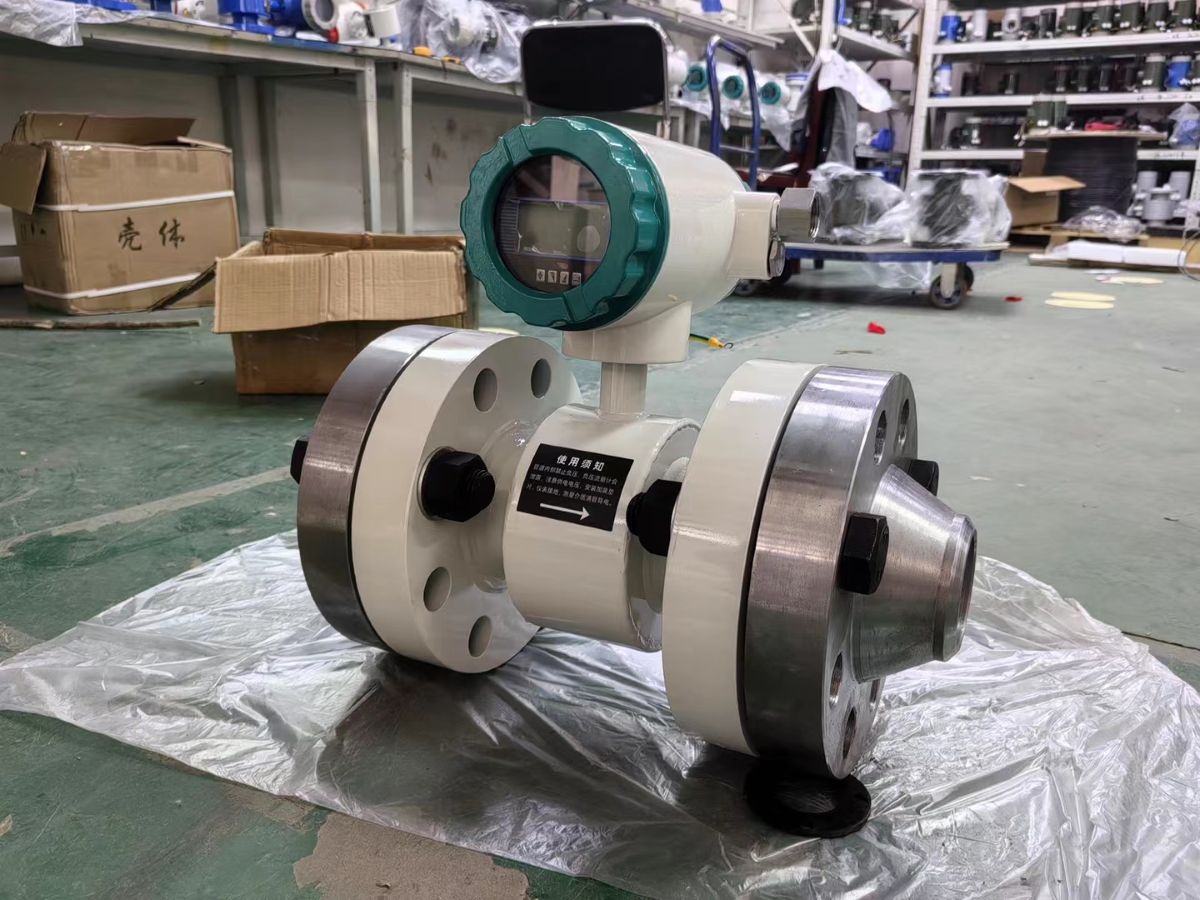

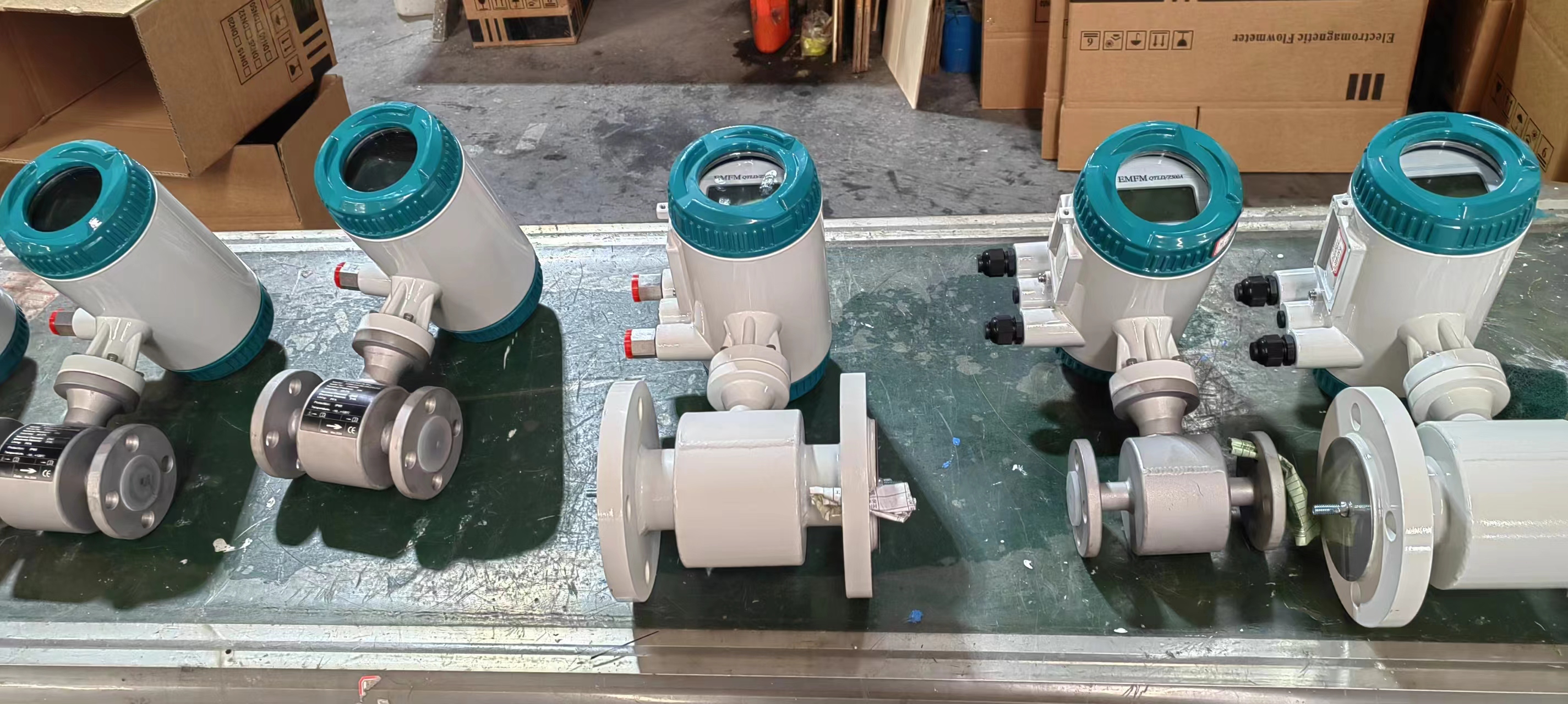

Factory Liquid Water Electromagnetic Intelligent Magnetic Flowmeter Transmitter Flow Meter

Selecting the right electromagnetic flowmeter involves considering various factors to ensure it meets the specific requirements of your application. Here’s a step-by-step guide to help you choose an electromagnetic flowmeter:

Fluid Conductivity:

Electromagnetic flowmeters are suitable for measuring electrically conductive fluids. Ensure that the fluid in your application has sufficient conductivity for accurate measurements.

Material Compatibility:

Consider the materials used in the construction of the flowmeter. Ensure that they are compatible with the properties of the fluid being measured, and that they can withstand the chemical and physical characteristics of the process.

Flow Range:

Determine the expected flow range in your application. Choose an electromagnetic flowmeter that is capable of measuring the minimum and maximum flow rates with the required accuracy.

Pipe Size:

Select a flowmeter with an appropriate pipe size that matches the diameter of the pipe in your system. Ensure that the flowmeter’s measurement range is suitable for the chosen pipe size.

Accuracy Requirements:

Determine the required level of accuracy for your application. Electromagnetic flowmeters are known for their high accuracy, but different models may have varying levels of precision. Choose a flowmeter that meets your accuracy requirements.

Output Signal and Communication:

Consider the output signal and communication capabilities of the flowmeter. Common output signals include analog (4-20 mA), digital (pulse or frequency), and digital communication protocols (MODBUS, HART, PROFIBUS, etc.). Choose the one compatible with your control or data acquisition system.

Power Supply:

Check the power supply requirements of the flowmeter. Ensure that your facility can provide the necessary power, and consider whether the flowmeter should have battery backup or low power consumption features.

Environmental Conditions:

Consider the environmental conditions at the installation site, including ambient temperature, humidity, and the presence of corrosive substances. Choose a flowmeter with appropriate environmental protection features.

Installation Considerations:

Evaluate the installation requirements of the flowmeter. Consider factors such as straight pipe lengths before and after the flowmeter, pipe material, and the availability of space for installation.

Maintenance and Calibration:

Assess the ease of maintenance and calibration procedures. Choose a flowmeter that is easy to maintain and calibrate to ensure long-term reliability and accuracy.

-.jpg)