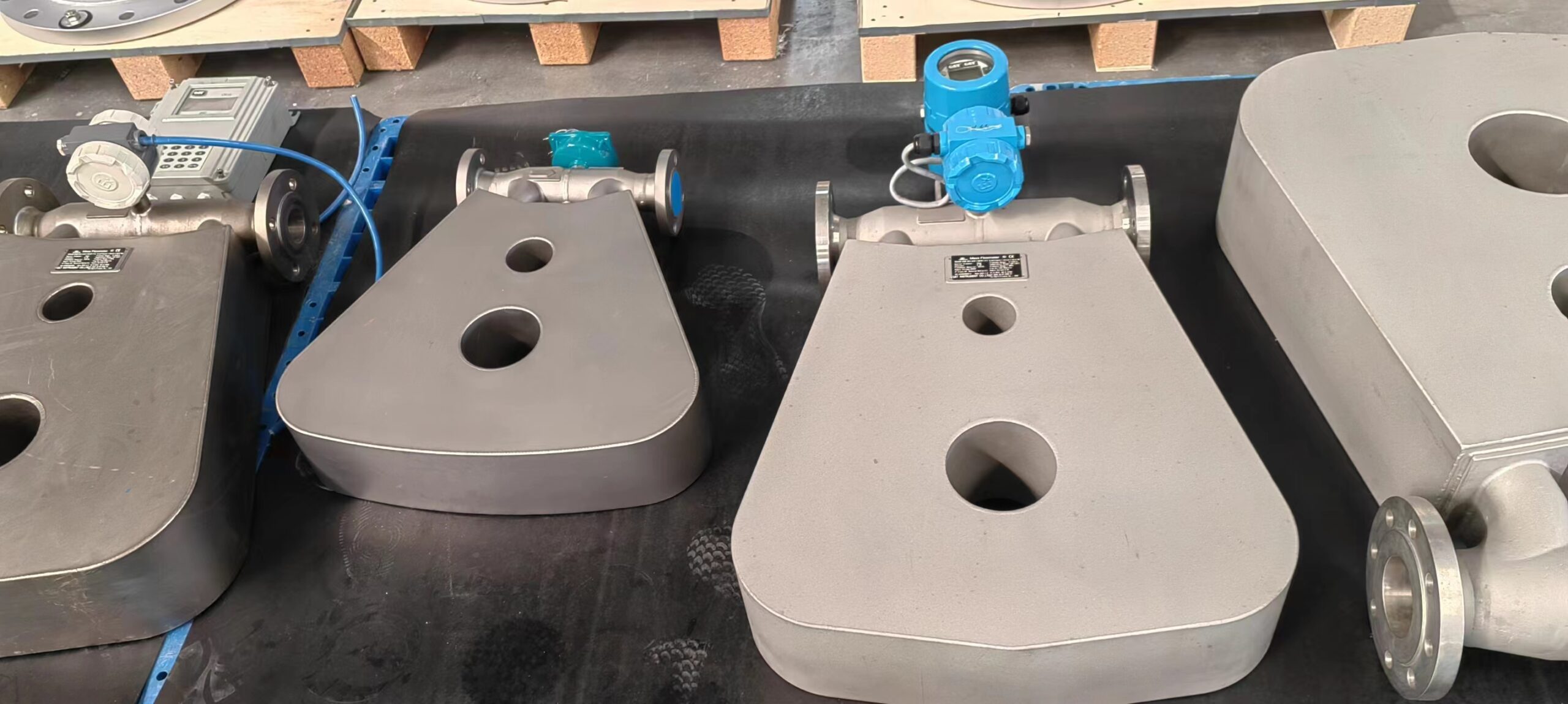

Common Faults and Solutions of Coriolis Mass Flowmeters

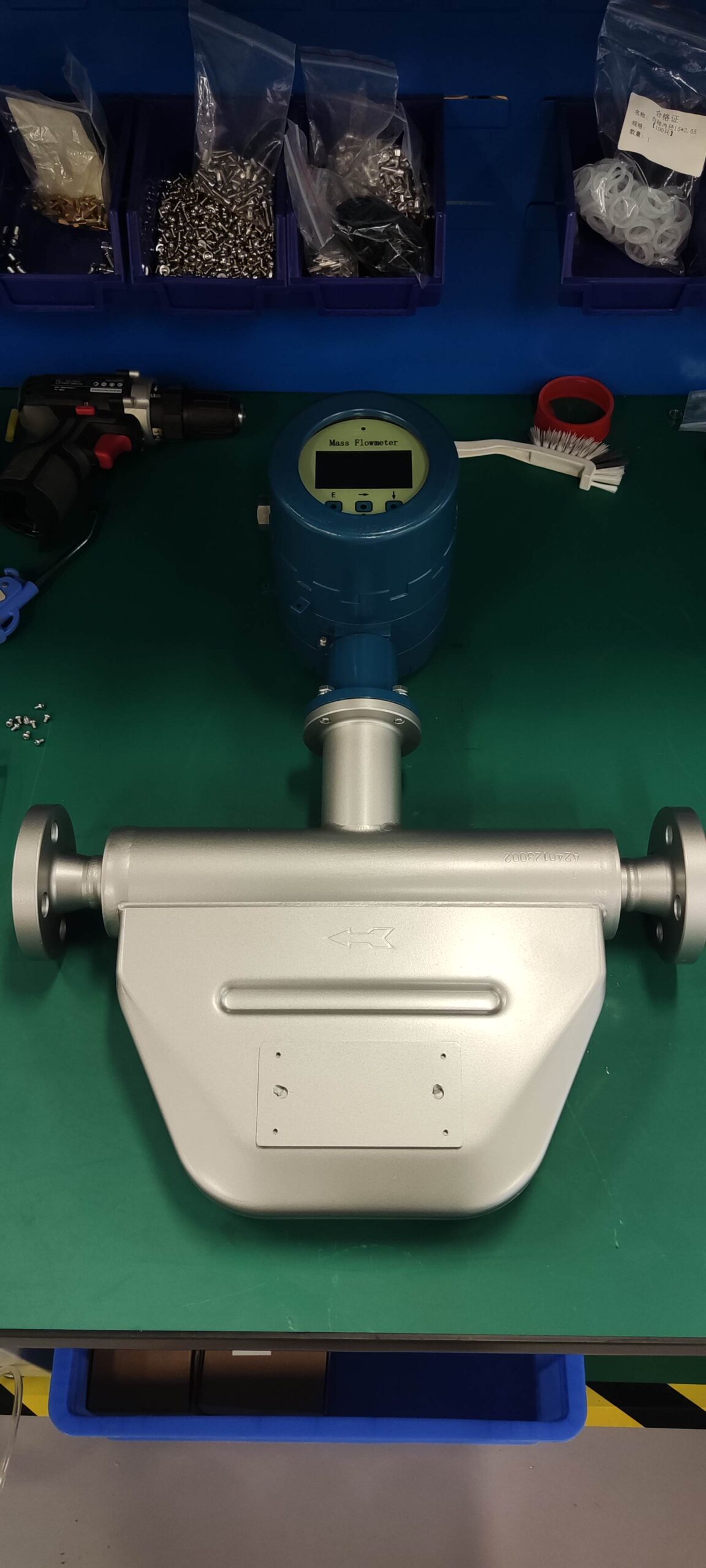

In the complex processes of industrial production, precise flow measurement is a key link to ensure production efficiency and product quality. Coriolis mass flowmeters, with their advantages of high precision and strong reliability, are widely used in many industries, such as petrochemicals, food and beverage, and pharmaceuticals. Mass flowmeters (based on the Coriolis effect) are widely used in industry to directly measure the mass flow rate of fluids, but they may malfunction due to various factors. The following are common problems and solutions:

Zero drift

Phenomenon: A non-zero value is displayed when there is no flow.

Possible causes:

– Installation stress or pipe vibration.

– Drastic temperature changes.

Residues adhere to the measuring tube.

– Sensor aging.

Solution

– Perform zero-point calibration (operated through the transmitter interface to ensure the fluid remains stationary).

Check if the installation is firm to avoid pipe stress.

Clean the measuring tube and remove the sediment.

– Replace the aging sensor.

2. Excessive measurement error

Phenomenon: The reading deviates significantly from the true value.

Possible causes:

– Changes in fluid density and viscosity.

The fluid contains bubbles or solid particles.

Improper installation location (such as near pumps/valves).

– Incorrect parameter Settings (such as density and temperature compensation).

– Solution:

Update the physical property parameters of the fluid in the transmitter.

