8 Key Points to Consider when Selecting a Vortex Flowmeter

In the field of flow measurement, choosing the wrong vortex flowmeter not only leads to measurement errors but also results in continuous waste of production costs and a nightmare for equipment maintenance. Mastering these key points for selection will help you avoid common pitfalls.

As a widely used instrument for industrial flow measurement, the selection rationality of vortex flowmeters is directly related to measurement accuracy and equipment service life. According to industry data, over 50% of flowmeter usage problems stem from improper initial selection. To ensure that you choose the right vortex flowmeter, we have compiled 8 essential points to read:

1. Clearly define the characteristics of the measured medium

First, it is necessary to confirm whether the measurement is for gas, liquid or steam (steam needs to be distinguished as saturated or superheated). The corrosiveness, viscosity and cleanliness of the medium directly affect the material selection. For instance, corrosion-resistant materials (such as 316L and Hastelloy) should be chosen for corrosive media. High-viscosity fluids (such as heavy oil) may not be suitable for vortex flowmeters.

2. Determine the flow range

Ensure that the common flow rate is between 30% and 70% of the range to avoid signal loss at low flow rates or exceeding the range at high flow rates. When the flow range exceeds the limit, reducing or expanding the diameter can be considered, but it should not be too large.

3. Temperature and pressure requirements

Select the corresponding grade according to the medium temperature: common type (-40℃ to 350℃), high-temperature type (up to 450℃) or low-temperature type. The pressure rating should be higher than the maximum working pressure of the system. Generally, it is recommended that the withstand pressure be at least 1.5 times the working pressure.

