In-depth Analysis of Vortex Flowmeter Probes: Key Technologies and Selection Guide

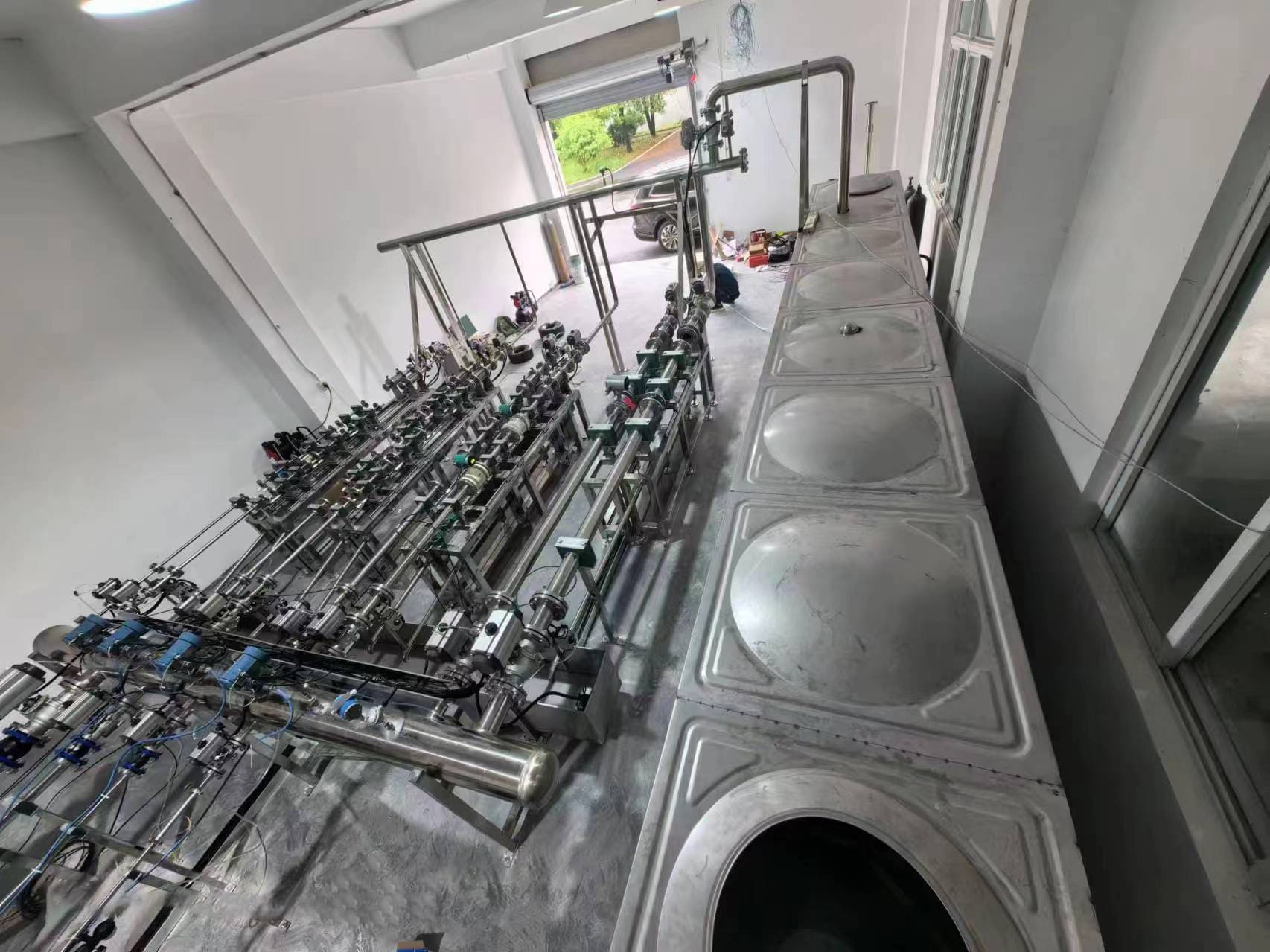

Vortex flowmeters play an important role in the measurement of steam, gas and liquid flow due to their simple structure, high reliability and wide application range. The probe, as its core sensing component, directly affects the measurement accuracy and stability of the instrument. This article will comprehensively analyze the key technologies of vortex flowmeter probes for you, helping you make a worry-free selection!

1. Probe working principle: Precise capture of the Karman vortex street effect

When a fluid flows through a blocking fluid (vortex generator), alternately arranged vortices (Karman vortex streets) will be generated behind it. The probe detects the vortex frequency through the built-in piezoelectric crystal or capacitive sensor and converts it into an electrical signal output, thereby calculating the flow rate.

