Vortex flowmeter Selection Must-read: How do Diameter and Range Ratio Affect Accuracy?

Vortex flowmeters, as important equipment in industrial flow measurement, whether their selection is correct directly affects the measurement accuracy and reliability. During the selection process, the diameter and range ratio are two of the most crucial parameters, which jointly determine whether the flowmeter can perform well under specific working conditions.

Aperture selection: The first line of defense for precision assurance

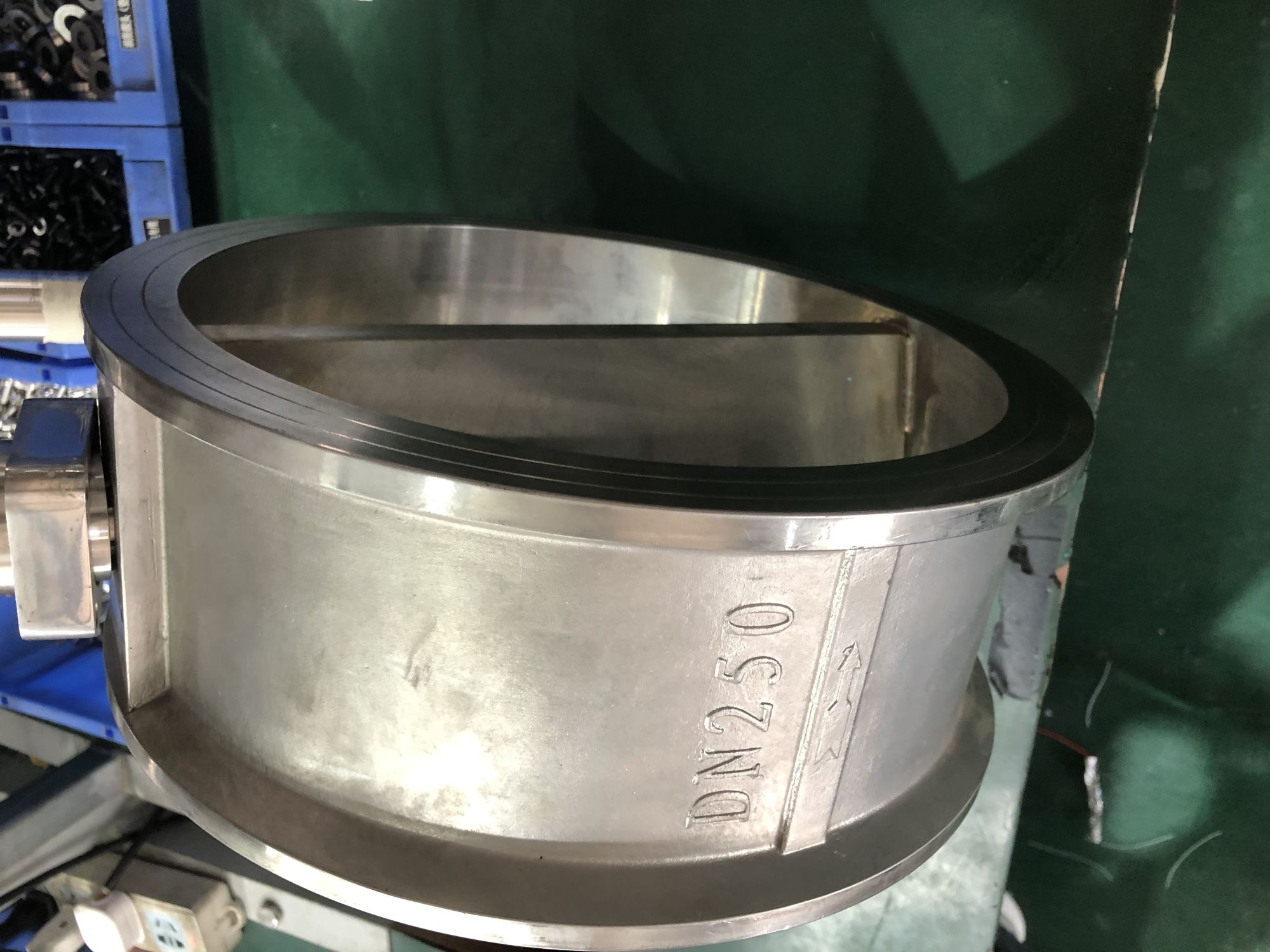

Choosing the correct diameter is the foundation for ensuring measurement accuracy. The diameter of the vortex flowmeter should match the inner diameter of the pipe (the error should be less than ±1%). Improper matching will cause significant measurement errors.

