What are the matters needing attention during the installation of a steam flowmeter

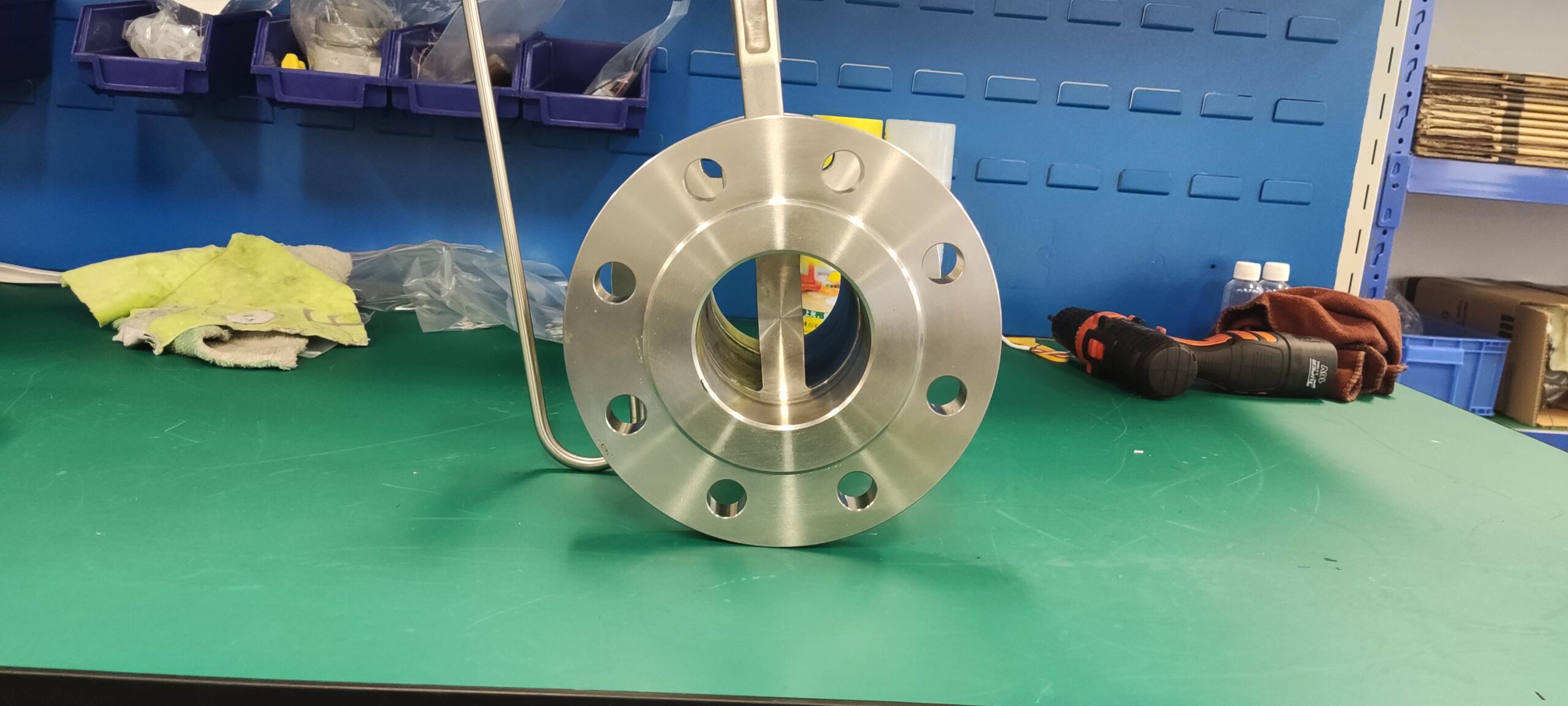

steam flowmeter can only measure in one direction. When installing, make sure that the flow direction of the medium is consistent with the direction indicated by the arrow on the flowmeter.

