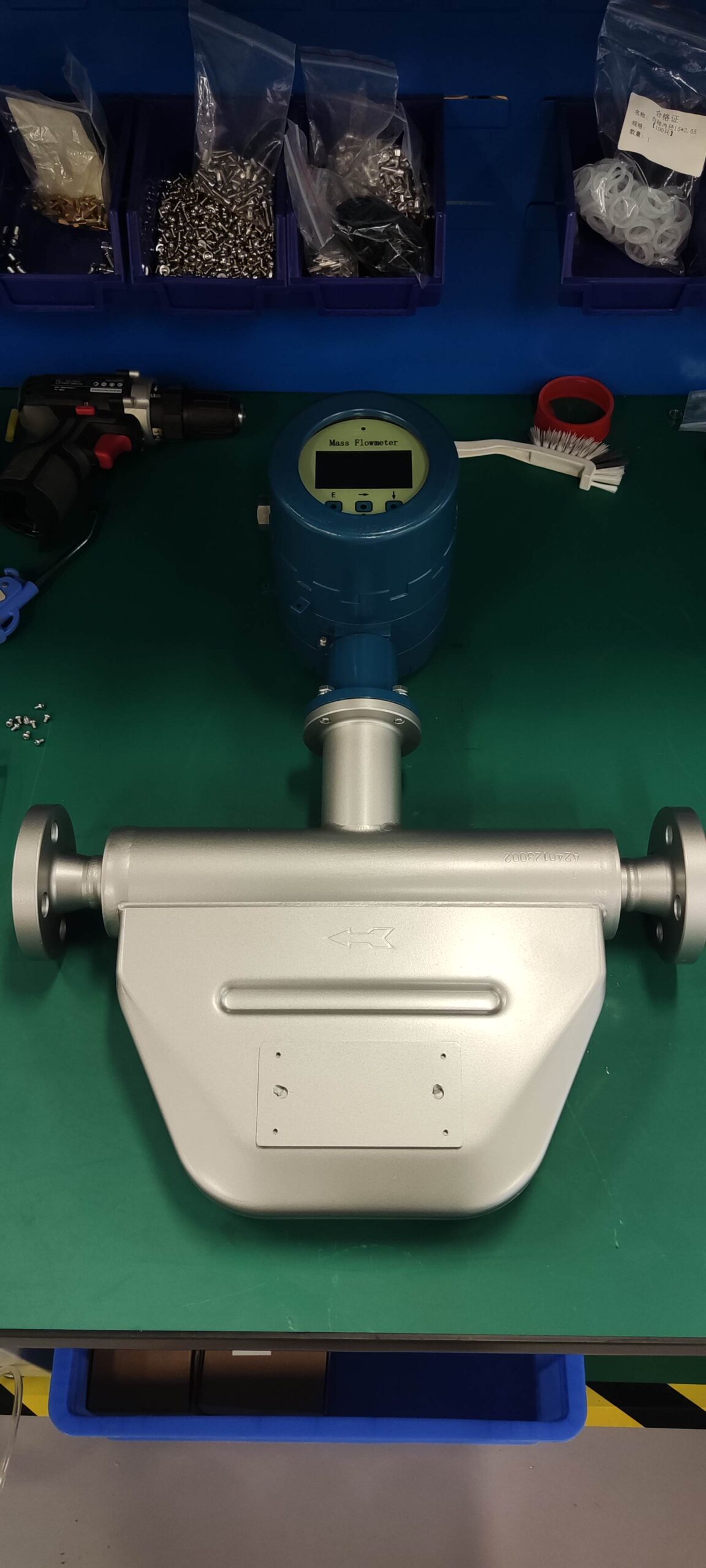

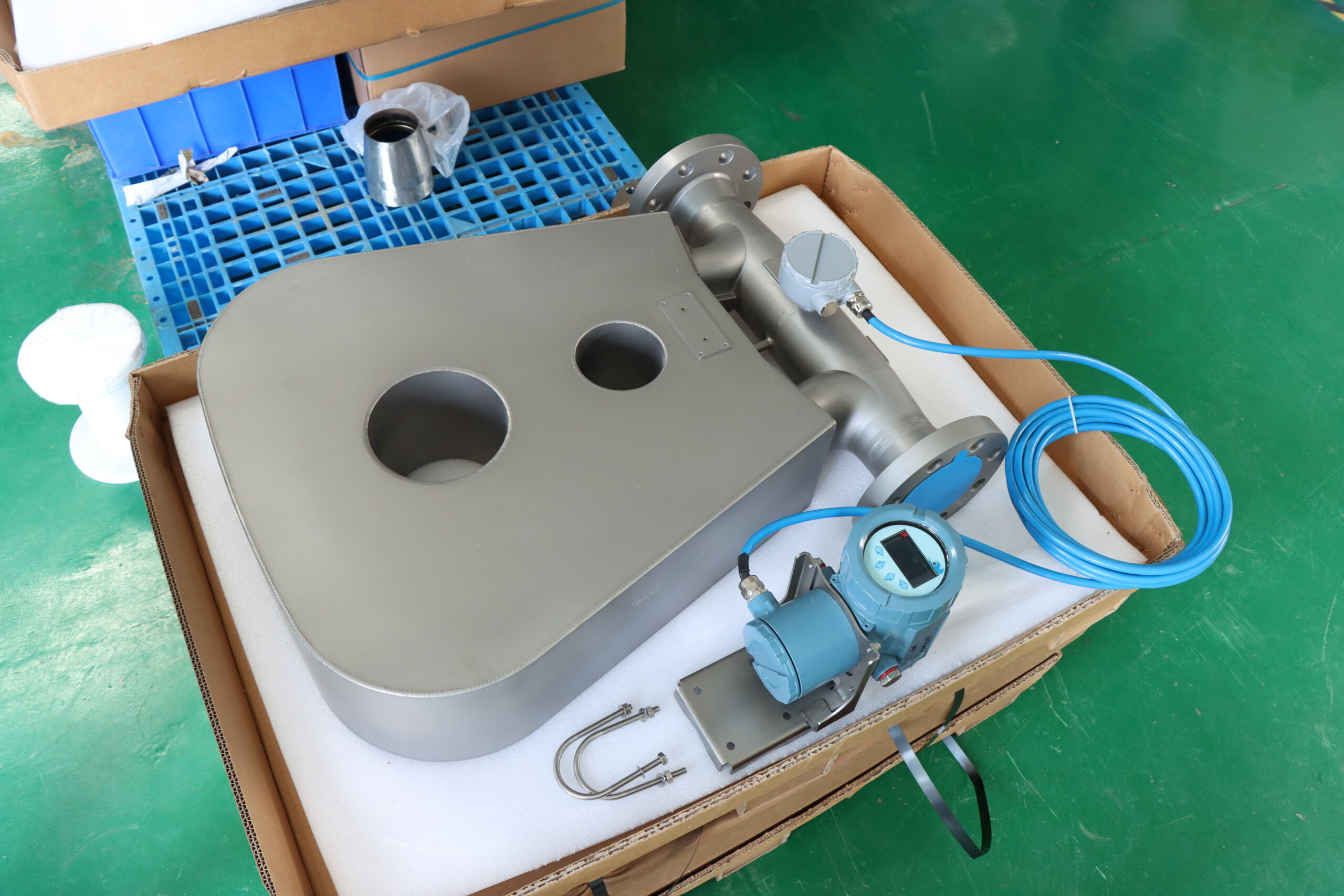

The internal structure of the Coriolis mass flowmeter

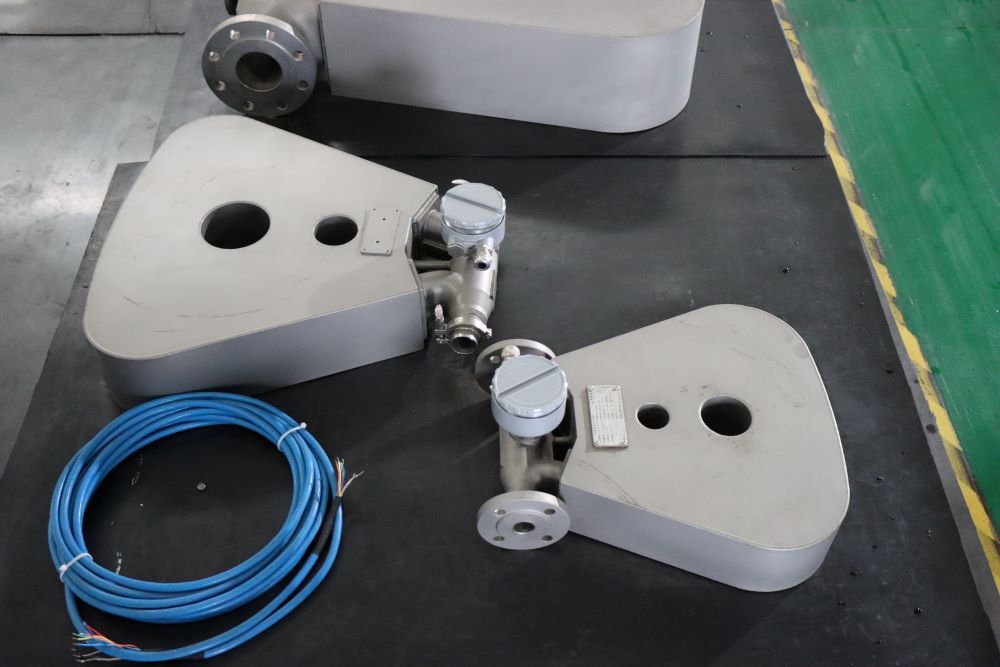

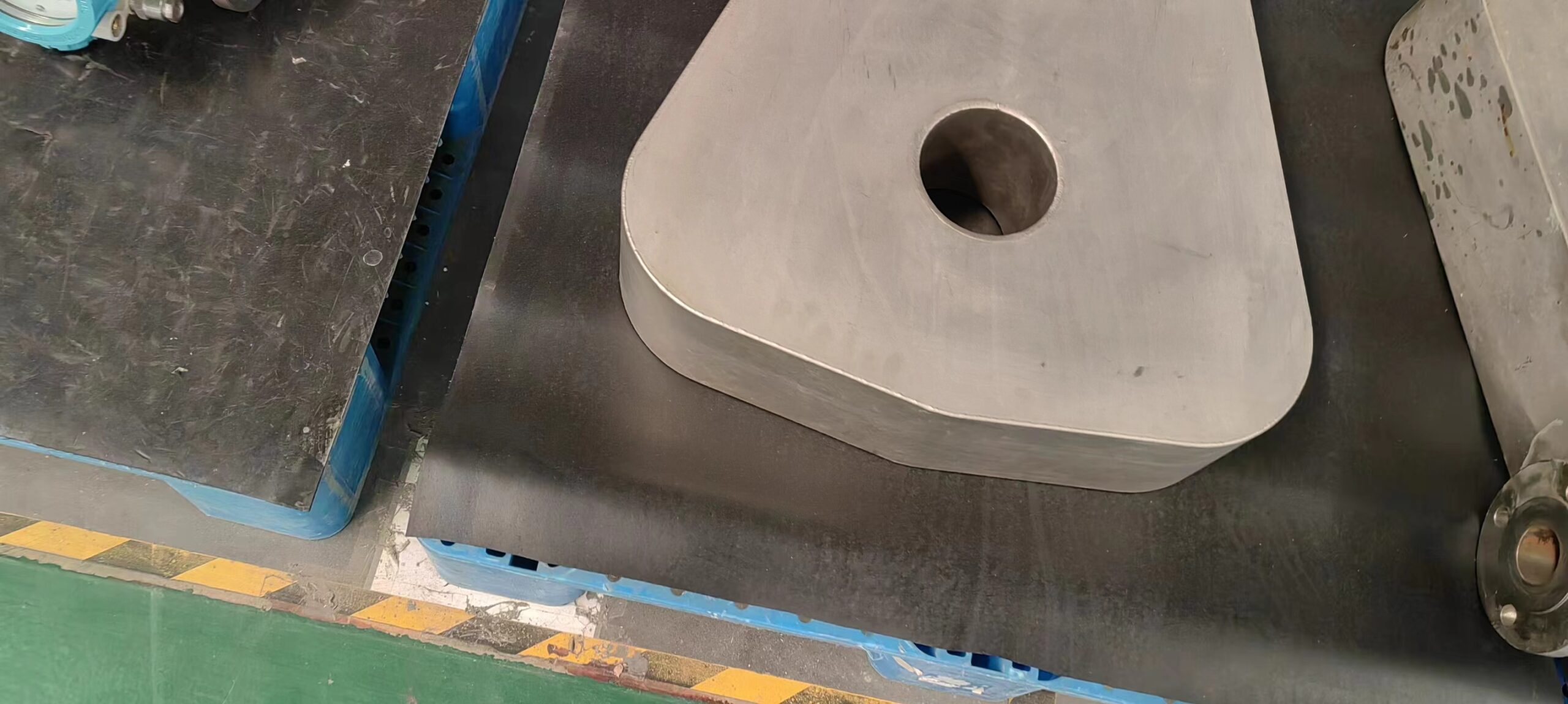

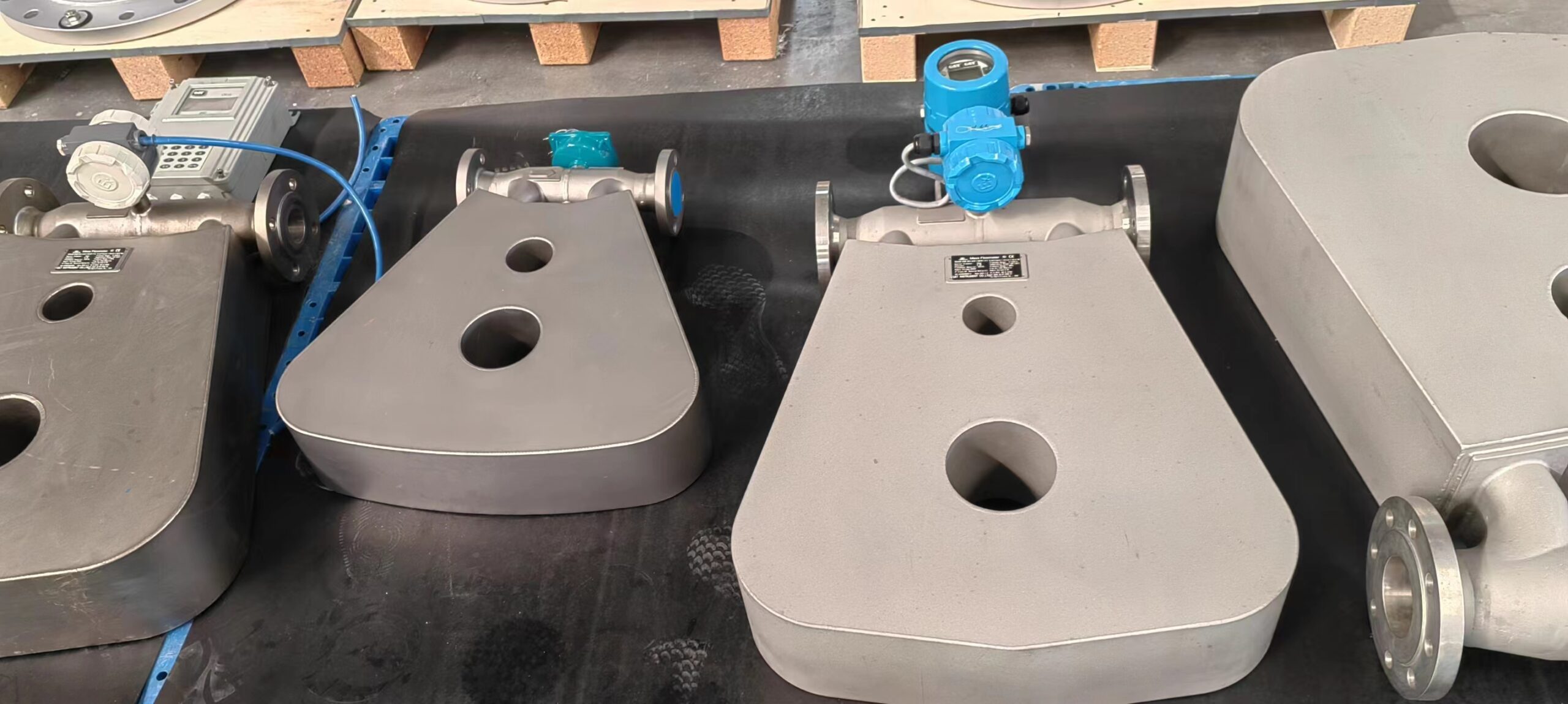

The internal structure of the coriolis mass flowmeter mainly consists of two parts: the flow measurement sensor and the signal converter . The flow measurement sensor is the core component, usually composed of a vibrating tube (measuring tube) and a driving coil. The vibrating tube can be a straight pipe or a curved pipe, a single pipe or multiple pipes. These different designs will affect the performance and applicable scenarios of the flowmeter.

