The connection mode of electromagnetic flow meter and pipeline is explained in detail

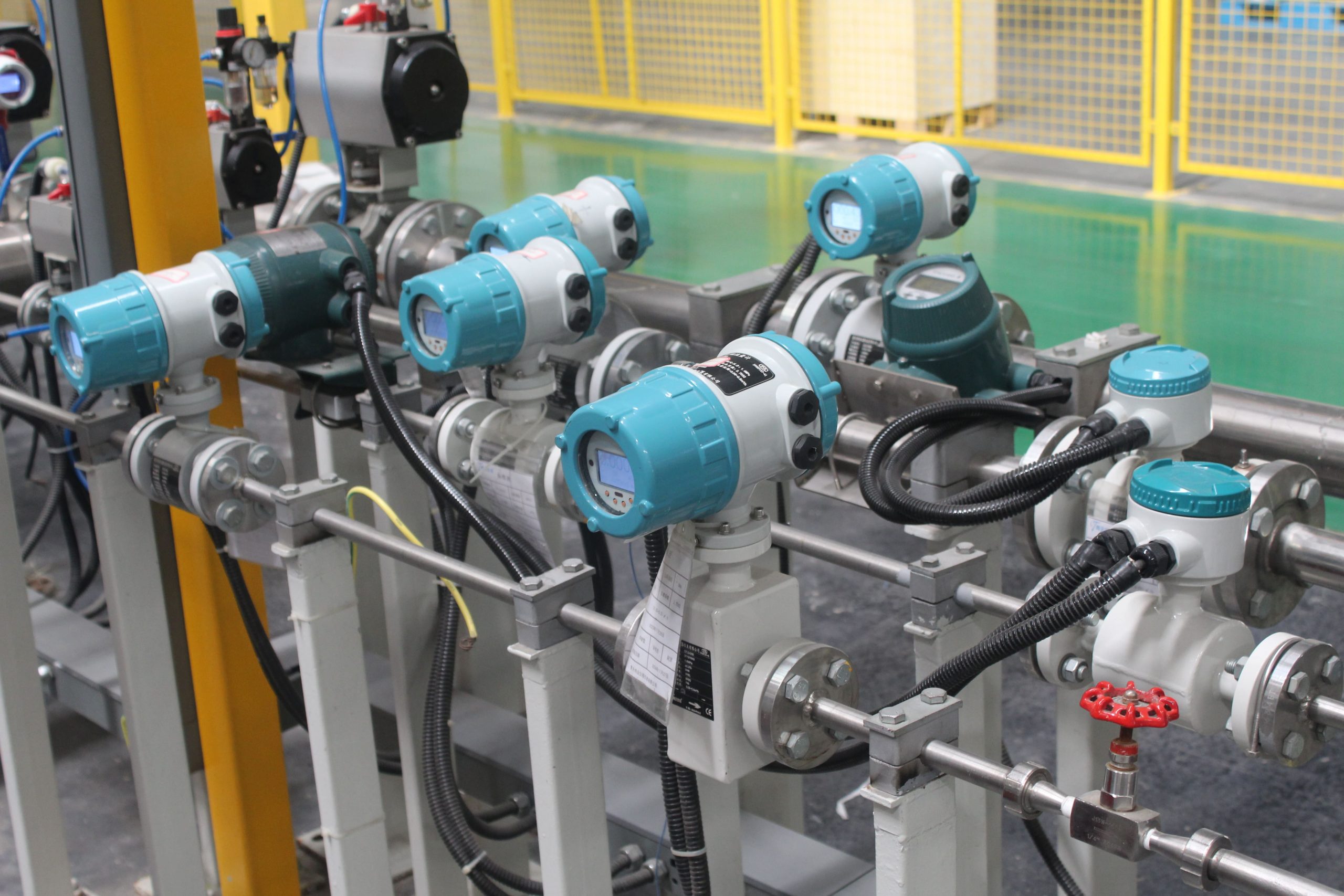

Electromagnetic flowmeter is a kind of high precision, high reliability and long service life flow surface, which is composed of two parts: the sensor that directly contacts the pipeline medium and the upper end signal converter.

It is based on Faraday’s law of electromagnetic induction operation, used to measure the conductivity of more than 5μs/cm of conductive liquid flow, is a measure of conductive medium flow surface. In addition to measuring the flow rate of usually conductive liquids, it can also be used to measure highly corrosive liquids such as strong acids and alkali and uniformly containing liquid-solid two-phase suspension liquids, such as mud, pulp, pulp, etc.

