5 methods for detecting and testing electromagnetic flow meter failures

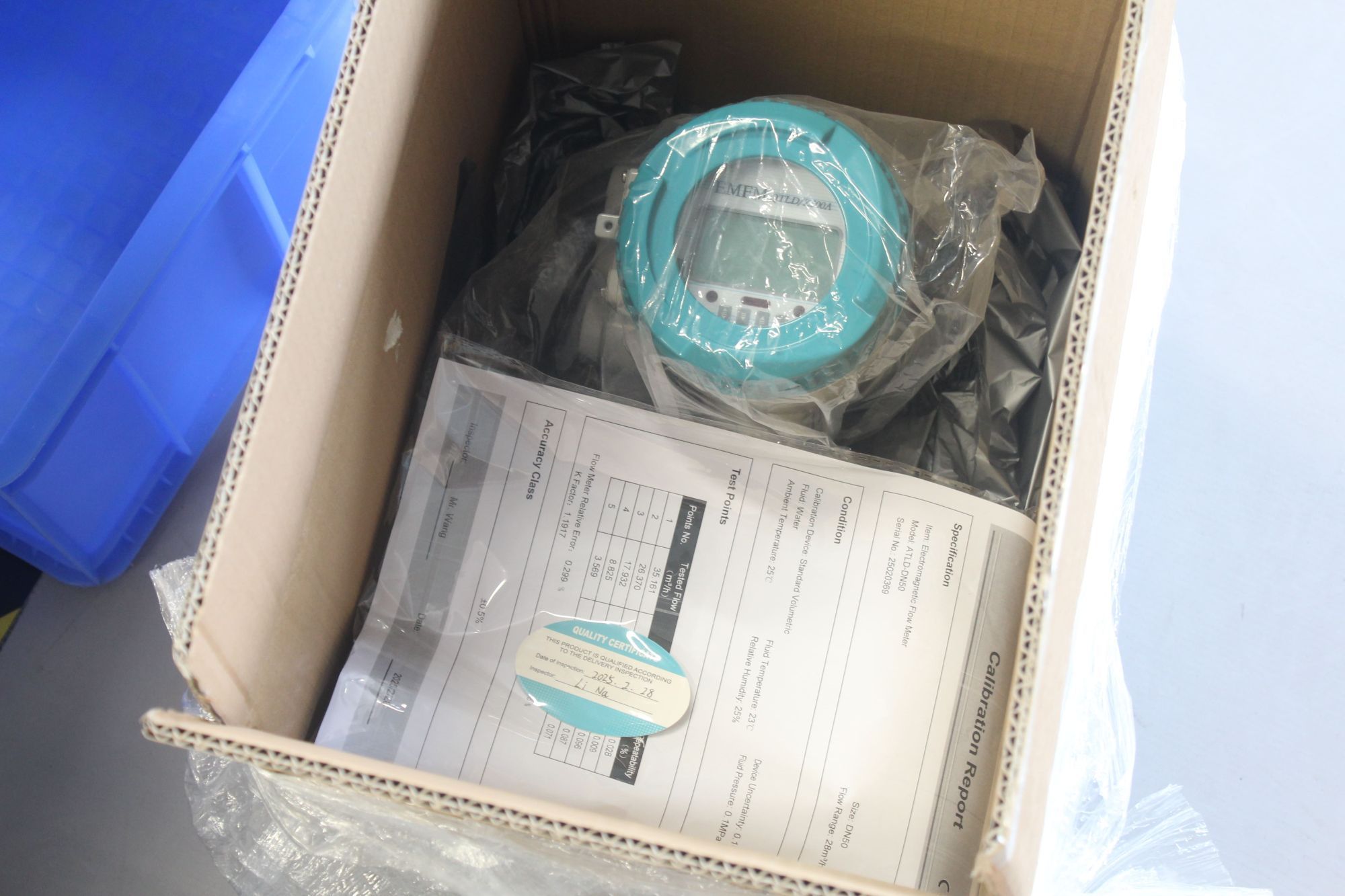

Electromagnetic flowmeter in the use process will produce some faults affect the normal work of the instrument, how to find the cause behind the fault is a very important work, we need to identify through a variety of different types of detection methods, in general, we for electromagnetic flowmeter routine testing, usually including electrode contact resistance, electrode polarization voltage, Signal cable interference, the determination of whether there is a grounding potential and the flow of stray current in the pipeline five aspects, these five aspects can be carried out separately, in fact, but also interrelated, any change in the factor may cause other changes, this reminds everyone in the detection of special attention:

1. Electrode contact resistance measurement Measurement, electrode and liquid contact resistance value, can not remove the flow sensor from the pipeline and indirectly estimate the general condition of the juice electrode and lining layer surface, help to analyze the cause of failure.

