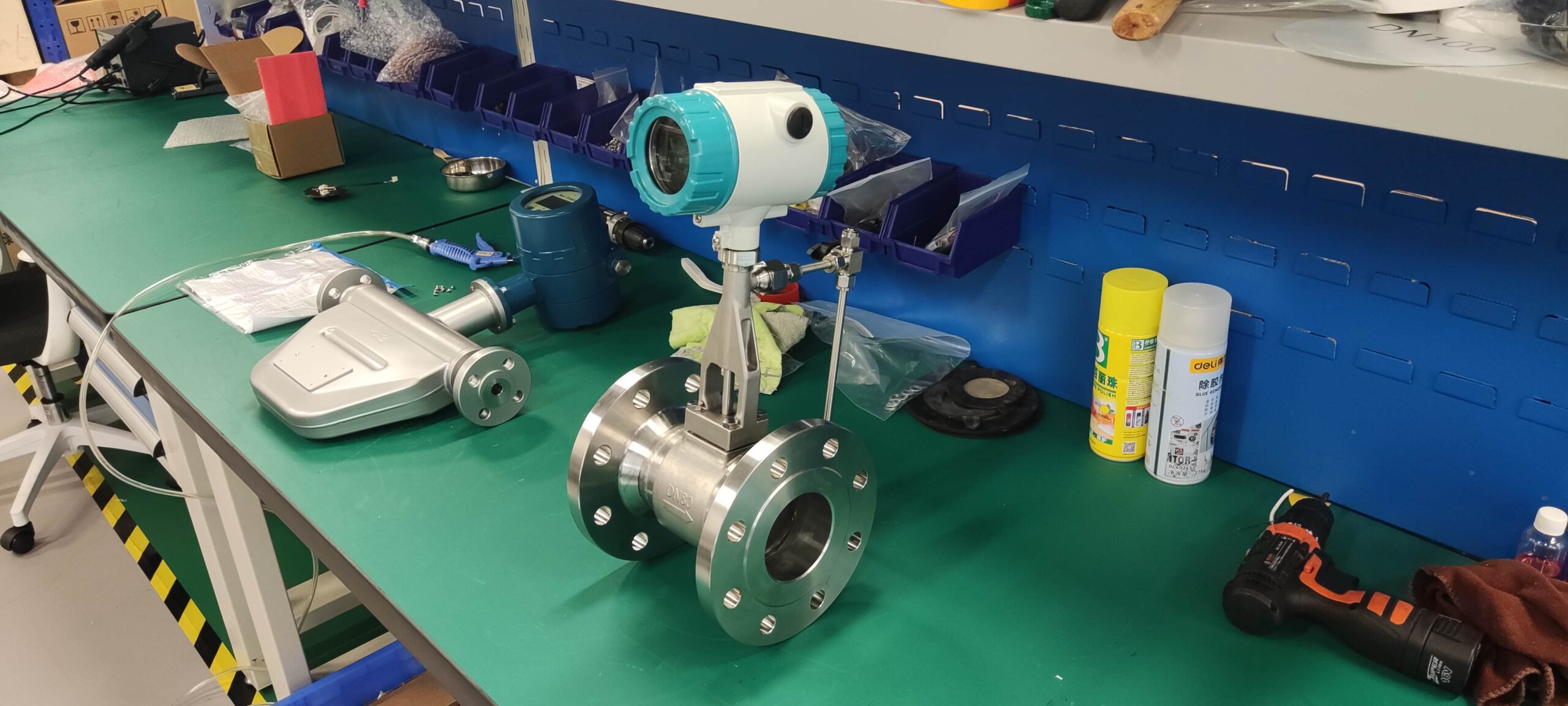

Vortex flowmeter: The “Flow Guardian” of Modern Industry

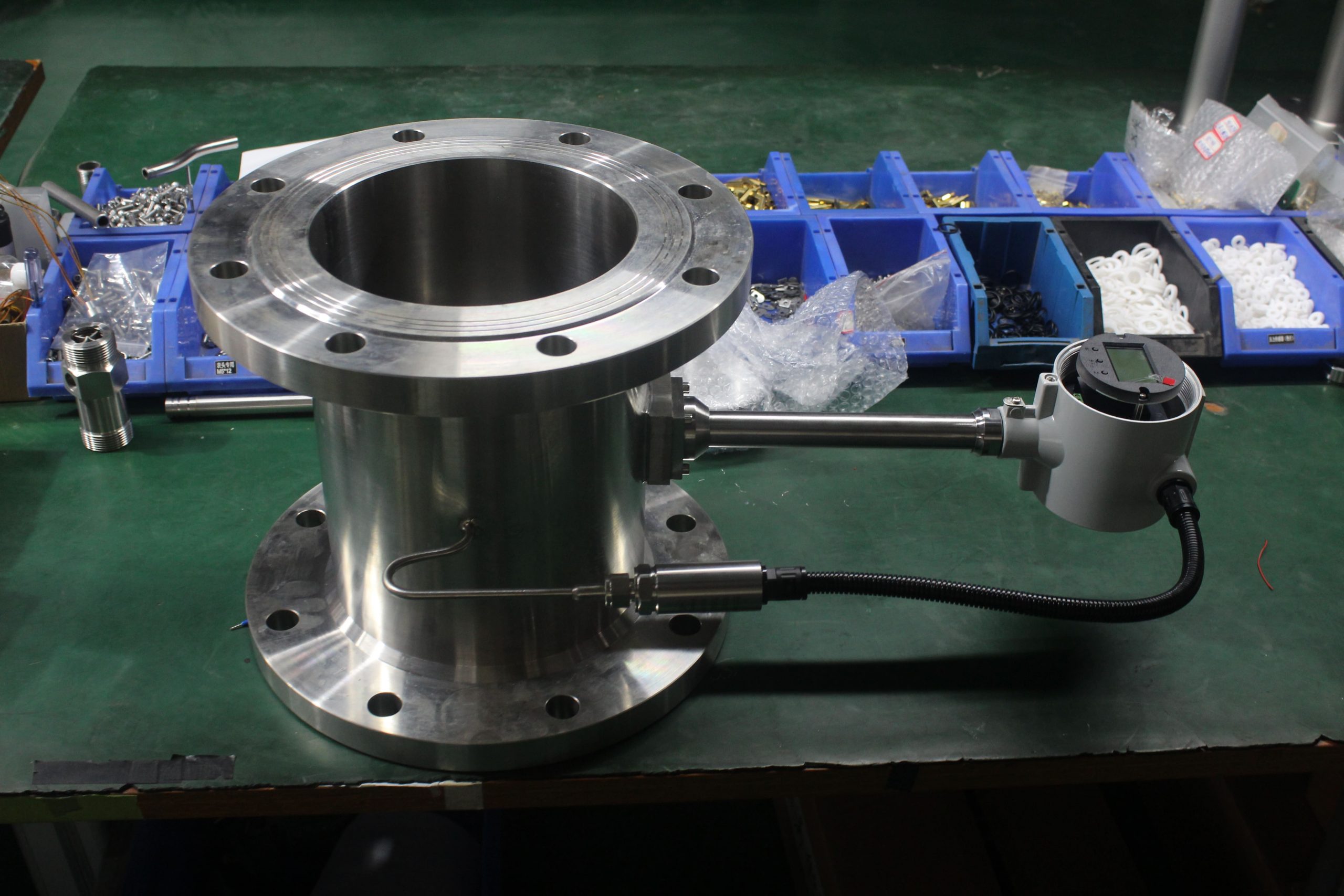

In modern industrial production, efficient and accurate flow measurement is the key to ensuring process stability and improving energy efficiency management. Vortex flowmeters, with their advantages of simple structure, high reliability and wide application range, have become the “main force” in flow monitoring in industries such as petrochemicals, energy and power, metallurgy and pharmaceuticals, providing solid support for the intelligent upgrade of industry.

In modern industrial production, efficient and accurate flow measurement is the key to ensuring process stability and improving energy efficiency management. Vortex flowmeters, with their advantages of simple structure, high reliability and wide application range, have become the “main force” in flow monitoring in industries such as petrochemicals, energy and power, metallurgy and pharmaceuticals, providing solid support for the intelligent upgrade of industry.

