Gas turbine flowmeter common problem solution

Gas turbine flowmeter common problem solution

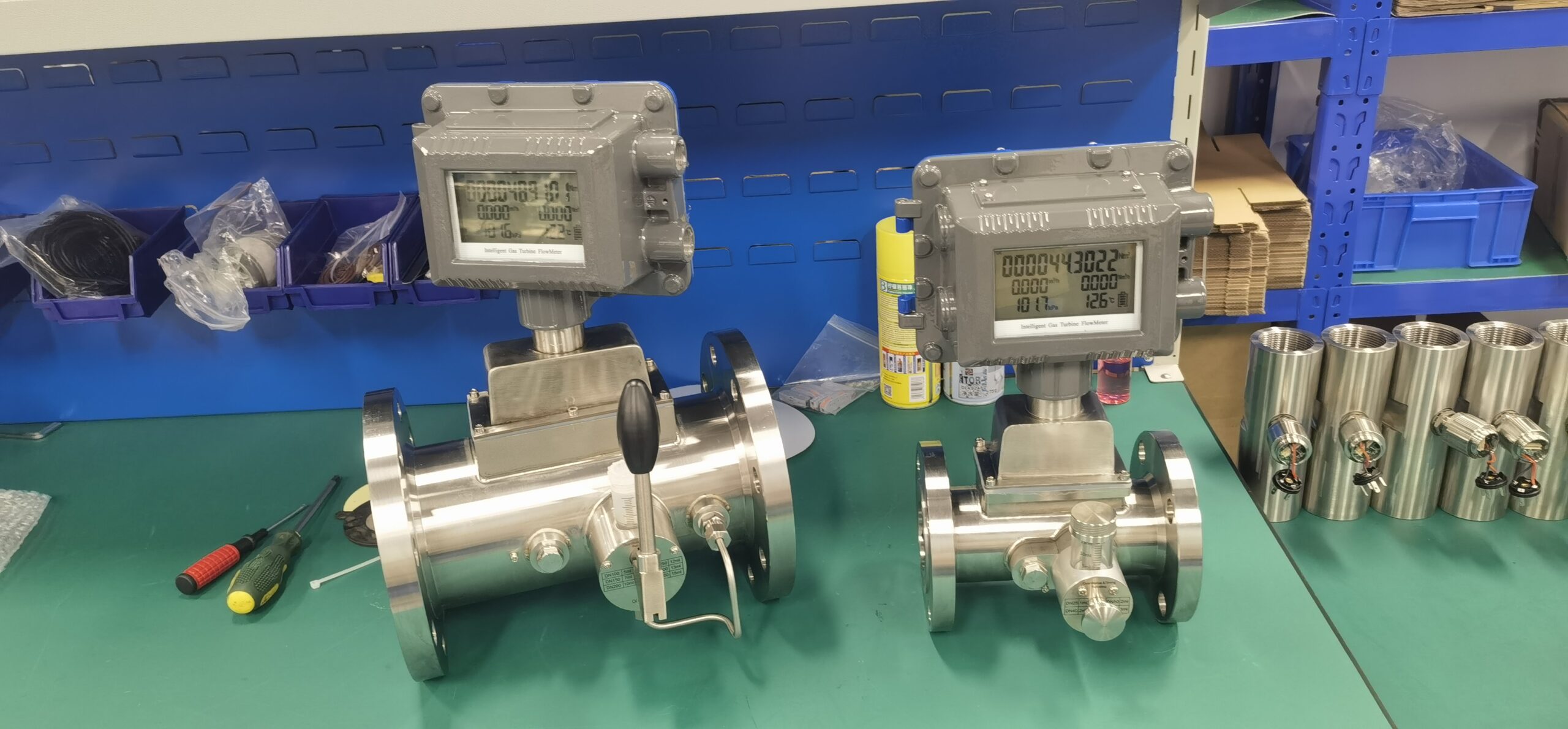

1. In the process of installation and connection of gas turbine flowmeter, it is necessary to ensure the accuracy of every link, including on-site inspection before installation, wiring of gas turbine flowmeter during installation, system grounding wire, etc., so as to ensure the detection of real data and accurate output.

2. For the operating measurement system, the method of “double-track measurement, comparison and confirmation” and the “alternative method” can be used to confirm and eliminate the fault of the metering gas turbine flowmeter in operation.

3, the gas turbine flowmeter regularly cleans the gas turbine flowmeter as a whole, and if necessary, the sensing head part of the gas turbine flowmeter can be purged to avoid the condensation of impurities at the sensing head. In the cold season, the addition of heat tracing devices in the metering straight pipe section and the gas turbine flowmeter section is also conducive to easing the condensation of impurities in the metering gas turbine flowmeter.

4, the gas turbine flow meter regularly drains the pipeline, especially the water in front of the straight pipe section, and sets a special person to discharge regularly according to the specific situation, so as to reduce the water in the metering pipe section as much as possible and eliminate the pulsation in the fluid to a greater extent.