Before customers purchase electromagnetic flowmeters, they must first connect the electromagnetic flowmeter with the pipeline. It is also different from the method of pipe connection, and the connection method is as follows:

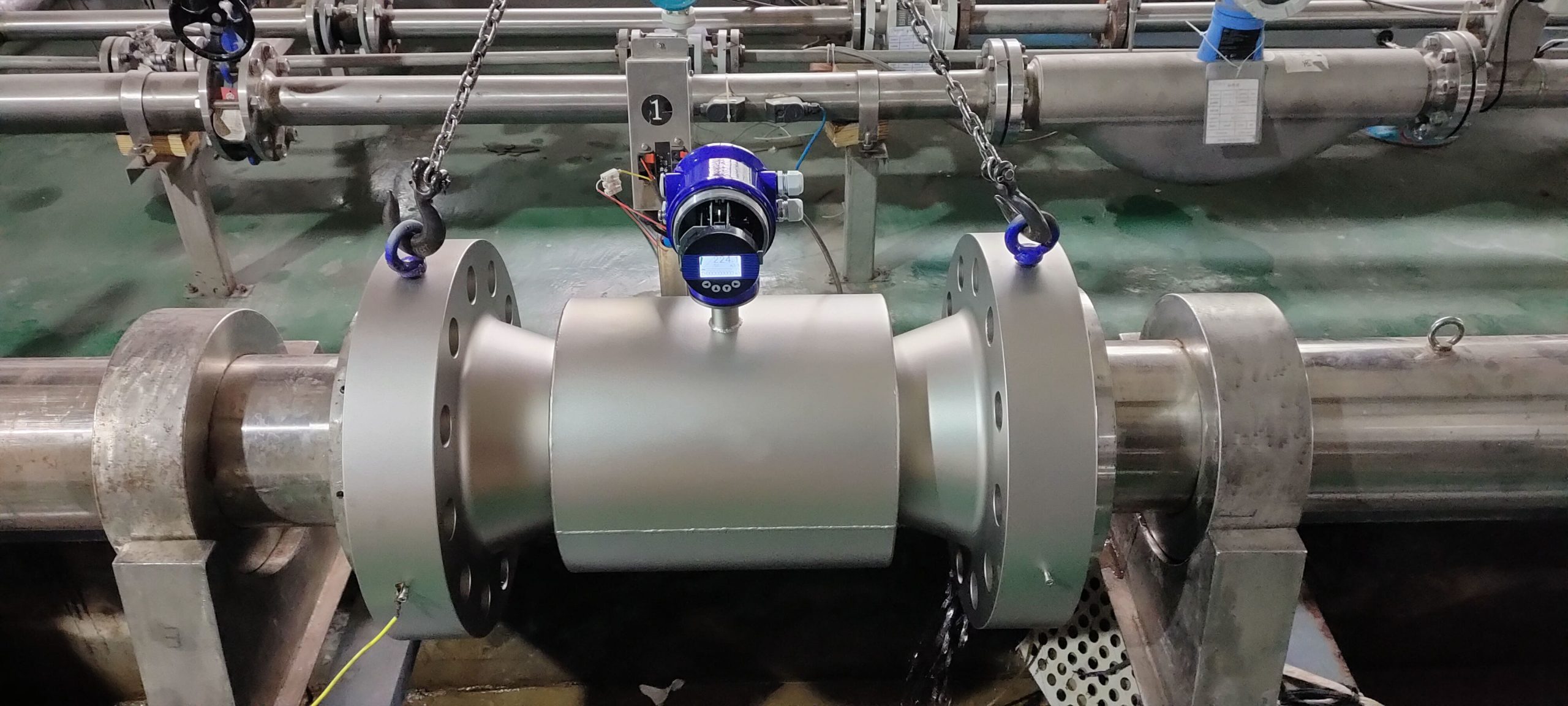

1. Flange connection: This connection method is more traditional, both ends of the electromagnetic flowmeter can be connected to the flange, in the connection with the pipe, as long as the two ends of the flange and the pipe flange with bolts fixed on it, this connection can be one-way device. The connected sensor is relatively small in size and is only suitable for use in small pipes.