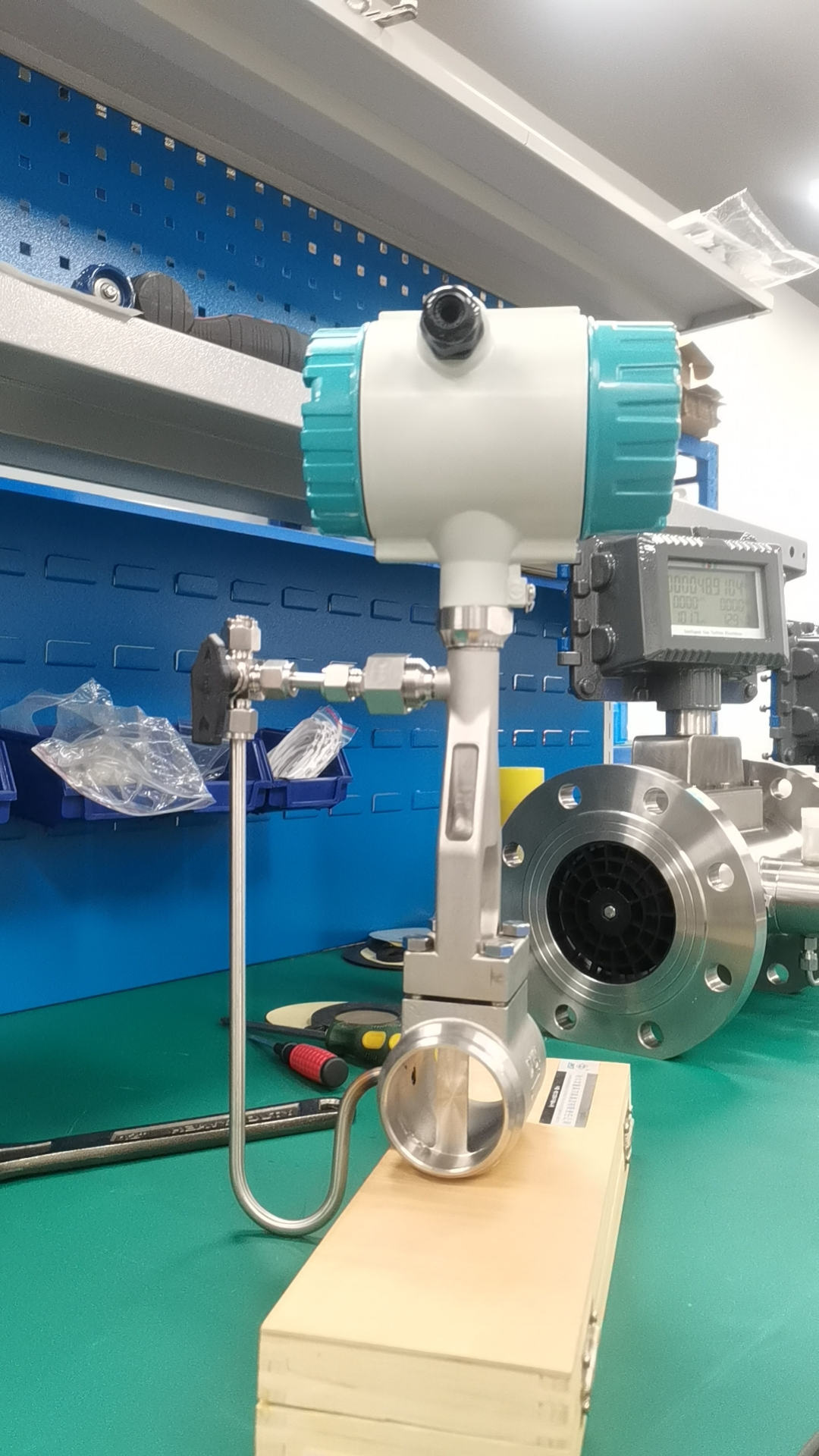

2. The steam flowmeter is installed vertically, and the medium passes through the flowmeter from bottom to top. The flowmeter is installed on a vertical pipe, and the flow direction is from bottom to top.

3. When installed horizontally, the flowmeter must be installed in the high-pressure area of the entire system and ensure the corresponding outlet pressure. Do not install it at the highest point of the pipeline, as gas tends to accumulate at the highest point of the mouth. If the pipeline is not fully filled, the outlet cannot be directly vented.

4. When measuring high-temperature fluids, vertical installation should be adopted as much as possible. If horizontal installation is necessary, please install the transmitter part of the flowmeter vertically downward or horizontally to avoid excessive temperature. Pay attention to the air flow or good ventilation at the installation location.

5. Requirements for straight pipe sections: It is necessary to ensure that the pipe diameter before the flowmeter is at least 15 times and after the flowmeter is at least 5 times. If there are interference sources such as elbows, dents or expansions in front of the flowmeter, it is necessary to ensure that the pipe diameter before the flowmeter is 30 to 40 times and the pipe diameter after the flowmeter is 6 times. Flowmeters should be installed upstream of control valves, pressure or temperature sensors.