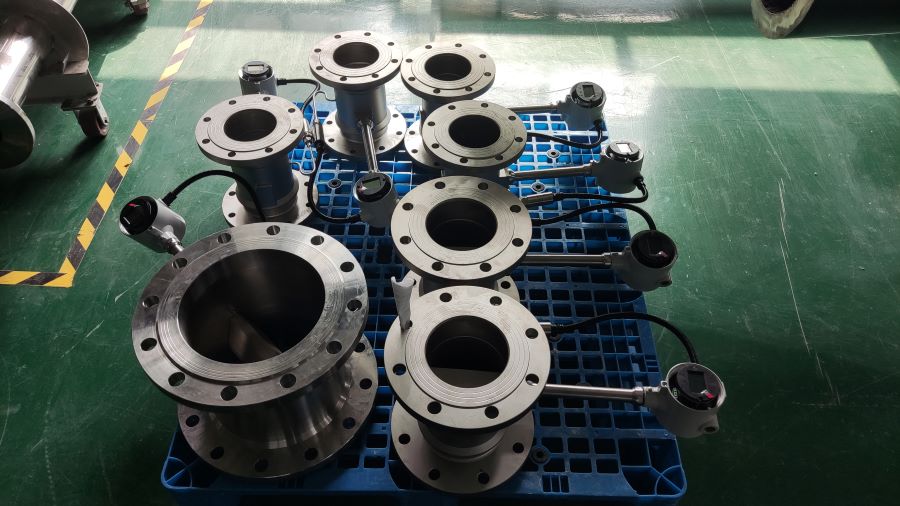

If the flowmeter’s diameter is too large, it will result in a weak signal at low flow rates. If the diameter is too small, it will increase the pressure loss and even make it impossible to measure high flow rates. The standard diameter range varies from DN15 to DN300.

Suggested flow rate range: liquid 0.5-7m/s, gas 5-50m/s, steam 8-50m/s. When the actual pipe diameter does not match the selected flowmeter diameter, a contraction pipe or an expansion pipe should be used for diameter reduction treatment.

Range ratio: The key to determining the range of flow measurement

The range ratio is the ratio of the maximum to the minimum measurable flow rate, which directly reflects the adaptability of the flowmeter. A higher range ratio means that the flowmeter can maintain stable accuracy over a wider flow range.

The range ratio of vortex flowmeters is usually 10:1, and high-quality models can reach 15:1 or even 30:1. The larger the range ratio, the more stable the accuracy is within a wide flow range.

When selecting the type, the commonly used flow rate should be controlled at the upper-middle part of the flowmeter’s measurable range (1/2 to 2/3 of the flow range), and the measurement of the lower limit should be avoided as much as possible.

The synergy effect of the ratio of caliber to range

The ratio of diameter to range jointly determines the working range of the flowmeter. When selecting a model, it is necessary to comprehensively consider the process flow range, medium characteristics, and working pressure and temperature conditions.

High-range-ratio flowmeters allow for the selection of smaller diameters without sacrificing the measurement range, but it must be ensured that the flow velocity remains within the allowable range at the minimum flow rate. For flow conditions with large fluctuations, a model with a larger range ratio should be selected to ensure accurate measurement under different loads.

Practical suggestions for selection

Clarify the process parameters: including the type of medium, flow range, working temperature and working pressure. Consider the medium characteristics: viscosity limit (usually required to be less than 30 cP), corrosiveness and cleanliness.

Verify the installation conditions: Ensure there are sufficient straight pipe sections before and after (upstream ≥10D, downstream ≥5D). Select the appropriate precision: for liquids, it is usually ±1.0%; for gases/vapors, it is ±1.0% to ±1.5%.

The correct selection of the diameter and range ratio of a vortex flowmeter is a key factor in ensuring measurement accuracy. Only by comprehensively considering the actual working conditions can the most suitable flowmeter be selected to provide reliable data support for industrial process control and energy management.