Precautions for the installation process of compressed air vortex flowmeters

In this article, the Aister instrument staff will explain the key points to note when installing a compressed air vortex flowmeter

1. Choose the installation site and environment reasonably.

Consider the convenience of installation and maintenance, and avoid strong power equipment, high-frequency equipment, and strong power switch equipment. Avoid the influence of high-temperature heat sources and radiation sources, as well as strong vibration sites and highly corrosive environments.

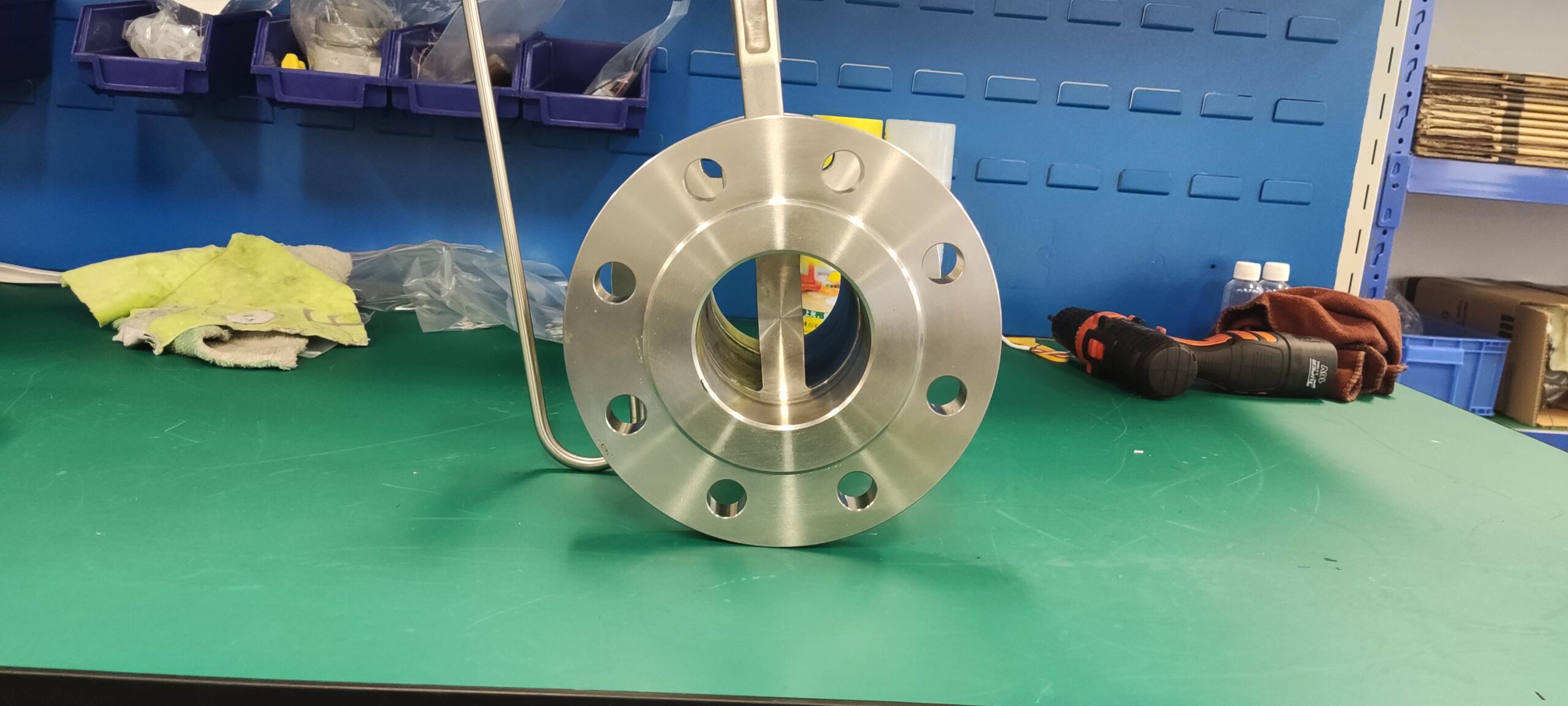

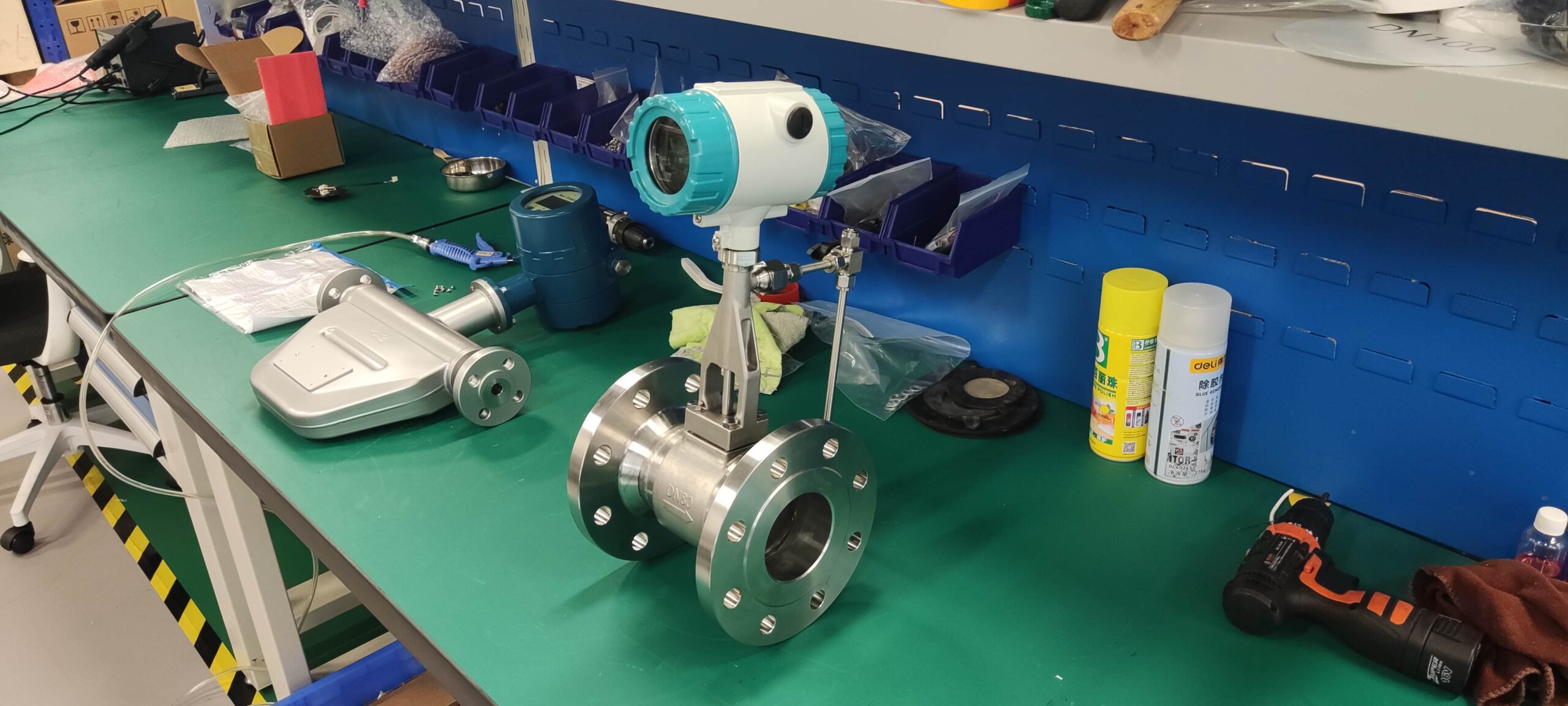

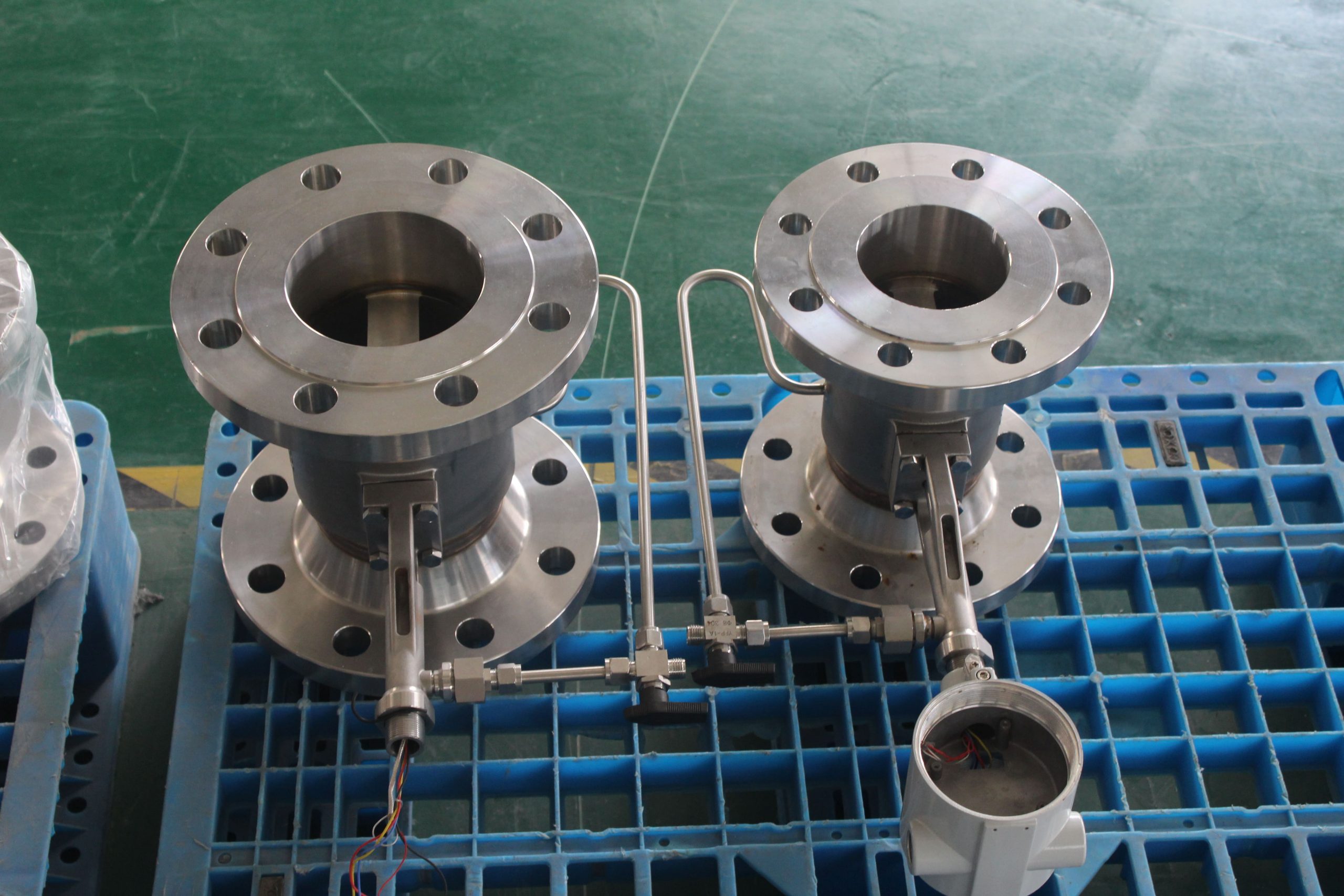

2. There must be sufficient straight pipe sections upstream and downstream.

If there are two 90-degree elbows on the same plane upstream of the sensor installation point, then the upstream straight pipe section shall be ≥25D and the downstream straight pipe section shall be ≥5D.

If there are two 90-degree elbows upstream of the sensor installation point, the upstream straight pipe section shall be ≥40D and the downstream straight pipe section shall be ≥5D.

The regulating valve should be installed at least 5D downstream of the sensor. If it must be installed upstream of the sensor, the straight pipe section upstream of the sensor shall not be less than 50D and downstream shall not be less than 5D.