Install a filter or gas-liquid separator to eliminate bubbles/particles.

Ensure the length of the straight pipe section (10D before and 5D after, where D is the pipe diameter).

Recalibrate the flowmeter.

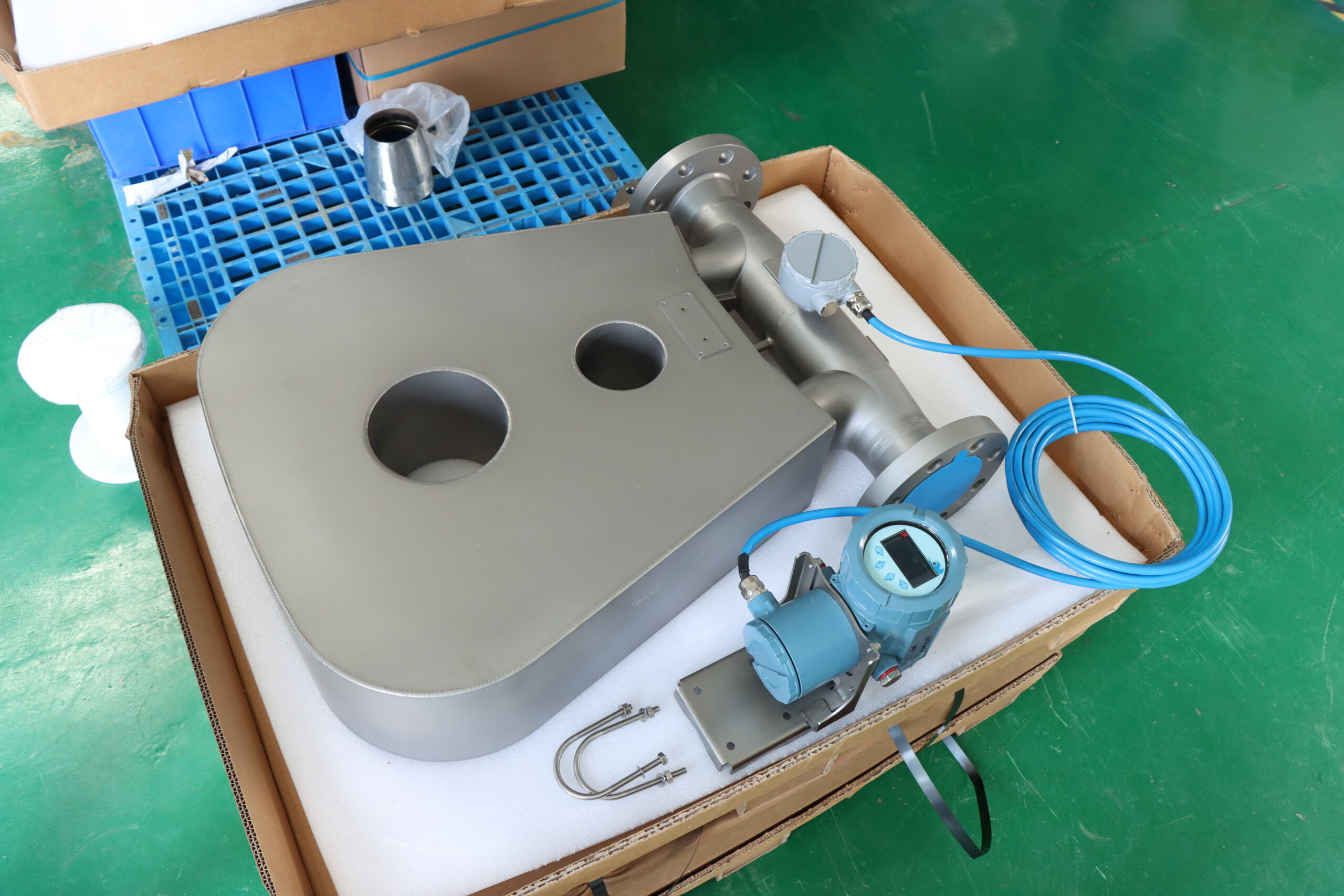

3. No output signal

– Phenomenon: No flow signal or abnormal output.

– Possible causes:

Power failure (power outage, unstable voltage).

– Wiring error or cable damage.

The sensor/transmitter is damaged.

– Solution:

Check the power line and measure the voltage with a multimeter.

