Analysis of the Application and Advantages of Vortex Flowmeters in Gas measurement

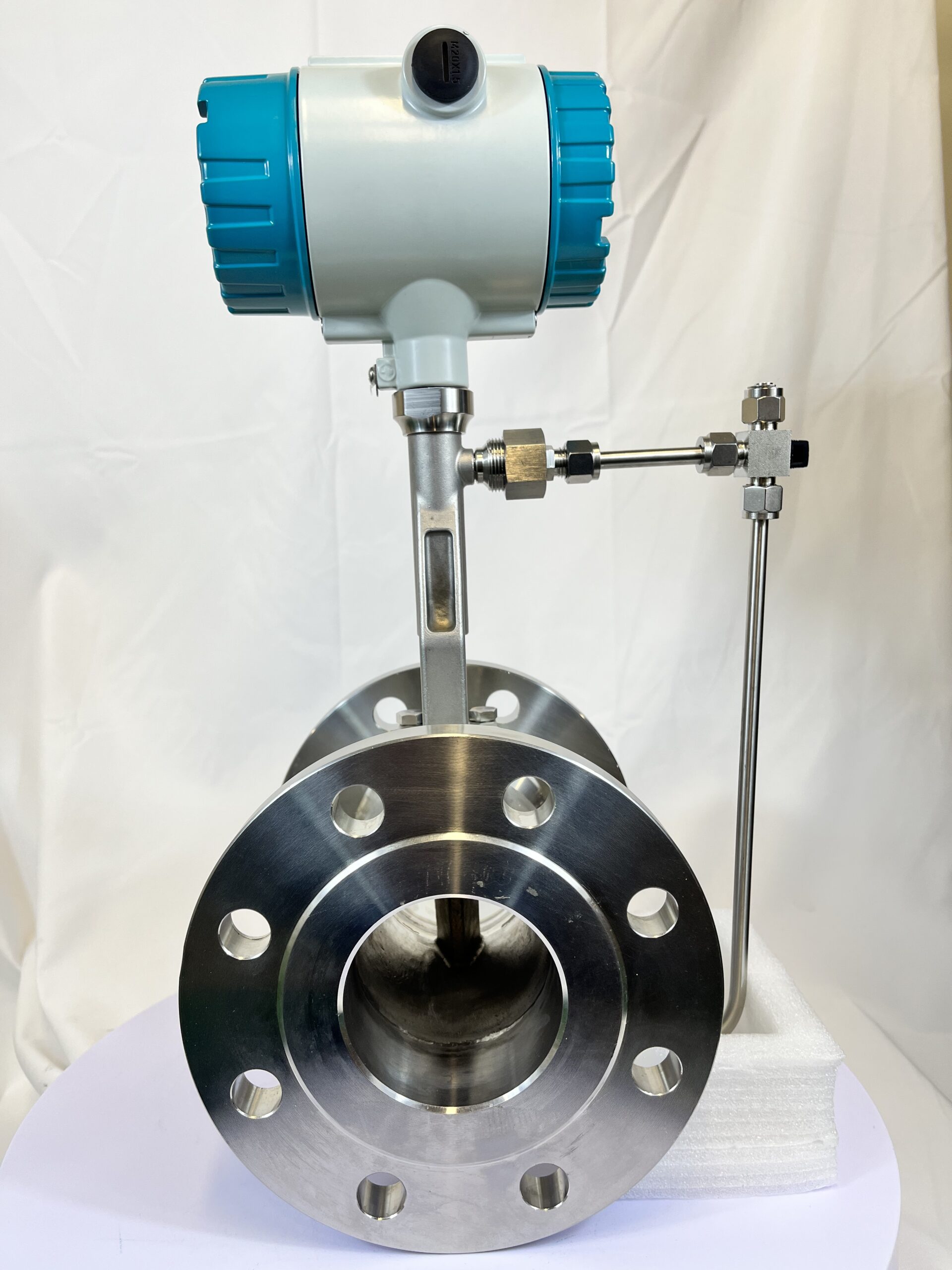

In the field of industrial gas flow measurement, vortex flowmeters, with their simple structure, high stability and wide application range, have become the ideal choice for monitoring the flow of various gases such as natural gas, steam and compressed air. Based on the Karman vortex street principle, it calculates the flow rate by detecting the vortex frequency generated when the fluid passes through the blocking fluid, and can achieve high-precision measurement without temperature and pressure compensation. The following is an analysis of the typical applications and technical advantages of vortex flowmeters in gas measurement.

Natural gas and gas metering

Vortex flowmeters are commonly used instruments in the transportation of urban gas, liquefied natural gas (LNG), and compressed natural gas (CNG). Its high-pressure resistant design (up to over 10MPa) and wide range ratio (10:1) can adapt to flow monitoring under different pressure environments, with an accuracy of ±1.0%, meeting the requirements of trade settlement.

