Several common minor faults of liquid turbine flowmeters

1.The pulsating flow of water sources has a relatively large impact on the fluctuation of flow rate.

Solution: Increase the distance of the straight pipe between the pump and the flowmeter to stabilize the flow rate.

1.The pulsating flow of water sources has a relatively large impact on the fluctuation of flow rate.

Solution: Increase the distance of the straight pipe between the pump and the flowmeter to stabilize the flow rate.

2. The installation position of the liquid turbine flowmeter is too close to the valve or elbow. When the raw material passes through the valve or elbow section, it causes flow fluctuations.

Solution: At this point, staying away from the valve and elbow positions and ensuring a certain number of straight pipe sections before and after is a good way to solve the problem.

3. There are interference sources such as motors, frequency converters, and strong currents near the turbine flowmeter.

Solution: Ground the flowmeter instrument or add a filter capacitor. If the problem still cannot be solved, a better way is to stay away from the source of interference.

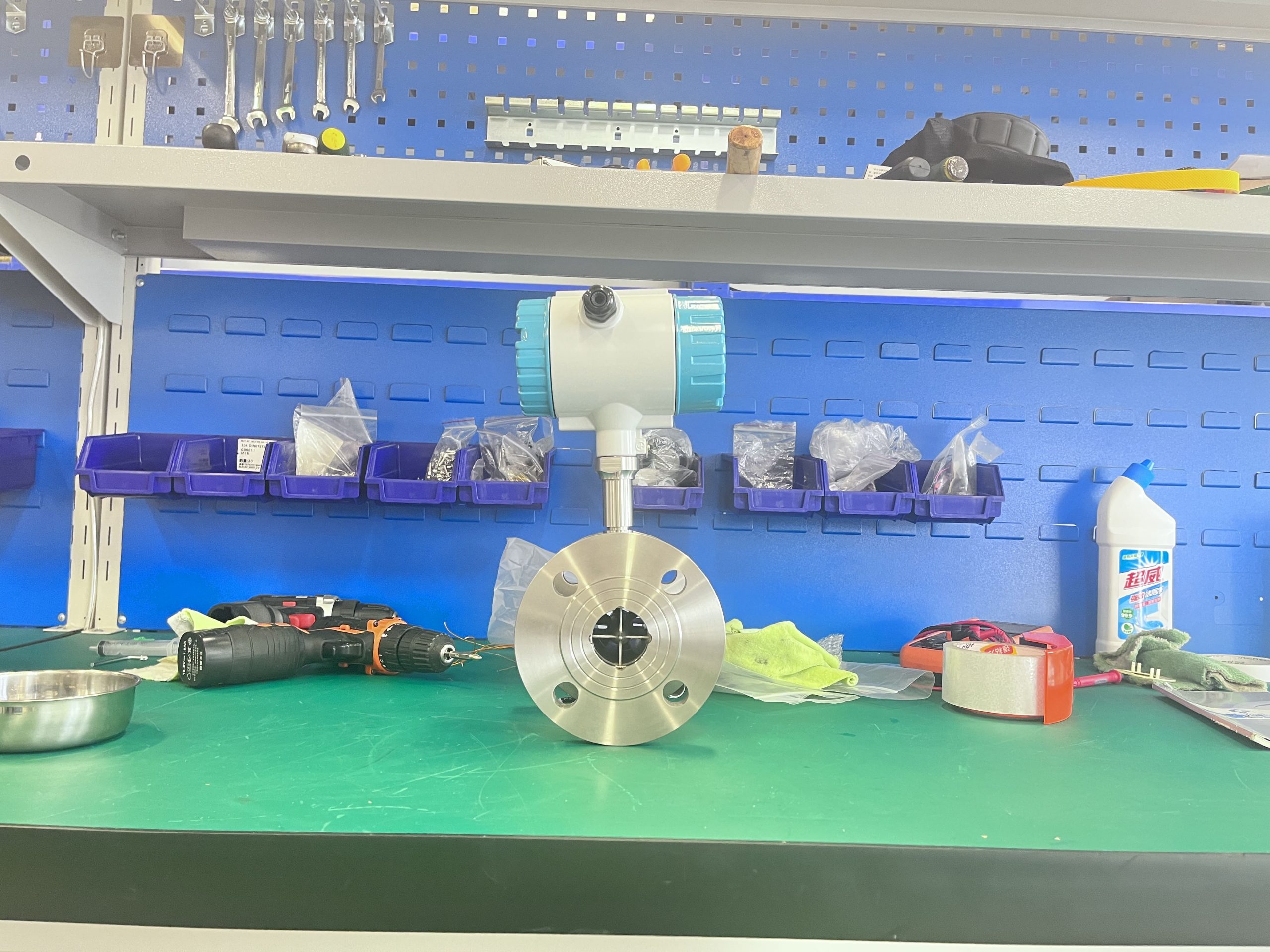

