How to choose a vortex flowmeter?

In industrial flow measurement, vortex flowmeters have become the preferred equipment for measuring the flow of gases, liquids and steam in many industries due to their wide application range, high accuracy and low pressure loss. However, in the face of a rich variety of models and complex working conditions in the market, how to scientifically select the right type has become a key issue. This article sorts out five key factors and specific selection steps for you, helping you make an accurate choice.

Five key selection factors

Measure the characteristics of the medium

Clearly define the type of fluid (gas, liquid or steam), temperature, pressure, density, viscosity and corrosiveness.

High-viscosity media (such as heavy oil) may not be applicable.

Steam needs to be distinguished between saturated steam and superheated steam because of their different densities and properties.

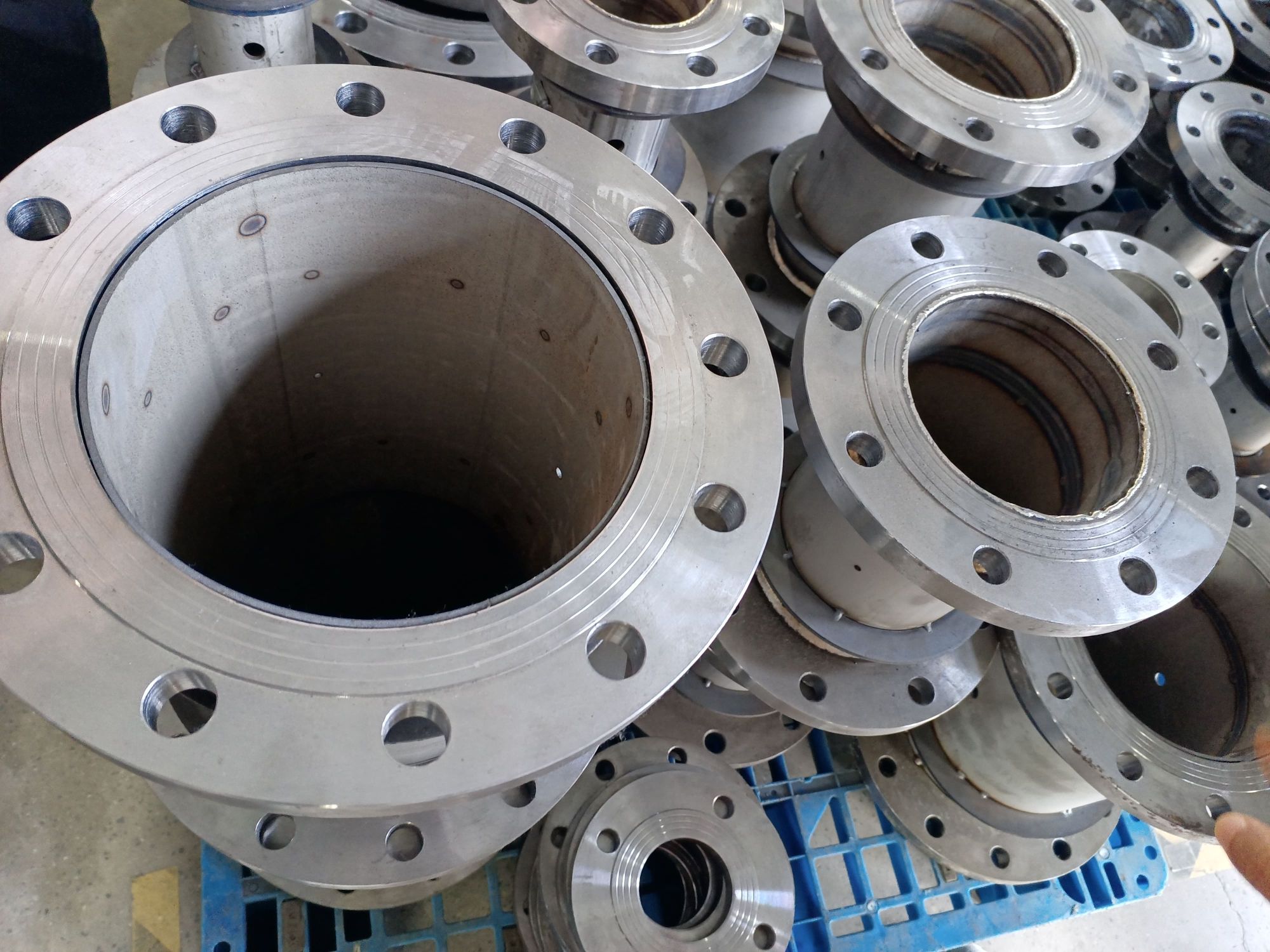

For corrosive media, corrosion-resistant materials (such as 316L stainless steel, Hastelloy) should be selected.

