How to choose vortex flowmeters used in industrial production

When selecting a vortex flowmeter, it is necessary to provide the measured medium, product density and viscosity, working condition temperature, working condition pressure (, maximum flow rate, normal flow rate).

2. Depending on the medium and requirements, it is also necessary to supply small flow rates, pipeline inner diameters, flow velocity constraints, the percentage of mixed gas, working conditions and standard density, desired equipment methods and pipeline standards, etc.

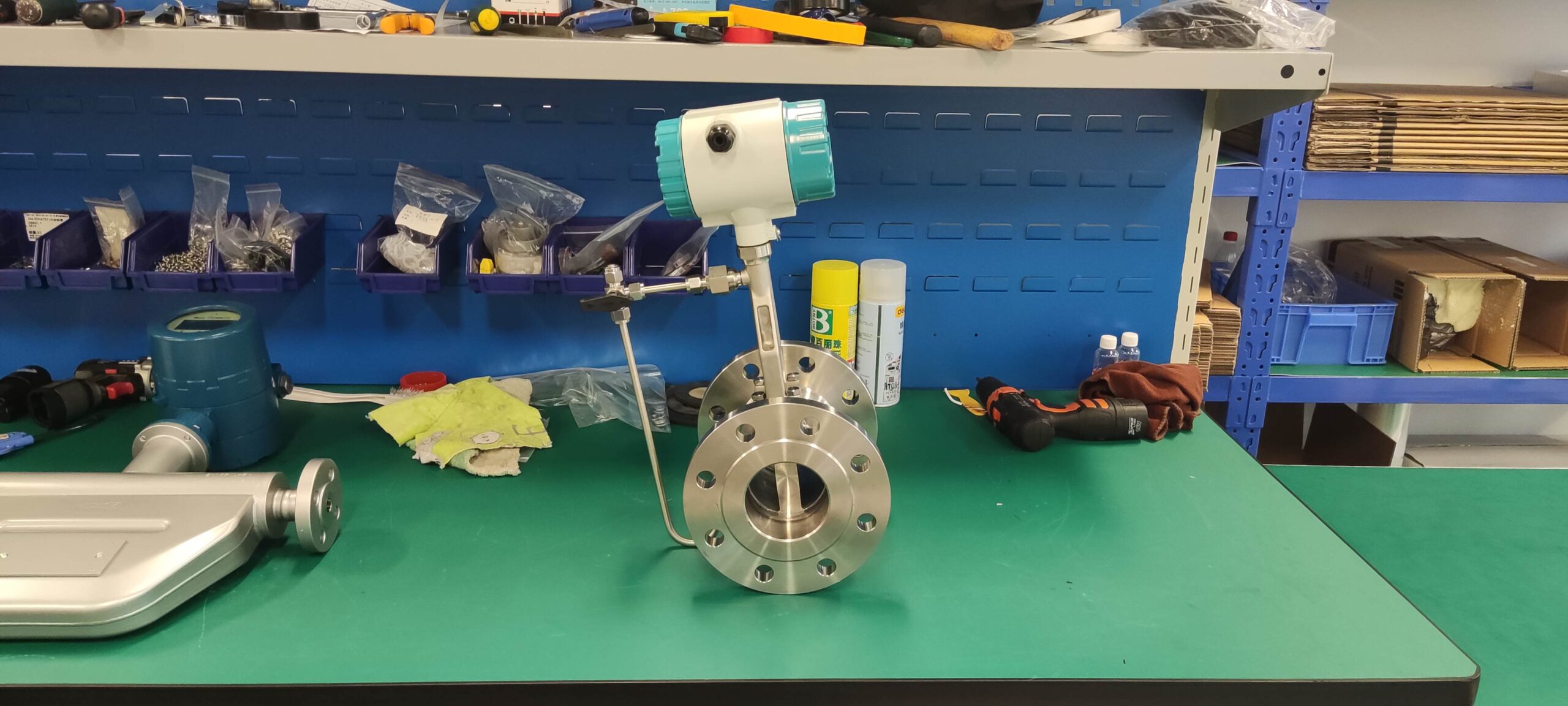

