Five major limitations of vortex flowmeters: Improper selection may cause significant errors

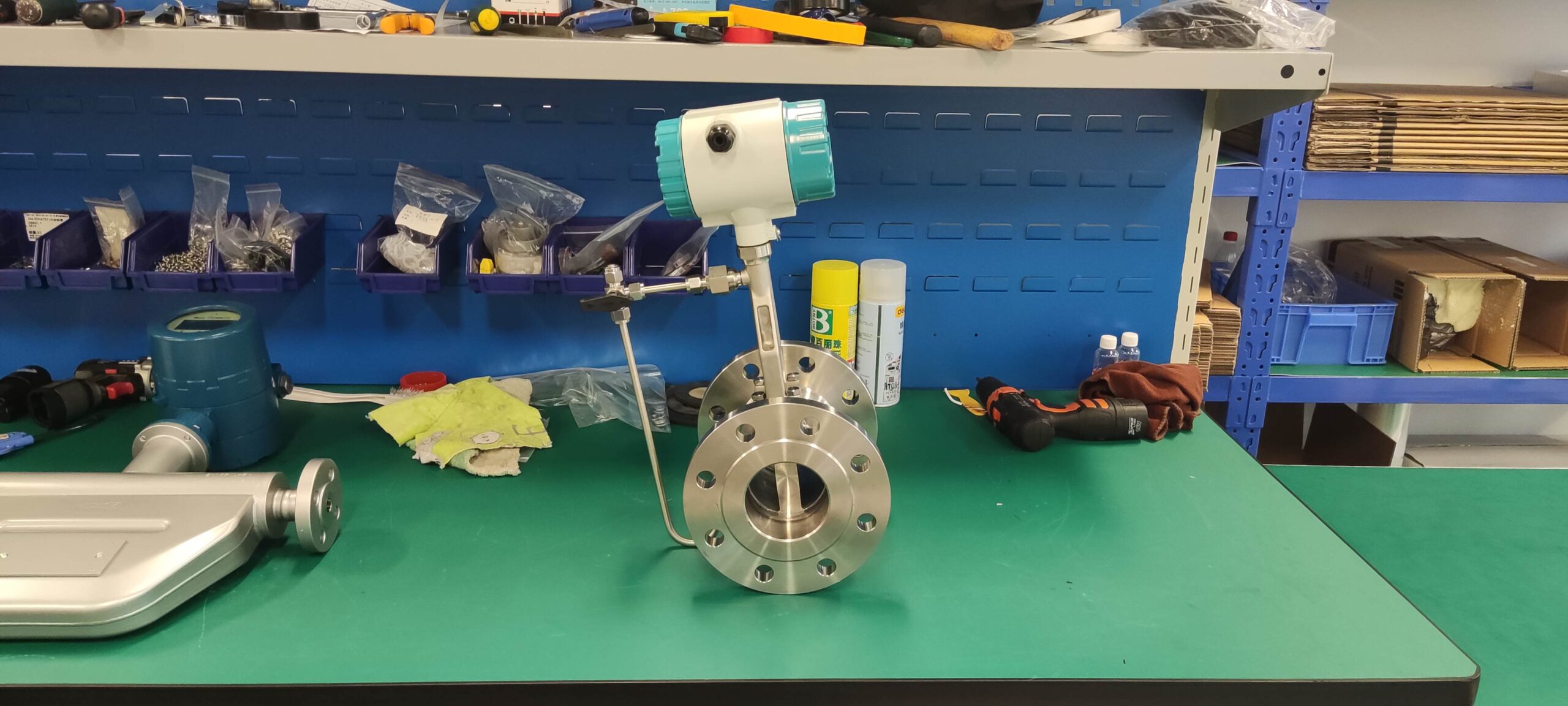

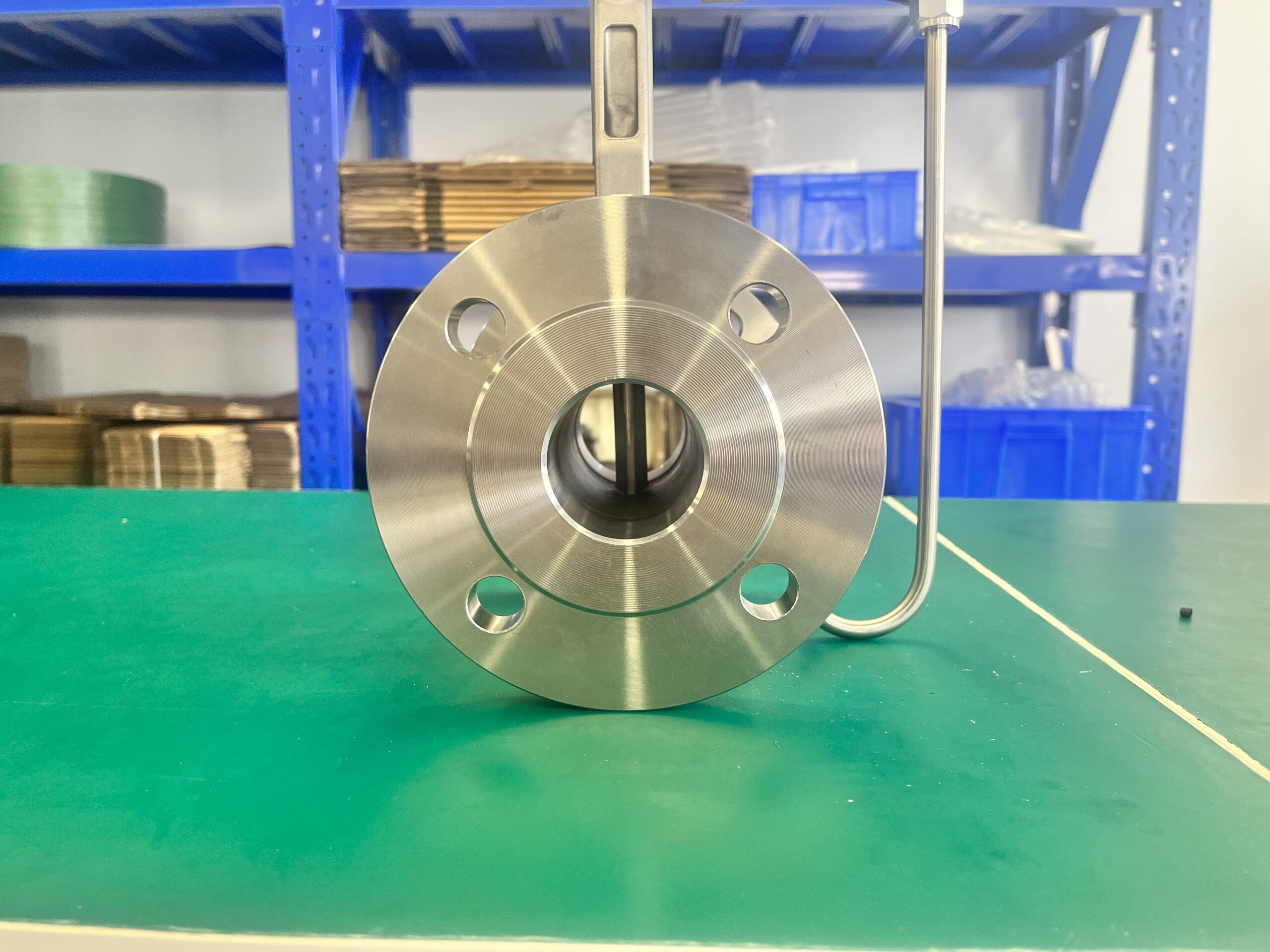

Vortex flowmeters are widely used in the measurement of steam, gas and liquid flow due to their simple structure, high reliability and wide application range. However, this type of flowmeter is not omnipotent and may experience severe errors or even failure under certain working conditions. This article will reveal five key limitations of vortex flowmeters to help users avoid selection risks.

1. Low flow rate conditions: Signal loss, measurement failure

Vortex flowmeters are based on the Karman vortex street principle and can only stably generate vortex street signals when the medium flow rate reaches a certain threshold. When the liquid flow rate is lower than 0.5m/s or the gas flow rate is lower than 5m/s, the vortex street shedding frequency is too low, resulting in the sensor being unable to detect the effective signal. For instance, when a certain chemical plant operates at low load at night, the vortex flowmeter frequently shows “zero flow”, while there is still medium flowing in the actual pipeline, resulting in a measurement deviation as high as 20%.

2. Vibration interference: False signals, errors soar

Vortex flowmeters are extremely sensitive to mechanical vibrations. If installed on pumps, compressors or pipelines with significant vibration, external vibration may be misjudged as vortex street signals, resulting in an inflated flow reading. Due to the interference of pipeline vibration, the measured value of the steam metering system in a certain power plant was 15% higher than the actual flow rate. Eventually, it was forced to switch to an ultrasonic flowmeter with better vibration resistance.

3. High-viscosity media: The shedding of vortex streets is hindered, and the accuracy decreases

When measuring high-viscosity liquids (such as heavy oil and asphalt), the viscous force of the medium will inhibit the normal shedding of vortex streets, resulting in weakened or even lost signals. A certain petrochemical enterprise adopted vortex flowmeters in the monitoring of residual oil flow. However, due to the excessively high viscosity of the medium, the measurement error exceeded 10%, and it was necessary to replace it with a volumetric flowmeter.

