Analysis of High-temperature Probe Technology for Vortex Flowmeter: Can It Handle Extreme Working Conditions?

In industries such as petrochemicals, energy and power, and metallurgy, the flow measurement of high-temperature media (such as superheated steam, heat transfer oil, and high-temperature gas) has always been a technical challenge. Vortex flowmeters are widely popular due to their simple structure and high stability, but how do they perform in high-temperature environments? Can high-temperature probes ensure long-term reliable operation? This article will conduct an in-depth analysis from aspects such as principle, temperature resistance design and industry application.

The working principle of vortex flowmeters

Vortex flowmeters are based on the “Karman vortex street” principle. When a fluid flows through a blocking fluid (vortex generator), it will generate alternately arranged vortices downstream. The frequency of these vortices is directly proportional to the flow velocity. By detecting the vortex frequency, the flow rate can be calculated.

2. Challenges of high-temperature environments to vortex flowmeters

(1) Temperature resistance limit of the sensor

The temperature resistance of a common piezoelectric ceramic sensor is usually ≤200° C. If the medium temperature exceeds this limit, it may cause signal drift or damage.

Electronic components (such as amplifiers) are prone to aging when working at high temperatures for a long time, which affects their stability.

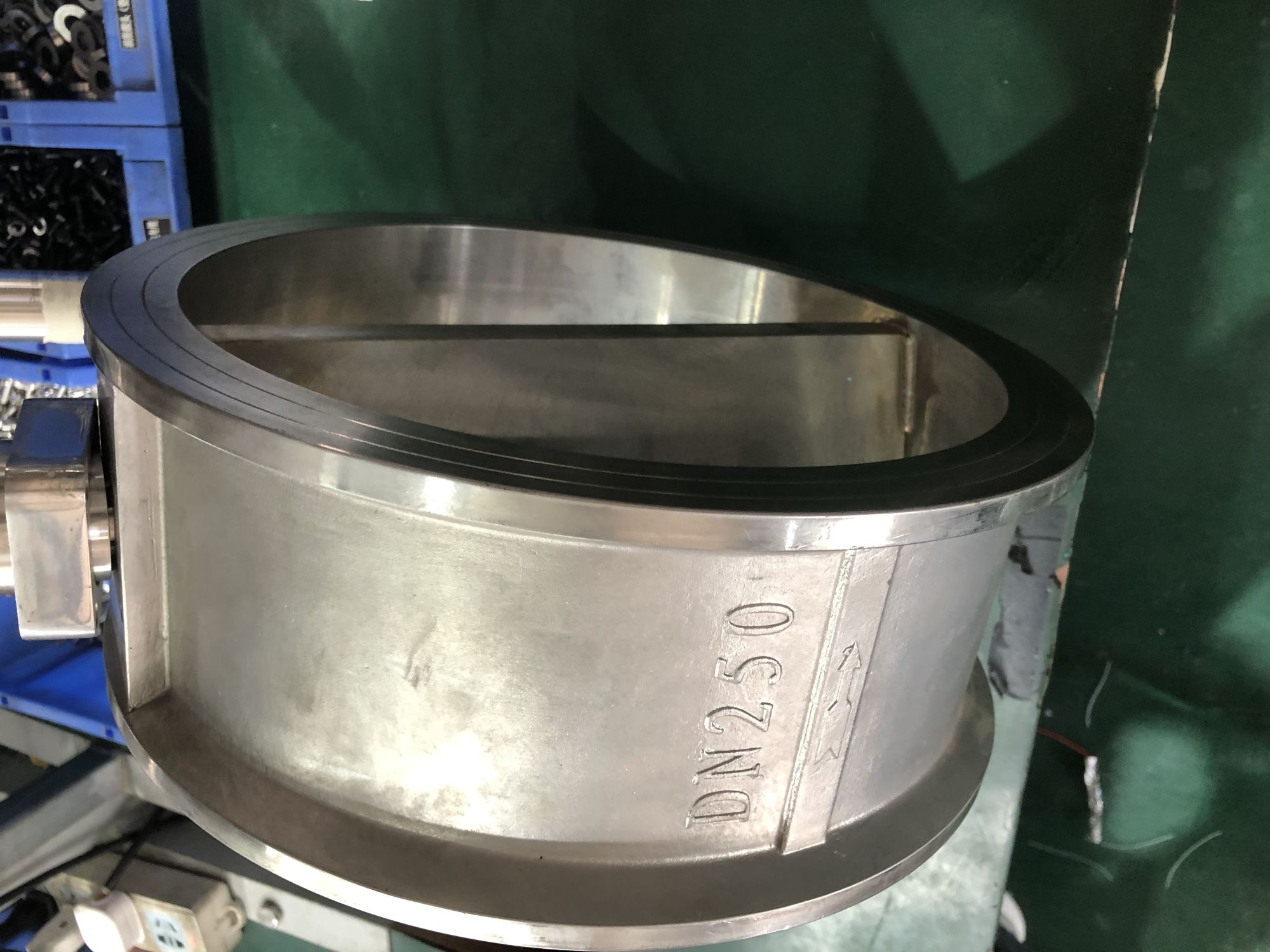

(2) Mechanical thermal deformation

At high temperatures, metal components such as the vortex generator and the gauge body may undergo thermal expansion, changing their geometric dimensions and affecting measurement accuracy.

Sealing materials (such as gaskets and O-rings) may fail, leading to leakage risks.

(3) Changes in medium characteristics

The density of high-temperature gas decreases, which may affect the intensity of the vortex signal and lead to inaccurate measurement at low flow rates.

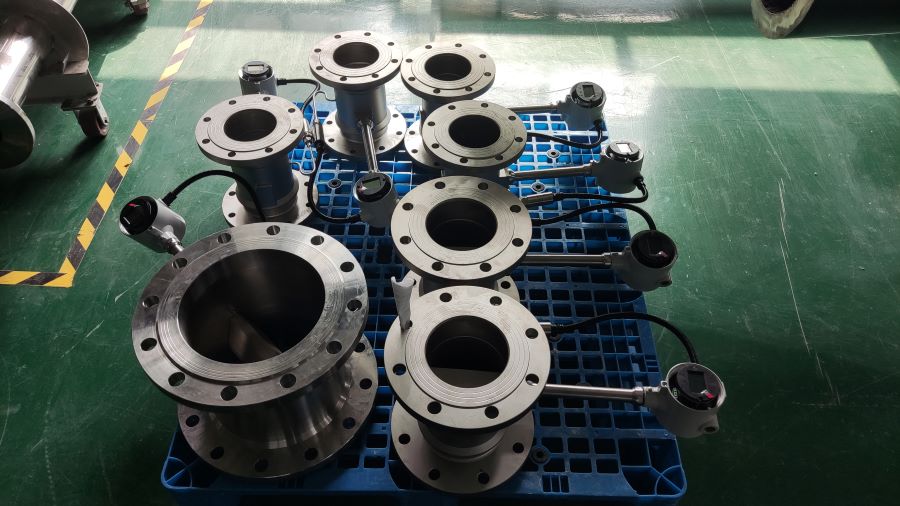

3. Key technical solutions for high-temperature probes

To cope with the challenge of high temperatures, manufacturers usually adopt the following optimized designs:

