Does a vortex flowmeter need temperature and pressure compensation when measuring steam

Whether vortex flowmeters need temperature and pressure compensation when measuring steam mainly depends on the nature of the steam being measured and the requirements for measurement accuracy.

For saturated steam:

The density of saturated steam is directly corresponding to the pressure and temperature of saturated steam. Therefore, when measuring saturated steam, vortex flowmeters generally only need to perform either pressure compensation or temperature compensation, and do not need to perform both simultaneously. This is because, as long as one of the indicators (temperature or pressure) is measured, the density of the steam can be calculated through the corresponding formula or data table, thereby accurately calculating the flow rate of the steam.

For superheated steam:

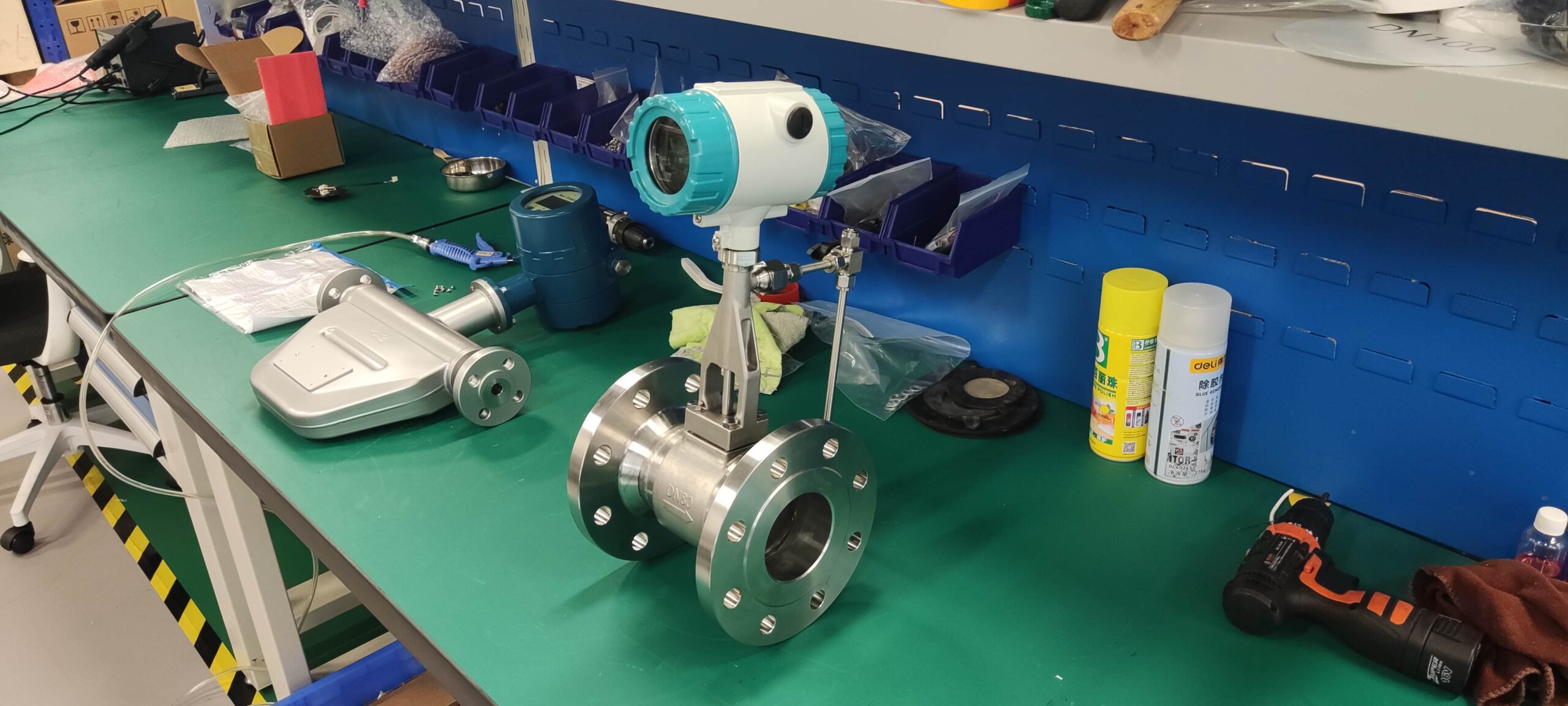

The density of superheated steam is closely related to both temperature and pressure. When measuring superheated steam, in order to improve the measurement accuracy, it is usually necessary to install temperature and pressure compensation simultaneously. This is because the density of superheated steam changes significantly with variations in temperature and pressure. Without temperature and pressure compensation, the true flow rate of the steam cannot be accurately calculated.

The implementation methods of temperature and pressure compensation:

