How to select a biogas flowmeter? Five key factors help you measure accurately!

Biogas, as a renewable and clean energy source, is widely used in power generation, heating, chemical engineering and other fields. However, biogas has a complex composition (containing CH₄, CO₂, H₂S, water vapor, etc.) and is characterized by corrosiveness, high humidity and large pressure fluctuations, which poses higher requirements for flow measurement. How to choose the right biogas flowmeter? The following five key factors will be analyzed for you!

1. Measurement principle selection: Adapt to the characteristics of biogas

The selection of biogas flowmeters should be matched based on their composition, pressure and flow rate. Common types include:

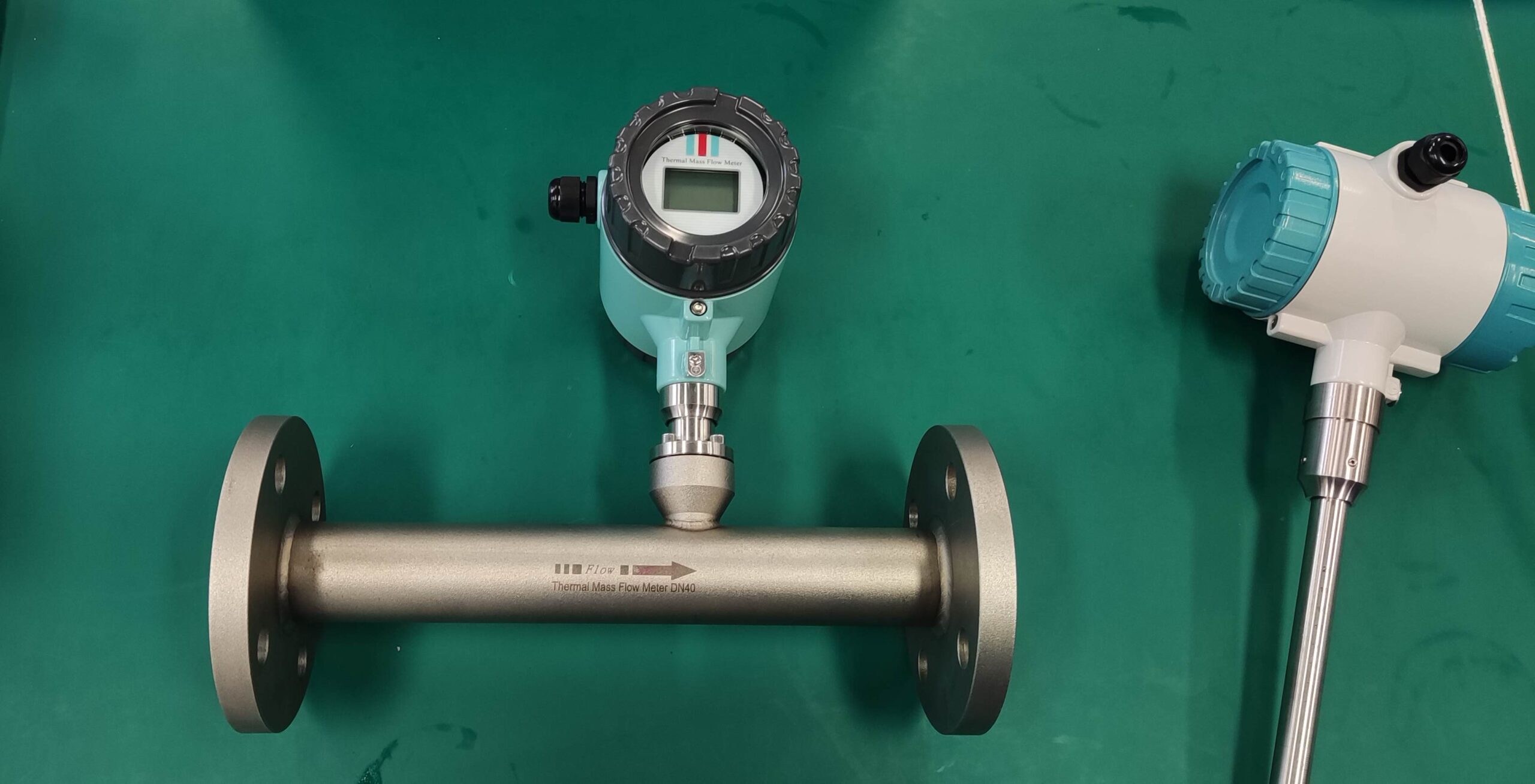

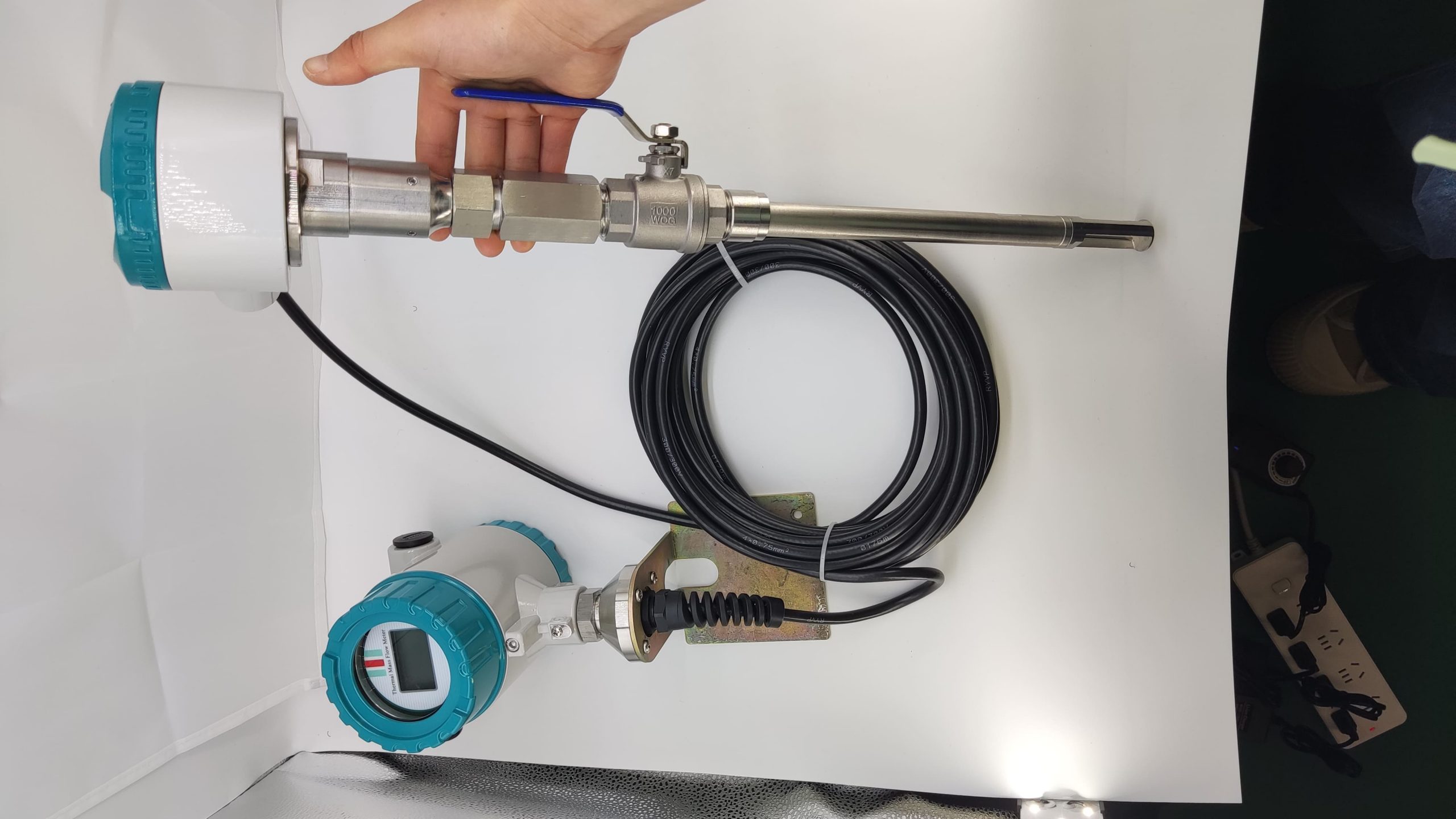

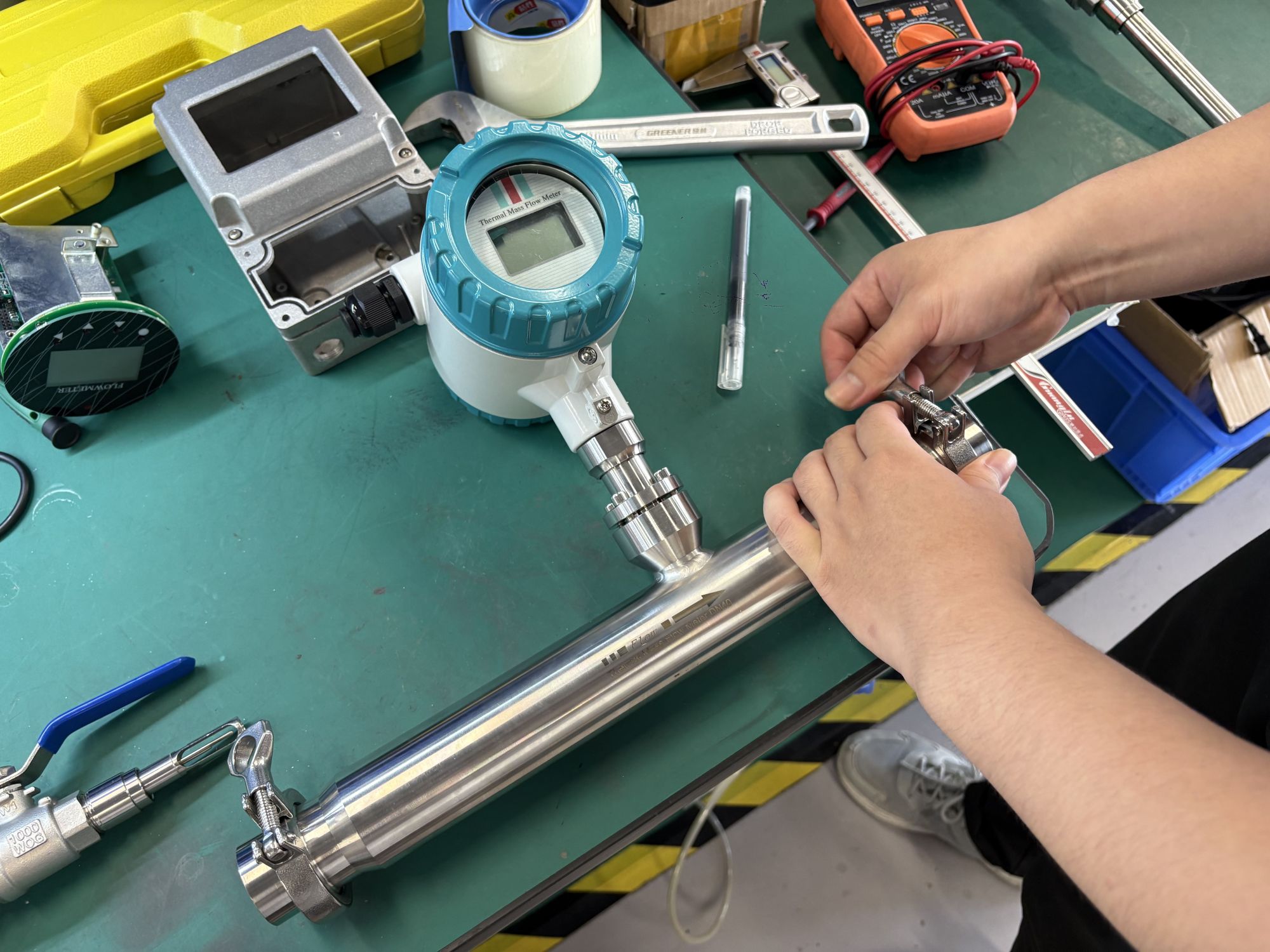

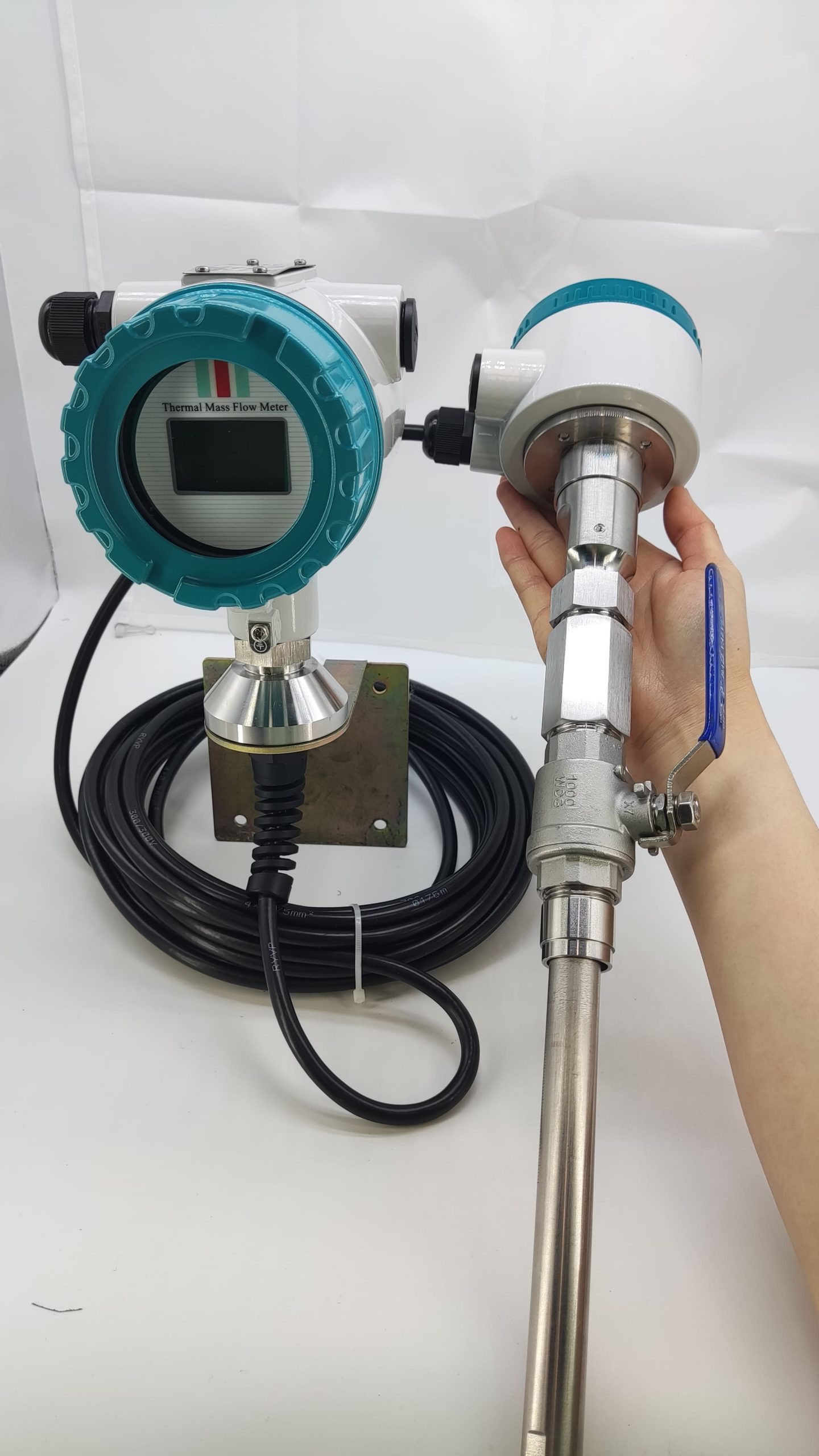

