The application of Coriolis mass flowmeters in the petrochemical and natural gas industries

In the petrochemical and natural gas industry, precise flow measurement is crucial for production efficiency, product quality, cost control and trade fairness. The Coriolis Mass Flow Meter (CMF), with its unique measurement principle, can directly measure the mass flow rate of fluids and is not affected by fluctuations in parameters such as temperature, pressure, density, and viscosity. It has become a trusted core measurement device in the industry, especially with significant advantages in complex working conditions and high-precision requirements scenarios.

Working principle

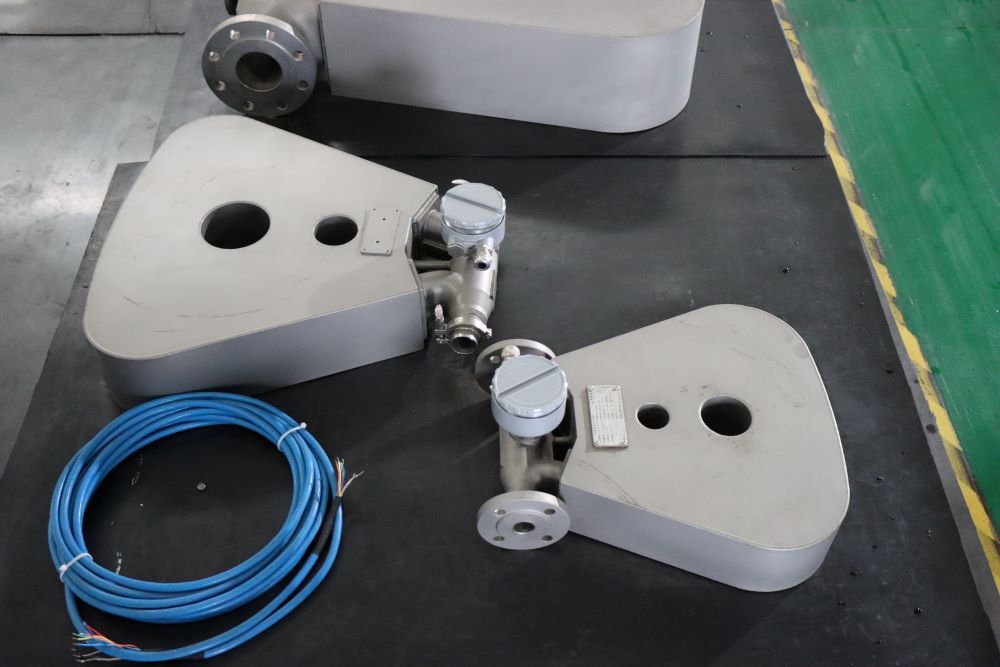

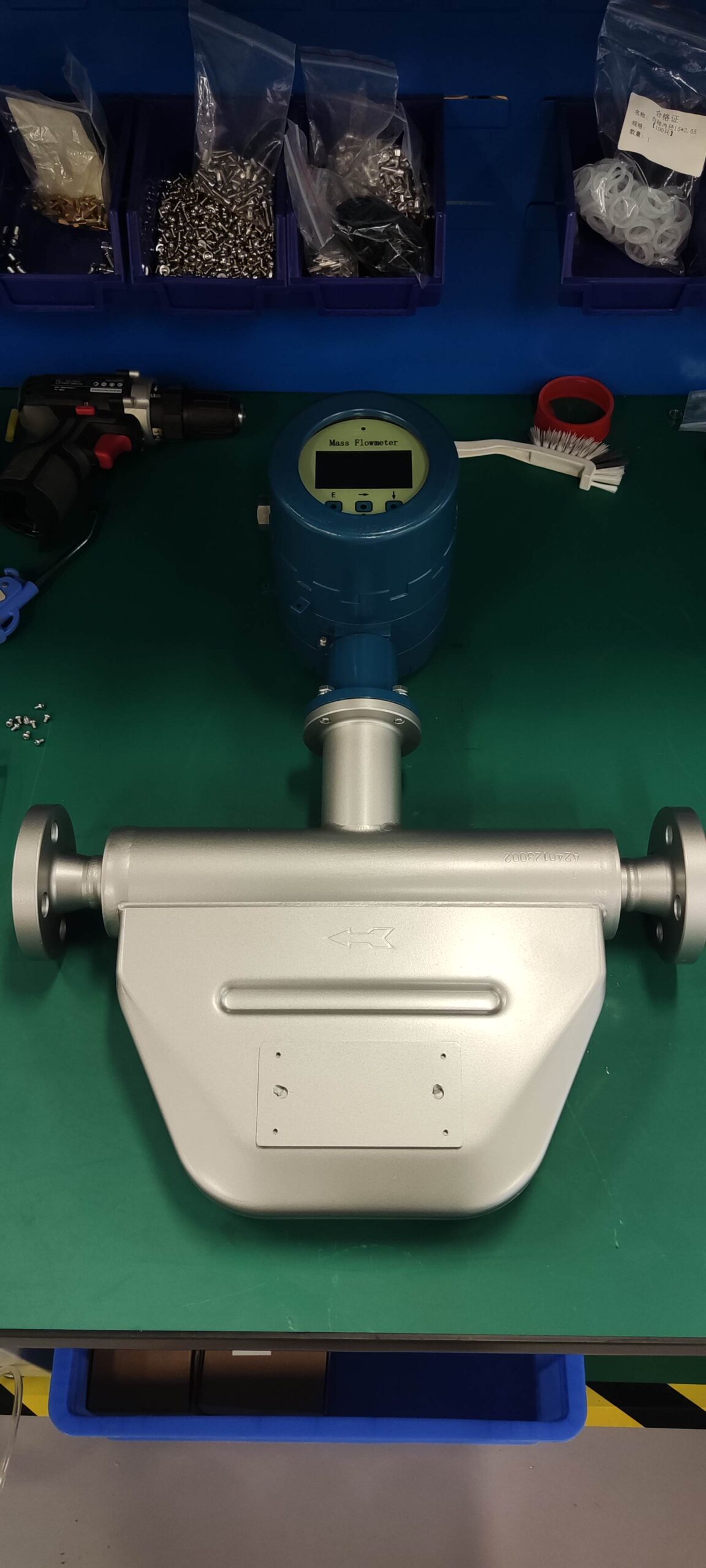

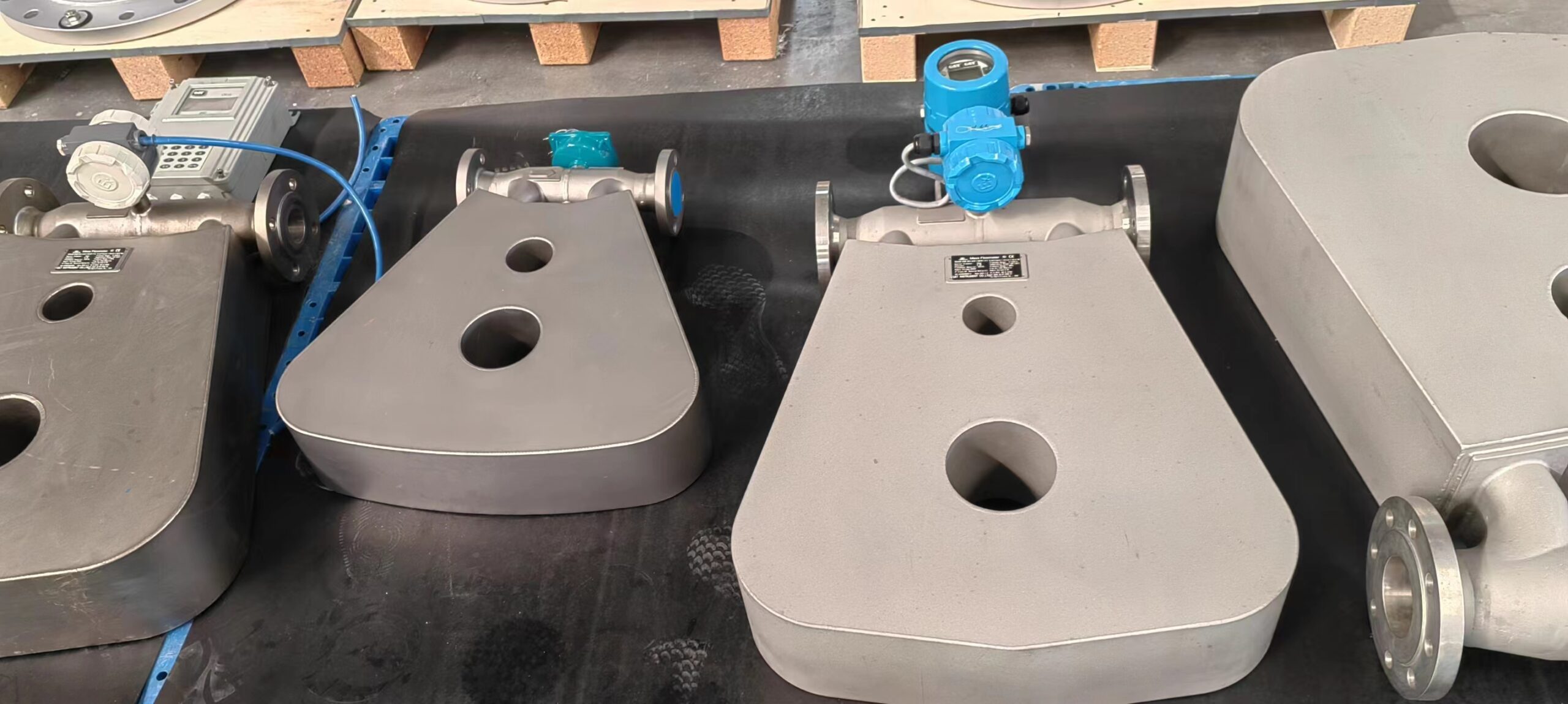

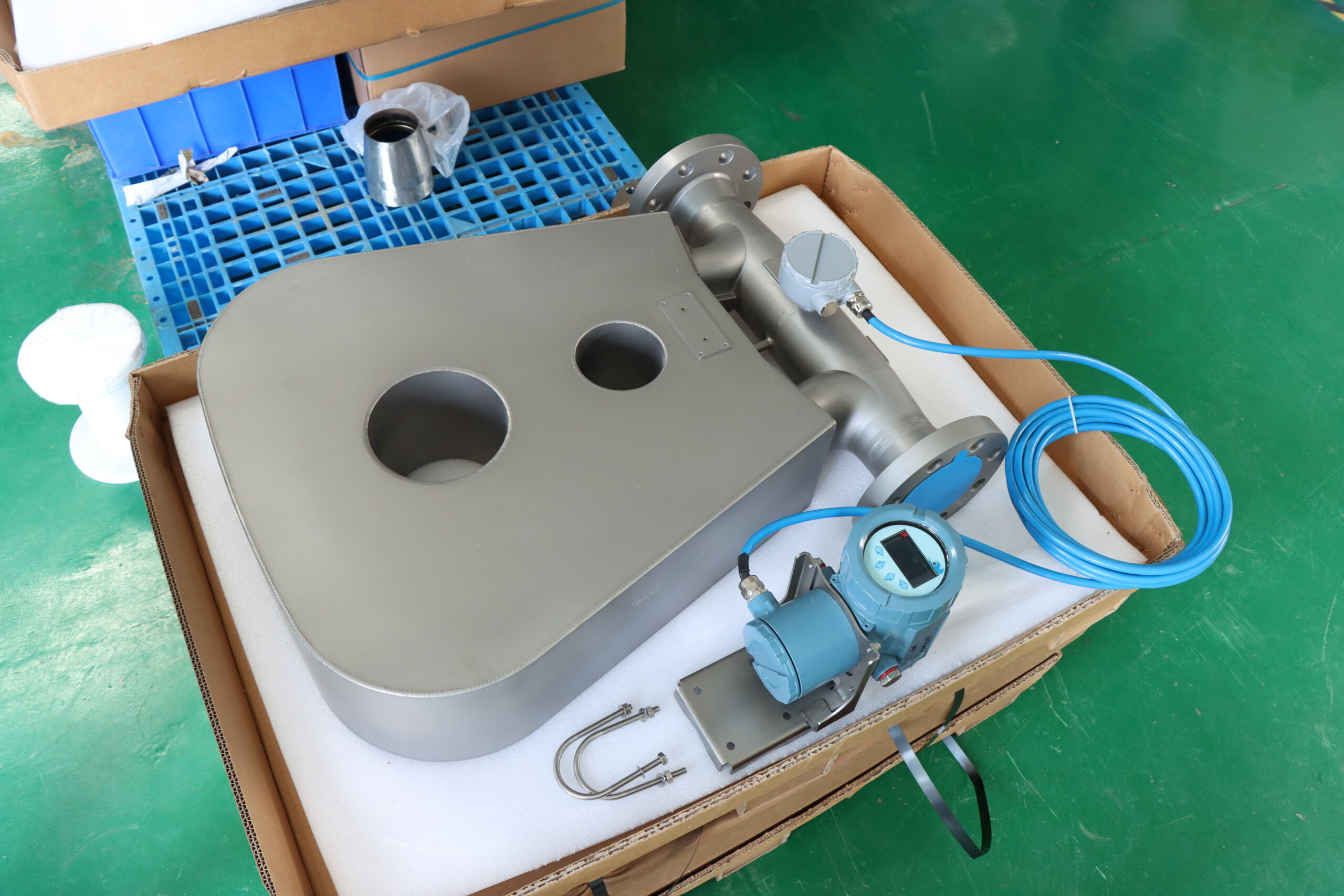

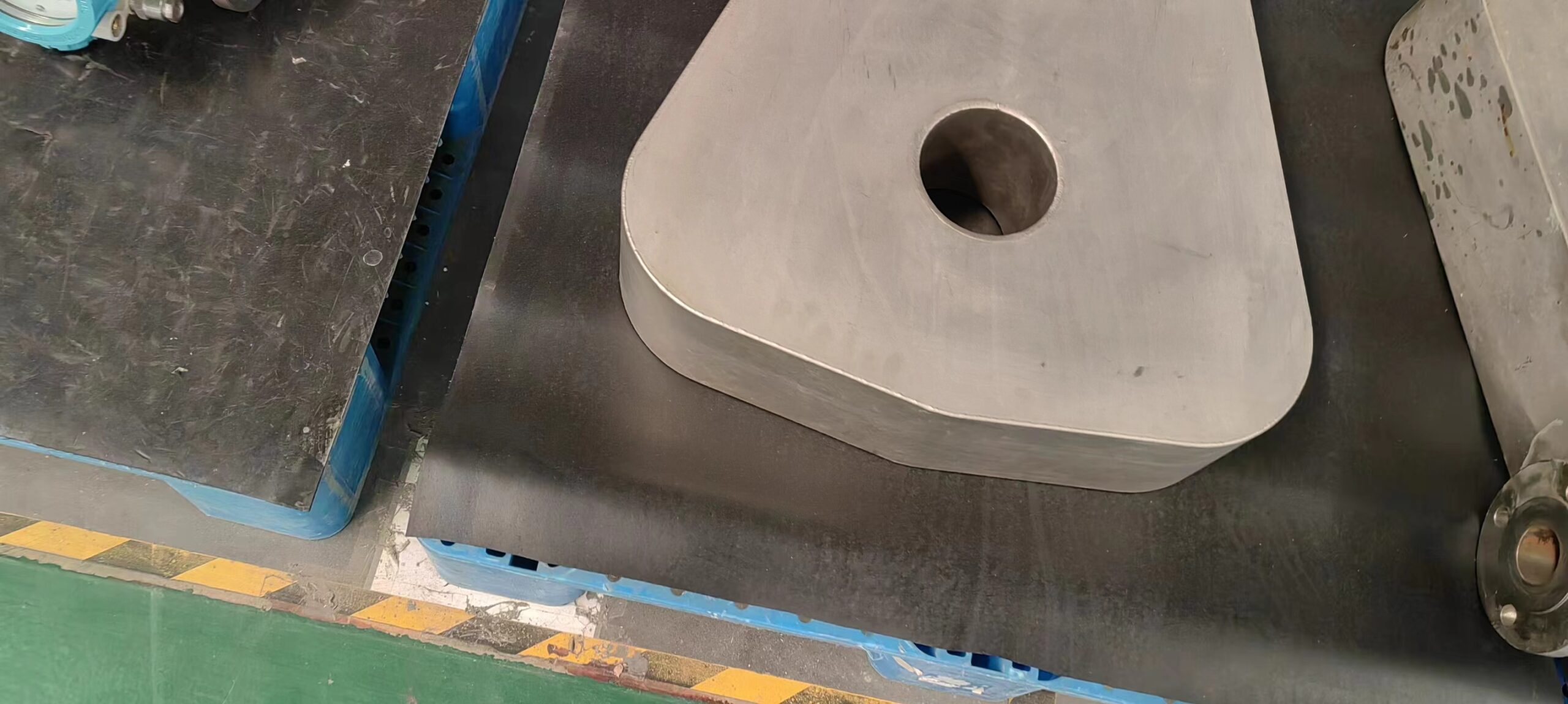

According to the principle of Coriolis force, when a fluid flows in a vibrating pipe, it exerts a Coriolis force proportional to the mass flow rate on the pipe, causing it to twist and deform. The Coriolis mass flowmeter accurately calculates the mass flow rate of the fluid by detecting the degree of distortion (phase difference) of the vibrating tube. Its core components include vibration measurement tubes, drive systems, detection sensors and signal processing units. For instance, the Aister Coriolis flowmeter adopts a double U-shaped measuring tube design. The drive system makes the measuring tube vibrate at its natural frequency. When the fluid flows through, the detection sensor captures the phase difference of vibration at the inlet and outlet of the measuring tube caused by the Coriolis force. The signal processing unit converts it into parameters such as mass flow rate, density, and temperature for output.