2. Industrial steam measurement

In steam transmission systems of thermal power plants, chemical plants, etc., vortex flowmeters can accurately measure the flow of saturated steam and superheated steam. Its high-temperature resistance (up to 400℃ for some models) and anti-vibration design ensure long-term stability under high-temperature and high-pressure conditions, helping enterprises achieve energy consumption monitoring and optimization.

3. Compressed air and inert gases

The energy consumption management of the factory’s compressed air system relies on flow data. Vortex flowmeters have excellent measurement effects on dry air, nitrogen and other inert gases. Its low-pressure loss characteristic (compared with orifice plate flowmeters) reduces energy waste, and it has no moving parts, resulting in extremely low maintenance costs.

4. Special gas monitoring

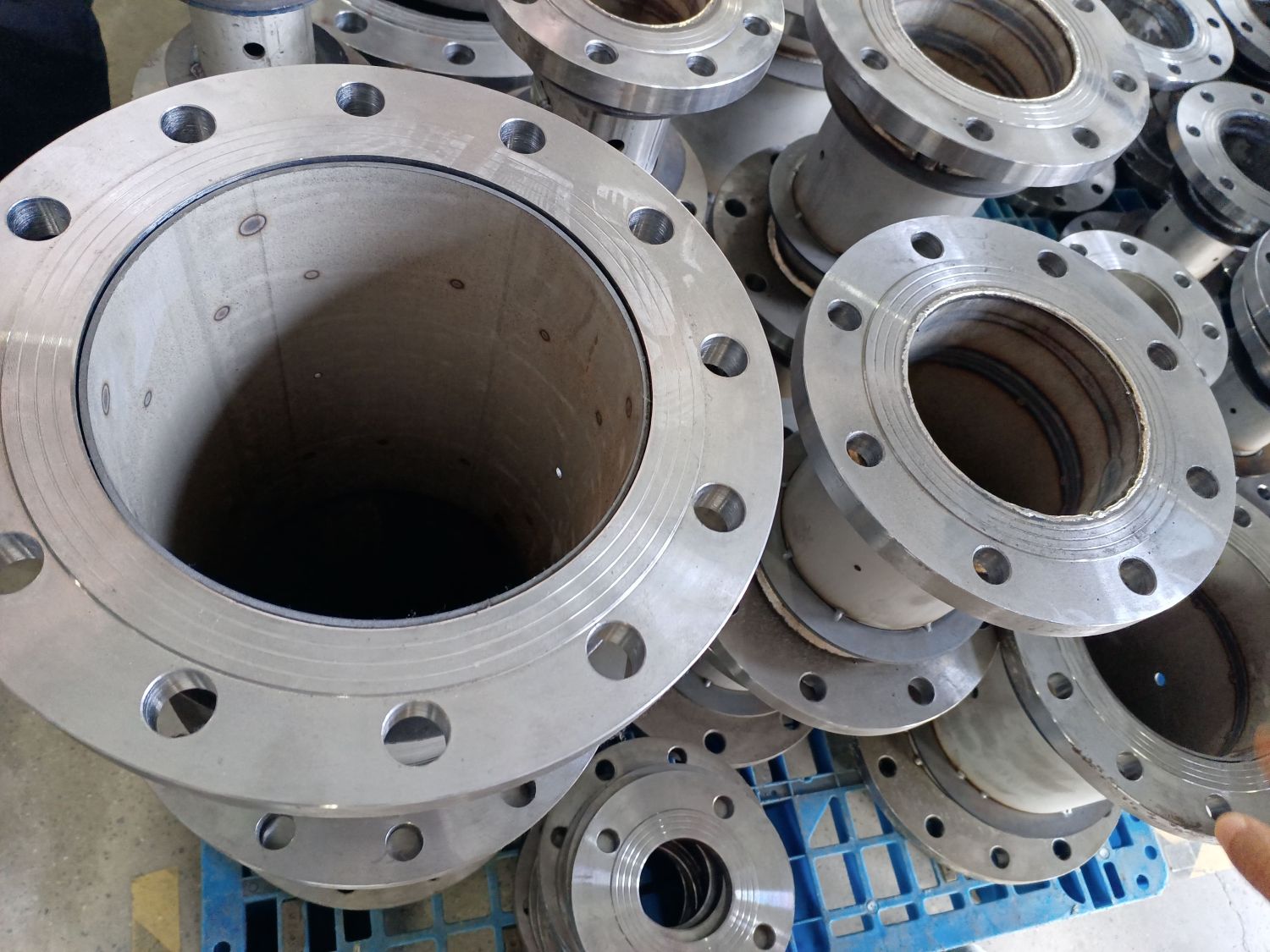

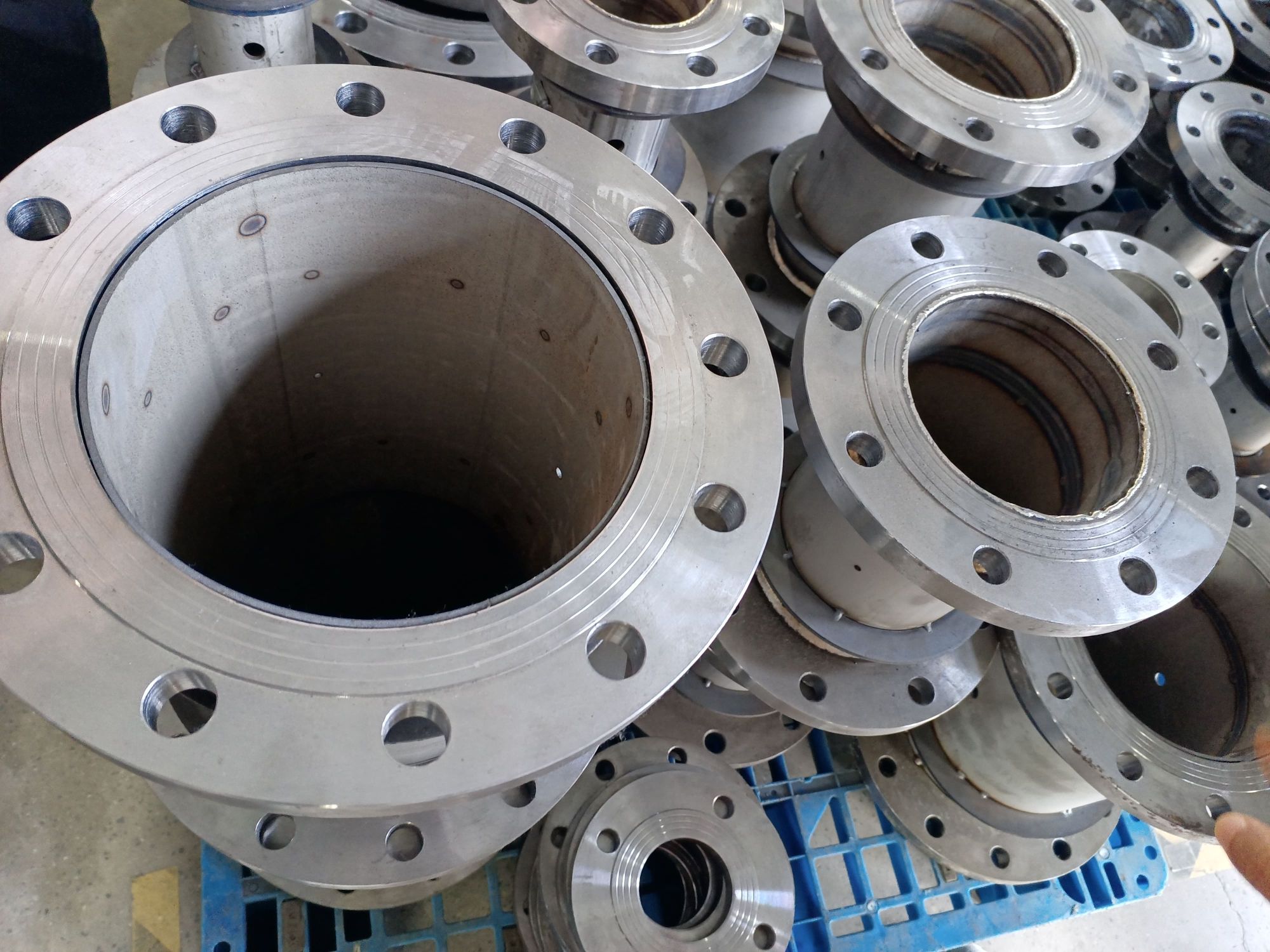

Through material optimization (such as 316L stainless steel, titanium alloy), vortex flowmeters can be adapted to corrosive gases (such as chlorine, ammonia) or high-purity gases (such as argon, hydrogen in the semiconductor industry), meeting the strict requirements of the chemical, electronic and other industries.

Summary of Core Advantages

Wide gas adaptability: It can cover everything from atmospheric air to high-pressure natural gas.

High cost performance: No additional temperature and pressure compensation required, and low installation and maintenance costs.

Long-term stability: No mechanical wear parts, and the service life can reach 8 to 10 years.

Intelligent expansion: Supports pulse output, MODBUS protocol, and is compatible with the Internet of Things platform.

Selection suggestions

Attention should be paid to the characteristics of different gases:

Density and viscosity: Extremely low-density gases (such as hydrogen) require custom calibration.

Pressure and temperature range: Special materials are required for ultra-high temperature or high-pressure working conditions.

Explosion-proof requirements: In the petrochemical field, explosion-proof certified models must be selected.