Flow range and pipe diameter

The flow range is the core: it is necessary to ensure that the commonly used flow is at 1/2 to 2/3 of the flowmeter’s range to avoid unstable measurement at low flow rates or exceeding the range at high flow rates.

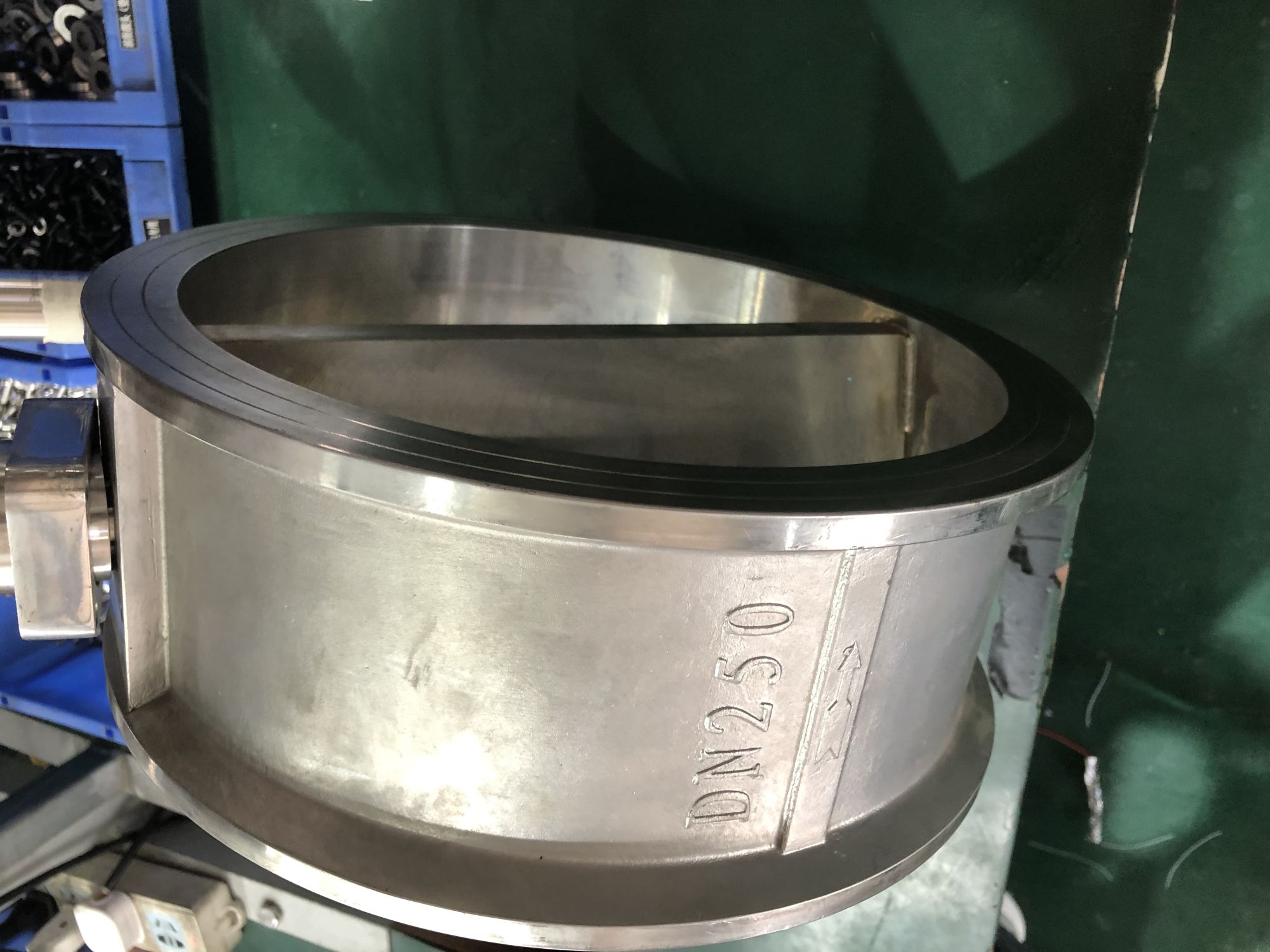

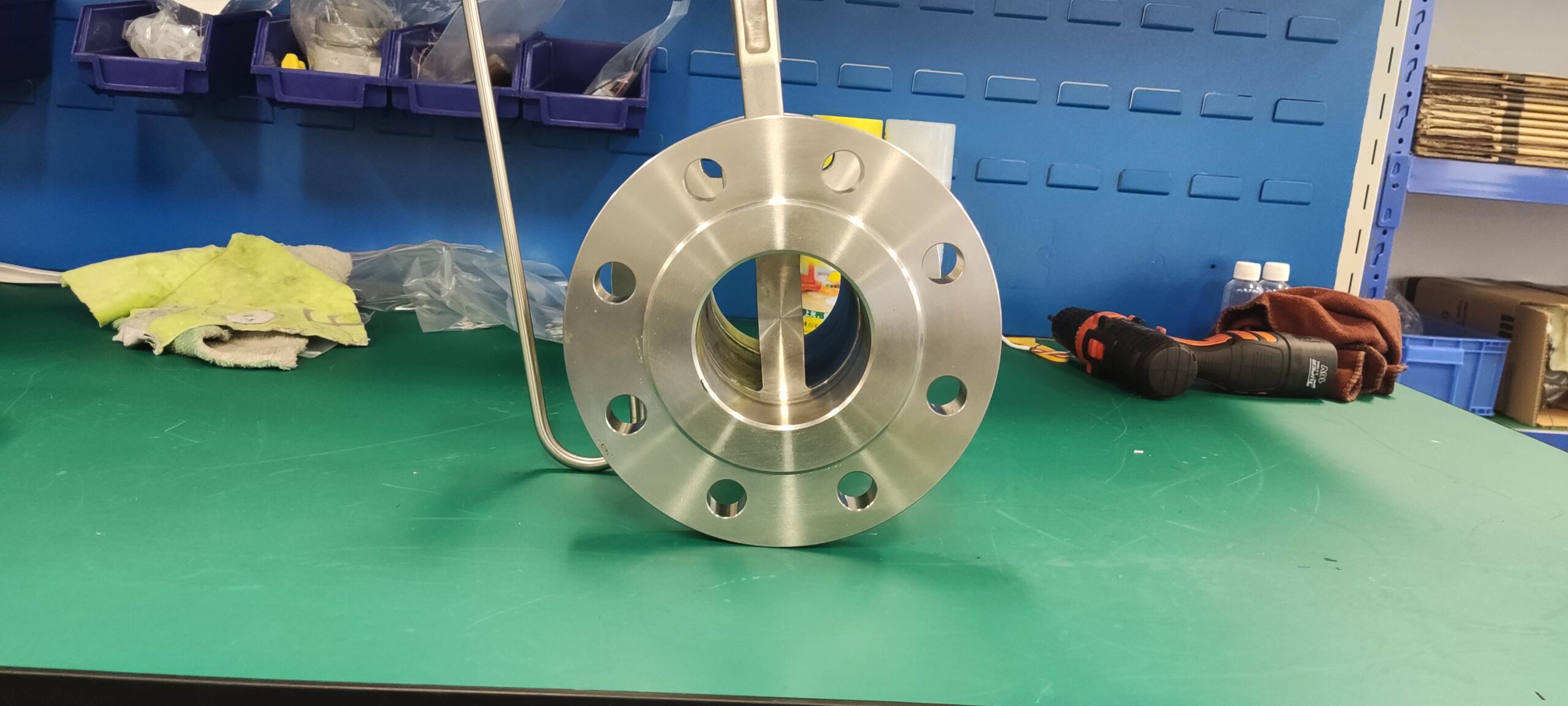

The pipe diameter needs to match: If it does not match the flowmeter diameter, a diameter reduction treatment (reducing or expanding the diameter) can be adopted, but it should not be too large to avoid additional resistance or cavitation. The standard diameters range from DN15 to DN300.

Operating temperature and pressure

Temperature: Ensure that the medium temperature is within the rated range of the flowmeter (typically supporting -40℃ to 350℃, and the high-temperature type can reach over 400℃).

Pressure: The nominal pressure rating (such as PN16, PN25, PN40) should be higher than the system’s maximum working pressure.

Installation and environmental conditions

Straight pipe section requirements: Generally, it is necessary to ensure a straight pipe section of 10D before and 5D after (D is the pipe diameter) to stabilize the flow field.

Vibration interference: Avoid installing near vibration sources such as pumps and compressors, or choose models with vibration compensation.

Protection level: Select the IP protection level based on the installation environment (for example, IP65 is used indoors, and IP68 is used in situations where it may be flooded).