Technical advantage

High-precision measurement: The measurement accuracy can reach ±0.1% or even higher, meeting the strict requirements for high precision in trade settlement and process control in the petrochemical and natural gas industries. In the handover of crude oil trade, even minor flow errors can lead to huge economic losses. The high precision of Coriolis flowmeters ensures fair and just trade.

Wide range ratio: The range ratio can reach 100:1 or even higher, allowing for switching between high and low flow conditions, and adapting to flow changes at different production stages. For instance, when the flow rate in the early and middle to late stages of natural gas extraction varies greatly, a wide range ratio can ensure precise measurement throughout the entire process.

Multi-parameter measurement: It can simultaneously measure multiple parameters such as mass flow rate, density, and temperature, providing rich data for process optimization. In chemical production, density measurement can monitor the changes in product composition in real time, and process parameters can be adjusted promptly to ensure product quality.

Strong anti-interference ability: No moving parts, the full diameter design of the measuring tube reduces fluid resistance and clogging risk, and has strong adaptability to complex fluids, such as high-viscosity crude oil and natural gas containing impurities. The Aister Coriolis flowmeter adopts special anti-vibration and anti-electromagnetic interference technology, ensuring stable operation under harsh working conditions.

Crude oil/refined oil product trade settlement

Oil pipeline measurement: On long-distance crude oil transportation pipelines, Coriolis mass flowmeters are installed at key nodes to measure the mass flow of crude oil in real time and accurately, providing authoritative data for trade settlement of upstream and downstream enterprises. For instance, a large oil pipeline transportation company has adopted the Coriolis flowmeter from Aister , reducing the trade measurement error from ±0.5% of traditional flowmeters to within ±0.15%, and saving economic losses by tens of millions of yuan annually.

Oil depot and refinery metering: High-precision metering is required in the oil depot’s receiving and dispatching process, as well as in the refinery’s crude oil entry and refined oil exit. Aister Coriolis flowmeters feature rapid response and stable measurement characteristics. They accurately measure under frequent start-stop and flow fluctuation conditions, safeguarding the economic interests of enterprises.

Feed control for chemical reaction vessels

The ratio of monomers to catalysts: In the polymerization reactions of chemical monomers such as ethylene and propylene, precisely controlling the feed ratio of monomers to catalysts is the key to ensuring product quality and performance. The Coriolis mass flowmeter can precisely control the flow rate to ensure the stable progress of the reaction. After a large petrochemical enterprise adopted the Aister Coriolis flowmeter, the product qualification rate increased from 92% to 97%, effectively reducing the defect rate and production costs.

High-viscosity fluid transportation: High-viscosity fluids are often involved in chemical production, such as asphalt and polymer melts. Traditional flowmeters have large measurement errors. Coriolis mass flowmeters are not affected by viscosity and can accurately measure and control flow. In the production and transportation of asphalt, the Aister Coriolis flowmeter operates stably, providing high-quality asphalt for road paving.

Liquefied natural gas (LNG) measurement

LNG receiving terminal metering: The loading and unloading, storage and gasification processes of LNG receiving terminals require precise measurement of the mass flow rate of LNG. The Coriolis mass flowmeter can operate in a low-temperature environment (-162℃), directly measuring mass flow rate and avoiding measurement errors caused by the variation of LNG density with temperature. The Coriolis flowmeter designed by Aister specifically for LNG applications has been verified through actual operation to feature high measurement accuracy and good stability, and is widely used in multiple LNG receiving terminals in China.

LNG transport tanker measurement: During the loading and unloading process of LNG transport tankers, the Coriolis mass flowmeter can measure quickly and accurately, ensuring reliable transportation handover data. The Aister Coriolis flowmeter can be used to achieve automated measurement during the loading and unloading process of tank trucks, improving operational efficiency and measurement accuracy.

Industry development trends

With the digitalization and intelligence development of the petrochemical and natural gas industries, Coriolis mass flowmeters will evolve towards higher precision, wider measurement range, multi-functional integration and intelligence. Integrating with Internet of Things, big data and artificial intelligence technologies, it enables remote monitoring of equipment, fault prediction and optimized operation and maintenance. Aister and other enterprises will continue to increase their investment in research and development, launch new products that better meet the needs of the industry, and provide solid technical support for the efficient, safe and green development of the petrochemical and natural gas industries.