Advantages and Disadvantages of Vortex Flowmeters and Selection Guide

Vortex flowmeters, as a commonly used flow measurement instrument, have extensive applications in the industrial field. The following is a detailed analysis of the advantages and disadvantages of vortex flowmeters and their selection guidelines:

Advantages

Wide measurement range: The vortex flowmeter has a large range ratio, usually reaching 1:10 or higher (some special equipment can reach 1:35), which can meet the measurement requirements of different flow ranges.

High precision: Vortex flowmeters have high accuracy in measuring volumetric flow under working conditions, with relative deviations typically ranging from ±1% to ±1.5%. Moreover, their measurement is basically unaffected by parameters such as fluid density, pressure, temperature, and viscosity.

Low pressure loss: The design of the vortex flowmeter results in a relatively small pressure loss during the measurement process, which helps to reduce the operating costs of the system and has a certain energy-saving effect.

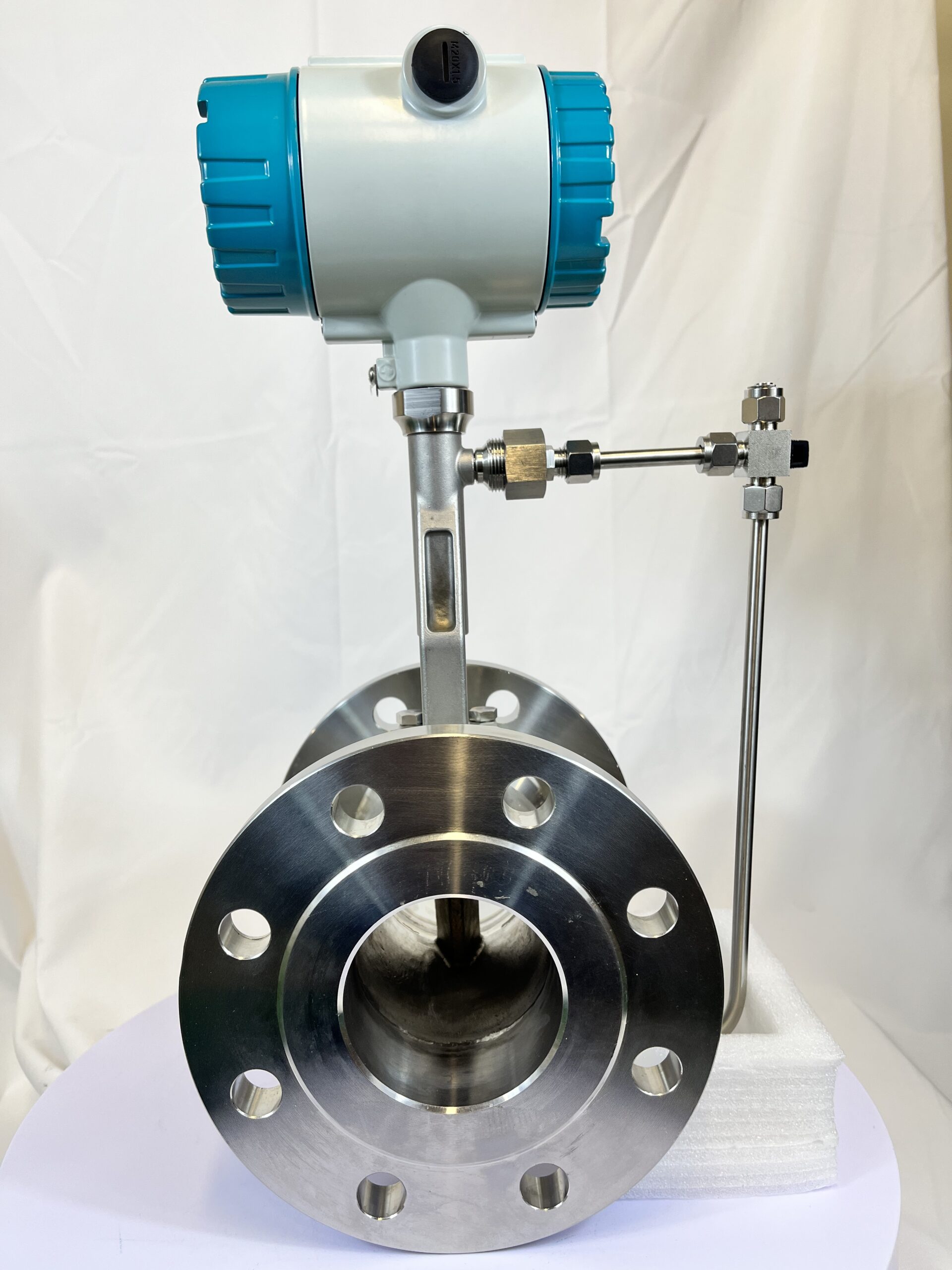

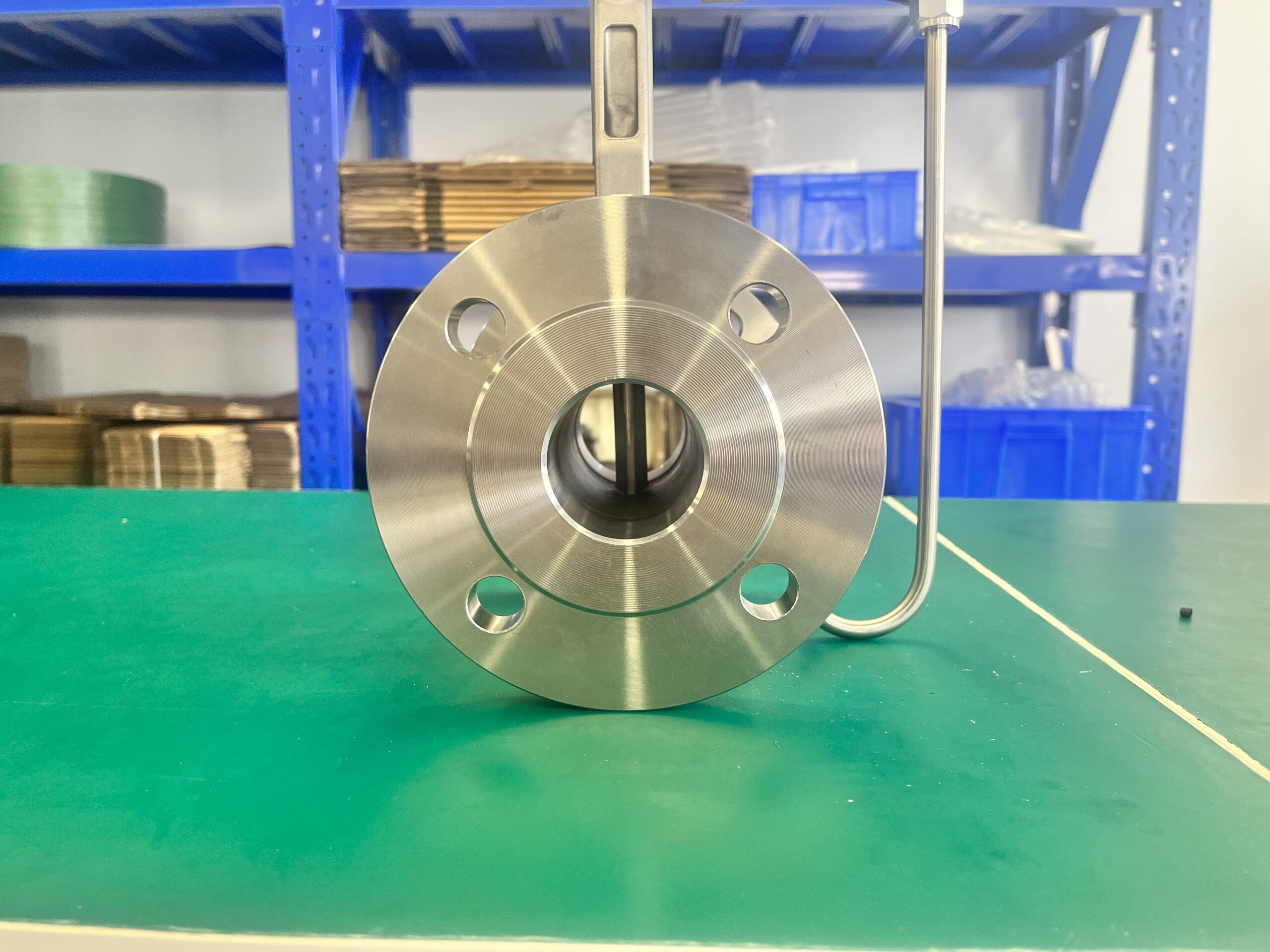

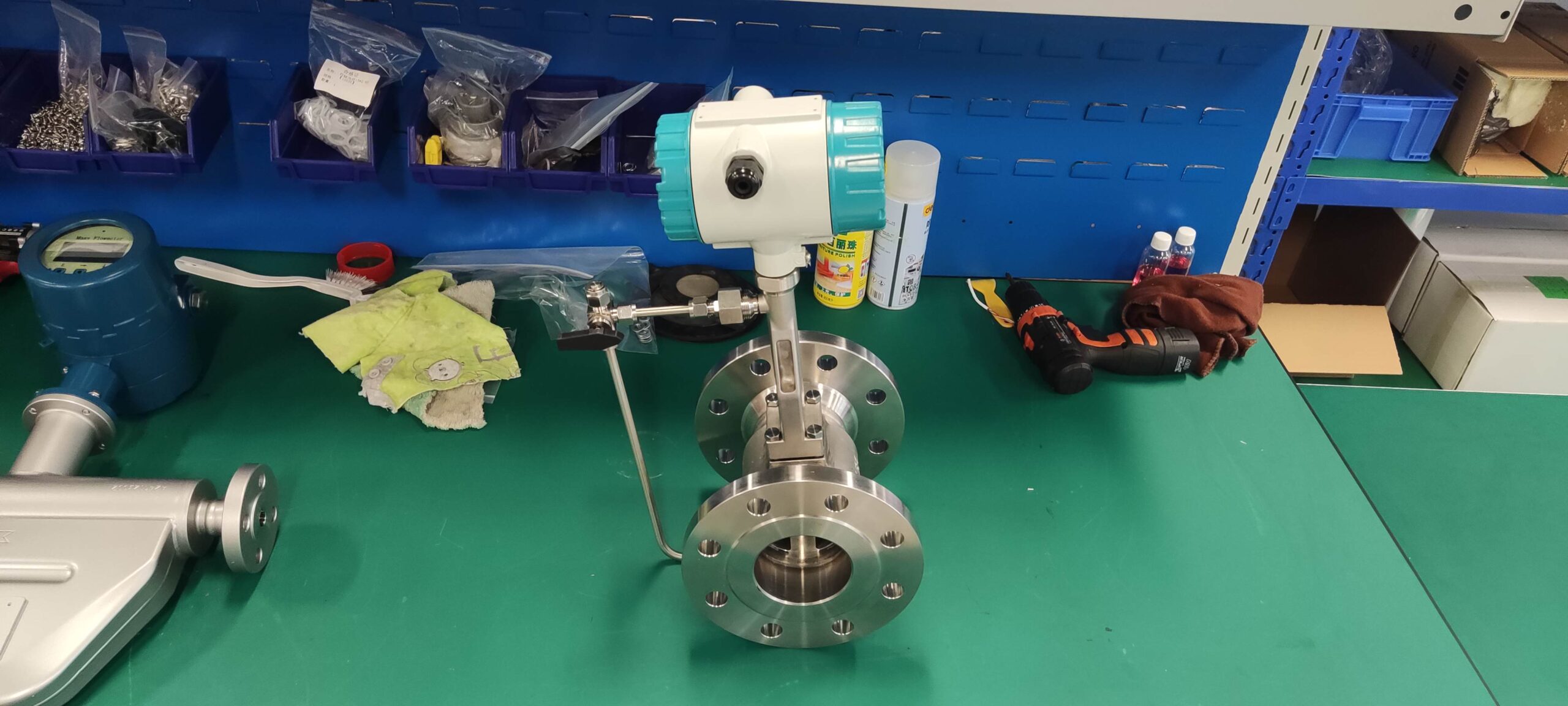

Simple and sturdy structure: The vortex flowmeter has no moving parts, featuring a simple and sturdy structure, and is highly reliable for long-term operation.