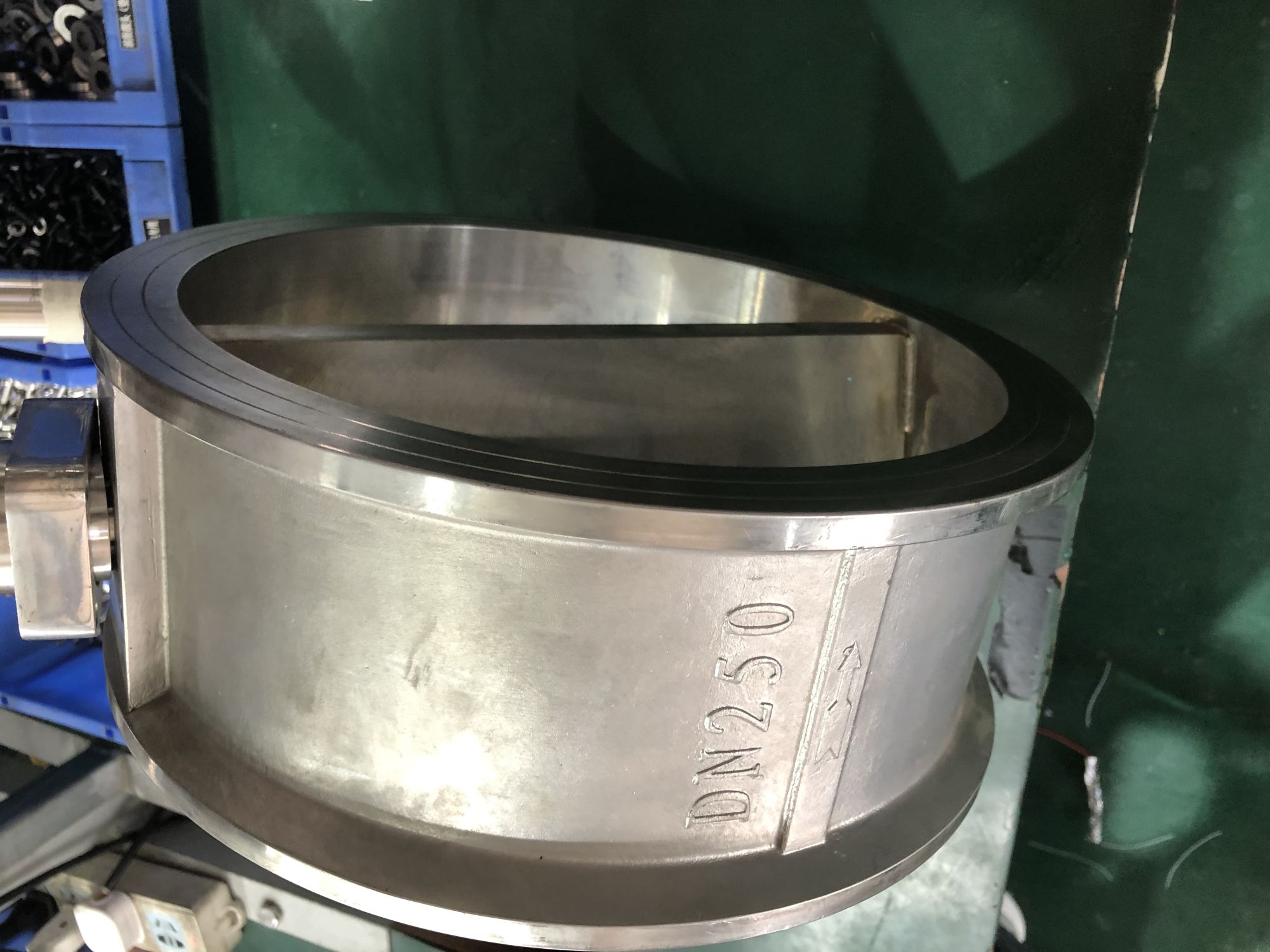

6. When installing, please note that the pipe diameter should be slightly larger than or equal to the inner diameter of the instrument.

7. When using the sealing ring, note that the inner diameter of the sealing ring should be slightly larger than or equal to the inner diameter of the instrument.

8. Cable inlet sealing

When the instrument is electrically connected, it is essential to pay attention to the sealing of the inlet hole. The corresponding sealing interface must be selected based on the entry model of the instrument cable and installed correctly and firmly. One of the common reasons for the damage of vortex steam flowmeters is the absence of a sealing joint or improper installation, which fails to achieve a sealing effect.