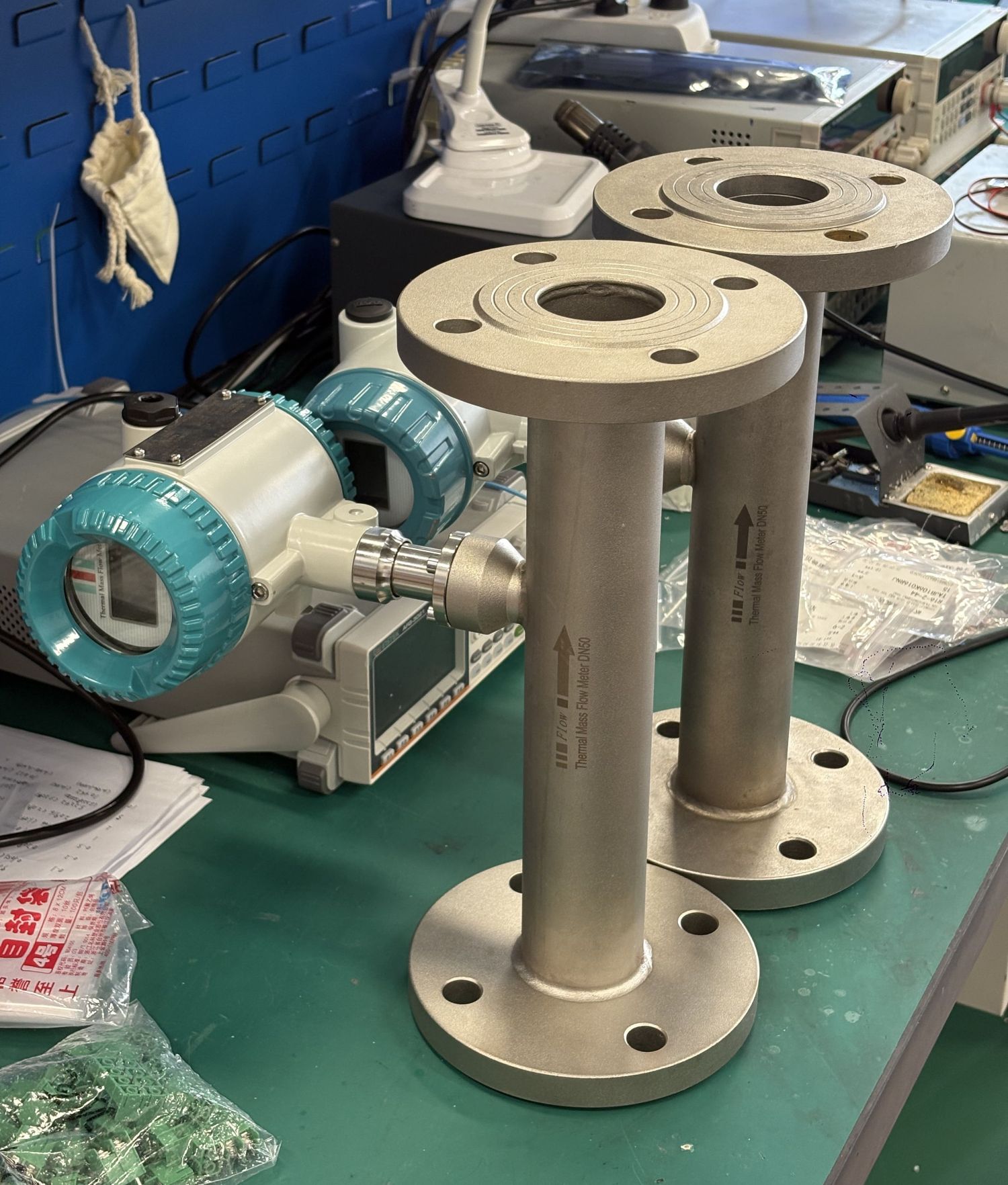

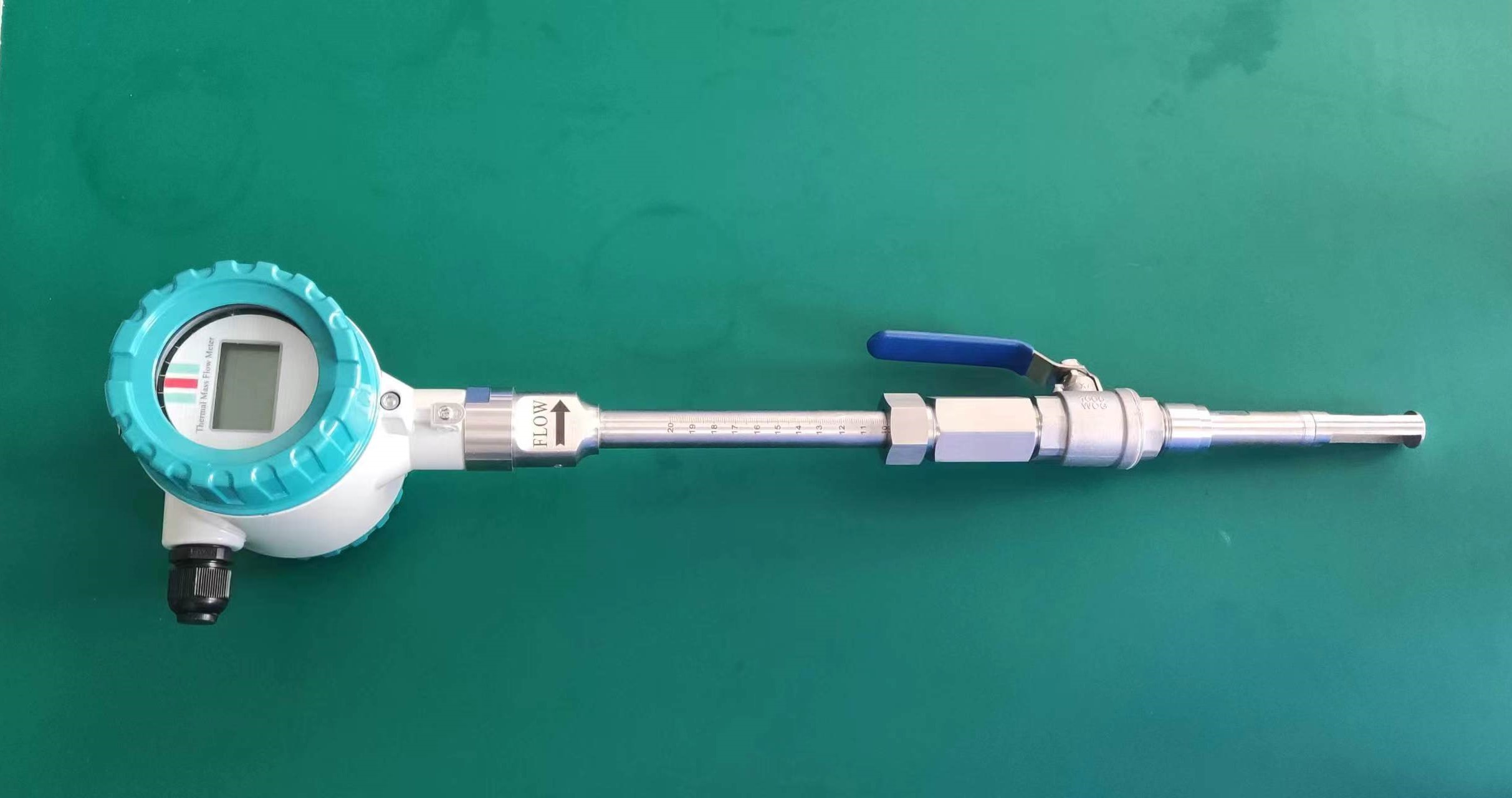

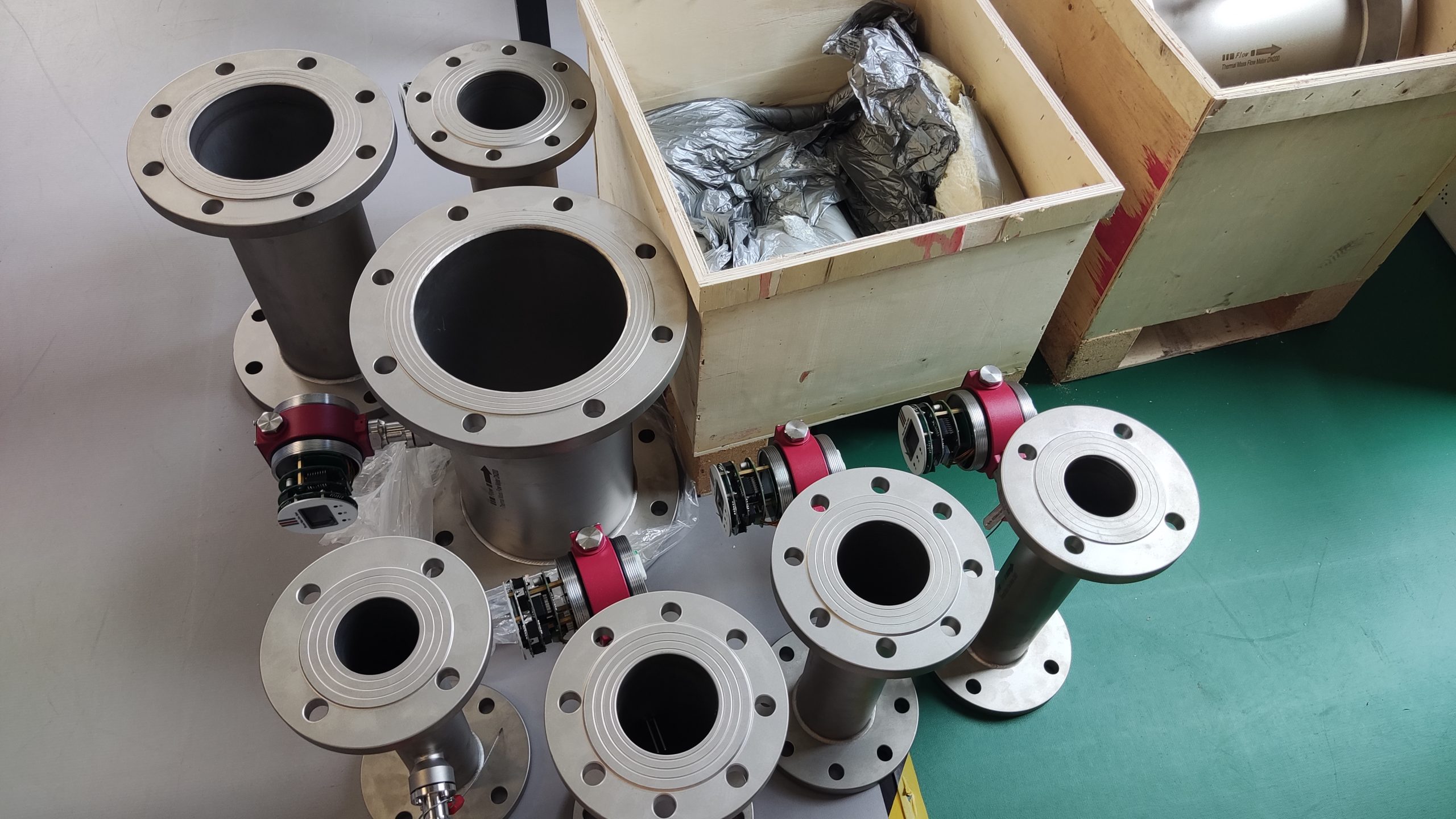

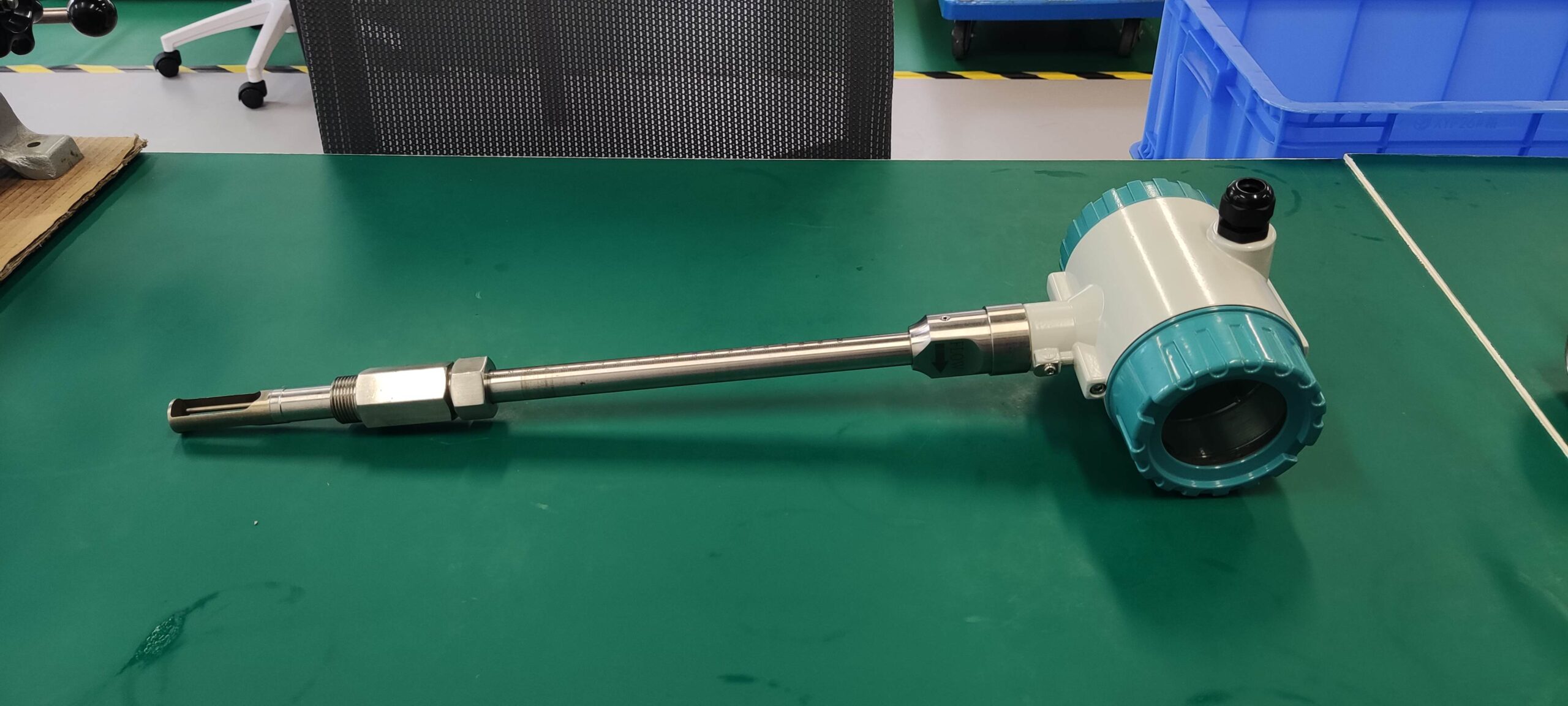

Thermal mass flowmeter: It directly measures the mass flow of gas and is not affected by changes in pressure and temperature. It is suitable for low-pressure biogas (such as anaerobic fermentation biogas), but a high-humidity environment may affect its accuracy.