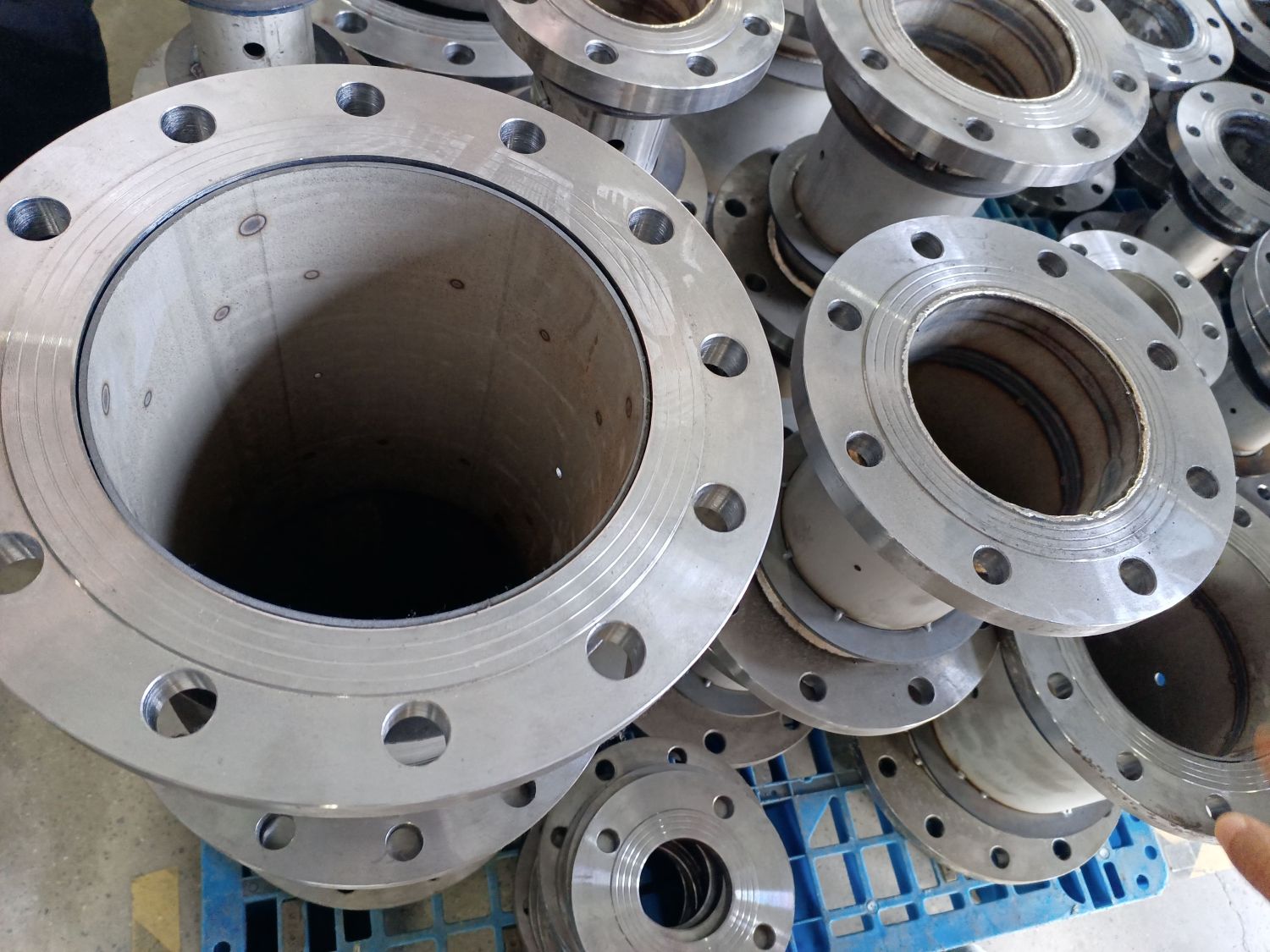

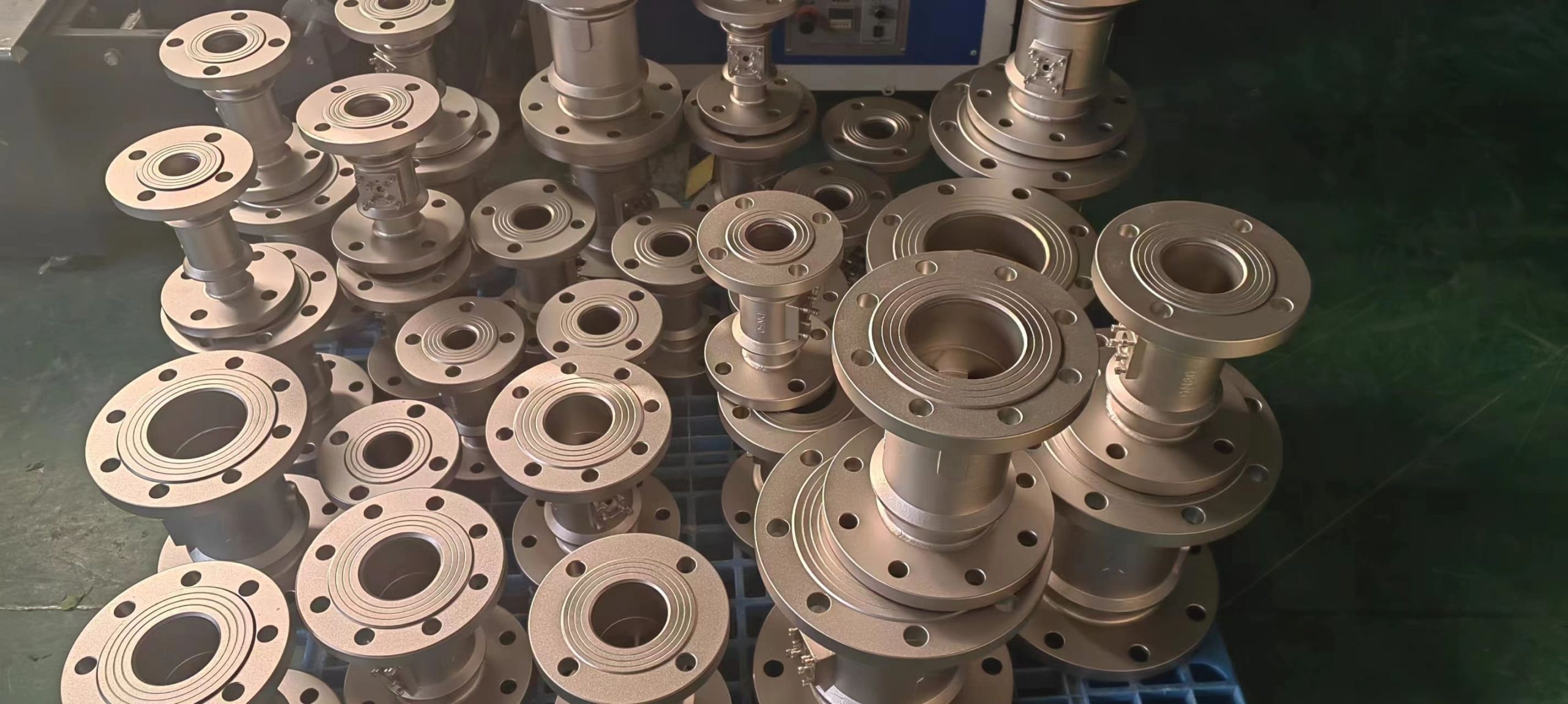

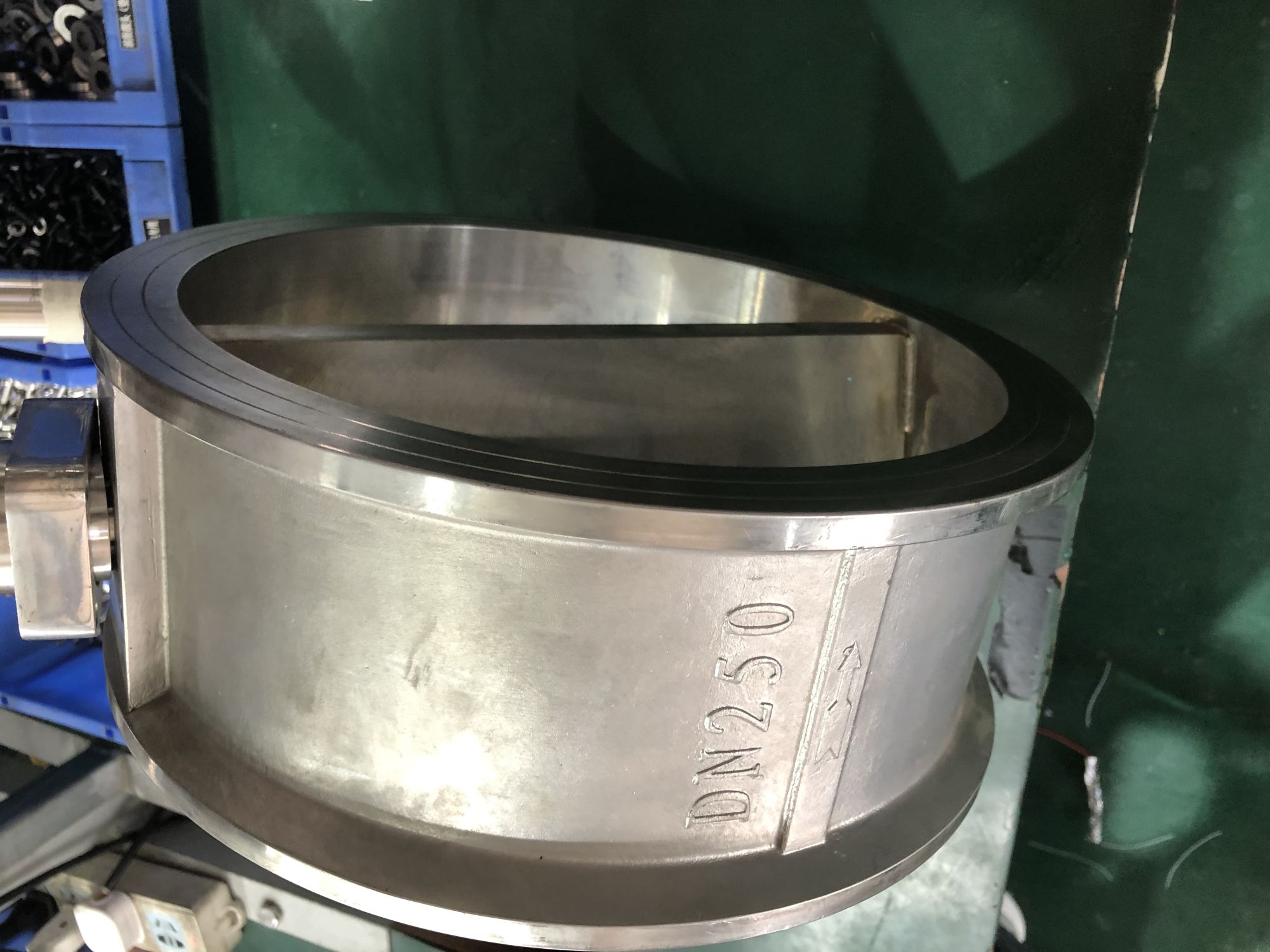

4. Pipe diameter matching

Select the matching diameter based on the pipe size. The standard diameters range from DN15 to DN300. Suggested flow rate range: 0.5-7m/s for liquids, 4-60m/s for gases.