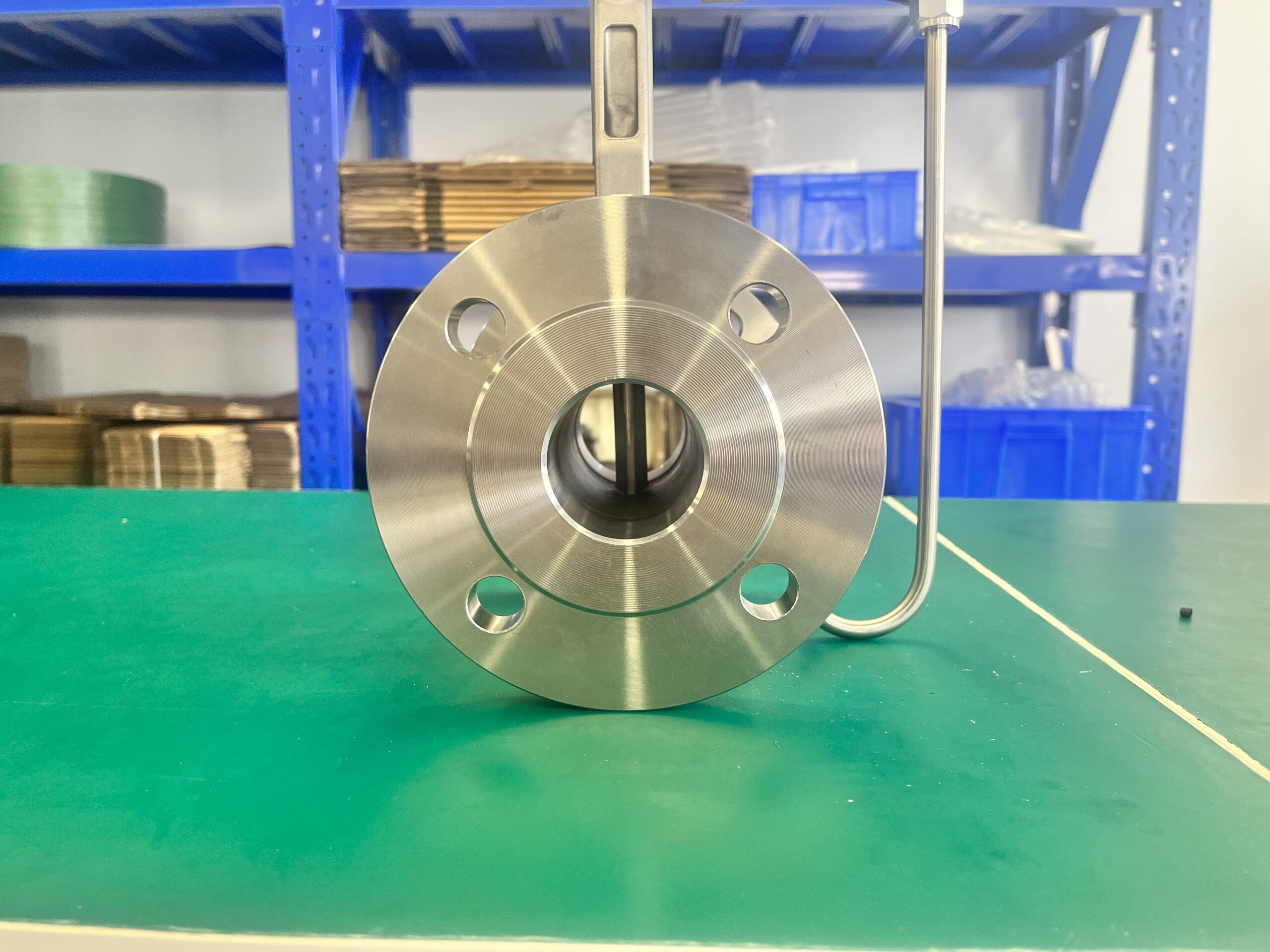

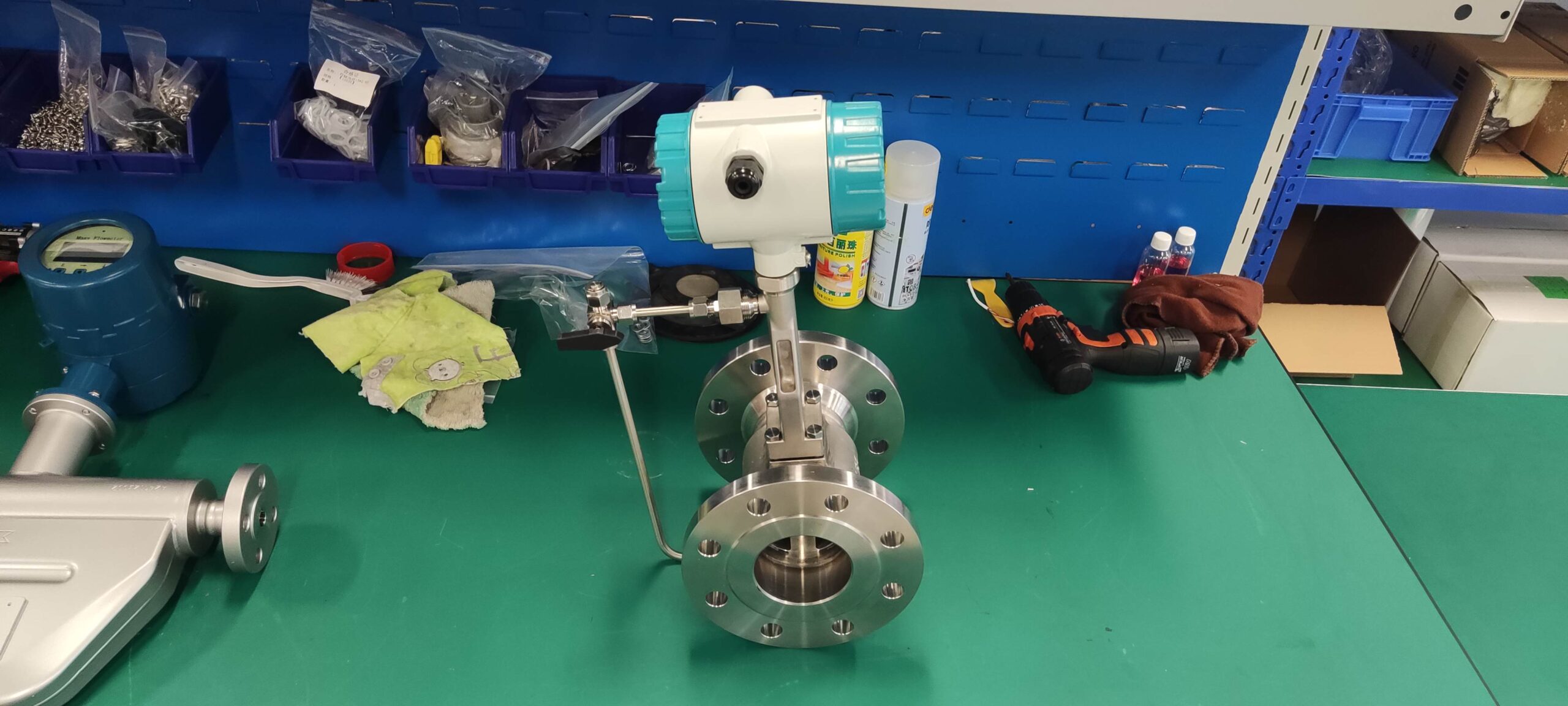

3. The sensor is installed on the pipeline with an insulation layer.

The insulation layer shall not exceed one third of the height of the support.