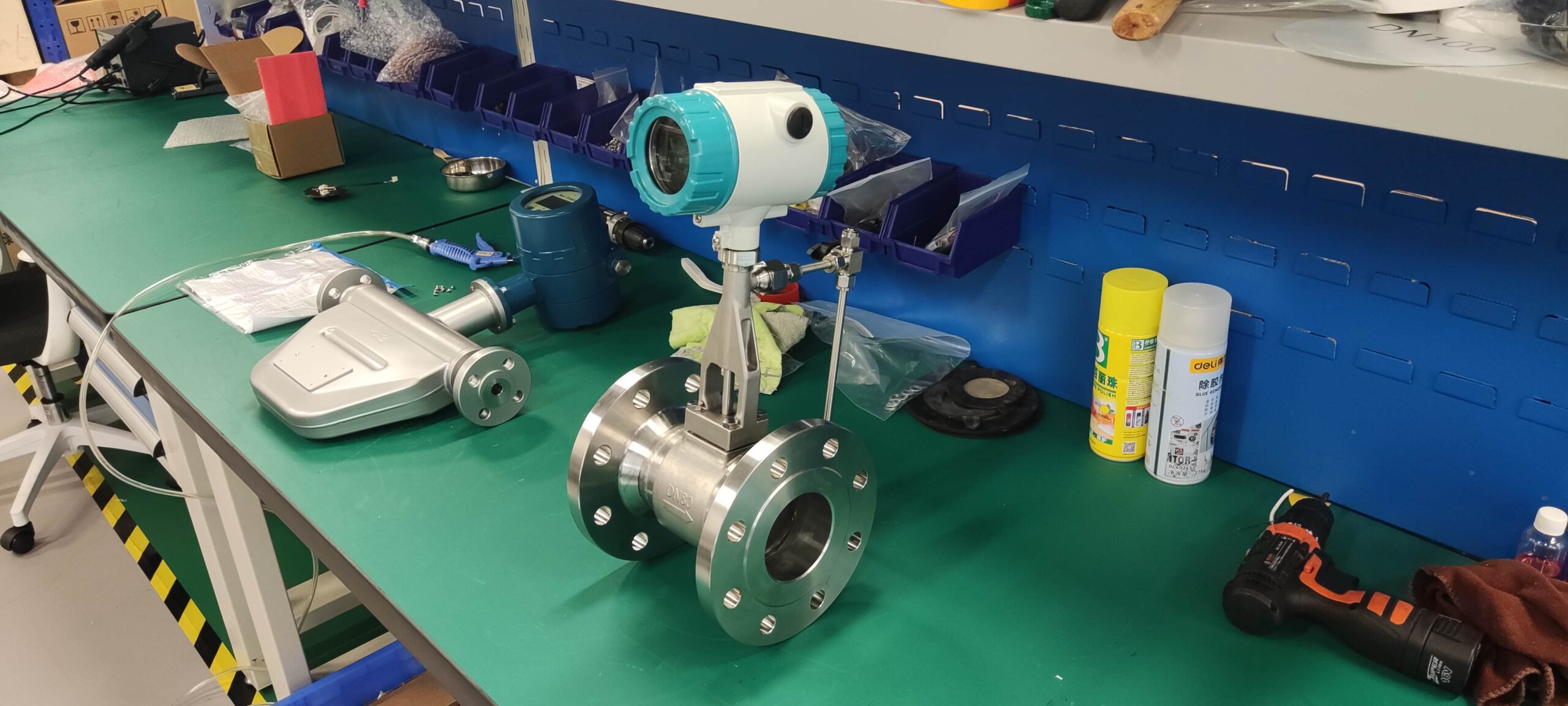

3. For general measurement of high-temperature media or overhead pipelines, it is recommended to use split type gauges.

4. The surface diameter is calculated and selected through the selection software based on the parameters provided by the user. It is recommended that the surface be operated at 1/2 to 2/3 of the large flow rate.

The equipment on the surface is also an important link in use. Only with scientific and reasonable equipment can external factors such as interference and unstable measurement be prevented, ensuring the safe and reliable use of the surface.