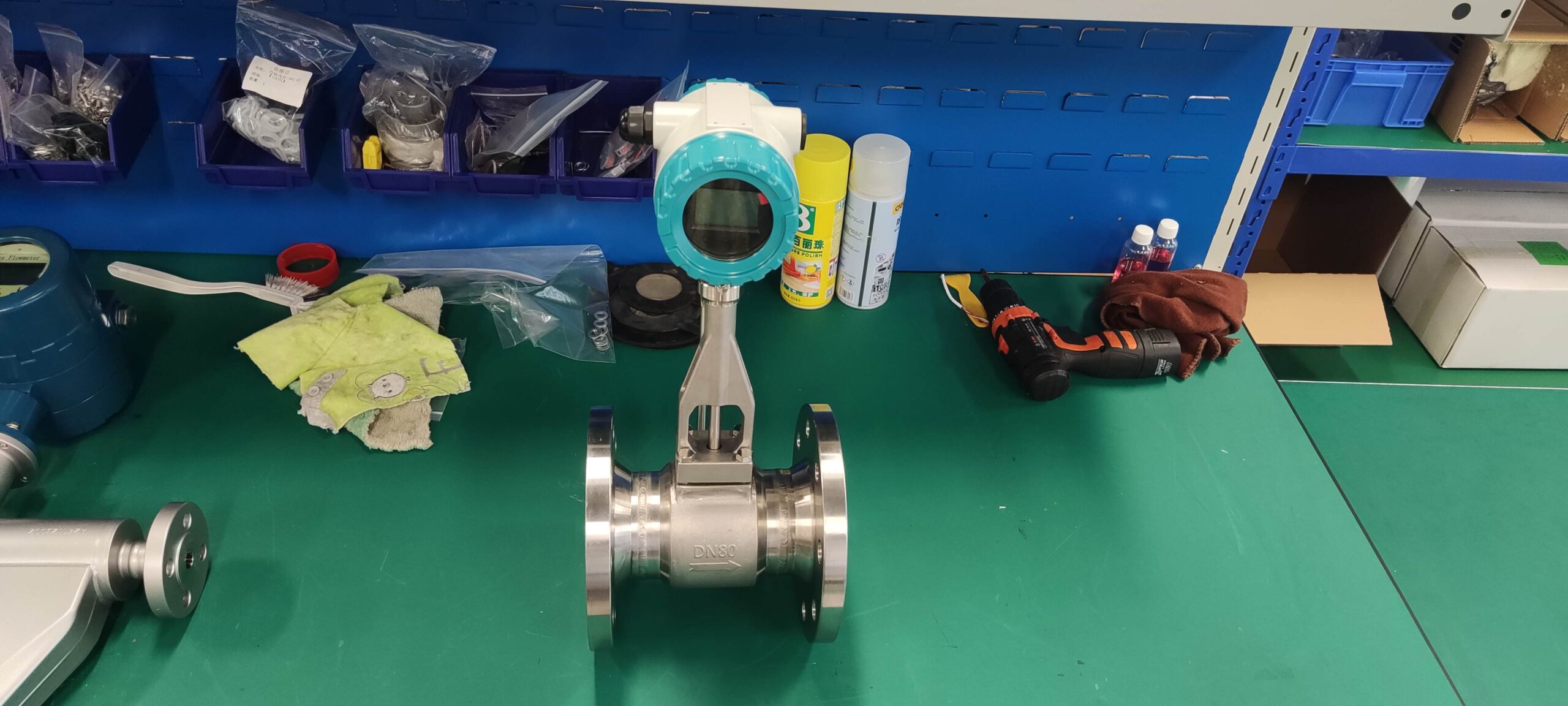

5. Precision grade selection

The accuracy of the pipeline vortex flowmeter for measuring liquids is usually ±1.0%, and for measuring gases/steam, it is ±1.0% to ±1.5%. The high-precision model can reach ±0.5%.

