Application effect and characteristics of electromagnetic flow meter for sewage

The reason why the measurement error is large is that the amount of oil and suspended matter in the water from the sewage station is high, and the treated sewage has a small amount of oil and suspended matter in the water, and the error of electromagnetic flowmeter measurement is also small.

At present, ultraviolet sterilization system and dosing system have not been put into use, and the treatment of suspended solids is poor. We assume that if suspended solids in sewage are treated better, the comparative analysis results will be more obvious. The reasons why the measurement results of electromagnetic flowmeter are affected by oil and suspended matter in sewage are:

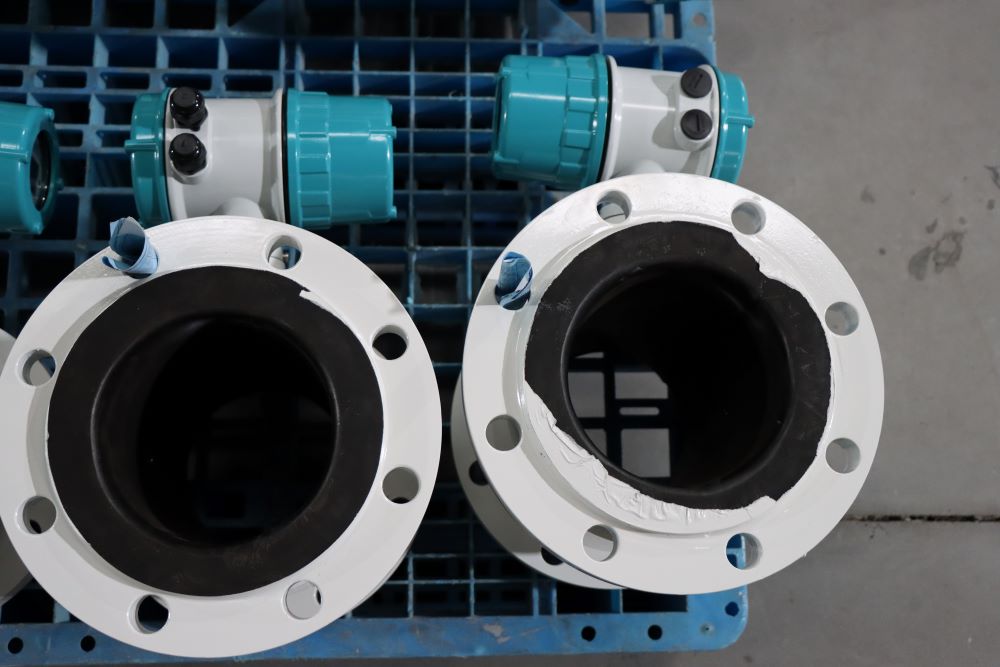

1) The measurement principle of the sewage electromagnetic flowmeter is Faraday’s law of electromagnetic induction, that is, when the conductor cuts the magnetic field line in the magnetic field, the induced electromotive force is generated at both ends, and the induced electromotive force is calculated by amplifies the liquid flow.

2) If there is more oil and suspended matter in the water, it will affect the electrical conductivity of the sewage, and then affect the measurement accuracy of the sewage.

3) The content of oil and suspended matter in the sewage treated by the sewage station and the sewage injected by the water injection station is low, and the measurement accuracy of the electromagnetic flowmeter is high.