Rewire or replace the cable.

Test the sensor/transmitter and replace the faulty component.

4. Influence of temperature/pressure

Phenomenon: Inaccurate measurement under high temperature or high pressure.

– Possible causes:

– Exceeded the rated working range of the sensor.

– Temperature compensation failed.

– Solution:

Install the radiator/pressure reducing valve, or replace it with a high-temperature/high-pressure resistant model.

Check the temperature compensation module and recalibrate it.

5. External vibration interference

– Phenomenon: Fluctuation or abnormality in the reading.

– Possible causes:

Vibration transmission from nearby equipment (pumps, compressors).

– Solution:

Reinforce the pipe supports and use shock-absorbing brackets.

Isolate the flowmeter from the vibration source.

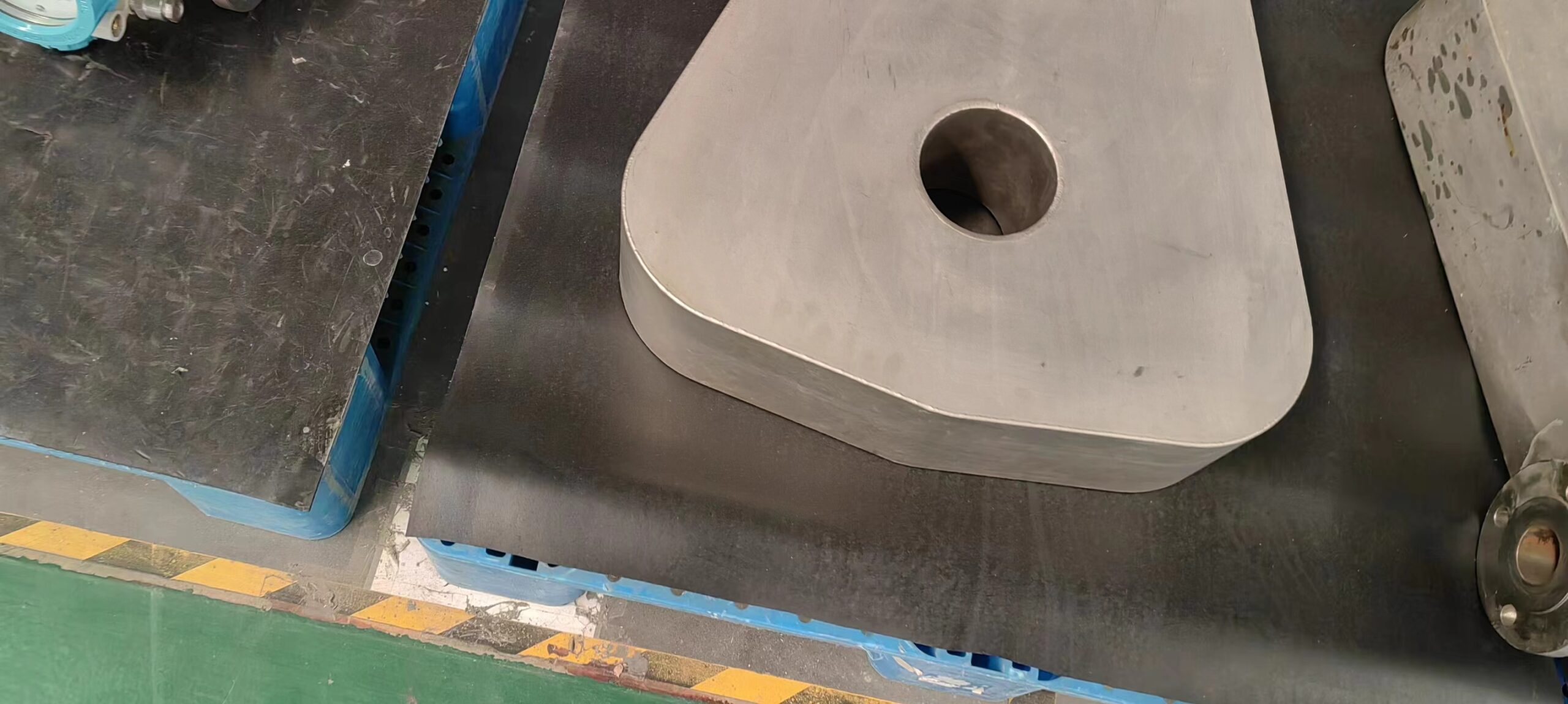

6. Mechanical damage

Phenomenon: Deformation and corrosion of the measuring tube.