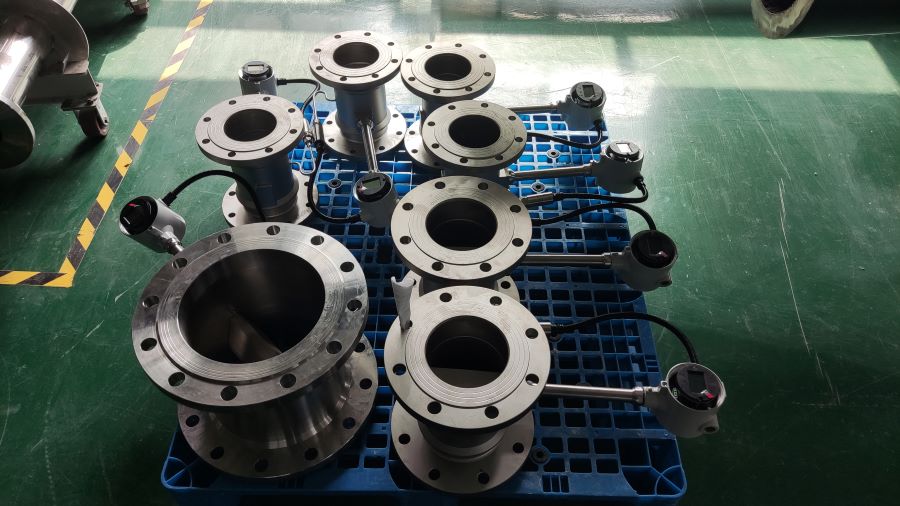

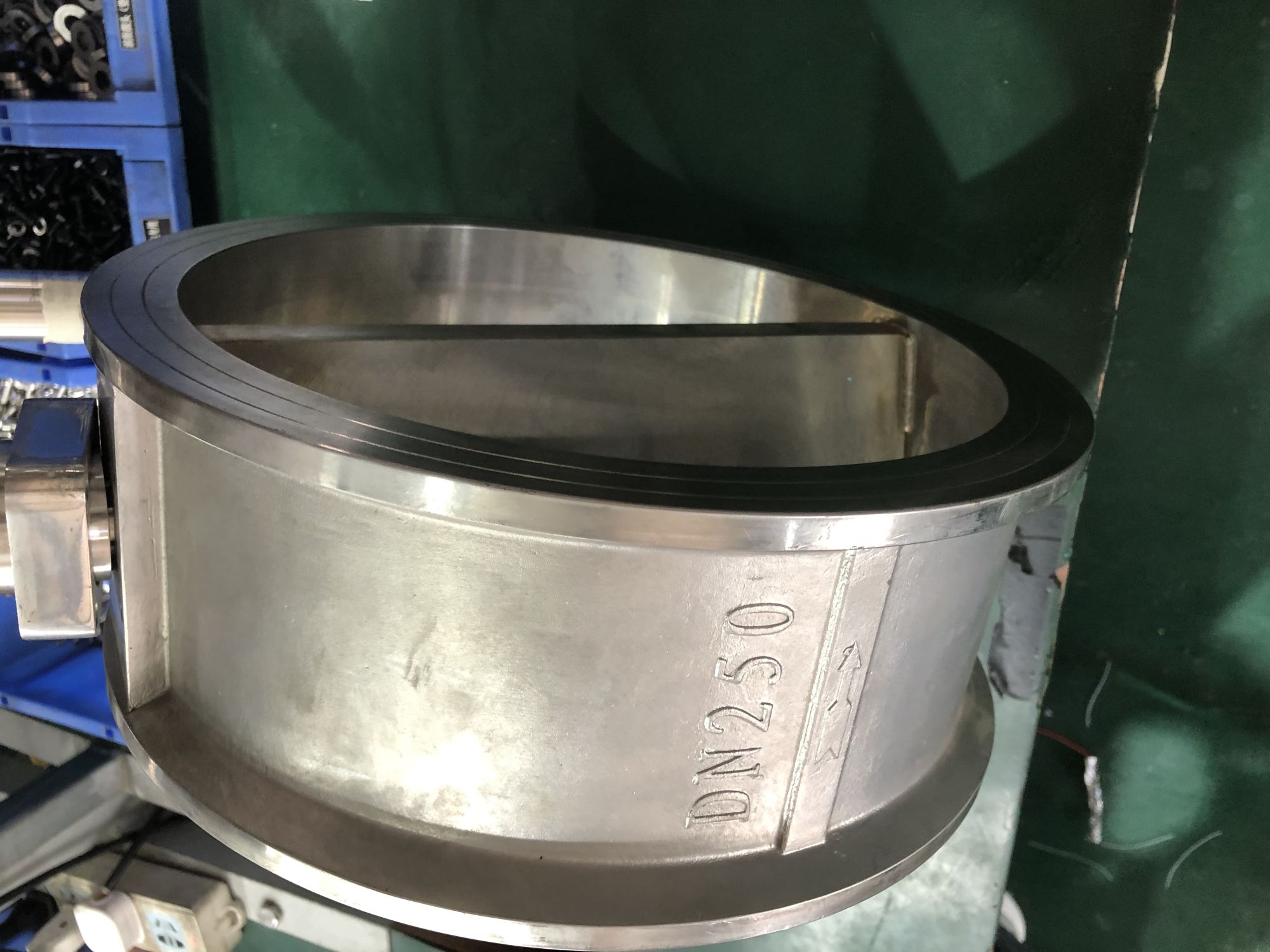

Integrated temperature and pressure compensation: The temperature and pressure sensors are integrated into the flowmeter for operation, measurement and display. This flowmeter, in an intelligent form, is equipped with built-in temperature and pressure compensation functions. The converter can directly convert and process the signals of volume, temperature, flow rate and pressure measured by the sensor, achieving the goal of integrated on-site display.

Split-type temperature and pressure compensation: It is composed of four instruments: a simple vortex sensor, a separate temperature sensor, a separate pressure transmitter, and a display instrument flow integrator. This approach requires users to install and configure sensors and transmitters by themselves, and process and display the data through a flow integrator.

Summary: Whether temperature and pressure compensation is required for measuring steam with a vortex flowmeter should be determined based on the nature of the steam to be measured (saturated steam or superheated steam) and the requirements for measurement accuracy. When choosing a vortex flowmeter, users should select the appropriate compensation method and flowmeter model based on their actual needs to ensure the accuracy and reliability of the measurement results.