Output signal and compensation requirements

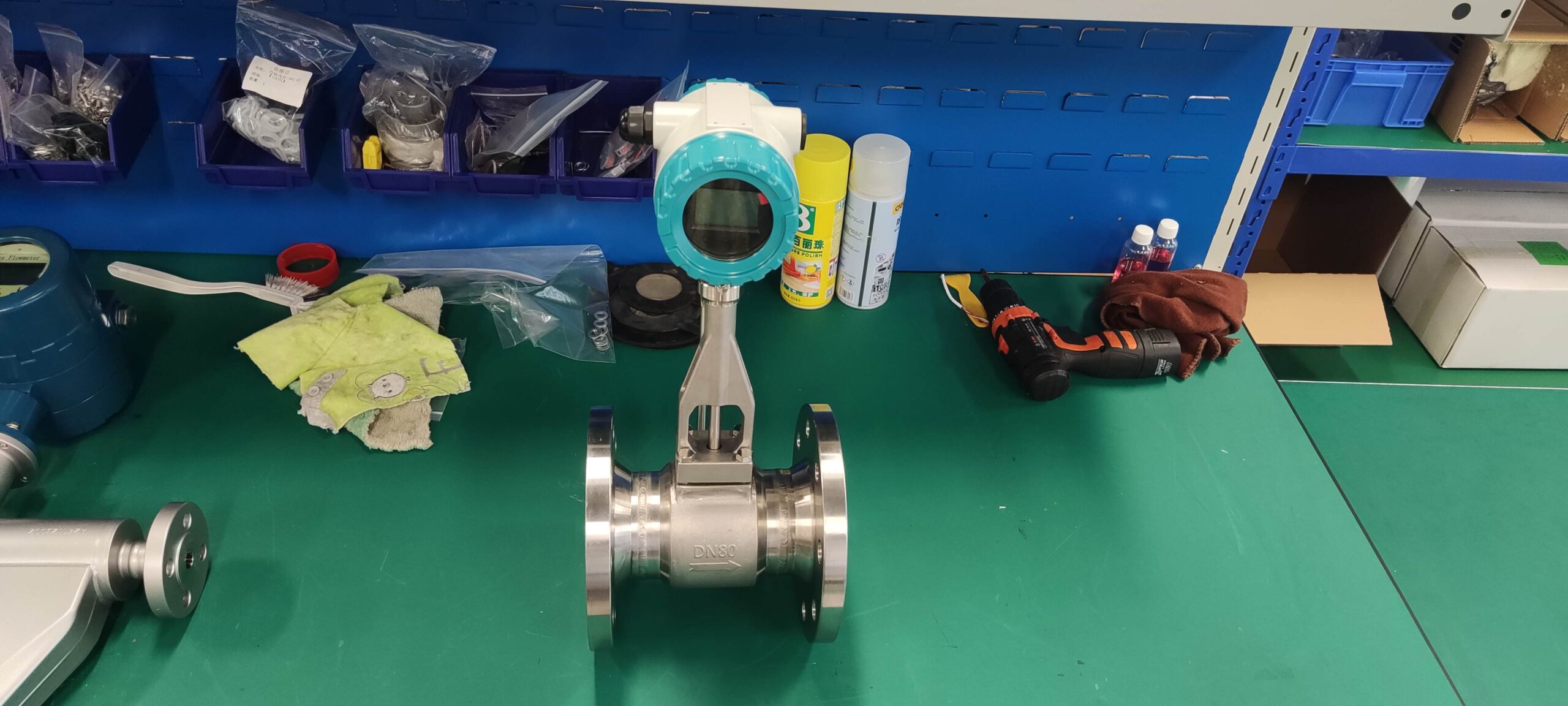

Output signal: According to the requirements of the control system, select 4-20mA analog quantity, pulse output or digital communication such as RS485/HART.

