Will the temperature and pressure of steam affect the measurement of steam flowmeters

The measurement accuracy of the steam flowmeter is closely related to the pressure and temperature of the steam. Pressure compensation is recommended for measuring saturated steam, while temperature and pressure compensation is adopted for measuring superheated steam.

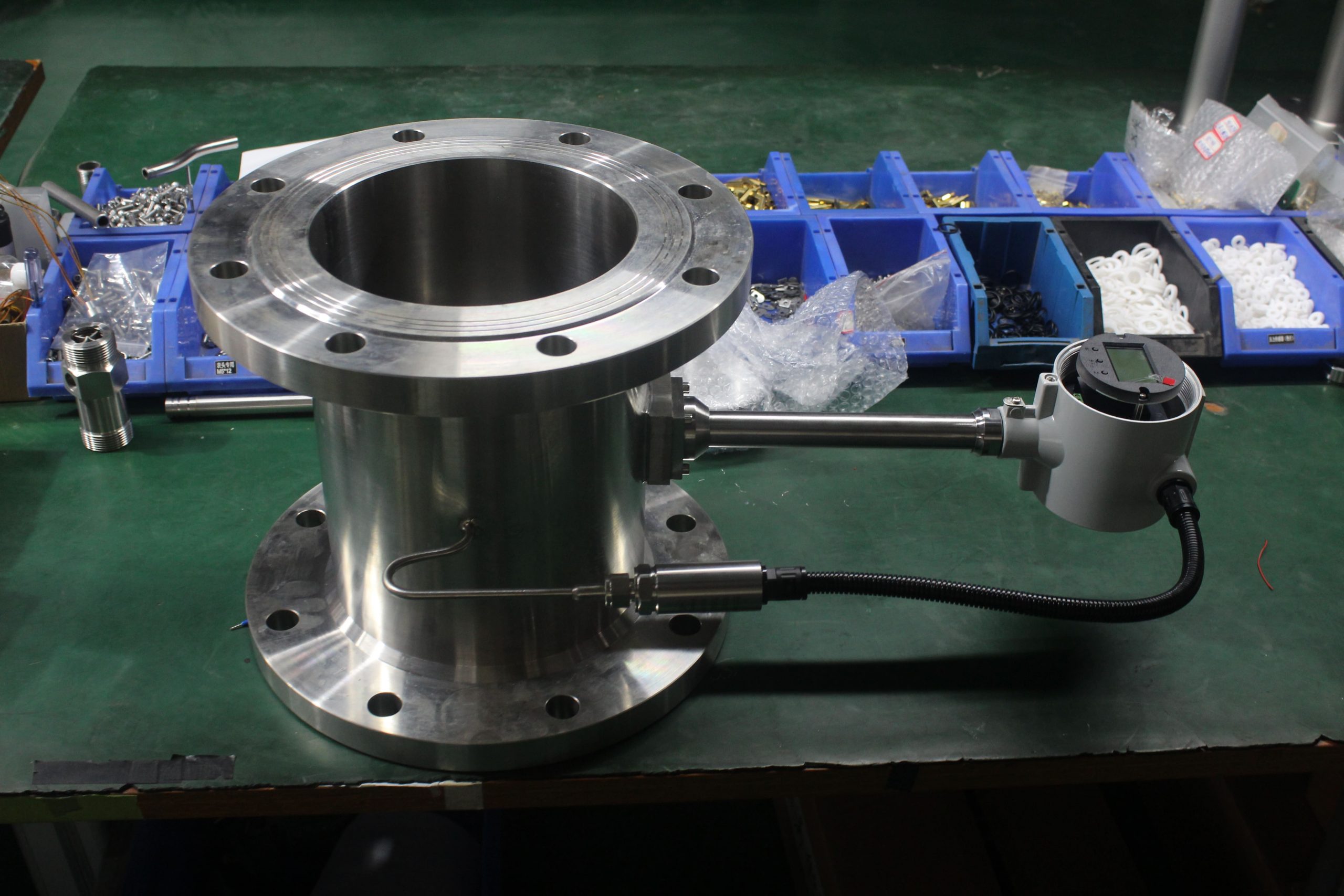

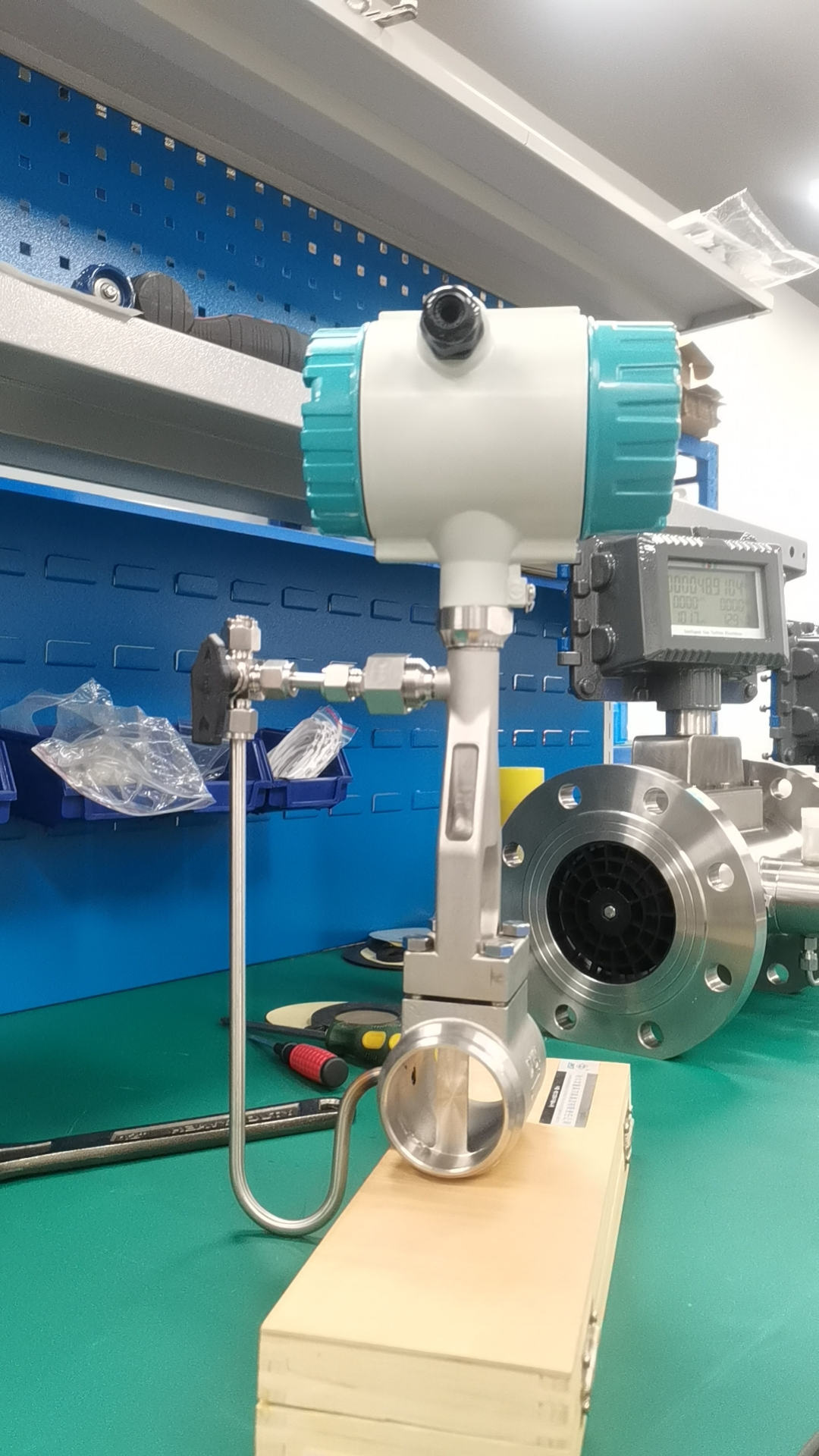

The measurement accuracy of the steam flowmeter is closely related to the pressure and temperature of the steam. Pressure compensation is recommended for measuring saturated steam, while temperature and pressure compensation is adopted for measuring superheated steam. The commonly used steam flowmeters nowadays are the traditional standard orifice plate flowmeter and the vortex flowmeter. If a wide measurement range is required, the vortex flowmeter should be selected. If the flow rate is relatively stable within a certain range, the standard orifice plate flowmeter should be chosen. Secondly, it is necessary to clarify the following parameters of steam flow: common flow rate, maximum flow rate, minimum flow rate, common pressure, common temperature, and installation method.

1. Range issue: A large amount of experimental data has proved that the reason why the steam flow measurement is abnormal is mostly caused by incorrect range selection of the steam flowmeter. Everyone knows that during the peak season of steam consumption, the steam consumption is quite large, while during the off-season, it is very small. Such a huge gap in steam consumption makes it difficult for ordinary steam flowmeters to adapt. Therefore, when choosing a steam flowmeter, it is essential to first clarify the flow measurement range of the steam flowmeter. Then, select the steam metering instrument that meets the relevant operating parameters; otherwise, it will be difficult for the steam flowmeter to play its due role.

2. Pipe diameter issue: When designing the throttling device for steam flowmeters, the nominal pipe diameter value provided by the process is basically adopted. However, in reality, there is an error between the nominal pipe diameter value and the actual pipe diameter value. Especially for coiled pipes, the difference between the nominal pipe diameter value and the actual pipe diameter value can sometimes be even greater, increasing the measurement error. Ultimately, it leads to the difficulty in achieving the expected measurement accuracy of the steam flowmeter.