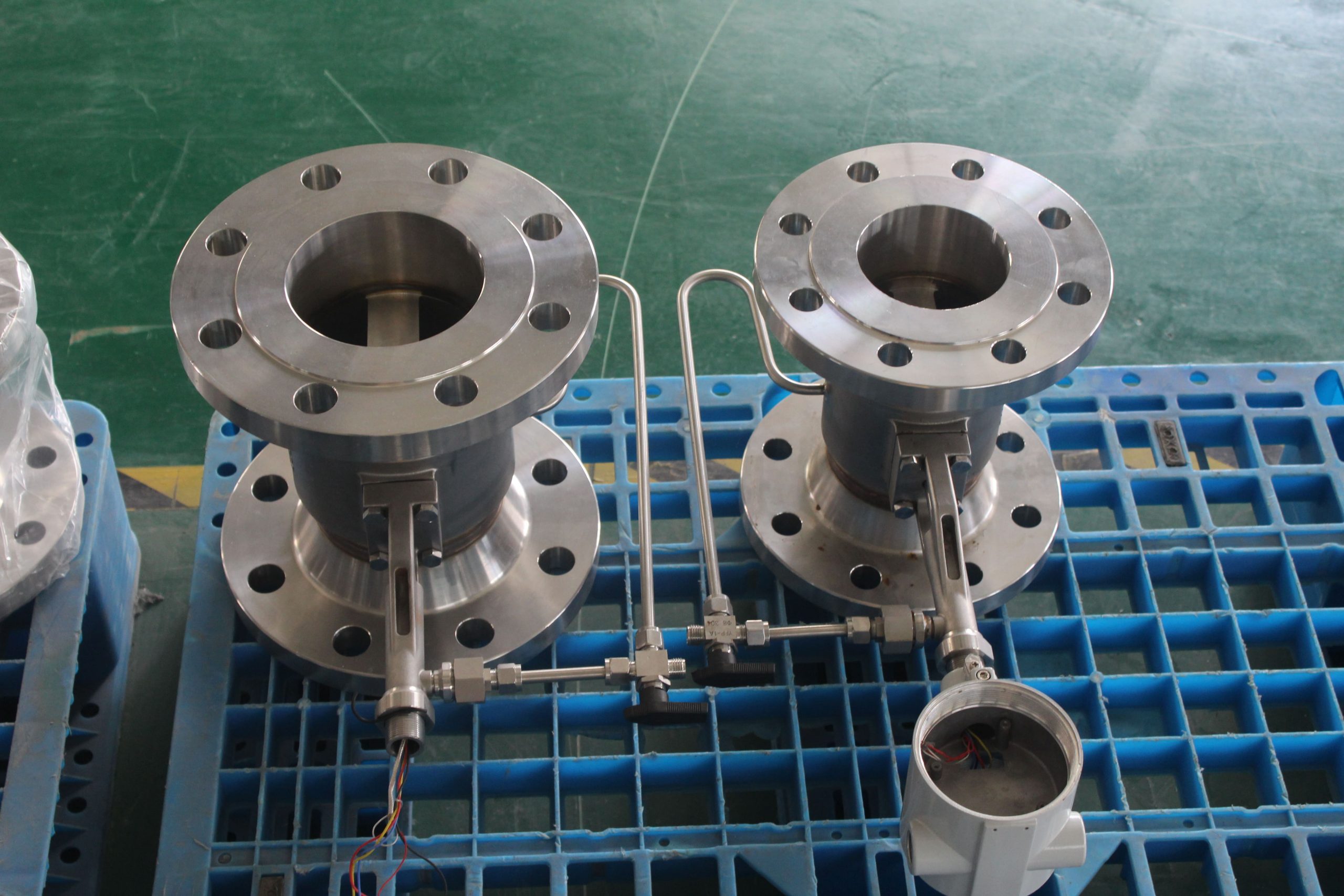

1. Petrochemical industry: Stable monitoring to ensure safe production

In the petroleum, natural gas and chemical processes, vortex flowmeters can accurately measure the flow of gases, steam and liquids, and are not affected by the electrical conductivity of the medium. Its high pressure and high temperature resistance makes it suitable for harsh environments such as cracking units and oil pipelines. It can provide real-time flow data, facilitating process optimization and safety control.