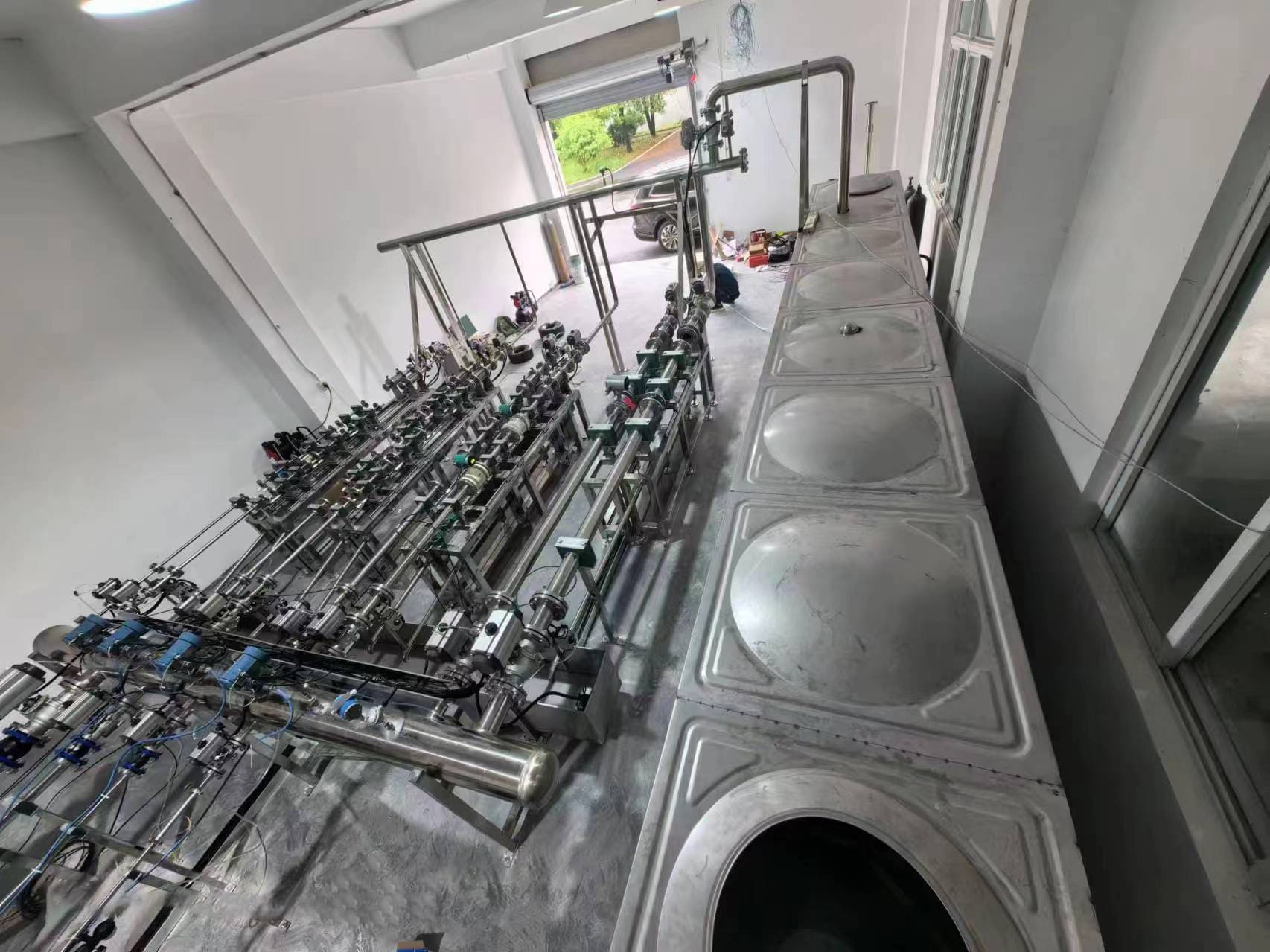

1. The flow direction is the same. The horizontal pipeline vortex generator body is a straight device. The straight pipeline requires the bottom in and top out direction.