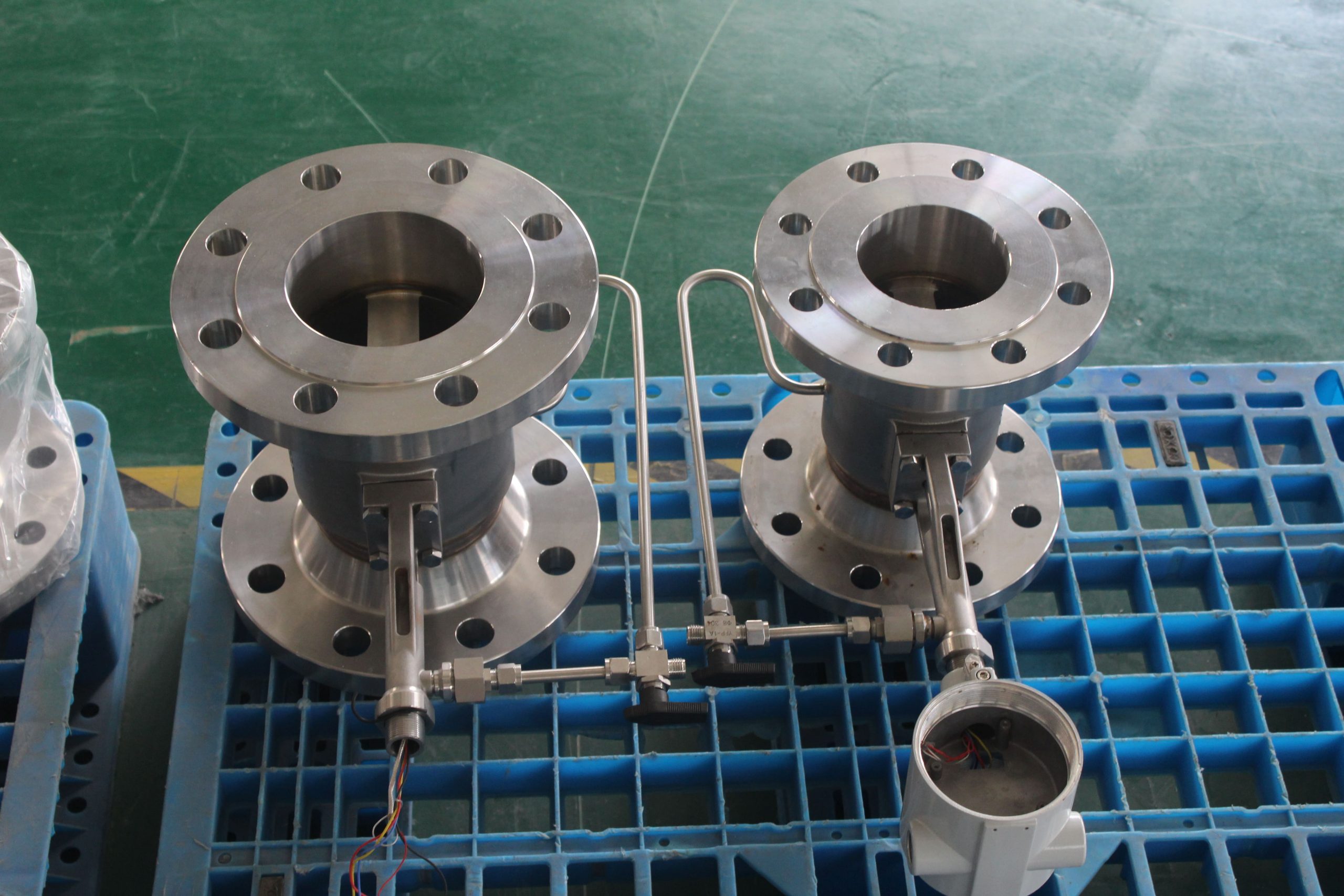

Temperature and pressure compensation: For gas, steam or working conditions with large fluctuations in temperature and pressure, temperature and pressure compensation (built-in or external sensors) must be equipped to ensure accuracy. For instance, when measuring gases, simultaneous compensation for temperature and pressure is required, while saturated steam can be compensated for either temperature or pressure alone.

2. Four-step selection process

Clarify the basic parameters

Collect the medium name, composition, working temperature, working pressure, maximum/common/minimum flow rate, pipe size, etc.

Preliminary selection and verification

Preliminarily screen the applicable model based on the medium type and parameters.

Verify the Reynolds number: Ensure that the Reynolds number at the minimum flow rate is higher than the limit value (usually Re > 2×10⁴) to guarantee the measurement linearity.

For liquids, it is also necessary to check whether the minimum working pressure is higher than the saturated vapor pressure at that temperature to prevent cavitation.

Determine the specific specifications

Select the material, pressure rating, precision grade (±1.0% for liquids and ±1.5% for gases/vapors), output signal and protection grade.

Consider the installation method (flange type, clamping type, etc.) and the environmental vibration conditions.

Confirmation and Consultation

For complex working conditions (such as high viscosity, pulsating flow, and strong vibration), it is recommended to consult the manufacturer or professional technicians and provide detailed parameters to obtain a customized solution