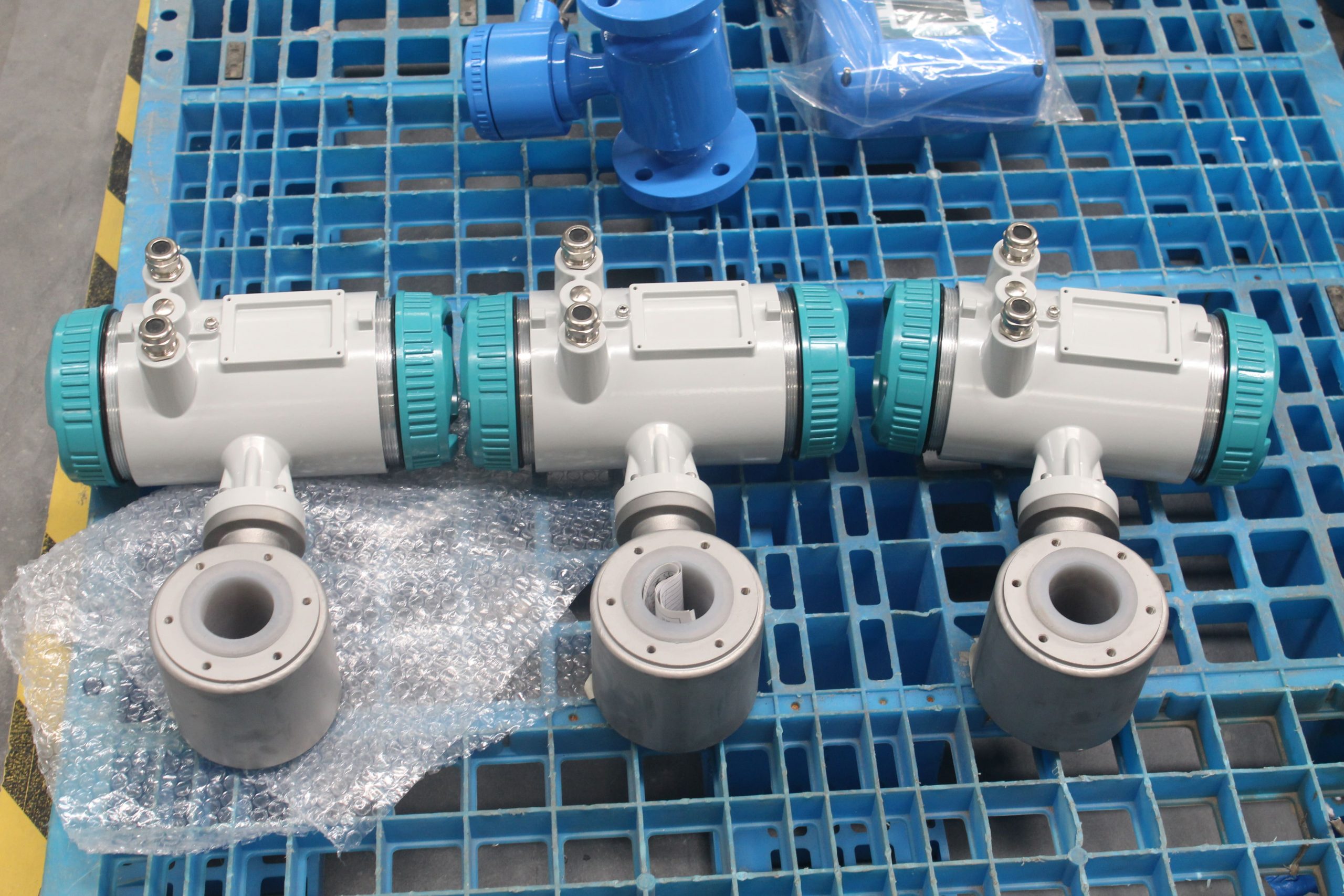

2. Clamping connection: This connection method is more advanced, and some electromagnetic flowmeters without flanges themselves use this connection, which can be clamped between two flanges in the pipeline with bolts, and the connection method is relatively simple. It is necessary for us to know the installation method of the electromagnetic flowmeter, and there will be no errors when clamping and connecting.

3. Threaded connection: There are also some small-caliber electromagnetic flowmeters that use threaded connections, which are usually used in the medical and food industries. In addition, this connection is also used in oil and exploration.

4. Clean connection: Now some small-caliber pipes are used for this connection, we often call the clean connection a clamp connection, through this connection, you can speed the device and disassemble the electromagnetic flowmeter, its usual cleaning and protection is also very convenient.

-.jpg)

-.jpg)