– Possible causes:

– Fluid corrosion or wear.

– External force impact.

– Solution:

Regularly inspect and replace the measuring tubes made of corrosion-resistant materials.

Avoid mechanical shock and install a protective cover.

7. Two-phase flow or uneven fluid distribution

Phenomenon: Data jumps when gas and liquid are mixed.

– Solution:

Install a gas-liquid separator upstream.

Ensure that the fluid is completely liquid and flows stably.

8. Communication failure

– Phenomenon: Unable to communicate with the control system.

– Possible causes:

The communication protocol does not match.

– Cable interference or damage.

– Solution:

Check the protocol Settings (such as HART, Modbus).

Use shielded cables and keep away from strong electromagnetic interference sources.

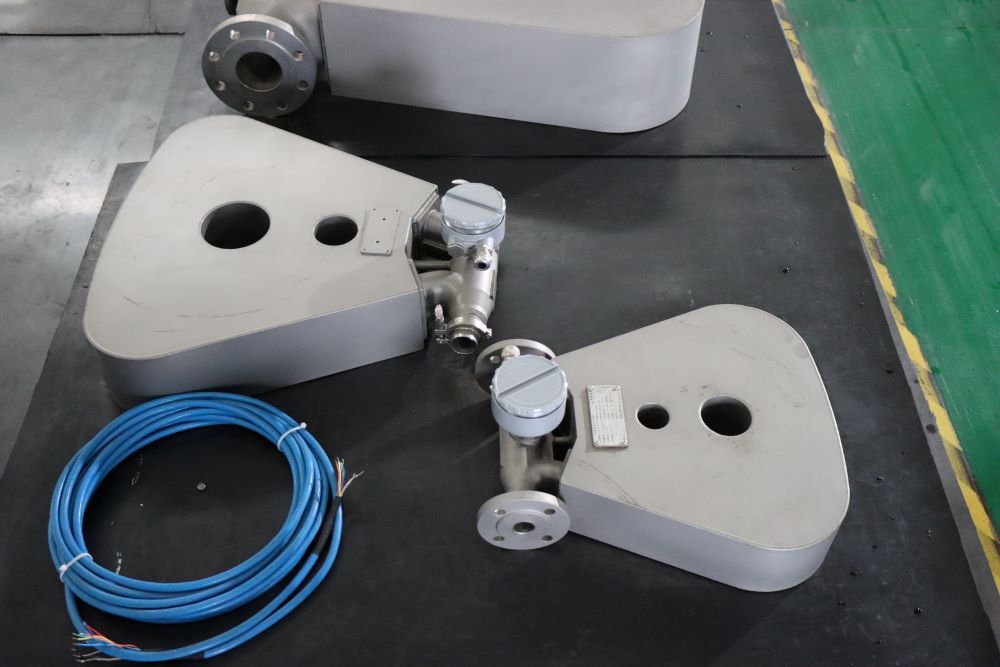

9. Installation issues

– Phenomenon: Long-term zero drift or error.

– Possible causes:

Insufficient pipe support or uneven force distribution on the flange.

– Solution:

Reinstall to ensure that the pipes are naturally aligned and stress-free.

– Use flexible joints to reduce stress.

Maintenance suggestions

– Regular calibration: Perform zero-point calibration every 6 to 12 months or after changes in working conditions.

– Cleaning and maintenance: Clean the measuring tube when the machine is shut down to prevent scaling.

– Check the seal: Prevent leakage from causing moisture to the electrical components.

– Record data: Track historical data and issue early warnings for potential faults.

Professional training: Operators need to be familiar with equipment operation and basic fault handling.

Coriolis mass flowmeters play a significant role in industrial production. Although various faults may occur, as long as we are familiar with the manifestations, causes and solutions of common faults, we can handle them in a timely and effective manner to ensure their stable operation, provide accurate and reliable flow data for production, and help enterprises achieve efficient production. In case of complex malfunctions (such as sensor damage), it is recommended to contact the manufacturer or professional technicians to avoid misoperation that may exacerbate the problem. Through system maintenance and correct installation, the service life of mass flowmeters can be significantly prolonged and the measurement accuracy can be improved.