Vortex flowmeter: Suitable for medium and high-pressure biogas pipelines, it is resistant to dirt but sensitive to vibration, and it is necessary to avoid the deposition of water vapor and impurities.

Ultrasonic flowmeter: Non-contact measurement, suitable for large pipe diameter and high-pressure biogas transportation, with strong corrosion resistance, but relatively high price.

Differential pressure flowmeters (orifice plate, V-cone) : Low cost, suitable for stable working conditions, but with large pressure loss, regular maintenance is required.

2. Material and anti-corrosion design

The H₂S, moisture and other substances in biogas are corrosive. The contact components of the flowmeter should be selected as:

316L stainless steel (resistant to general corrosion)

Hastelloy or PTFE lining (resistant to H₂S corrosion)

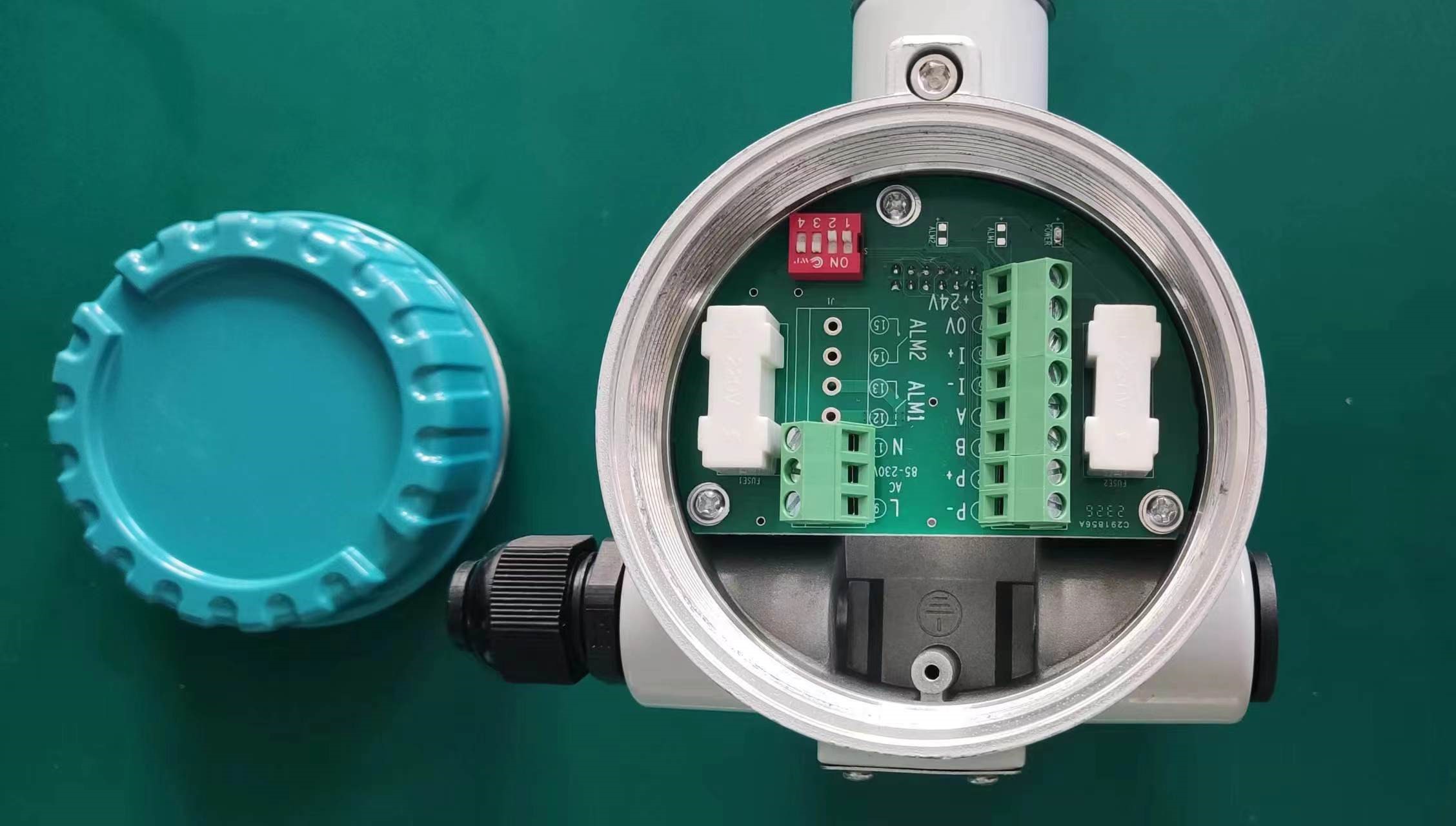

Fully sealed design (to prevent moisture from entering and damaging the sensor)