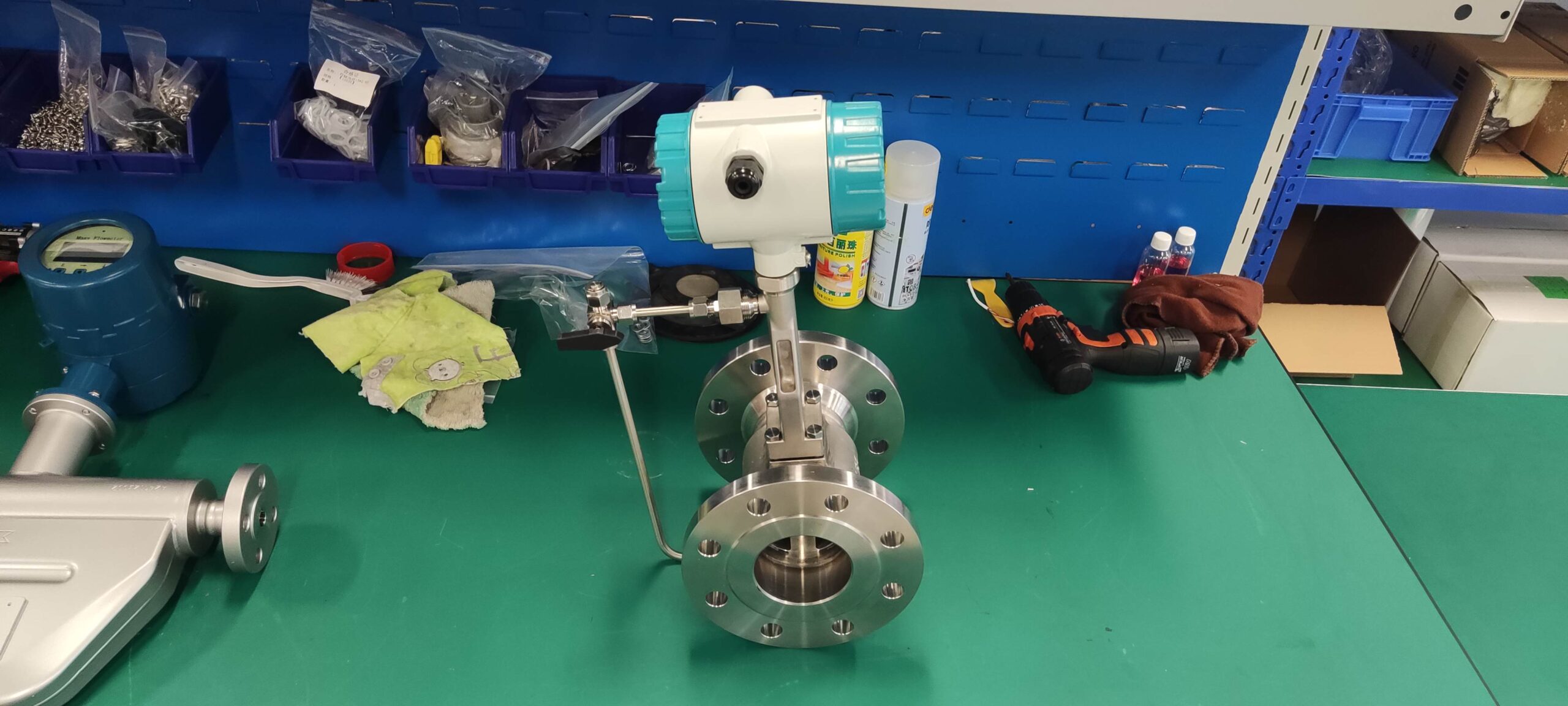

2. Energy and Power: Efficient metering, facilitating energy conservation and consumption reduction

In cogeneration and boiler systems, vortex flowmeters are widely used for steam flow measurement, helping power plants monitor energy consumption and optimize combustion efficiency. Its low-pressure loss design reduces energy waste. Combined with an intelligent control system, it can achieve dynamic adjustment and significantly lower carbon emissions.