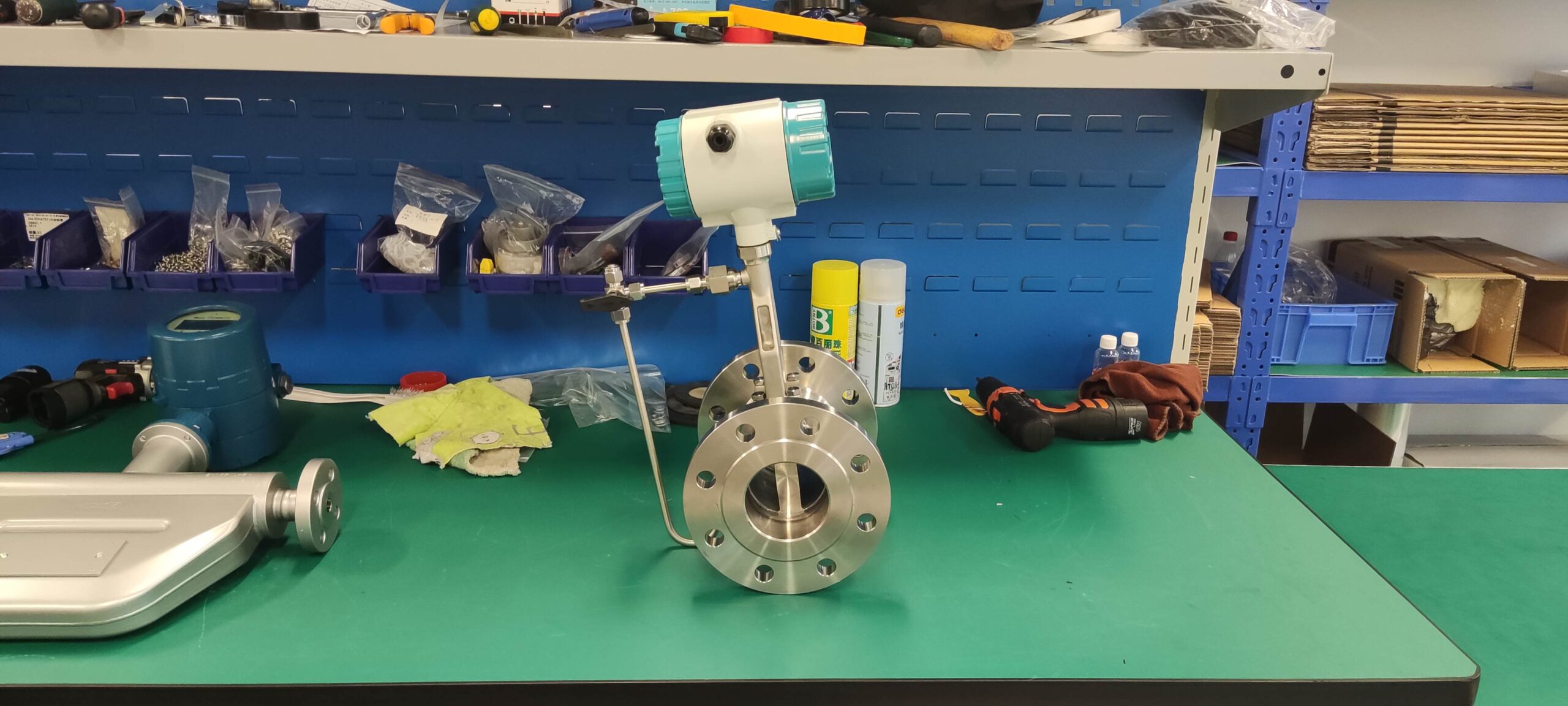

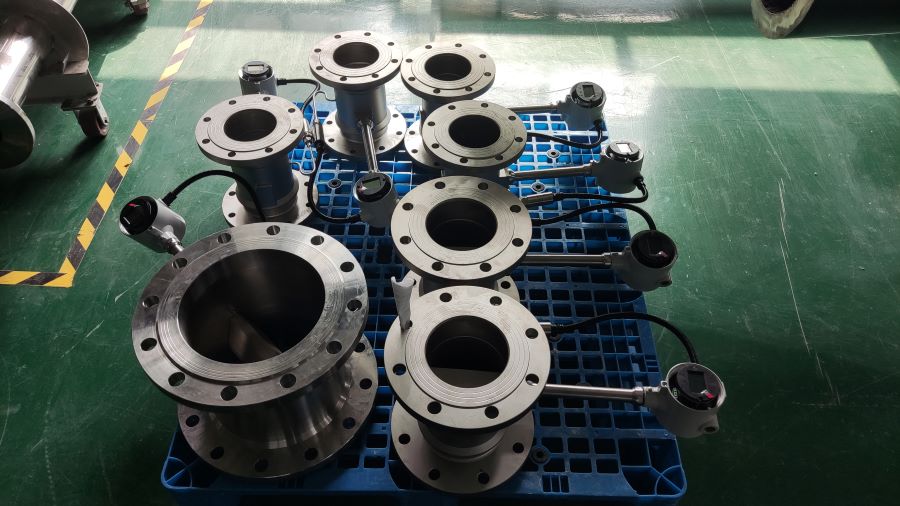

4. When measuring compressed air, the sensor can be installed on a vertical pipe with an infinite flow direction.

Installation of vortex flowmeters: Select a location where the pipeline does not vibrate for installation. Vortex flowmeters are relatively sensitive to mechanical vibration, and their measurement results are prone to interference. Therefore, reliable support designs should be made for the pipelines before and after the flowmeter. Sufficient straight pipe sections should be left before and after the sensor. The installation requirements for the straight pipe sections before and after the vortex flowmeter are approximately 20D and 5D respectively. If there are insufficient straight pipes upstream and downstream, the fluid cannot fully unfold, and vortices and distortions will occur in the flow velocity distribution profile.