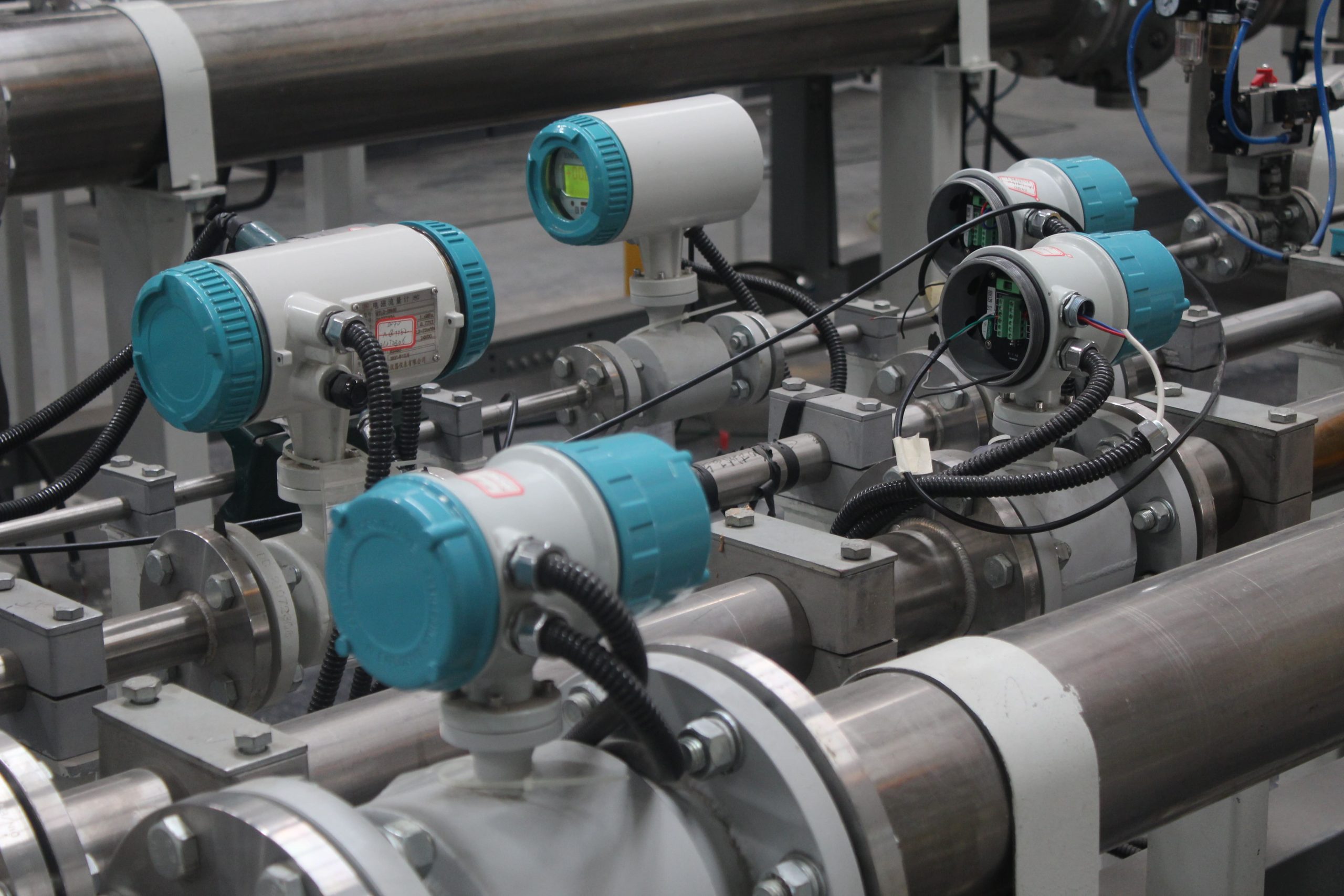

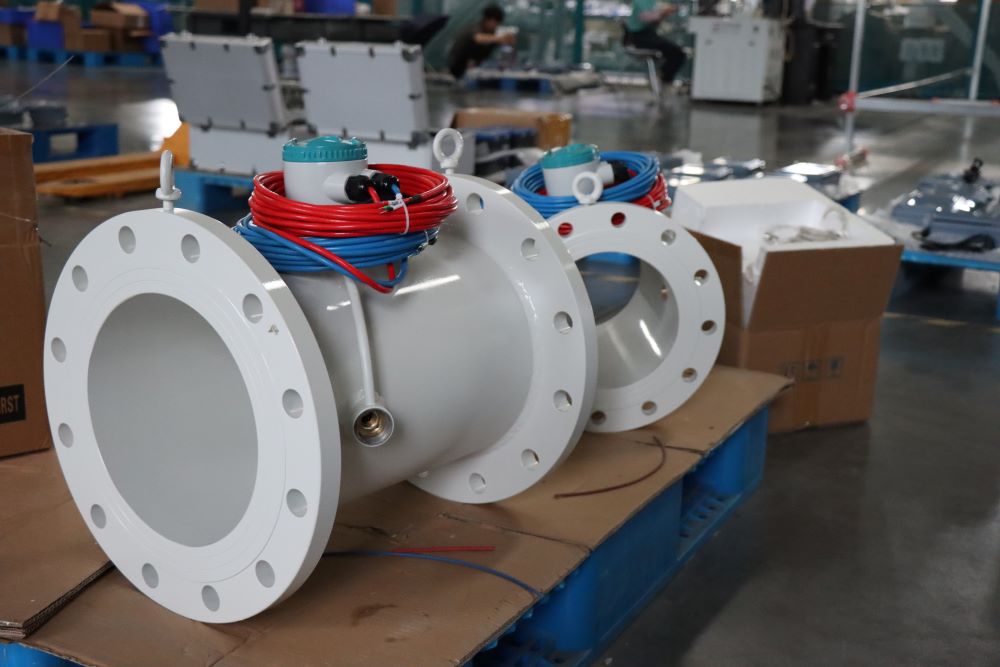

Sewage electromagnetic flowmeter has simple structure, firm and reliable, long service life no moving parts and resistance parts in the measuring tube, no pressure loss, will not cause obstruction reliable measurement, strong anti-interference ability small size, light weight, easy installation, small maintenance, large measurement range, measurement is not affected by temperature, density, pressure, viscosity, conductivity and other changes can be installed in the old pipe to open a small mouth The construction and installation is simple, the engineering amount is small, and the electromagnetic flowmeter can realize the uninterrupted water installation. The cost and installation cost of the electromagnetic flowmeter are lower than that of the general electromagnetic flowmeter, and it is especially suitable for the measurement of the flow of large and medium-sized pipes using advanced processing technology, flowmeter, solid state package, anti-penetration, long life, so that the instrument has good measurement accuracy and stability.

-.jpg)