Working principle

The working principle of the Coriolis mass flowmeter is based on the Coriolis force. When fluid flows in a pipe, the flowing fluid causes the pipe to twist, and this twist is directly proportional to the mass flow rate of the fluid. By measuring this distortion, the mass flow rate of the fluid can be calculated. Specifically, when a pipe rotates around a fixed point, the movement of the fluid in the pipe is affected by an inertial force, which is the Coriolis force. By measuring this force, the mass flow rate of the fluid can be indirectly measured.

Design differences among various types

Youdaoplaceholder0 Straight pipe type and elbow type : Straight pipe type flowmeters are not prone to gas accumulation. The sensor size is small and the weight is light, but the natural frequency is high, the pipe wall is relatively thin, and it is prone to wear and corrosion. The elbow flowmeter is wear-resistant and corrosion-resistant, but it has a low natural frequency and is prone to accumulate gas and residue.

Youdaoplaceholder0 single-tube type and multi-tube type : The single-tube flowmeter does not split, and the flow rate is equal everywhere in the measuring tube, which is conducive to stabilizing the zero point and cleaning. For multi-tube types (such as double-tube types), the flow rate is calculated by measuring the phase difference of the tubes.

Application field

Coriolis mass flowmeters are widely used in various industrial fields, including

Youdaoplaceholder0 Measurement of fluid energy and raw materials : such as loading (onto ships), unloading (from ships) and packaging measurement of petroleum and chemical raw materials and products.

Youdaoplaceholder0 Online measurement of high-viscosity materials : such as asphalt, heavy oil, and grease measurement.

Youdaoplaceholder0 measurement of suspended matter and solid particulate matter materials : such as the measurement of cement slurry and lime slurry.

Precise measurement of medium and high-pressure gases in : such as the measurement of CNG natural gas.

Youdaoplaceholder0 micro-flow measurement : such as micro-flow measurement in the fine chemical and pharmaceutical industries.

Youdaoplaceholder0 measure the density of the medium online : and derive from this to measure the concentration of the solute in the solution.

Through these design features and a wide range of application fields, Coriolis mass flowmeters play a significant role in industrial production.