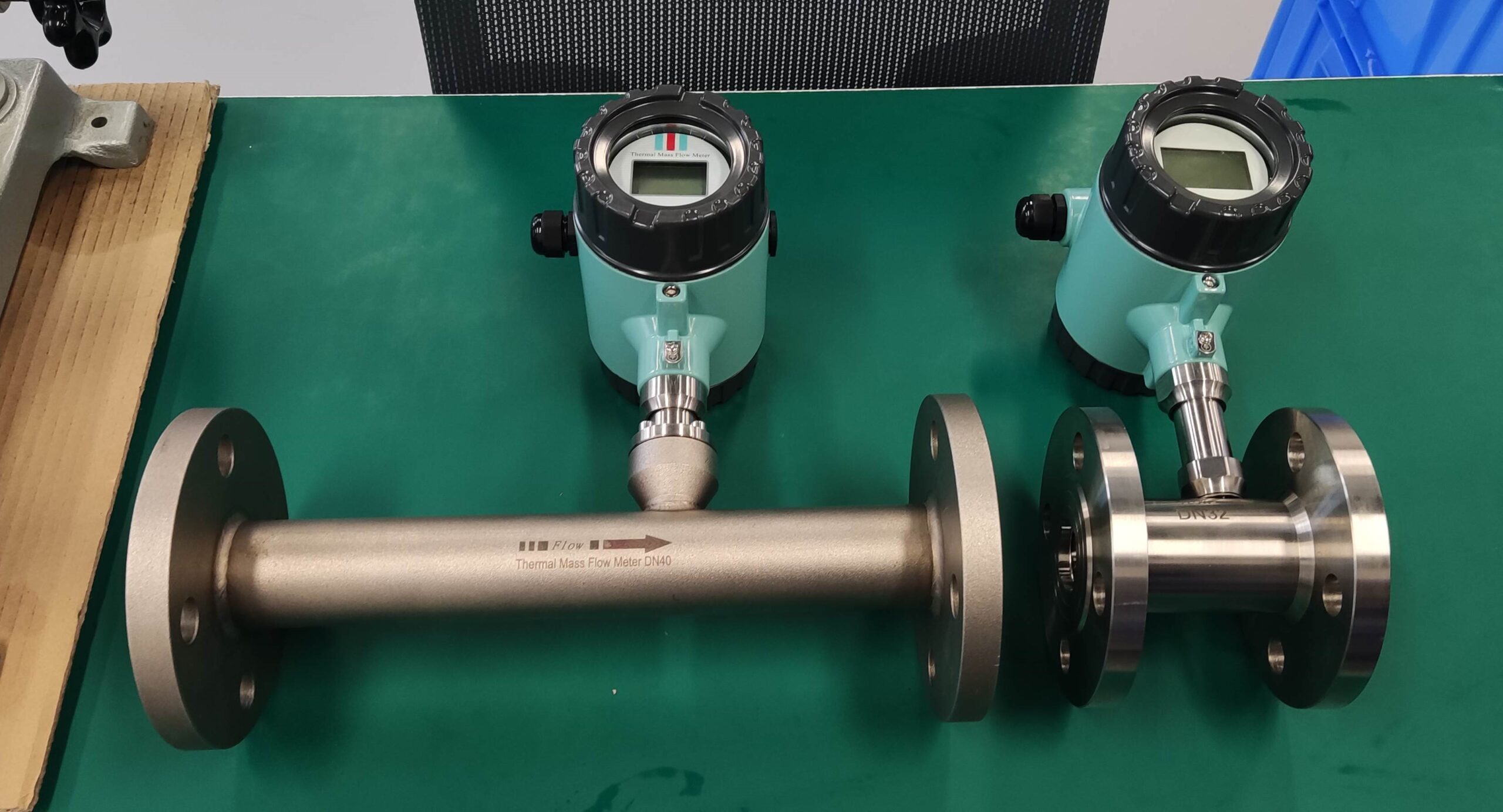

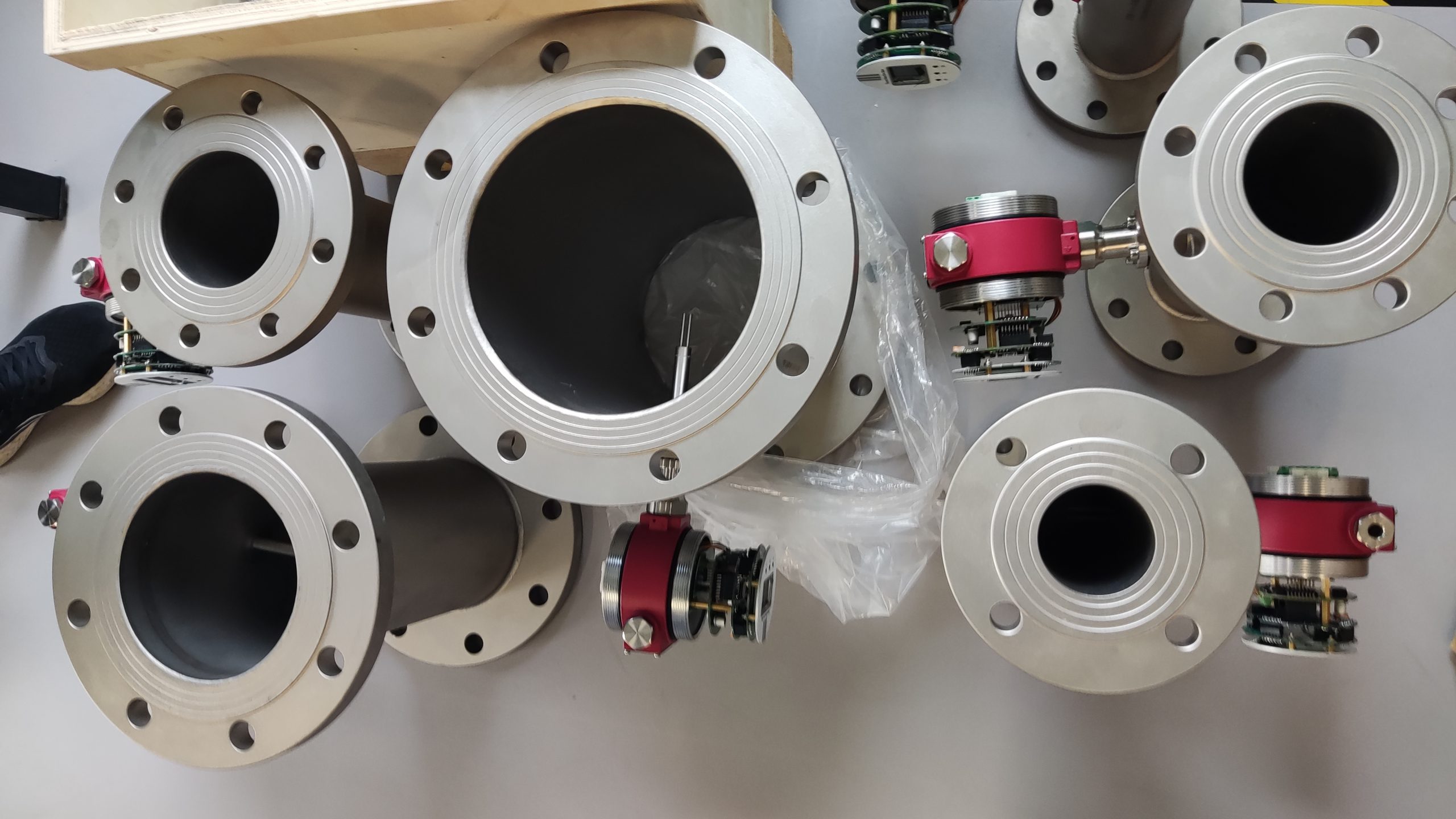

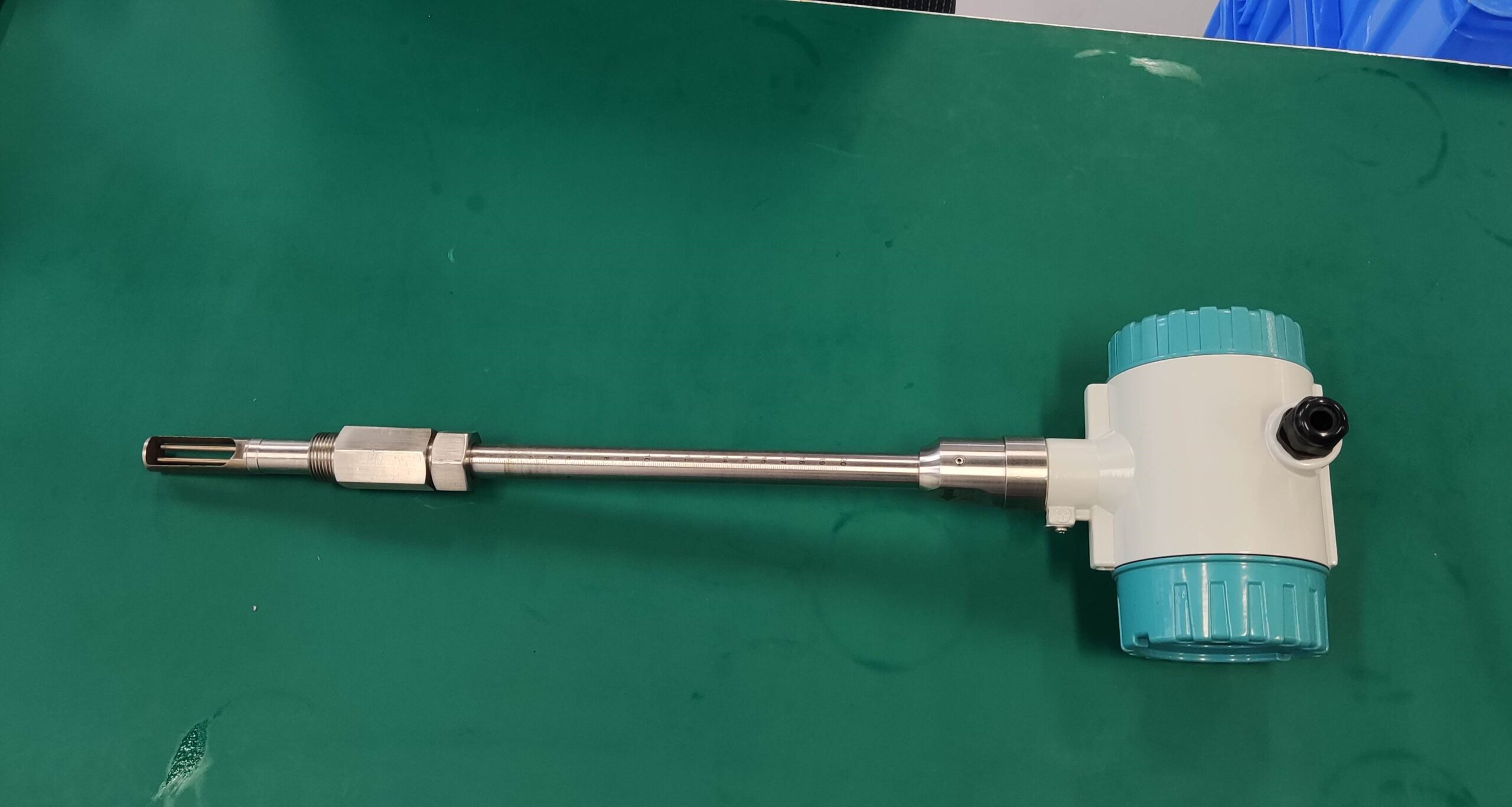

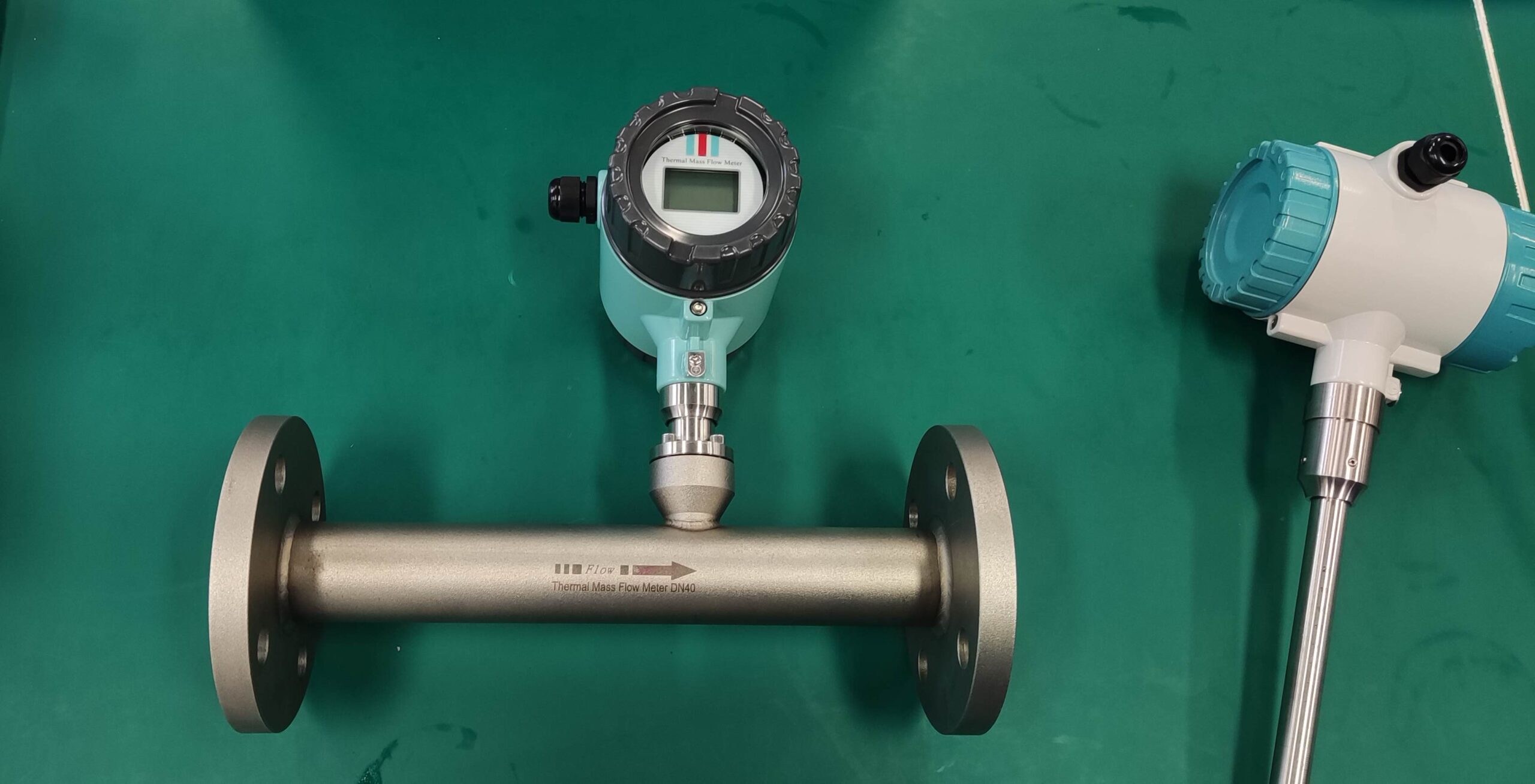

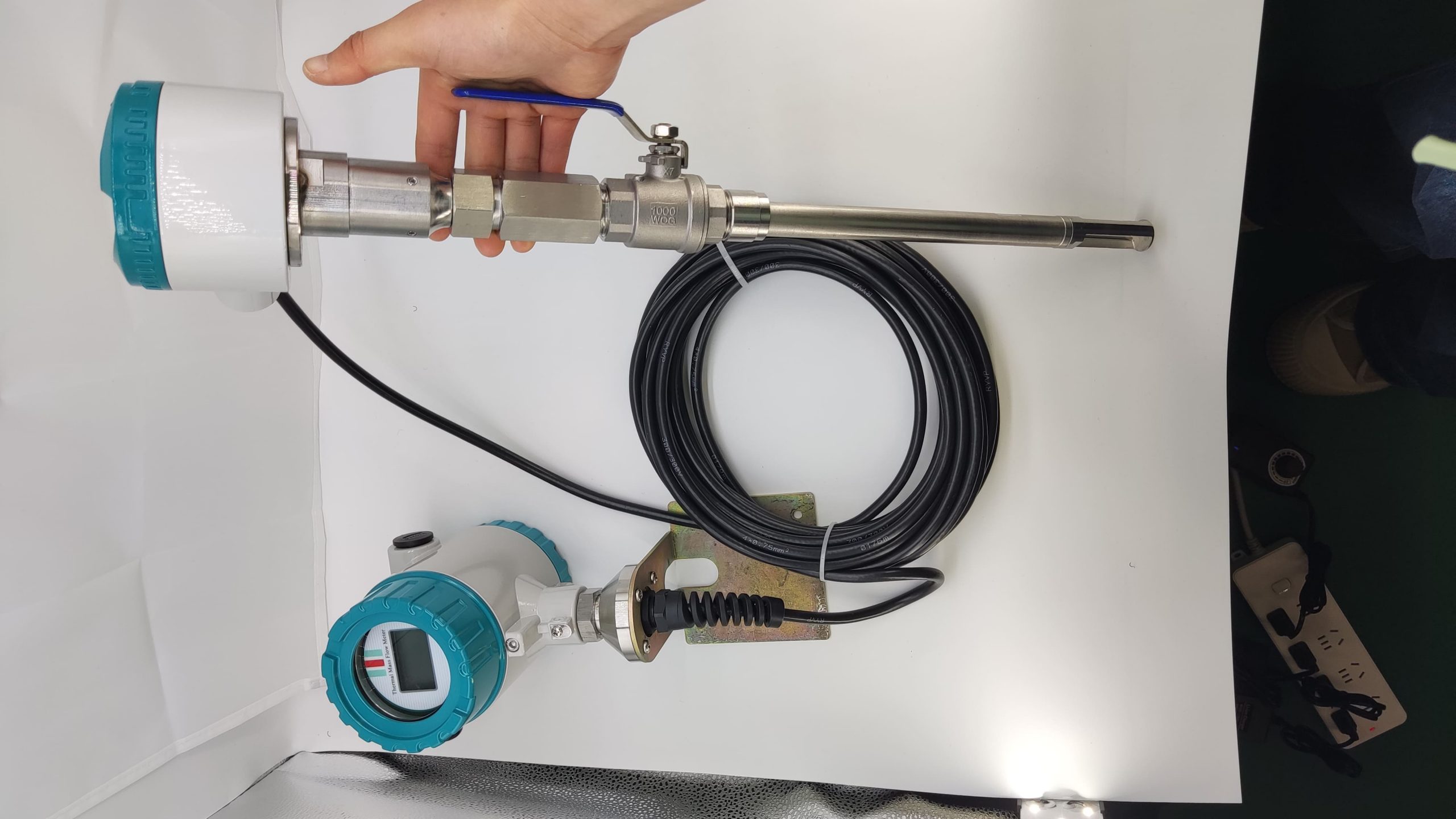

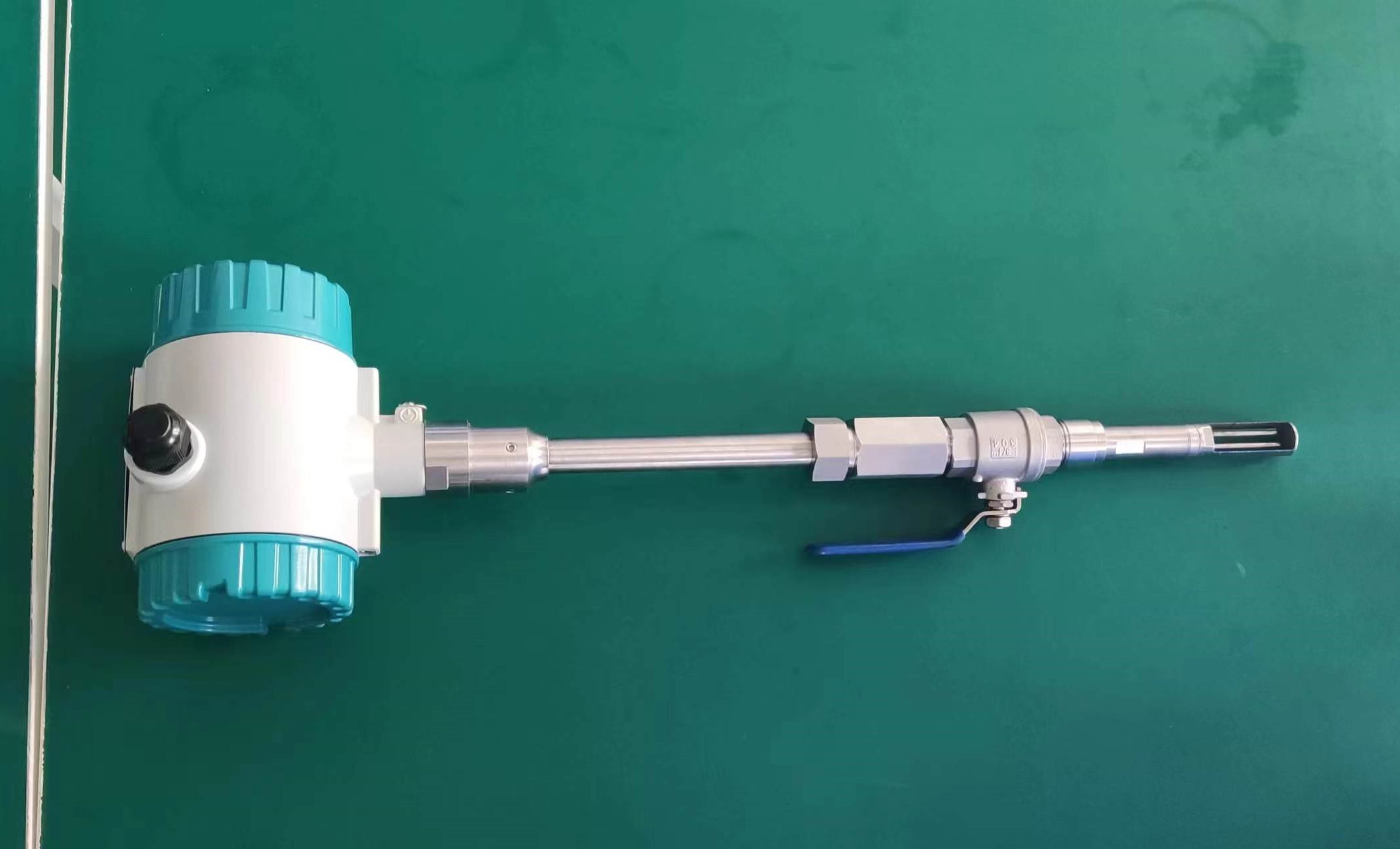

The thermal gas mass flowmeter is a thermal distributed flowmeter that utilizes the heat conduction distribution effect of the flowing fluid to transfer heat and change the temperature distribution of the measuring tube wall. It was once called the thermal TMF. 2) Utilize