Steam flowmeters must not be installed in environments with strong vibrations

The causes of faults in the on-site metering system of the steam flowmeter can be summarized into two major reasons: one is caused by the flowmeter or its related equipment; The second reason is not related to the flowmeter, that is, the flowmeter is normal, but the fault is caused by environmental or system reasons.

The causes of faults in the on-site metering system of the steam flowmeter can be summarized into two major reasons: one is caused by the flowmeter or its related equipment; The second reason is not related to the flowmeter, that is, the flowmeter is normal, but the fault is caused by environmental or system reasons. Such causes are difficult to identify. In addition to requiring technicians to be familiar with the performance of the instrument, they also need to have extensive knowledge and rich on-site experience to conduct analysis, reasoning and multiple tests before confirmation. Some malfunctions are still caused by some unexpected events. Faults not related to flowmeters are often manifested as unstable output signals.

Based on practical experience, the reasons for the unstable output signal when the steam flowmeter measures coke oven gas are as follows:

It is widely known that steam flowmeters are not suitable for installation in environments with strong vibration. However, in environments where magnetic fields frequently change, vortex flow sensors will also be disturbed and detect signals higher than the normal value. Practical experience has shown that in a field without gas flow, when the vortex flow sensor is in a changing magnetic field, at the moment of the magnetic field change, the vortex flow sensor will sense an incorrect signal output. When the change ends and the instrument is in a stable magnetic field, the instrument will output a normal signal.

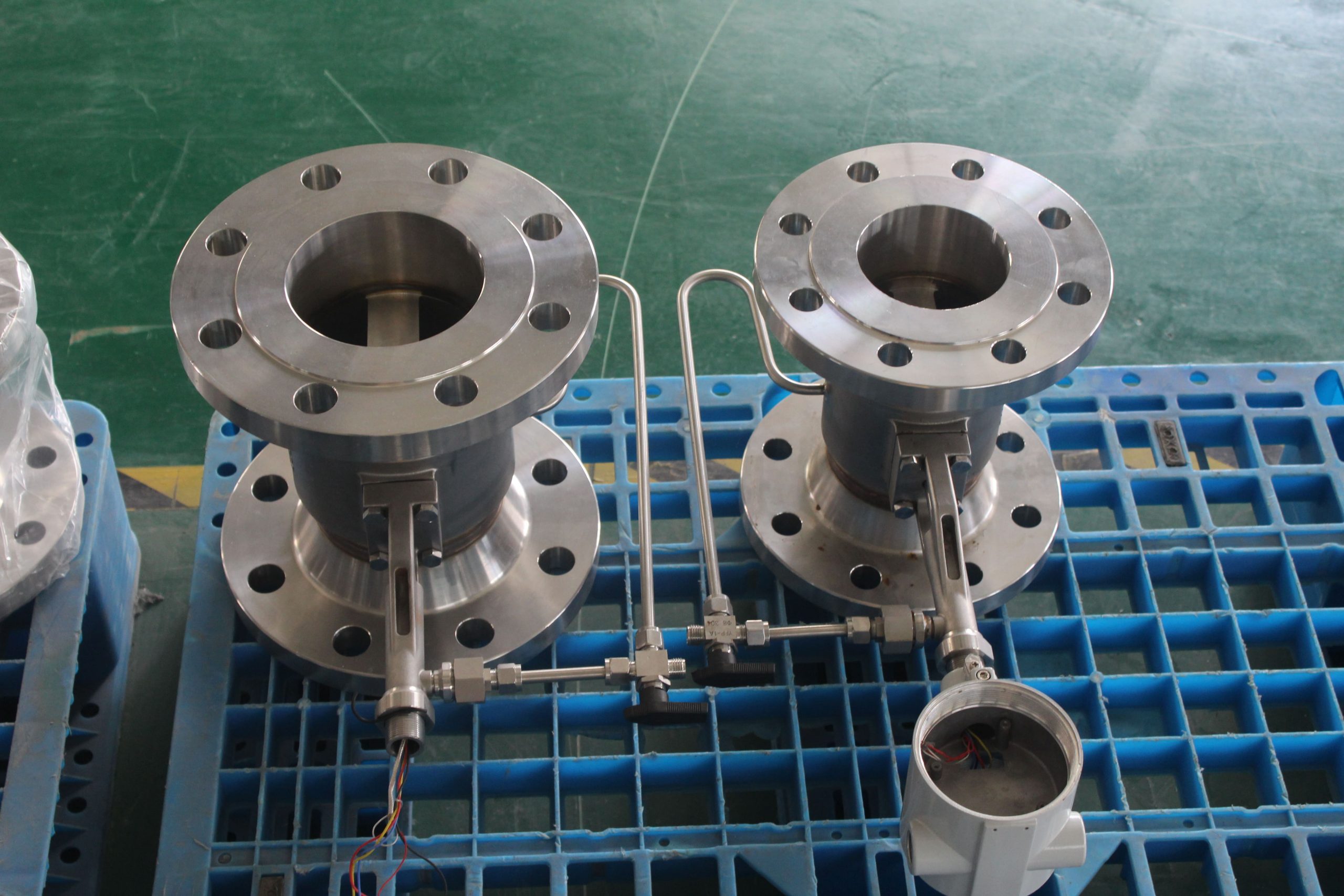

2. Due to the high temperature and humidity when coke oven gas leaves the factory, there will be moisture present during the gas transportation process. The flow of gas causes the moisture to fluctuate back and forth, thus forming a dynamic flow. When the vortex flow sensor is in this fluid state, the output data fluctuates greatly and cannot reflect the production status at all.