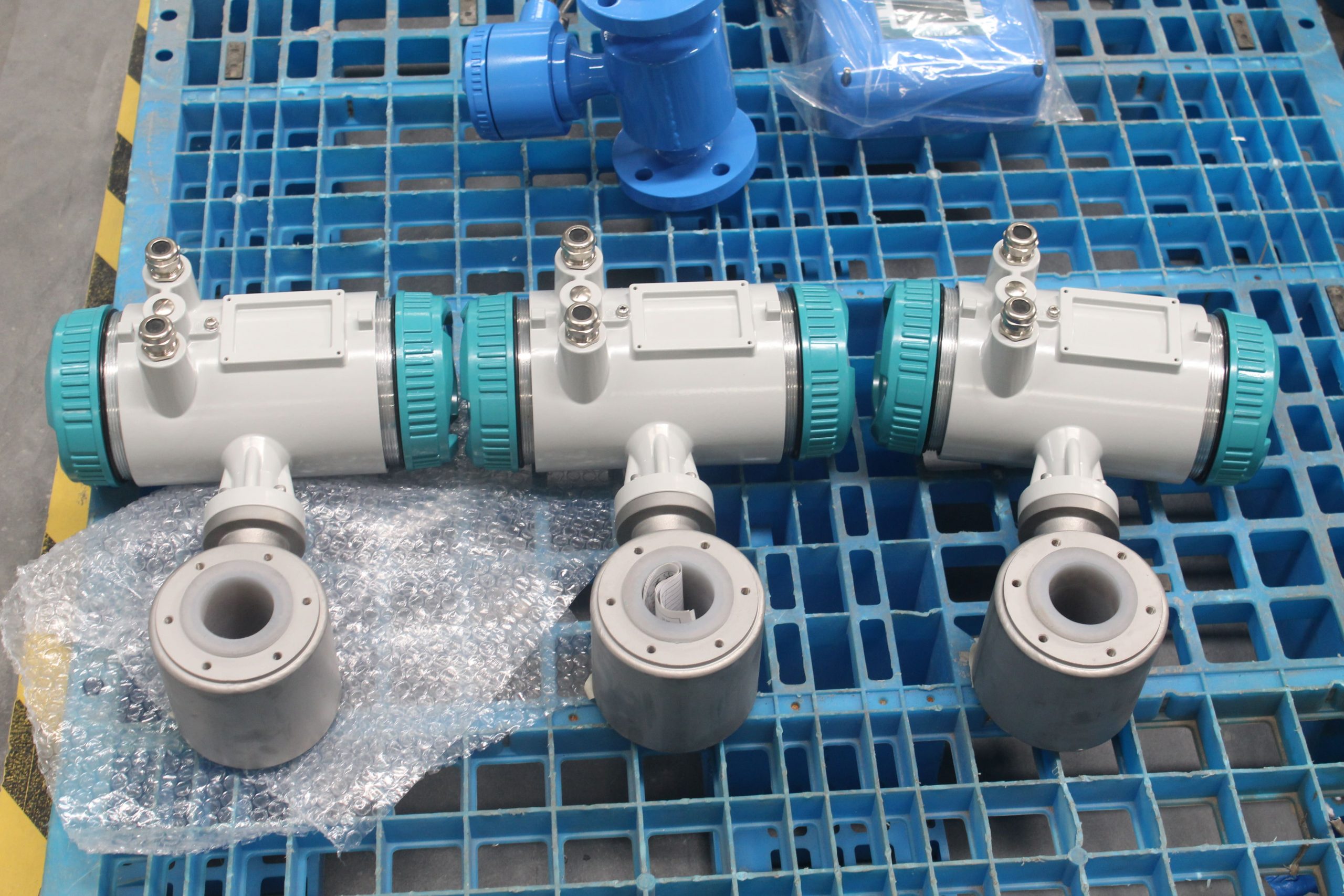

Measuring the contact resistance between the electrode and the liquid can indirectly assess the general condition of the electrode and lining layer surface without removing the flow sensor from the pipe, which helps to analyze the cause of failure. In particular, it brings great convenience to the inspection of large diameter electromagnetic flowmeters. This method can estimate the surface condition of the flow sensor measurement tube, such as whether the electrode and lining layer have sedimentary layers, whether the sedimentary layer is conductive or insulating, and the electrode surface contamination status.

2. The polarization voltage of the electrode Measuring the polarization voltage between the electrode and the liquid will help to determine whether the fault of zero instability or output sloshing is caused by the electrode being contaminated or covered. With a digital multimeter 2V DC, respectively measure the polarization voltage between the two electrodes and the ground (electromagnetic flowmeter can be measured without power failure or power failure). If the two measurements are nearly equal, the electrode is not contaminated or covered; otherwise, the electrode is contaminated or covered. The polarization voltage depends on the “electrode potential” of the electrode material and the properties of the liquid, and the measured value may range from a few mV to several hundred mV. Because in fact, the contamination of the two electrodes in operation can not be exactly symmetrical, so the voltage on the two electrodes forms an asymmetric common mode voltage. The asymmetric common-mode voltage becomes a differential mode signal, resulting in zero shift.

3.Measurement of signal cable interference Signal cable by external electrostatic induction and electromagnetic induction interference will make the electromagnetic flowmeter zero change. In order to determine whether the zero change is affected by the signal cable interference potential, it is necessary to determine the general range of interference and the degree of influence on the electromagnetic flowmeter.

4. Determine whether there is a ground potential electromagnetic flow juice in the normal use process, such as changes in the state of the electrical (force) machine near the sensor (such as leakage), the ground potential will change and cause zero change. To check whether there is any influence in this regard, you can short-circuit the C terminal of the converter’s working ground and the G terminal of the protective ground, and determine whether there is a ground potential by the change of zero (or indicating value).

5. The identification of the flow direction of stray current in the pipeline is sometimes used to find the interference source of stray current in the upstream of the flow sensor, so as to narrow the search scope and try to reduce or eliminate the interference effect of stray current.

-.jpg)

-.jpg)