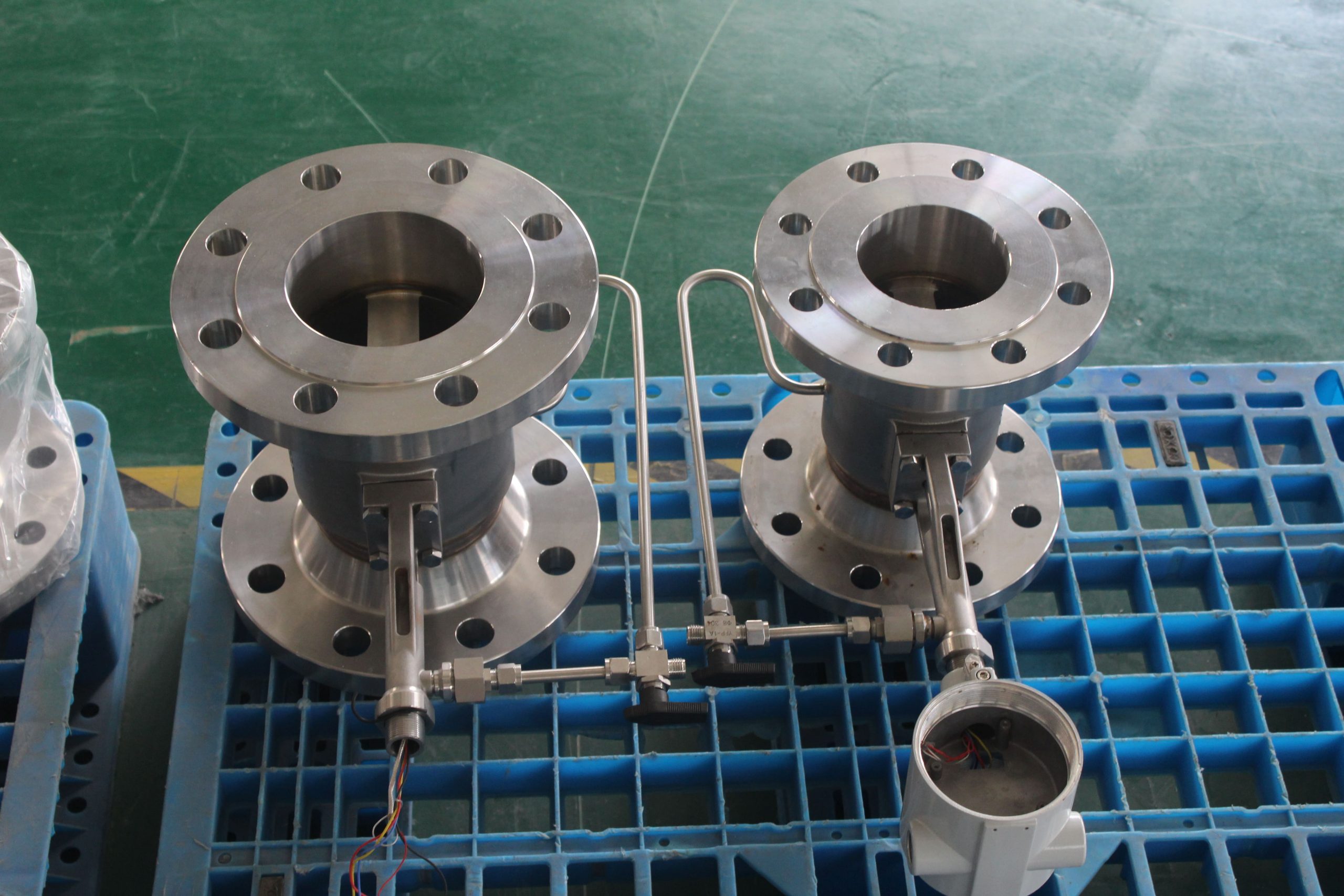

2. Comparison of probe types: Piezoelectric vs. capacitive

Piezoelectric probe

Advantages: Fast response, high sensitivity, suitable for gas and steam measurement.

Disadvantages: It is susceptible to mechanical vibration interference and shock absorption devices need to be installed in environments with strong vibration.

Capacitive probe

Advantages: Strong anti-vibration ability, suitable for measuring liquids and high-pressure gases.

Disadvantages: High cost and high requirements for the cleanliness of the medium.

Selection suggestion: Piezoelectric probes should be given priority for steam measurement. Capacitive probes are recommended for liquid or vibrating environments.

3. Probe material selection: The key to corrosion resistance and high-temperature resistance

Stainless steel (304/316) : Economical and practical, suitable for most non-corrosive media such as water and air.

Hastelloy: Resistant to strong acids and alkalis, suitable for corrosive media in the chemical industry.

Ceramic coating: Wear-resistant and high-temperature resistant, suitable for media containing particles or high-temperature steam.

4. Key points for probe installation and maintenance

Installation location: Ensure that there are sufficient straight pipe sections before and after (usually 10D before and 5D after, where D is the pipe diameter) to avoid flow field disturbances affecting accuracy.

Anti-vibration measures: Use flexible connections or shock-absorbing brackets in vibrating environments.

Regular inspection: Scaling or wear on the probe surface can affect signal strength and requires regular cleaning or calibration.

Recommendation of Applicable scenarios

Steam metering: Piezoelectric probe + stainless steel material, resistant to high temperature and high pressure.

Chemical corrosive medium: Hastelloy alloy probe, with strong corrosion resistance.

Liquid flow measurement: Capacitive probe, high stability.