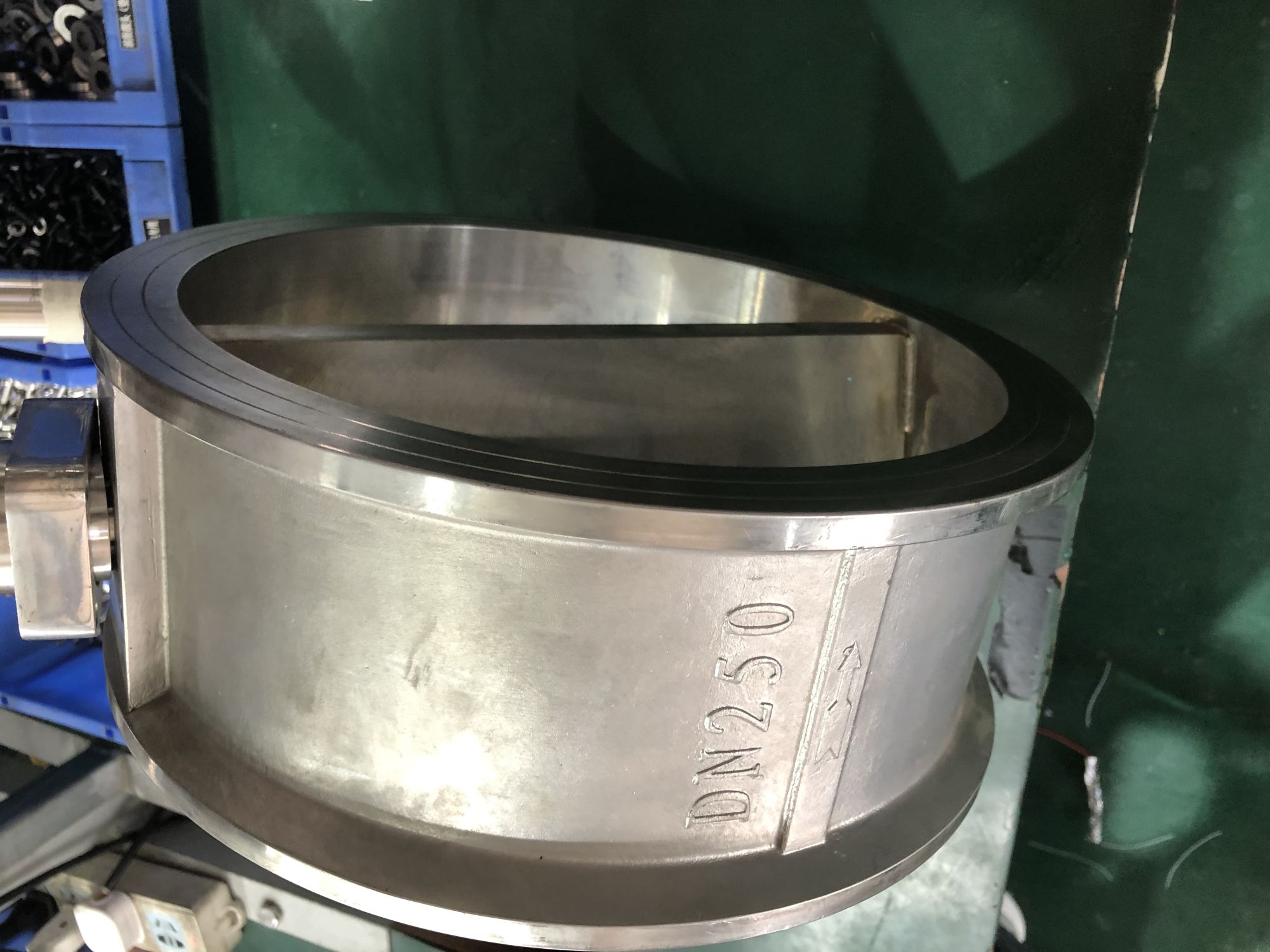

4. Solid-containing media: Intensified wear and shortened service life

If the fluid contains solid particles (such as pulp or sewage), the high-speed flowing particles will constantly impact the vortex generator, causing mechanical wear. Just half a year after a certain sewage treatment plant started using vortex flowmeters, the vortex generator was severely corroded, the measurement accuracy dropped significantly, and the maintenance cost soared.

5. Pulsating flow condition: Measurement distortion, large data fluctuations

In pulsating flow scenarios such as at the compressor outlet and in reciprocating pump pipelines, the periodic fluctuations of the fluid can cause the vortex street signal to become disordered, resulting in sharp jumps in the output value of the flowmeter. A certain natural gas metering station failed to consider the influence of pulsating flow, and the trade settlement error once reached 8%, causing huge economic losses.

Conclusion: Reasonable selection is the key

Although vortex flowmeters have many advantages, their limitations cannot be ignored. Under conditions of low flow rate, high vibration, high viscosity, solid content or pulsating flow, it is recommended to switch to more suitable solutions such as electromagnetic flowmeters, ultrasonic flowmeters or mass flowmeters. Before selection, it is essential to conduct a comprehensive assessment in combination with the medium characteristics, flow velocity range and installation environment to ensure the accuracy and reliability of flow measurement.