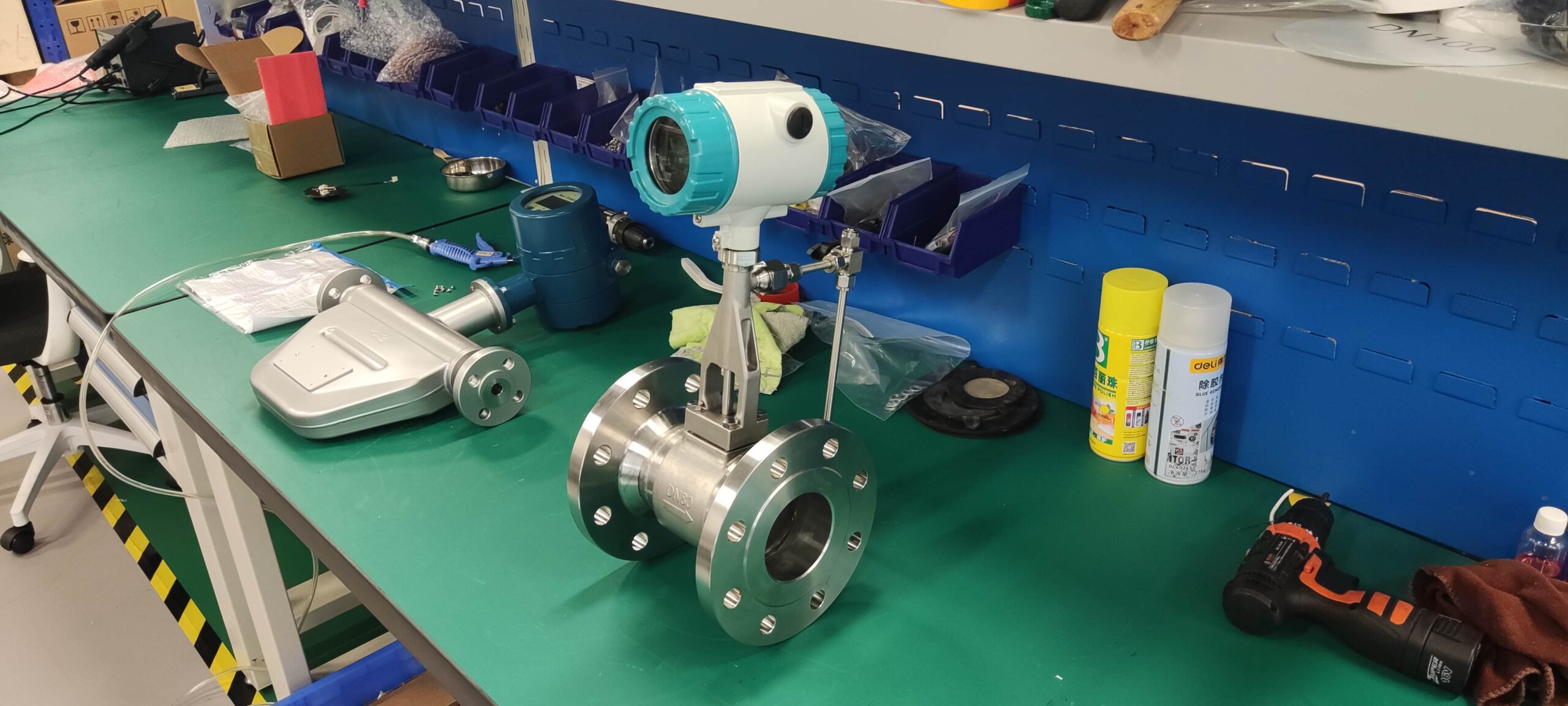

High-temperature resistant sensor

High-temperature piezoelectric crystals (such as lithium niobate) or capacitive detection technology are adopted, with a temperature resistance of over 400°C.

Some models are equipped with heat sinks or cooling cavities to reduce the temperature of the probe.