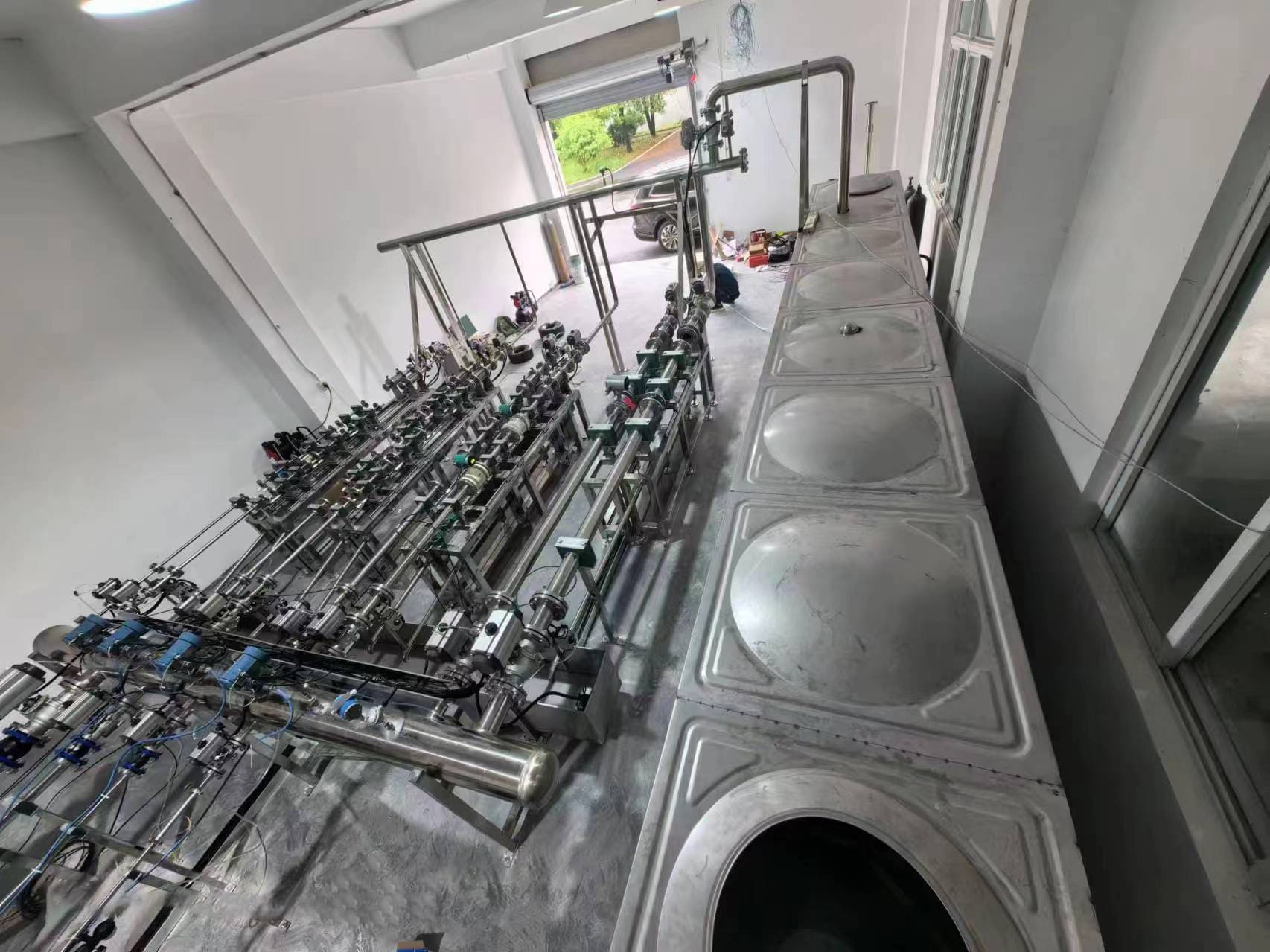

3. Pipeline vibration issue: Effectively fixing the pipeline to reduce or eliminate the vibration amplitude of the pipeline will greatly improve the accuracy of the steam flowmeter measurement process.

Generally, vortex flowmeters and traditional standard orifice plate flowmeters are still adopted. In recent years, better multi-hole orifice plate (balanced) flowmeters have emerged in the latter. In fact, the measurement accuracy is also related to whether automatic compensation for temperature and pressure is adopted. Because the actual working conditions are changing, and the calculation and calibration of the flowmeter are carried out by converting the design working conditions into standard conditions.

For vortex flowmeters, there are often misunderstandings, thinking that temperature and pressure compensation is not necessary. What it actually measures is the working condition flow rate under a specific working condition (design working condition) (the working condition flow rate is converted into the standard condition flow rate during calibration). If the working conditions change, what is measured is the flow rate under the new working conditions. If it is still converted to the standard conditions according to the original assumed working conditions, it will be incorrect from the calibration.