King’s Law of the heat dissipation (cooling) effect. Also, due to the fact that the detection element extends into the measuring tube in its structure, it is also called an immersion type or an intrusion type. Some instruments that are inserted into the process tube from the outside during use are called insertable types.

2. Advantages of thermal gas mass flowmeters

Thermal distributed flowmeters can measure small flow rates at low flow rates (gas 0.02 to 2m/s). Immersion type can measure low to medium-high flow rates (gas 2 to 60m/s), while insertion type flowmeters are more suitable for large pipe diameters.

The flowmeter has no moving parts. It is a thermal distributed instrument without a split pipe and has no flow-blocking components, resulting in very little pressure loss. Thermal distributed instruments and immersion instruments with split pipes, although equipped with flow-blocking components in the measuring pipeline, have relatively small pressure losses.

The performance of the flowmeter has relatively improved. Compared with the derivational mass flow meter, it does not require temperature sensors, pressure sensors, computing units, etc. It only has a flow sensor, which is simple in composition and has a low probability of failure.

Thermal distributed instruments are used for diatomic gases such as H2, N2, O2, CO, and NO that are close to ideal gases. They do not need to be specially calibrated with these gases and can be directly calibrated with air. Experiments have proved that the difference is only about 2%. For single-atom gases such as Ar and He, multiply by a coefficient of 1.4. For other gases, specific heat capacity conversion can be used, but the deviation may be slightly larger.

The specific heat capacity of a gas varies with pressure and temperature, but a slight change near the temperature and pressure in use can be regarded as a constant.

3. Disadvantages of thermal gas mass flowmeters

The thermal mass flowmeter has a slow response.

In places where the components of the measured gas vary greatly, due to the changes in cp value and thermal conductivity, the measured values will have significant variations, resulting in errors.

For small flow rates, the instrument will bring considerable heat to the gas being measured.

For thermal distributed flowmeters, if the measured gas deposits a scale layer on the pipe wall, affecting the measurement value, regular cleaning is essential. It has the disadvantage of being more prone to clogging for thin-tube type instruments and generally cannot be used.

The use of pulsating flow will be restricted.