3. Explosion-proof and safety certification

Biogas is flammable and explosive (with a methane concentration of 50% to 70%), and the flowmeter must comply with explosion-proof standards:

Flameproof type (Ex d) or intrinsically safe type (Ex ia)

Certified by ATEX, IECEx, CNEX and other certifications to ensure safe operation

4. Adaptability to humidity and impurities

Biogas usually contains saturated water vapor and particulate impurities. When selecting the type, the following should be noted:

Equipped with an automatic drainage function (to prevent condensate water from affecting the measurement)

Self-cleaning design (such as ultrasonic flowmeters can reduce the influence of dirt)

Filtering device (the pre-filter can protect the sensor)

5. Convenience of installation and maintenance

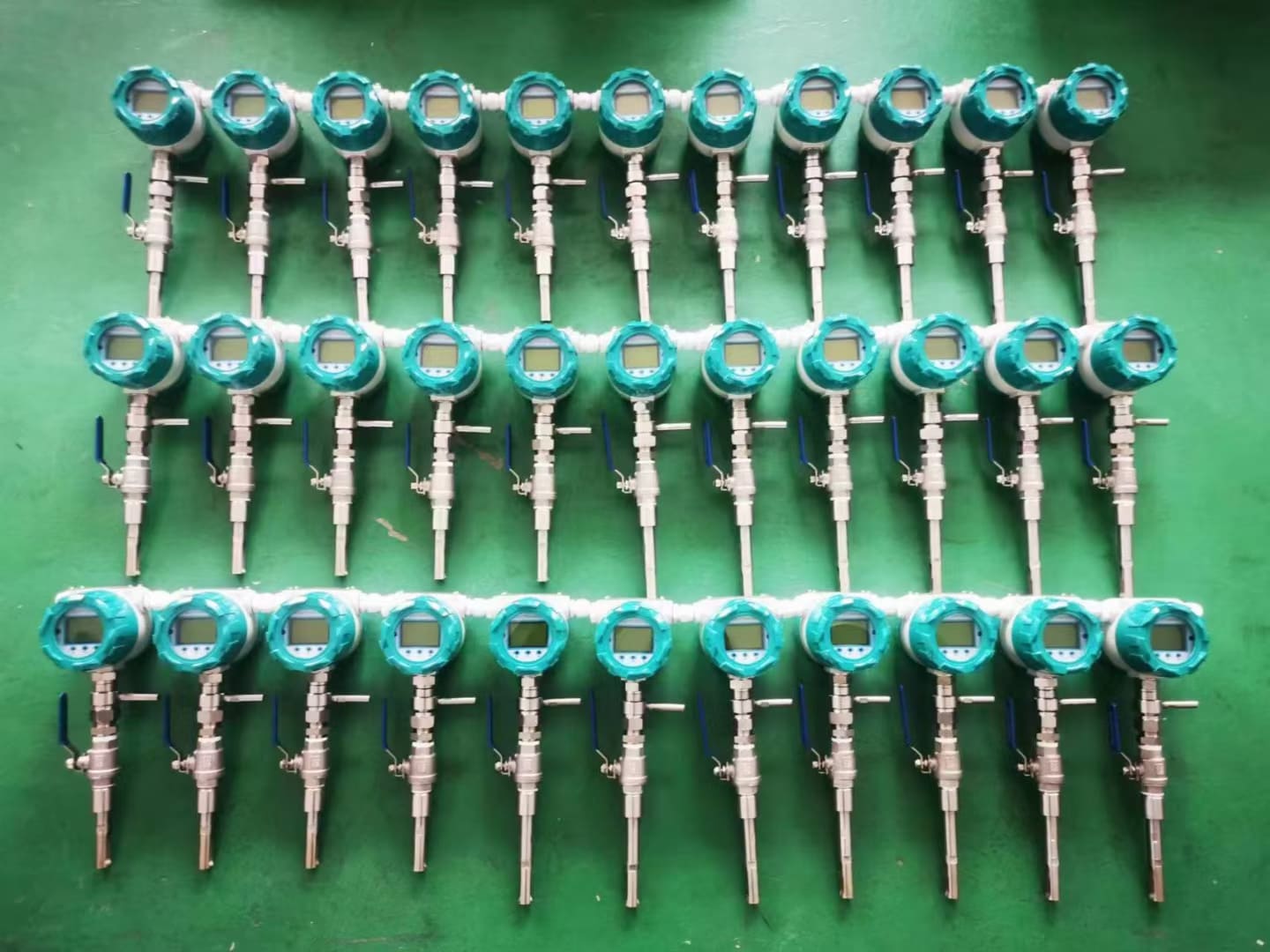

Insertable flowmeter: Suitable for the renovation of existing pipelines, and easy to install.

Pipeline flowmeter: High precision, but it needs to be installed without gas supply.

Wireless remote transmission function: Applicable to distributed biogas projects (such as rural biogas stations), for real-time data monitoring.

Conclusion: Precise measurement of biogas enhances energy utilization efficiency!

For different application scenarios:

Low-pressure biogas (such as fermentation tanks) → thermal mass flowmeter

Medium and high-pressure conveying pipelines → vortex or ultrasonic flowmeters

Trade settlement → High-precision ultrasonic or Coriolis flowmeters