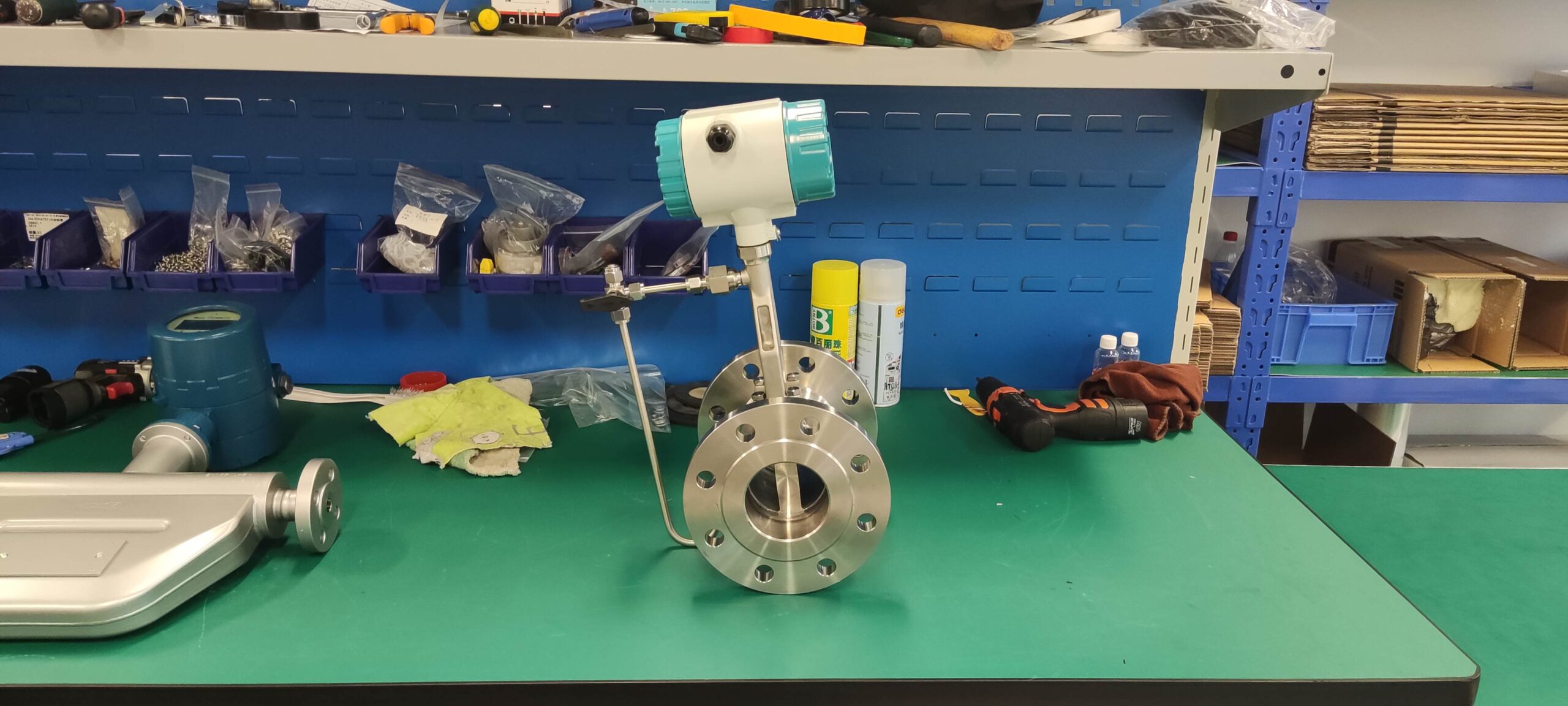

6. Considerations for installation environment

Vortex flowmeters are susceptible to vibration. Their installation locations should be far away from vibration sources such as pumps and compressors, or anti-vibration models should be selected. Ensure that there are sufficient straight pipe sections before and after (usually 10 days before and 5 days after).

7. Output signal and communication

Select the output signal type according to the requirements of the control system: 4-20mA (analog quantity), pulse output, RS485/HART (digital communication). For remote monitoring requirements, products that support communication protocols such as Modbus can be selected.

8. Protection and explosion-proof grade

Select the IP protection level (such as IP65, IP67, IP68) based on the installation environment. Explosion-proof vortex flowmeters must be selected in flammable and explosive environments.