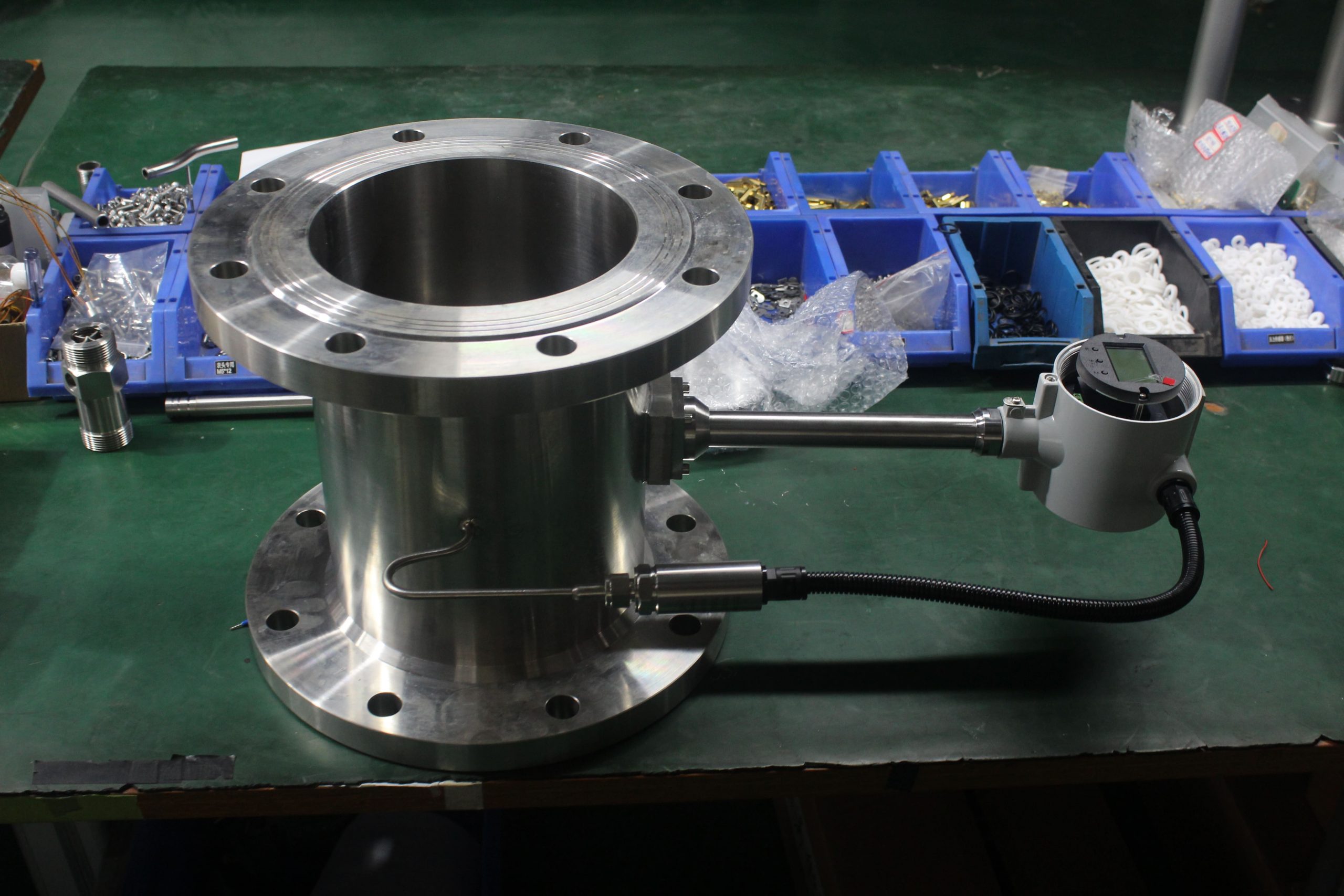

(2) Split structure

Separate the sensor from the signal processing unit. Only heat-resistant components are retained in the high-temperature part, and electronic components are kept away from heat sources.

(3) Material optimization

The vortex generator is made of 310S stainless steel or Hastelloy, which is resistant to high-temperature corrosion.

Metal seals are adopted instead of rubber seals to avoid failure at high temperatures.

(4) Temperature compensation algorithm

Built-in temperature sensor, real-time correction of errors caused by thermal expansion or changes in medium density.

