What advantages does the intelligent vortex flowmeter have

Vortex flowmeters have advantages that other flowmeters do not have and have developed rapidly since their introduction. According to statistics, the proportion of vortex flowmeters used in developed countries such as Japan, Europe and America has increased significantly and they have been widely applied in various fields. Judging from the current trend, vortex flowmeters will play a dominant role in future flow meters and are ideal alternatives to orifice plate flowmeters.

Let’s first take a look at what advantages vortex flowmeters have.

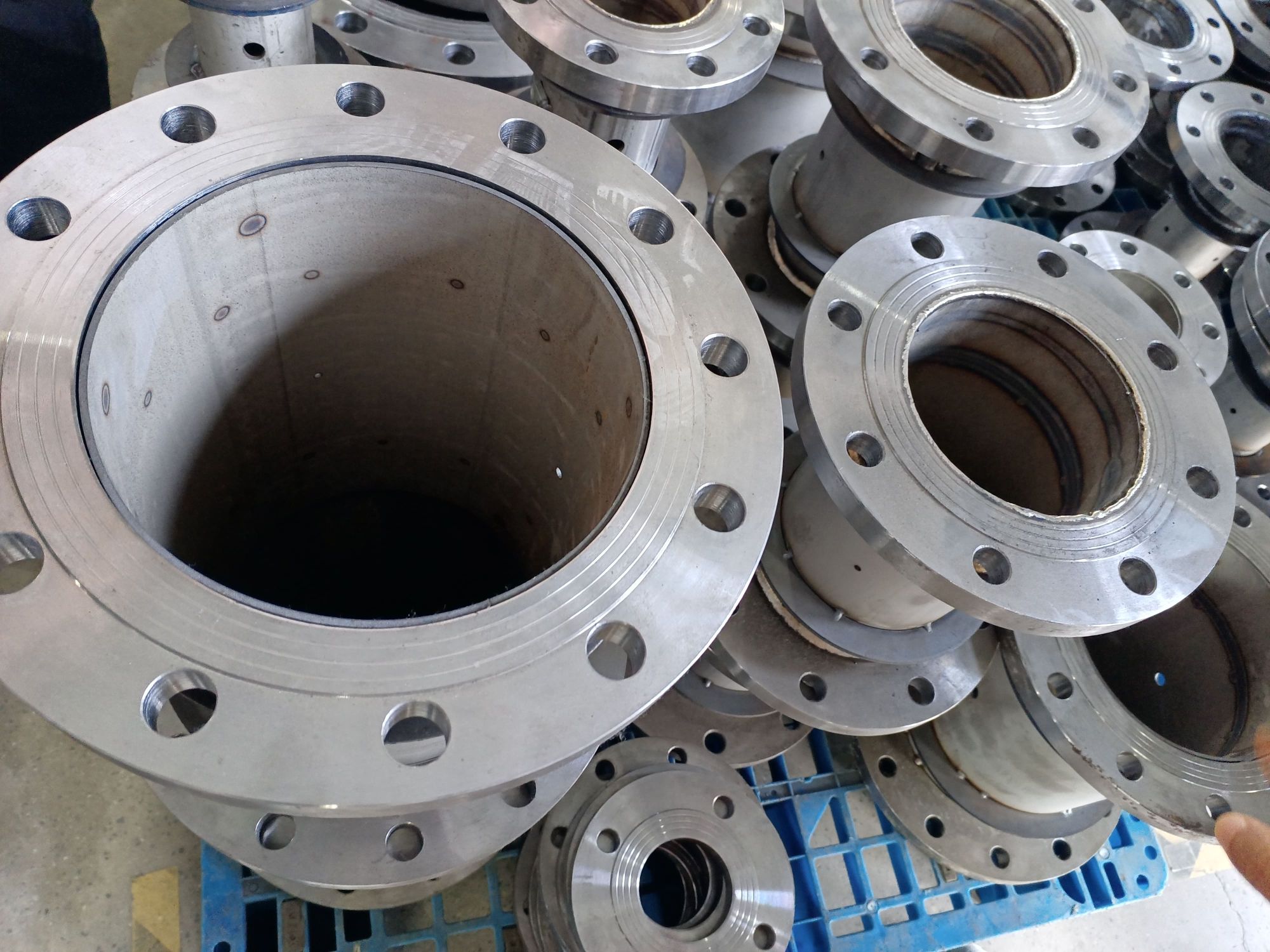

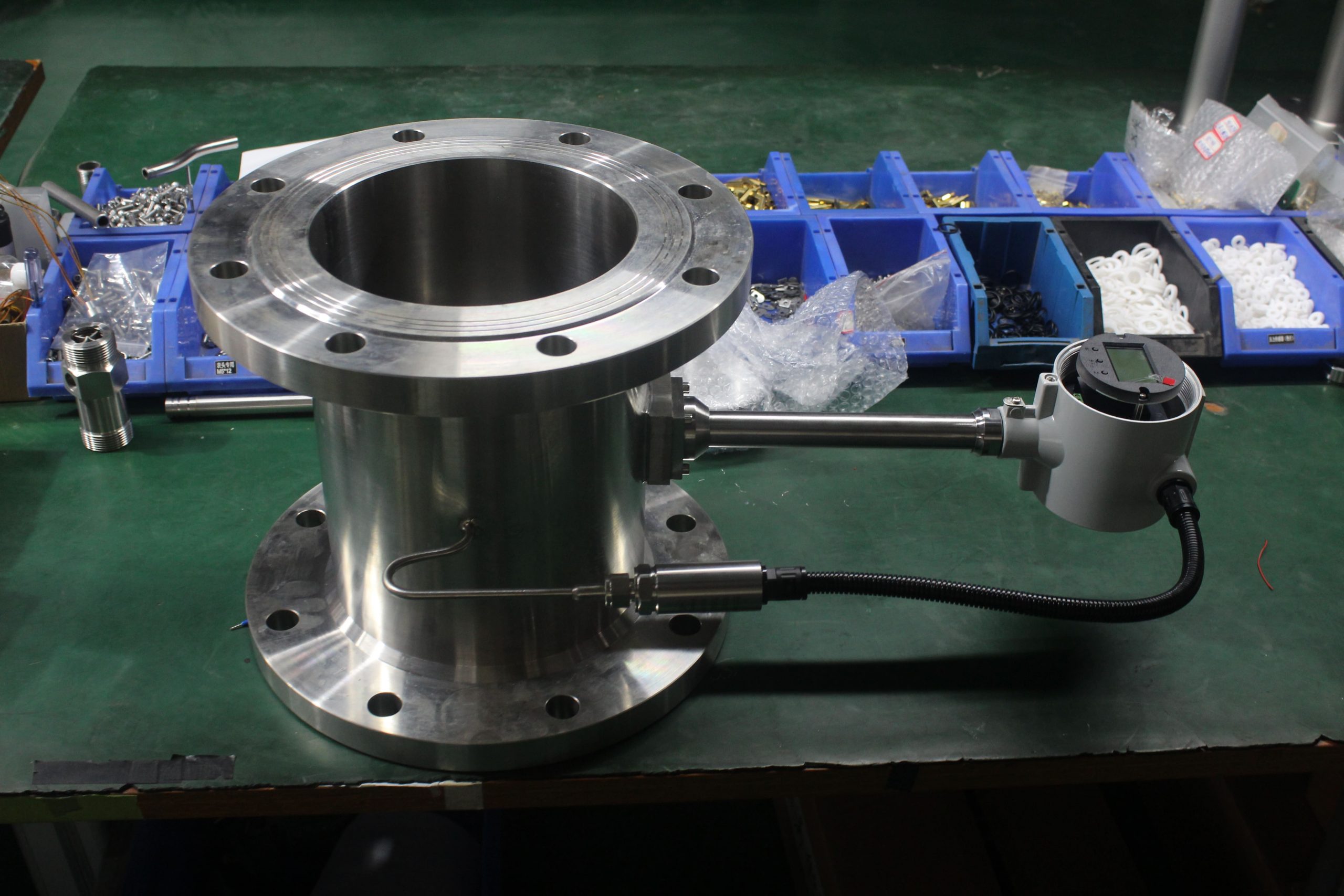

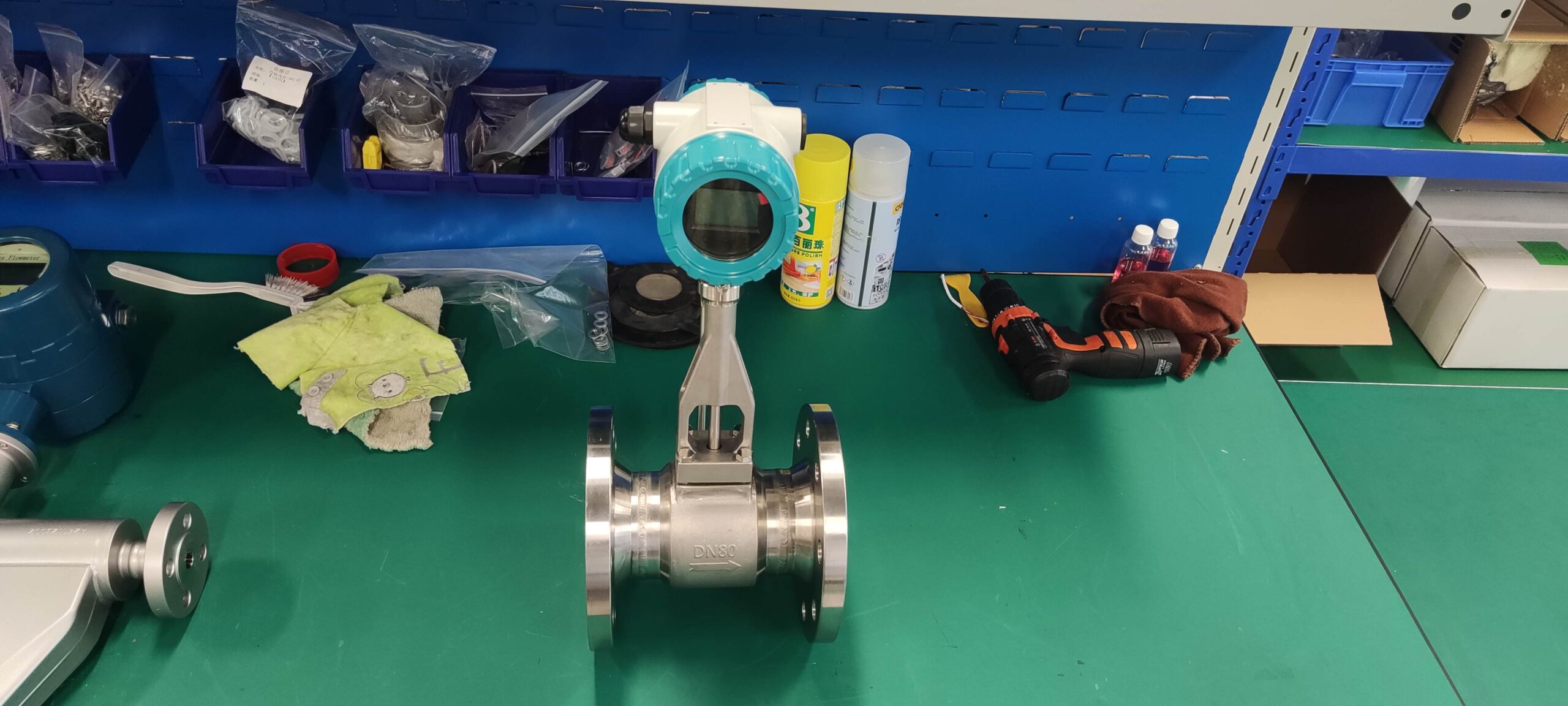

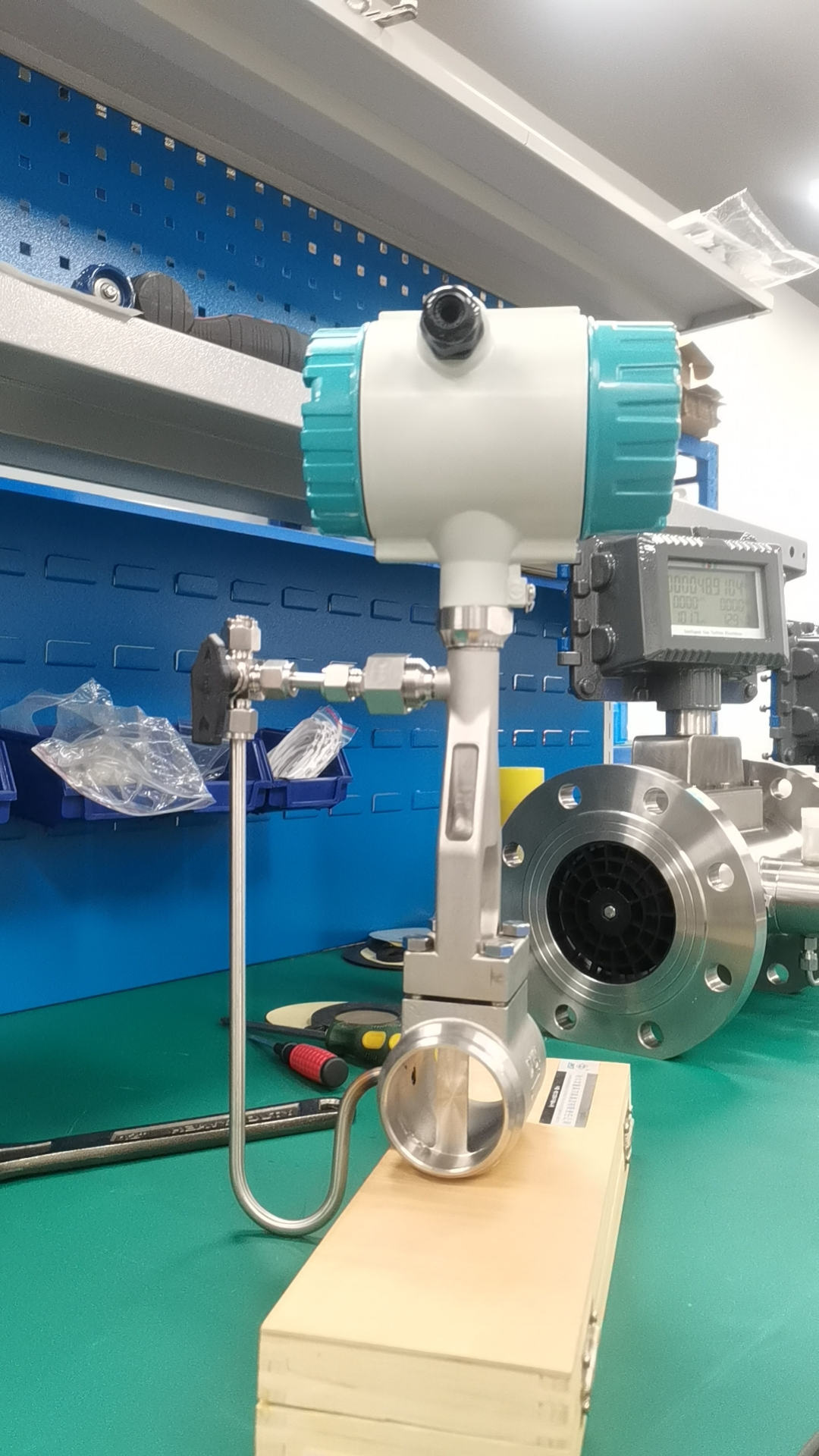

The structure is simple and sturdy, with no moving parts, and it operates very stably over a long period of time.

2. It is very convenient to maintain and has low installation costs.