Convenient maintenance: Due to the simple structure of the vortex flowmeter and the fact that the sensor does not come into direct contact with the measured medium, its maintenance is relatively convenient.

The signal output is diverse: The vortex flowmeter has both analog standard signal output and digital pulse signal output, which is convenient for use in conjunction with digital systems such as computers to achieve automatic control and remote monitoring.

Wide application range: Vortex flowmeters can be used to measure the flow of various media such as gases, liquids, and steam, and have a wide range of applications.

High reliability: The vortex flowmeter adopts piezoelectric stress sensors, which have high reliability and can operate normally within the working temperature range of -20℃ to +250℃ (some models can reach even higher temperatures).

Disadvantages

Poor seismic performance: Vortex flowmeters are highly sensitive to vibration. External vibration may cause measurement errors or even prevent them from functioning properly. Especially in the case of large pipe diameters, the influence of vibration on the measurement accuracy is more obvious. Although there are models with better seismic performance to choose from, this issue still needs to be noted during use.

High requirements for straight pipe sections: To ensure measurement accuracy, vortex flowmeters usually need to guarantee a straight pipe section length of 40D before and 20D after (D being the pipe diameter), which to some extent limits their application in certain complex pipeline systems.

Poor adaptability to dirty media: The generating body of the vortex flowmeter is prone to being contaminated by the medium or entangled by dirt, thereby affecting the measurement accuracy. When measuring fluids containing impurities, regular cleaning and maintenance are required.

Not suitable for large pipe diameters: Vortex flowmeters are generally not suitable for pipes with diameters greater than DN300mm (some insertable models can reach even larger diameters), as the flow coefficient is relatively small at this time, which may affect the measurement accuracy. However, by choosing the appropriate installation method (such as insertion type) and reducer head, this problem can be alleviated to a certain extent.

Selection Guide

Determine the measured medium: Select the appropriate vortex flowmeter model based on the properties of the medium to be measured (such as gas, liquid, steam, etc.) and its state (such as temperature, pressure, viscosity, etc.). For high-temperature, high-pressure or corrosive media, it is necessary to select flowmeters that are resistant to high temperature, high pressure or corrosion.

Determine the flow range: Select the appropriate vortex flowmeter model and specification based on the actual flow range to ensure measurement accuracy and reliability. It is usually recommended to control the common flow rate at the middle-upper part of the measurable range.

Consider the pipe size: Select the appropriate vortex flowmeter based on the inner diameter of the pipe to ensure measurement accuracy and stability. For large-diameter pipes, the insertable vortex flowmeter can be considered for use.

Consider environmental conditions: Select the appropriate vortex flowmeter model and specification based on the working environment conditions (such as temperature, humidity, electromagnetic interference, etc.). For situations where there are vibration sources, models with better seismic performance should be selected.

Consider the signal output requirements: Select the appropriate vortex flowmeter model based on the signal output requirements. If it needs to be used in conjunction with digital systems such as computers, a model with digital pulse signal output can be selected.

Consider maintenance and upkeep: Select a vortex flowmeter model that is easy to maintain and service to reduce later maintenance costs and enhance equipment reliability.