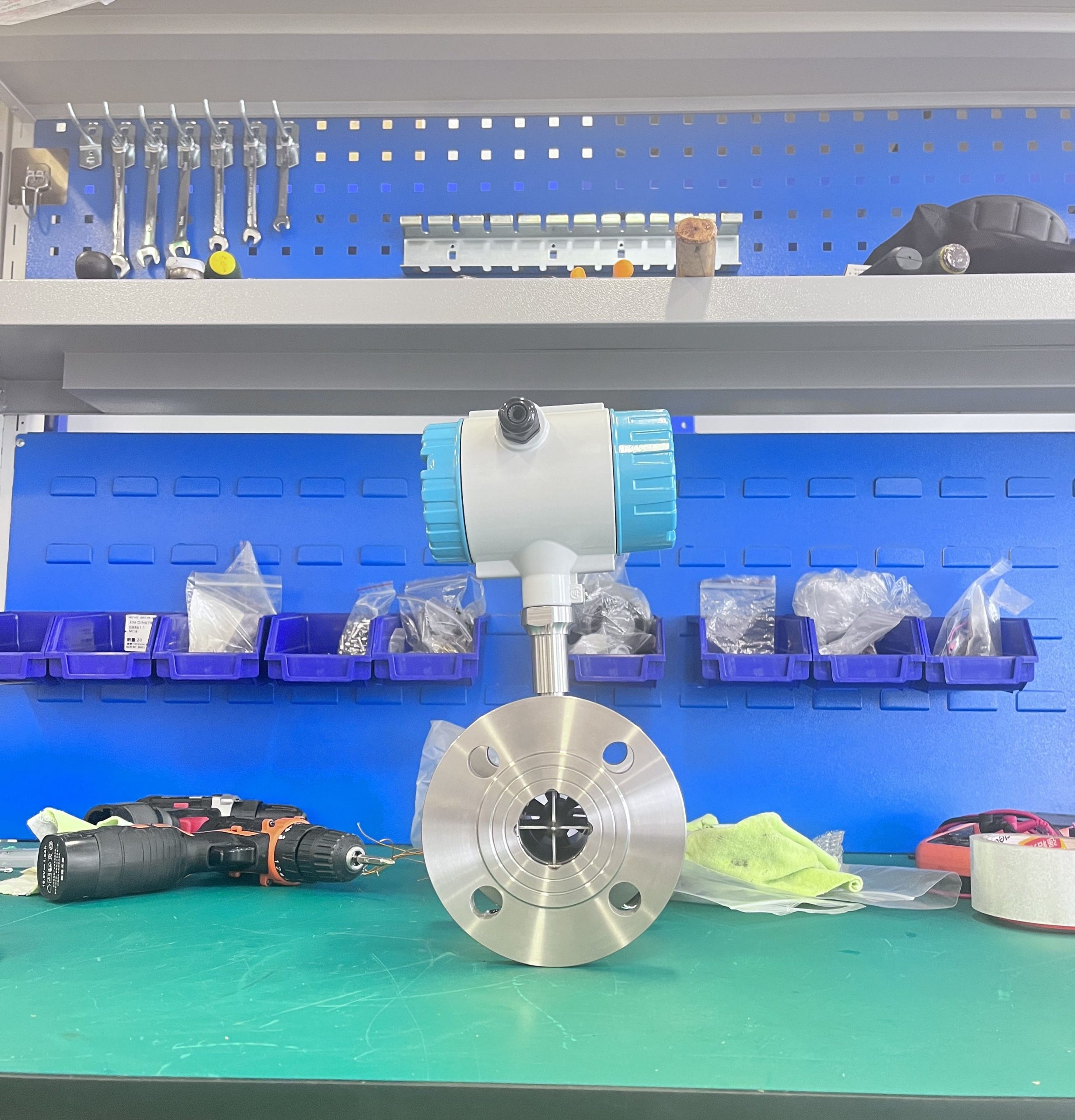

4. The turbine flowmeter has no flow display: First, check if there are any problems with the circuit, such as signal lines falling off or broken lines. Separate the sensor from the signal amplifier, and connect the signal amplifier to the instrument. Use an iron metal to swipe back and forth at a distance of 2 to 3mm from the bottom of the signal amplifier. If the instrument shows a display, it indicates that there is no problem with the display part.

Solution: Please remove the flow sensor from the pipeline and check whether the impeller of the flowmeter is entangled or damaged.

5. The flow rate displayed by the flowmeter is smaller than the actual flow rate: Generally, the reasons for this problem are that the impeller does not rotate fast or the blades are broken.

Solution: Remove the flowmeter from the pipeline and check if it is entangled or damaged.

6. The display error of the flowmeter is relatively large: First, check whether the flow sensor coefficient, that is, the K value, and other parameters of the instrument are set correctly; Where conditions permit, actual calibration and calibration should be carried out using an electronic scale.