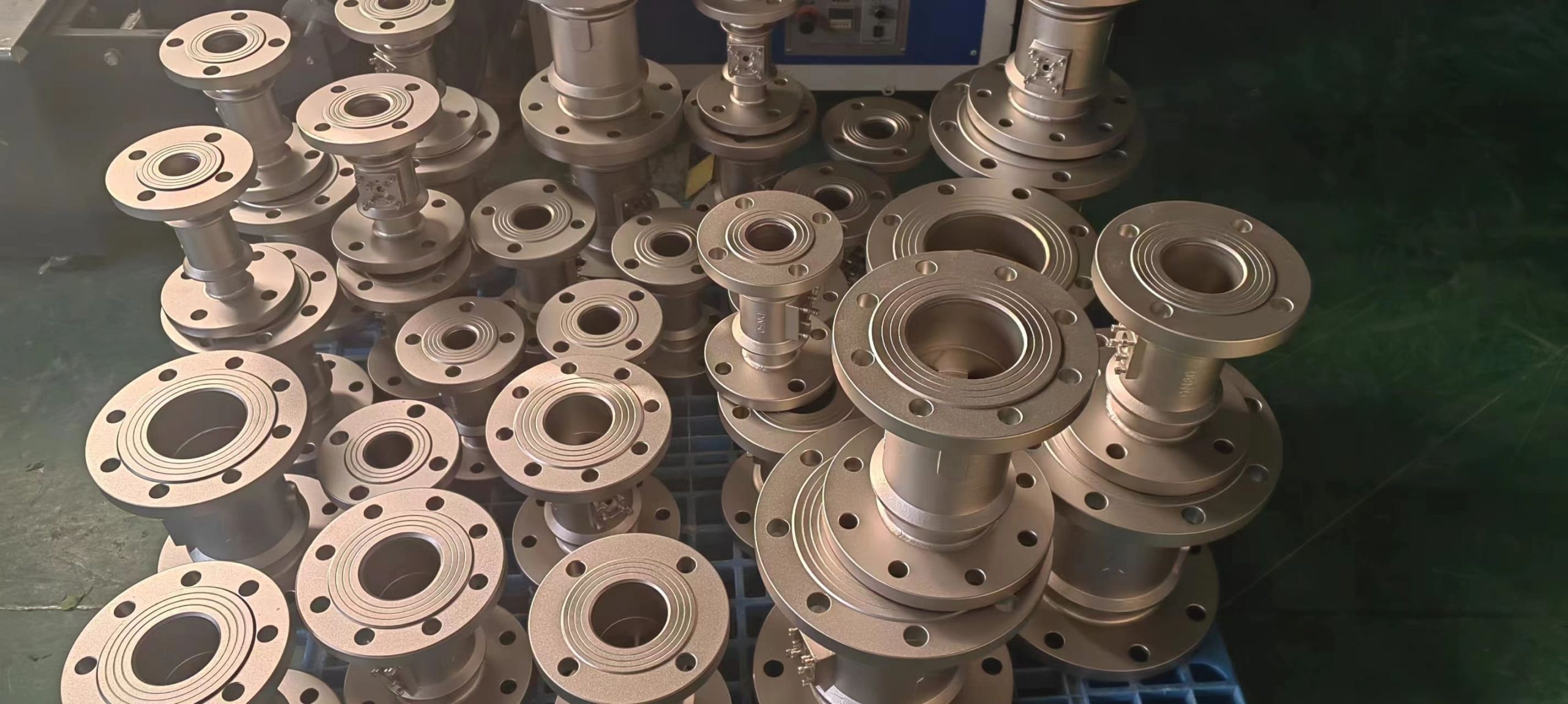

2. The pipe diameter should be the same as the outer diameter; otherwise, it needs to be reduced or expanded. Pay attention to the differences between the outer and inner diameters of DIN (German standard) and ANSI (American standard) and the national standard G.