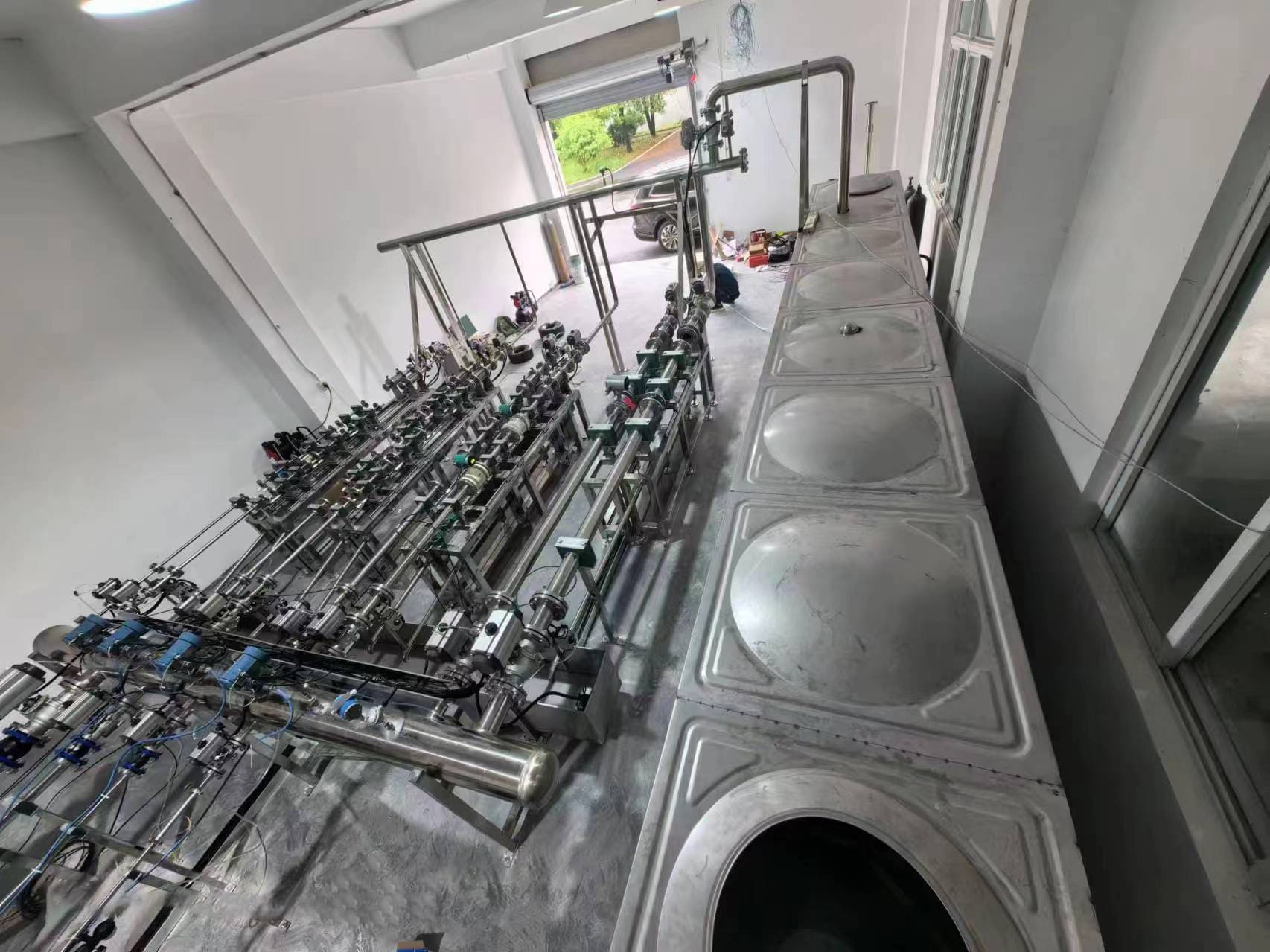

4. Practical Application and selection suggestions

The high-temperature probe of the vortex flowmeter has been successfully applied in:

Measurement of superheated steam in power plants (300-400°C)

Monitoring of heat transfer oil in the petrochemical industry

High-temperature gas flow measurement

Selection precautions:

Determine the medium temperature and select the matching temperature resistance grade.

Give priority to choosing a split design to avoid damage to electronic components due to high temperatures.

Consider the thermal expansion of the pipeline and reserve the installation allowance.