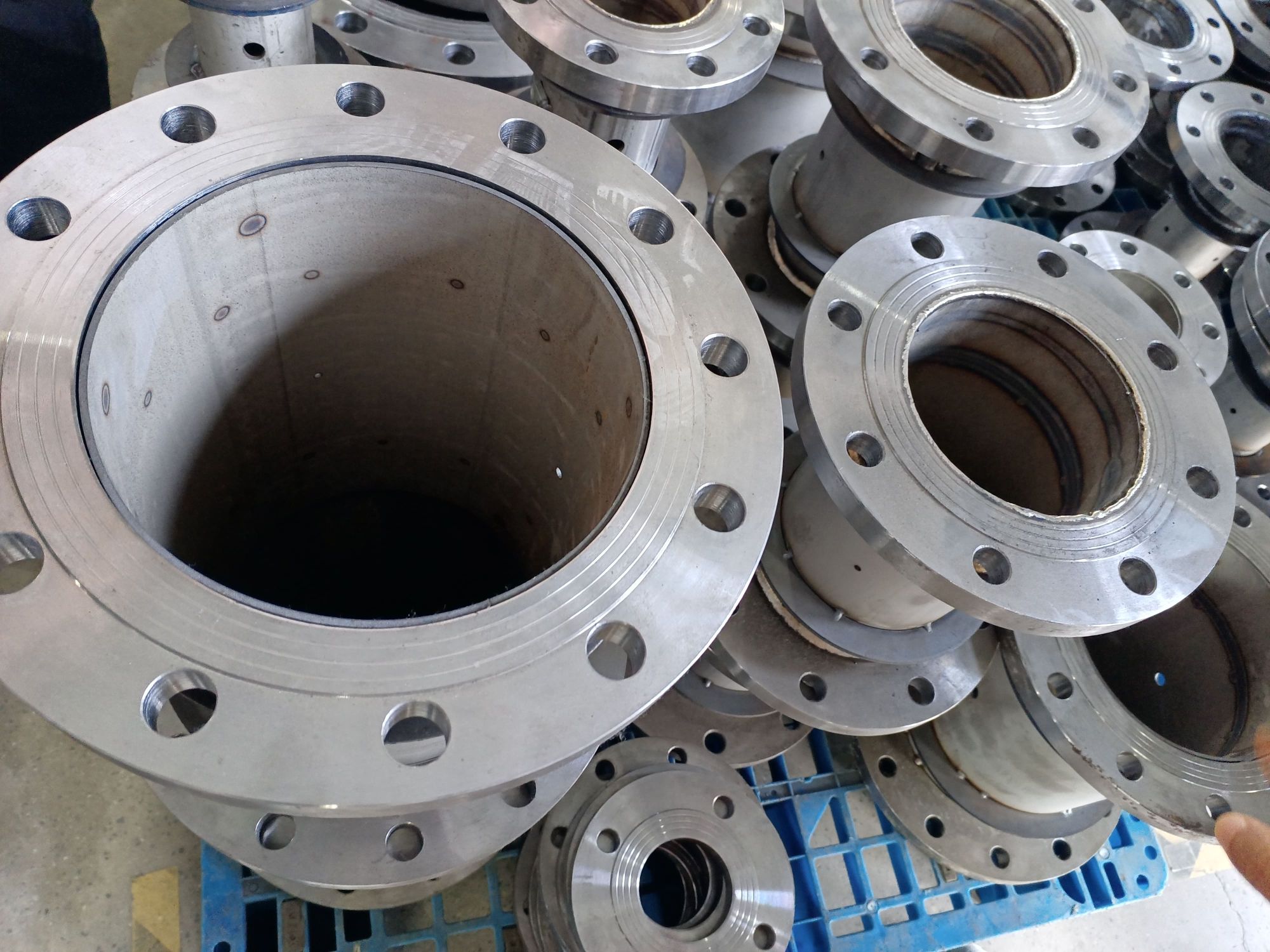

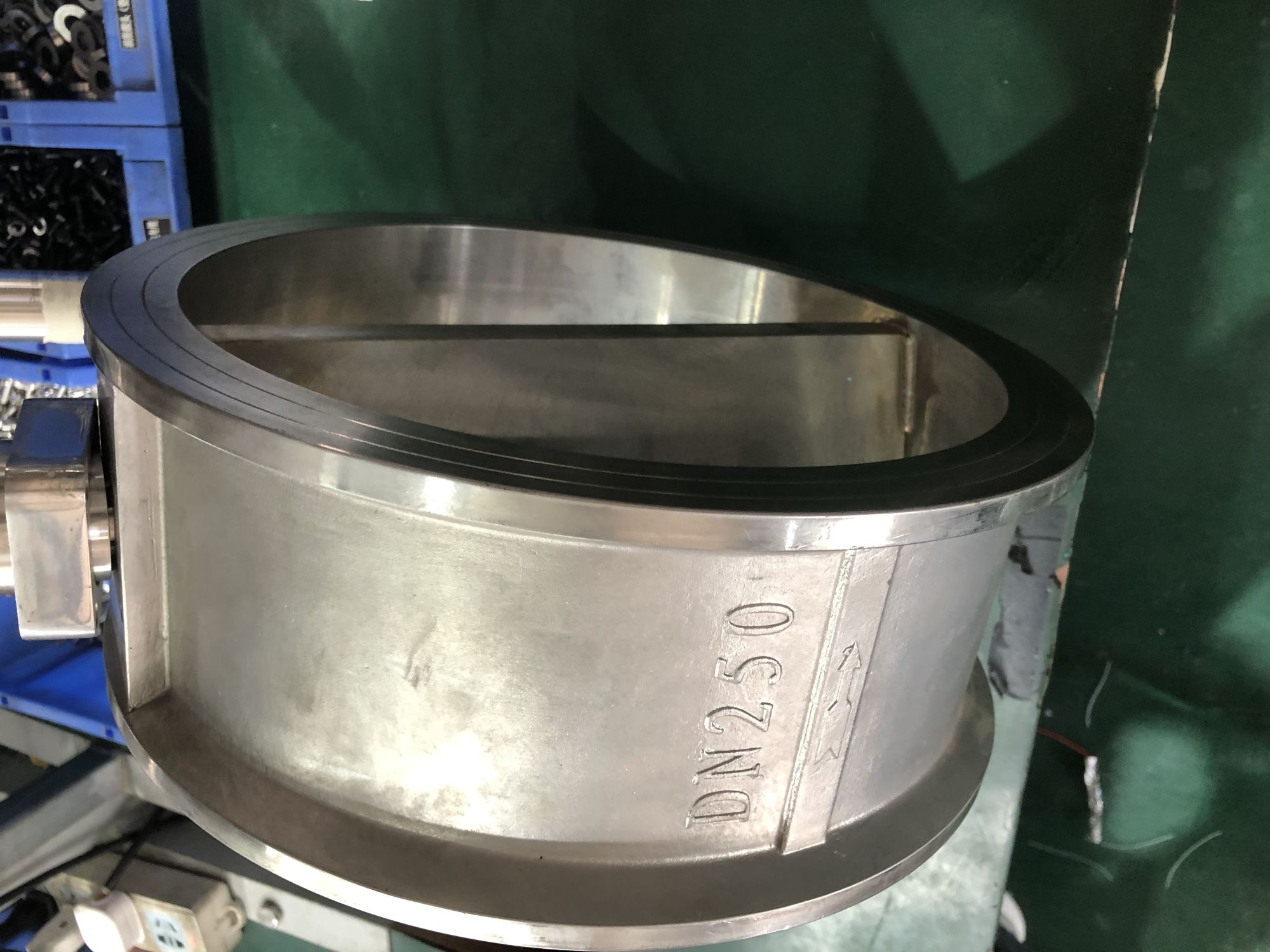

3. Metallurgy and pharmaceuticals: High hygiene standards, adaptable to complex media

In pharmaceutical, food-grade liquid transportation and metallurgical cooling systems, vortex flowmeters adopt a hygienic design with no dead corners for retention, meeting GMP certification requirements. Meanwhile, its strong anti-vibration performance can cope with high flow velocity and pulsating flow conditions, ensuring the long-term stability and reliability of measurement data.