3. The sensor does not come into direct contact with the medium, ensuring stable performance and a long service life.

4. Output pulse signals proportional to the flow rate, with no zero drift, high precision, and convenient for networking with a computer.

5. Wide measurement range, with a range ratio up to 1:10.

6. It has low pressure loss, low operating costs and is more energy-efficient.

7. Within a certain range of Reynolds numbers, the output signal frequency is not affected by changes in the physical properties and composition of the fluid. The instrument coefficient is only related to the shape and size of the vortex generator. There is no need for compensation when measuring the volume flow rate of the fluid. After replacing the parts, there is no need to recalibrate the instrument coefficient.

8. It has a wide range of applications and can measure the flow of both gases and liquids.

The verification cycle is 2 to 4 years.

Vortex flowmeters have many advantages and are also suitable for measuring flow in various working conditions. There is a lot of knowledge involved in the selection and installation of vortex flowmeters. When people choose and install vortex flowmeters, the following aspects should be carefully considered:

1. As the vortex flowmeter is a velocity-type flowmeter, the stability of vortex separation is affected by the flow velocity. Therefore, it has certain requirements for the straight pipe section, generally 10D before and 5D after.

When measuring liquids, the upper limit flow rate is generally 0.5 to 8m/s due to the pressure loss and cavitation phenomena.

When measuring gases, the upper limit flow rate is limited by the change in the compressibility of the medium, and the lower limit flow rate is limited by the Reynolds number and the sensitivity of the sensor. For steam, it is 8 to 25m/s.

4. As stress-type vortex flowmeters are relatively sensitive to vibration, when installing flowmeters in pipelines with significant vibration, certain vibration reduction measures should be taken for the pipelines.

5. As the stress-type vortex flowmeter uses piezoelectric crystals as the detection sensor, it is limited by temperature, generally ranging from -40 to +300℃.

In addition, many strict requirements for the installation of vortex flowmeters are that long straight pipe sections are needed before and after, which will increase the installation cost for users and is also easily restricted by the site. However, at present, some manufacturers can offer the design of reducing the diameter inside the flowmeter. Such a design significantly reduces the need for users to specially install straight pipe sections for vortex flowmeters, thereby saving a considerable amount of installation costs for enterprises.