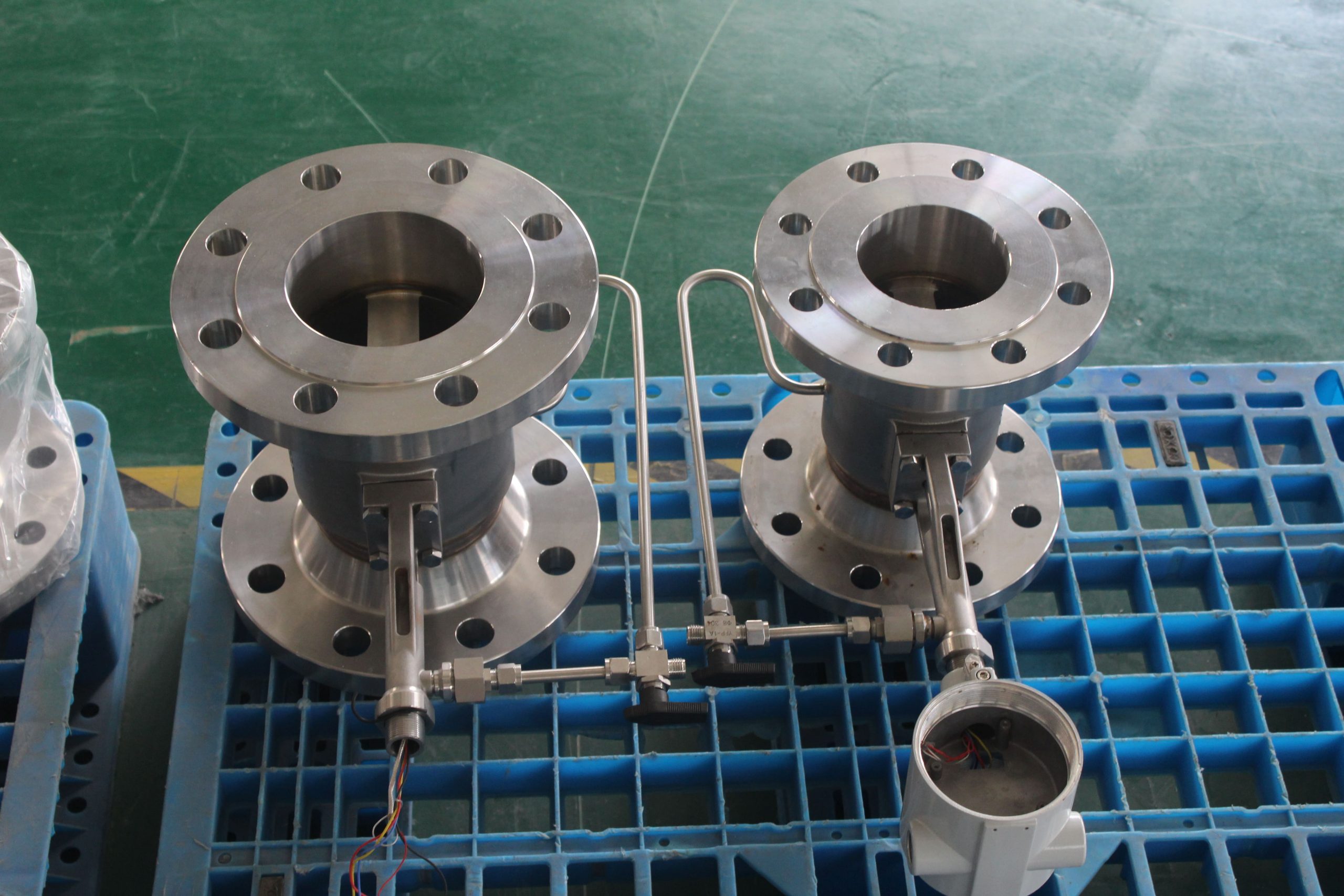

3. Ensure that the inner walls of the pipes at both ends of the flowmeter are lubricated and free from surfacing welding. Especially flange welding;

4. The flange must be welded first before installing the surface. Surface welding is not allowed.

5. The gasket must not be inserted into the pipeline. It is necessary to remove the surface to check the gasket marks.

6. Requirements for the length of straight pipe sections before and after the exterior: At least 20D for the inlet and at least 10D for the outlet. When there are multiple elbows, valves, etc. at the inlet, the straight pipe section should be longer.

7. Requirements for pipe vibration: Pipes must not have severe vibration; otherwise, support should be added or flexible hoses should be used for connection.

8. Environmental requirements for the converter: The ambient temperature for the common type converter should be between -20 ° C and 60 ° C. The EX type requires an ambient temperature range of -20 to 40 degrees. When measuring high-temperature media, please use a split equipment method.

9. Sealing requirements for the converter: Tighten the end cover, pay attention to sealing the cable interface, and set a drip point at the cable entrance.

10. Cable requirements: Shielded cables must be used for signal lines. The connection between the split-type surface sensor and the converter must use the dedicated cable provided by the manufacturer, and pay attention to wiring correctly according to the wire number.