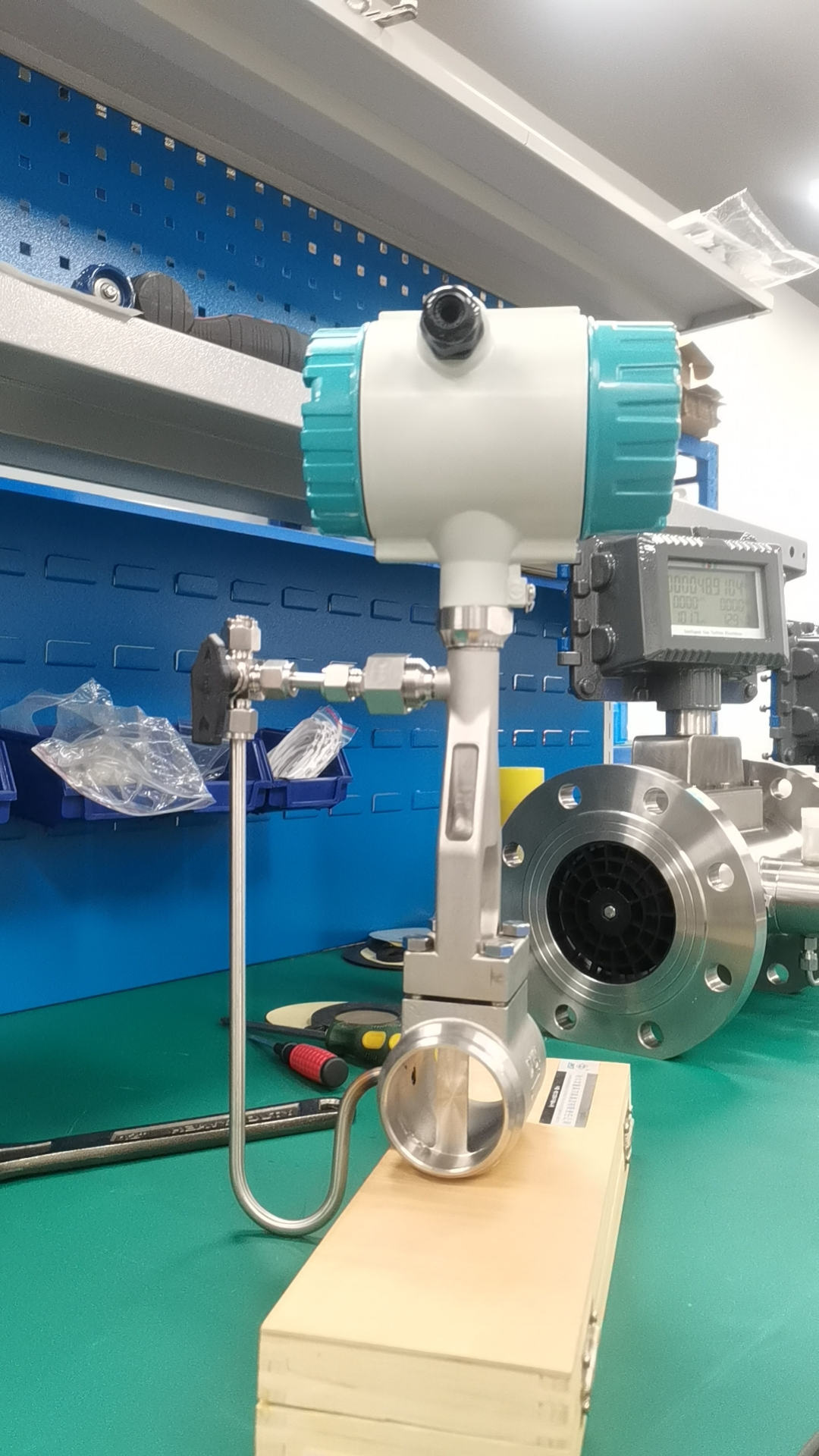

4. Smart Industry: Data integration, driving digital transformation

With the development of Industry 4.0, vortex flowmeters have been deeply integrated with the Internet of Things and cloud platforms, achieving remote monitoring and intelligent analysis of flow data. Factories can predict maintenance needs in real time through trend predictions, reduce the risk of downtime, and build a more efficient and low-carbon intelligent manufacturing system.