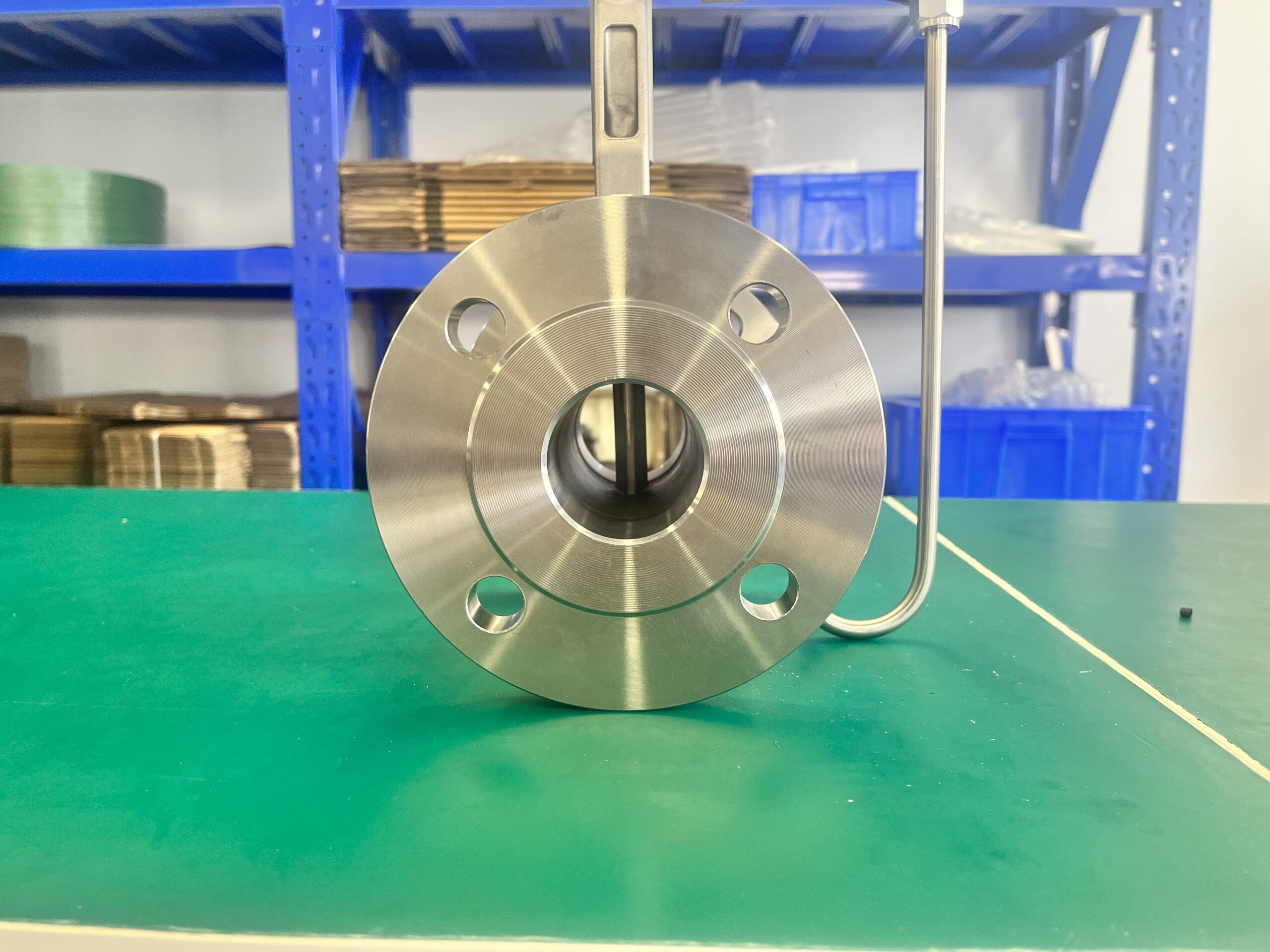

3. Due to the high impurity content in coke oven gas, which is prone to crystallization, the impurities condense on the sensor head, thus causing inaccurate measurement by the flowmeter. When the temperature rises, impurities volatilize, the sensitivity increases and the signal strengthens. On the contrary, it decreases. This leads to unstable data.

4. During the wiring process of the instrument, the wires were not pressed firmly, resulting in intermittent signals during transmission.

5. The grounding wire of the instrument does not meet the specification requirements, allowing 50Hz interference from the strong current to enter. When the normal signal is higher than 50Hz, the output signal is normal; otherwise, an incorrect signal will be output.

Solution:

During the installation and connection of the steam flowmeter, it is necessary to ensure the accuracy of every link, including the on-site investigation before installation, the wiring of the instrument during installation, the grounding wire of the system, etc., so as to ensure that the true data is detected and can be accurately output.

2. For the metering system in operation, the method of “dual-track metering and comparative confirmation” and the “substitution method” can be adopted to confirm and eliminate the faults of the metering instruments in operation.

3. Regularly clean the flowmeter as a whole. If necessary, blow off the sensor head part of the instrument to prevent impurities from condensing at the sensor head. In cold seasons, adding heating devices to the straight pipe section of the metering and the instrument part is also beneficial to alleviate the condensation of impurities at the flowmeter.

4. Regularly drain the pipes, especially the water before the straight pipe sections. Assign dedicated personnel to discharge it regularly based on specific circumstances to minimize the water content in the metering pipe sections and remove the fluid to the greatest extent possible.